Wholesale Machine Stretch Film | Cost-Effective Packaging

In an era where supply chain efficiency and cost control are non-negotiable for industrial operations, wholesale machine stretch film has emerged as a strategic lever

Experience industry-leading quality with PWP Stretch Film. Superior, eco-friendly packaging products designed to protect your goods, ensuring they arrive intact.

Hand stretch film is categorized into types like standard, pre-stretched, and cast, each designed for efficient load stabilization and protection during handling.

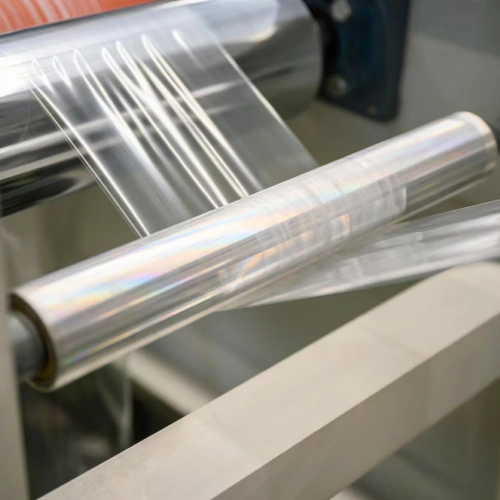

Machine stretch film, including blown and cast varieties, is used for efficient pallet wrap, offering strong load stability and protection in automated processes.

Color stretch film, available in various shades, enhances load visibility and security, and is a specialized type of stretch wrap used for both protective and aesthetic purposes in packaging.

Bundling stretch film, designed for tightly wrapping and securing groups of items, is a specialized form of stretch wrap that ensures efficient, compact packaging and protection during handling.

Mini stretch film, ideal for small and irregularly shaped items, offers the same protective qualities as pallet wrap, providing secure wrapping and stability while being more convenient for manual and tight applications.

Pre-stretch film is a high-performance wrap that is pre-stretched for enhanced strength and durability, reducing material usage while offering excellent load stability and protection.

VCI stretch film incorporates volatile corrosion inhibitors to protect metal surfaces from rust and corrosion, serving as a specialized type of pallet wrap that combines packaging strength with enhanced anti-corrosion properties.

UVI stretch film, enhanced with ultraviolet inhibitors, offers superior protection against sun damage and degradation, making it ideal for outdoor use while performing the same load-stabilizing functions as standard stretch wrap.

Breathable stretch film features micro-perforations that allow air circulation, preventing moisture buildup and condensation. It provides effective load stabilization and protection while maintaining ventilation, making it ideal for wrapping sensitive or perishable goods.

Years Of Experience

![]()

Globally Clients

At PWP Stretch Film, we are committed to exceeding our customers' expectations by delivering high-quality packaging solutions that ensure the safe distribution of their products. We understand that your goods are as important to you as they are to us, which is why we provide top-notch products designed to protect your merchandise throughout the transportation process. Our dedicated team of professional sales representatives, customer account specialists, and marketing experts are always ready to assist you, ensuring a seamless and supportive experience. With eighteen years of experience, PWP Stretch Film has established itself as a leading manufacturer and supplier of Stretch Film, Pallet Wrap, and Stretch Wrap. Our mission is to produce and deliver the finest stretch films in both domestic and international markets. Central to our manufacturing philosophy is the belief that our products must be effective, consistent, and readily available at every stretch film location. We recognize that various industries rely heavily on packaging, transportation, and industrial supplies to store, transport, and protect their products. Selecting a trustworthy manufacturer is crucial, given the wide array of packaging options available. PWP Stretch Film stands out as an industry leader by offering comprehensive, one-stop packaging solutions tailored to meet all your packaging needs. Our strong partnerships with premium suppliers enable us to provide the latest innovations in packaging materials, ensuring that we deliver cutting-edge solutions without compromising on quality. Our state-of-the-art automated palletizing and packaging systems, powered by advanced technology, set us apart from the competition. Supported by a team of knowledgeable experts and engineers, our dedicated production lines are designed to produce high-performance stretch films that meet your specific requirements. Additionally, we offer contract packaging services and custom design solutions, making us a trusted partner for businesses seeking reliable and customized packaging options. Choose PWP Stretch Film for your packaging and hygiene product needs and experience the difference that quality, consistency, and exceptional customer service can make. Let us help you protect and distribute your products with confidence. For more information, please contact us at pwpstretchfilm@gmail.com.

With 18 years in the industry, PWP Stretch Film brings unparalleled expertise and knowledge to meet all your packaging needs.

Our dedicated team is always ready to assist you, ensuring your requirements are met promptly and efficiently for an optimal customer experience.

All our products, from best-sellers to specialty items, are in stock and ready for immediate shipment, ensuring quick execution of your orders.

Committed to environmental responsibility, we use recycled materials and processes. All our products are 100% recyclable, helping reduce environmental waste.

Offering custom features and over 13,000 stock items, we provide a wide range of options to suit your specific packaging requirements.

We continuously evaluate our performance to ensure every roll of stretch film is flawless, providing you with the best products that meet the highest standards.

Partnering with industry pioneers in machinery and material production, we utilize state-of-the-art equipment to produce some of the thinnest specialty high-performance films.

We guarantee fair pricing on all products, offering larger discounts on bulk orders to provide exceptional value.

We help customers package products efficiently to reduce waste and ship from the nearest PWP Stretch Film location to minimize carbon emissions.

Our commitment to quality and safety is demonstrated by our SQF certification, awarded with an 'Excellent' rating.

| Gauge | Thickness (Microns) | Thickness (Mils) | Common Names/Examples | Applications | Key Features |

|---|---|---|---|---|---|

| 8 Gauge | 2 µm | 0.08 mil | Stretch Film 8 Gauge | Ultra-light wrapping, small items | Extremely thin, low cost, minimal protection |

| 80 Gauge | 20 µm | 0.8 mil | 2 Stretch Wrap | Light-duty boxes, uniform loads | Cost-effective, manual use, moderate strength |

| 100 Gauge | 25 µm | 1.0 mil | General-purpose film | Medium-duty pallets | Balance of flexibility and durability |

| 150 Gauge | 38 µm | 1.5 mil | 4 Stretch Film | Heavy industrial loads, sharp edges | High puncture resistance, machine-applied |

| 200 Gauge | 50 µm | 2.0 mil | 200 Gauge Stretch Film | Extreme-duty loads, hazardous conditions | Maximum durability, weather-resistant |

| N/A | 100 µm | 4.0 mil | Stretch Film 100mm | Specialized industrial use | Extremely thick, rare, for unique needs |

Whether you are a logistics company, factory or retailer, our hand-stretch film ensures that the goods are as stable as a rock during transportation and storage with its ultra-high elasticity, tear resistance and long-lasting adhesion. Environmentally friendly materials and flexible customization make packaging more labor-saving and economical!

✓ Super elasticity: stretch rate up to 300%, tightly wrapped without loosening

✓ Anti-puncture and tearing: multi-layer co-extrusion technology to protect sharp goods

✓ Eco-Friendly Packaging, Environmentally friendly and non-toxic: 100% recyclable LLDPE material, in line with EU ROHS standards

✓ Customized service: one-stop solution for thickness, width, color, and printing LOGO

① High cost-effectiveness, reducing overall costs

The length of a single roll can reach 1500 meters, with excellent pre-stretching performance, reducing consumables; supporting customized thickness (15μm-30μm), thin and strong, reducing customer packaging costs.

② Convenient operation, improving efficiency

Designed for manual operation, light and non-sticky, no complex equipment is required to quickly complete the package, and a single roll can cover 30+ standard pallets.

③ Adapt to extreme environments

Stable performance in -30℃ to 50℃ environment, anti-humidity, anti-static, suitable for special scenarios such as food cold chain, electronic components, chemical products, etc.

Engineered for high-speed automation, our Machine Stretch Film delivers unmatched load stability, durability, and efficiency. Perfect for logistics, manufacturing, and large-scale warehousing, it ensures seamless integration with automated systems while minimizing waste and maximizing cost savings.

Core Features:

✓ Automation-Ready: Compatible with semi- and fully automatic stretch wrappers, reducing downtime and labor costs.

✓ High Load Retention: Advanced multi-layer technology locks pallets securely, even under heavy or irregular loads.

✓ Eco-Conscious Material: Made with 100% recyclable LLDPE, meeting global sustainability standards.

✓ Customizable Solutions: Tailor thickness (12μm-35μm), width, core size, and UV/anti-static additives.

①Boost Productivity, Reduce Costs

Ultra-thin yet ultra-strong film reduces material consumption by up to 20% without sacrificing performance. Pre-stretch capabilities extend roll length (up to 5,000 meters), slashing replacement frequency and total packaging costs.

②Built for Speed & Precision

Optimized for high-output environments, our film ensures consistent tension and clarity for smooth machine operation. Ideal for fast-paced production lines, it prevents film breaks and maintains barcode visibility for seamless logistics.

③Engineered for Tough Conditions

Performs reliably in extreme temperatures (-40°C to 60°C) and humid environments. Resists punctures, tears, and static—perfect for electronics, chemicals, or cold-chain logistics.

Whether you are in machinery manufacturing, automotive parts, or metal processing industries, our VCI Stretch Film provides superior corrosion protection during transportation and storage. Integrated with volatile corrosion inhibitors, it forms an invisible shield to prevent rust, while maintaining high elasticity and durability. Eco-friendly materials and customizable options ensure both safety and cost-efficiency!

✓ VCI Anti-Corrosion Technology: Releases protective vapors to safeguard metal surfaces, no direct contact required

✓ Multi-Layer Barrier Protection: Resists punctures, tears, and moisture, ideal for sharp or heavy metal components

✓ Environmentally Safe & Recyclable: Made from 100% recyclable LLDPE, compliant with REACH and ROHS standards

✓ Tailored Solutions: Customize thickness (12μm-35μm), width, color, and printed markings for brand visibility

①Cost-Effective Long-Term Protection

A single roll length up to 1200 meters reduces material consumption. Thin yet robust design (as low as 12μm) lowers packaging costs while extending shelf life of metal goods, minimizing replacement and maintenance expenses.

②User-Friendly & Time-Saving

Lightweight and non-tacky, optimized for manual application. No specialized equipment needed—one roll covers 25+ standard pallets, boosting packaging efficiency by 40%.

③Built for Harsh Conditions

Performs reliably in temperatures ranging from -40°C to 60°C. Resists humidity, static, and chemical exposure, perfect for marine logistics, electronics, aerospace, and outdoor storage applications.

Protect Your Metals, Preserve Your Profits!

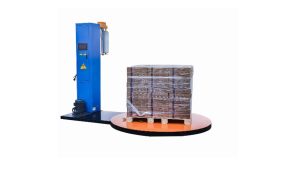

Stretch film is essential for wrapping pallets to bundle items together, providing stability and security during storage and transportation.

Ideal for bundling loose or irregularly shaped items like pipes, lumber, or textiles, ensuring they remain together and protected.

By tightly wrapping products, stretch film minimizes movement and shifting, reducing the risk of damage during shipping.

Acts as a barrier against dust, dirt, and moisture, keeping goods clean and preserving their quality.

Available in various colors, stretch film can be used to color-code products or shipments for easy identification and inventory management.

The flexibility of stretch film allows it to conform to items of various shapes and sizes that may not fit standard packaging.

Helps in organizing products within a warehouse by keeping stacked items secure and preventing them from toppling.

Provides an additional layer of security; tampering is easily noticeable if the wrap is compromised, deterring theft.

As an economical option, it reduces the need for additional packaging materials like tapes and straps, lowering overall packaging costs.

We've been using PWP Stretch Film for over a year now, and the quality is consistently top-notch. The film is durable and holds our pallets securely during transit. Highly recommended for anyone needing reliable pallet wrap solutions.

Logistics Manager at Global Shipping Co.

Switching to PWP Stretch Wrap has significantly reduced our packaging costs without compromising on quality. The film stretches well, reducing the amount needed per pallet, and saves us time in the packing process.

Operations Director at Fresh Produce Ltd.

PWP Stretch Film's offers superior cling and excellent transparency, which is crucial for our inventory management. It keeps our products secure and allows for easy scanning and identification.

Warehouse Supervisor at TechParts Inc.

Not only is the product excellent, but PWP Stretch Film's customer service is outstanding. They provided us with samples to test and helped us choose the right type of stretch wrap for our needs.

Purchasing Manager at HomeGoods Suppliers

We were looking for eco-friendly packaging solutions, and PWP Stretch Film delivered. Their range of recyclable stretch films has helped us reduce our environmental footprint while maintaining packaging efficiency.

Sustainability Coordinator at Organic Foods Co.

Our products often face harsh weather during shipping, but PWP Stretch Film's pallet wrap withstands extreme temperatures and humidity. It has improved the safety of our shipments significantly.

Export Manager at Arctic Supplies

Stretch film, also known as packing stretch wrap, is a highly stretchable plastic film commonly used for securing items during storage and transportation. stretch and wrap is designed to cling to itself when stretched, thereby stabilizing and protecting goods on pallets or other loads. Typically made from polyethylene, stretch film comes in various grades and thicknesses to suit different packaging needs.

While the primary function of stretch film is to secure and protect goods and offer shrink wrap service, it does offer some resistance to the passage of air. This means that in certain cases, it can help to reduce the escape of odors. However, stretch film is not specifically engineered to act as an odor barrier. For applications where odor control is crucial, additional specialized materials or films with enhanced barrier properties may be required.

When comparing classic (domestically produced) stretch film to imported stretch wrap packaging, several factors come into play:

Quality and Consistency:

Classic stretch film is often designed with proven domestic manufacturing techniques, ensuring consistent performance. Imported versions might incorporate advanced technologies or unique formulations, which can offer superior stretchability, clarity, or puncture resistance.

Cost and Availability:

Domestic products may be more cost-effective and easier to source locally, whereas imported stretch wrap could come at a premium price due to shipping costs and tariffs.

Performance Characteristics:

Differences can also be seen in the film’s thickness, elasticity, and adhesion properties. The choice between the two often depends on the specific packaging requirements, such as the weight of the load, environmental conditions, and the need for additional protective qualities.

Stretch wrapping is a critical process in ensuring that loads remain secure during transport. Here’s a basic guide on how to effectively stretch wrap:

Prepare the Load:

Ensure that the items are evenly stacked on a stable pallet. Verify that the load is secure and that there are no protruding parts that could puncture the film.

Select the Appropriate Film and Equipment:

Choose a film with the right stretch and thickness properties for your load. For machine wrapping, check that the equipment is properly set up, and for manual wrapping, make sure you have a roll of film that is easy to handle.

Start at the Base:

Begin wrapping at the bottom of the load. Secure the film by anchoring it firmly to the pallet, and use several initial wraps to establish a strong base.

Apply Consistent Tension:

Whether using a machine or wrapping manually, ensure that the film is stretched tight as you work your way up the load. This maintains a firm hold on the items, preventing movement during transit.

Overlap and Cover Completely:

Overlap each pass of the film sufficiently to cover the entire load. Consistent overlapping not only secures the items but also improves the overall stability and protection of the wrapped load.

Finish Securely:

Once the entire load is covered, finish by securing the end of the film. Trim any excess material if necessary, and inspect the load to ensure all areas are evenly wrapped.

By following these steps, you can achieve a secure, stable package that protects your products during shipping while also minimizing movement and potential damage.

Pallet wrap, commonly referred to as pallet wrap stretch film or pallet stretch wrap, is a highly elastic plastic film used to secure goods on pallets during storage or transportation. This stretch film plastic is designed to tightly conform to the shape of loads, stabilizing items by creating tension and preventing shifting, dust, or moisture damage. Its versatility makes it ideal for industries like logistics, manufacturing, and retail.

The feet of plastic stretch wrap required depend on the pallet’s height, load stability, and wrapping technique. On average, a standard 48”x40” pallet may need 200–300 feet of film when using manual methods. Automated systems optimize usage, reducing waste by precisely controlling tension and overlap. Factors like irregular shapes or heavy loads may increase the total footage.

Wrapping time varies by method: manual wrapping takes 5–10 minutes per pallet, while semi-automatic machines reduce this to 1–2 minutes. Fully automated systems can wrap a pallet in under 30 seconds. Efficiency improves with operator experience and proper pallet wrapping film selection, such as high-performance films from PWP Stretch Film that minimize downtime.

The amount of stretch film plastic needed per pallet is calculated by measuring film width, pre-stretch percentage, and total revolutions. For example, a 20” wide film stretched to 250% efficiency covers more area with less material. A typical pallet might require 0.5–1.5 pounds of film, depending on load size and film gauge.

Industry averages suggest 1–2 pounds of pallet wrapping plastic per standard pallet. Light-duty loads (e.g., boxes) use thinner films (60–80 gauge), while heavy or sharp-edged items require thicker gauges (90–120+), increasing material usage. Consistent pre-stretch and proper machine calibration help minimize excess consumption.

Optimal plastic wrap pallets configuration involves evenly stacking goods, avoiding overhangs, and using pallet skirts (corner guards) to protect edges. Irregular loads may need additional layers or reinforced films. Proper alignment ensures uniform tension distribution, reducing film tears and improving load stability.

The HS code stretch film is typically 3920.20.00, classifying it as “plastic sheets, film, or strip non-cellular and not reinforced.” Stretch wrap commodity code streamlines international trade documentation and customs clearance for suppliers like PWP Stretch Film.

A standard case of pallet wrapping film from PWP Stretch Film contains 12–24 rolls, depending on gauge and width. Bulk purchasing reduces costs, with cases tailored to manual or machine-use requirements. Proper storage in cool, dry environments preserves film integrity and stretchability.

By understanding these factors, businesses can optimize pallet wrap efficiency and cost-effectiveness. For premium-quality solutions, PWP Stretch Film remains a trusted provider of durable, high-performance stretch films tailored to diverse industrial needs.

Stretch wrap is primarily made from linear low-density polyethylene (LLDPE), a flexible and durable plastic polymer. This material offers superior elasticity, puncture resistance, and cling properties, making it ideal for securing palletized loads. Some variations may blend LLDPE with additives to enhance UV resistance, tear strength, or recyclability. As a leading plastic stretch film manufacturer, PWP Stretch Film utilizes advanced formulations to meet diverse industrial demands while prioritizing performance and sustainability.

The primary target of stretch wrap plastic film manufacturers is to stabilize loads during transit, prevent product damage, and reduce shipping costs. It is widely used in warehouses, logistics, and manufacturing sectors to secure irregularly shaped items, boxes, or bulk goods. High-performance films, such as those from PWP Stretch Film, also focus on minimizing material waste through pre-stretch technology, aligning with eco-conscious business practices.

Start at the base: Anchor the film by wrapping it tightly around the pallet’s bottom.

Maintain tension: Use consistent force to ensure the film conforms to the load without overstretching.

Overlap layers: Aim for 50–75% overlap to maximize coverage and stability.

Protect edges: Use corner guards or pallet skirts to prevent film tears on sharp edges.

Seal the top: Finish with a secure wrap around the pallet’s top to prevent unraveling.

Stretch wrap is designed to cling to itself and stretch up to 300%, creating tension to secure loads. In contrast, plastic wrap (e.g., household cling film) is thinner, lacks elasticity, and is used primarily for food preservation. Industrial-grade stretch film is engineered for heavy-duty applications, offering superior durability and load retention.

Used stretch film can be recycled through specialized programs or repurposed into composite materials. PWP Stretch Film supports sustainable practices by offering recyclable LLDPE options. Businesses should partner with certified waste management services to ensure proper disposal, reducing landfill contributions and aligning with circular economy goals.

Bio-based stretch films, made from renewable resources like sugarcane or cornstarch, provide an eco-friendly alternative to traditional plastics. These films decompose faster under industrial composting conditions while maintaining load-securing performance. PWP Stretch Film is actively exploring bio-plastic innovations to meet growing demand for sustainable packaging solutions.

Films designed for extreme cold environments, often termed polar plastics stretch film, retain flexibility and cling in sub-zero temperatures. These specialized films prevent brittleness and cracking, ensuring load stability during frozen goods transport. PWP Stretch Film offers cold-weather variants tested for reliability in harsh conditions.

Advanced hi tech plastics stretch film incorporates nanotechnology or multi-layer co-extrusion for enhanced strength, clarity, or anti-static properties. Such films are ideal for sensitive electronics or high-value goods. PWP Stretch Film’s R&D-driven products leverage cutting-edge technology to address niche industrial challenges while optimizing cost-efficiency.

By selecting the right stretch wrap type and techniques, businesses can improve safety, reduce waste, and streamline operations. For tailored solutions, PWP Stretch Film remains a trusted partner, delivering high-quality films backed by decades of expertise in the packaging industry.

Pallet wrap, a versatile packaging solution, is utilized across industries to secure and protect goods during storage or transit. From logistics giants to small businesses, its applications span manufacturing, agriculture, retail, and even personal use. Below, we explore key users and specialized scenarios where pallet wrap proves indispensable.

Students and families increasingly rely on plastic stretch wrap for dorm move-in to safeguard belongings during transportation. Wrapping furniture, boxes, or mattresses with stretch film prevents scratches, moisture damage, and shifting in transit. PWP Stretch Film offers lightweight, easy-to-handle options perfect for temporary bundling, ensuring items arrive intact at dorm rooms or apartments.

Industries handling bulky or irregularly shaped loads, such as construction or furniture manufacturing, depend on extra wide pallet wrap. This film, often 30–40 inches wide, reduces wrapping time by covering more surface area per revolution. PWP Stretch Film’s extra-wide variants provide superior load stability for oversized items like pipes, machinery parts, or palletized building materials.

For businesses prioritizing cost and material efficiency, mega stretch pallet wrap is a game-changer. Engineered to stretch up to 300%, it minimizes film consumption while maintaining load integrity. Logistics companies and high-volume warehouses favor PWP Stretch Film’s mega stretch options to reduce waste and lower shipping costs without compromising security.

Eco-conscious businesses and retailers opt for green pallet wrap, made from recycled or biodegradable materials. This sustainable alternative aligns with corporate ESG goals while offering reliable load stabilization. PWP Stretch Film’s eco-friendly range includes recyclable LLDPE films and bio-based options, reducing environmental impact without sacrificing performance.

High-visibility yellow pallet wrap is ideal for warehouses prioritizing safety and organization. The bright color helps workers quickly identify wrapped pallets in busy environments, reducing handling errors. PWP Stretch Film’s yellow variants combine clarity for load inspection with UV resistance, ensuring durability in both indoor and outdoor settings.

From individual movers to global supply chains, pallet wrap adapts to diverse needs. Whether securing dorm room essentials with lightweight film or stabilizing industrial machinery with heavy-duty options, PWP Stretch Film delivers tailored solutions that balance strength, efficiency, and sustainability. Explore their range to find the perfect fit for your packaging challenges.

If you’re looking to buy stretch wrap or buy pallet wrap, there are a few great options to consider. Whether you’re securing items for storage or shipping, stretch wrap is an essential material. At PWP Stretch Film, we specialize in providing high-quality stretch wrap products to meet various needs. If you’re asking yourself where can I buy stretch wrap, we offer a variety of options that suit both personal and business purposes. We make it easy to get stretch wrap whether you’re looking for it locally or online.

When searching for where to buy stretch film, PWP Stretch Film is the perfect place to turn. We offer an extensive selection of stretch films that vary in thickness and strength, allowing you to find the right solution for your packaging needs. Our stretch films provide the durability required for heavy-duty applications, ensuring your goods are securely wrapped.

If you’re asking where can I buy stretch film, rest assured that PWP Stretch Film has exactly what you’re looking for. We provide both small and bulk quantities, making it easy to get the right amount for your projects. From personal storage needs to large commercial shipments, PWP Stretch Film offers the flexibility and high-quality products you need.

If you’re wondering who sells stretch wrap locally, PWP Stretch Film can help! We have a network of suppliers and offer products directly from our website, making it easier than ever to purchase locally or online. No matter what you’re wrapping, from small items to large pallet loads, our products ensure the strength and reliability needed for secure wrapping.

The best place to buy stretch wrap is undoubtedly PWP Stretch Film. If you’re looking for durable and cost-effective stretch wrap, we provide a wide variety of options to suit your needs. Whether you need a small roll for household use or larger quantities for business, we have flexible solutions for both. Our website makes purchasing easy, so you don’t have to worry about finding stretch wrap at physical stores.

If you’re still wondering where to buy stretch wraps, you can trust PWP Stretch Film to deliver high-quality, reliable stretch wraps for all your packaging needs.

When it comes to finding stretch wrap for cheap, PWP Stretch Film offers competitive prices without compromising on quality. If you are trying to find affordable stretch wrap options, you can rely on us to provide high-quality materials at reasonable rates. By purchasing directly from PWP Stretch Film, you ensure that you get the best price for your stretch film while still receiving top-notch products.

If you prefer the convenience of buy pallet wrap online, PWP Stretch Film makes it easy to buy stretch film online. Our online platform allows you to browse a variety of options and place your order quickly. Whether you’re wondering where to buy stretch film for small personal projects or larger business needs, we offer a range of solutions that you can purchase from the comfort of your home.

Whether you’re asking where can I buy stretch film or simply looking for a reliable supplier, PWP Stretch Film is here to help with all your stretch wrap needs.

Finding reliable stretch wrap sale requires prioritizing suppliers that offer consistent quality, affordability, and logistical support. For pallet stretch wrap for sale, pallet stretch film suppliers – PWP Stretch Film is the optimal choice, providing a comprehensive inventory of hand wraps, machine rolls, and pre-stretched films to suit diverse packaging needs. Businesses aiming to pallet wrap bulk buy can leverage pallet wrap manufacturer bulk-order programs, which include volume discounts, custom packaging, and fast shipping to minimize downtime. Unlike generic marketplaces, PWP Stretch Film specializes exclusively in stretch films, ensuring expert advice on load types, film thickness, and application techniques. Our customer-centric approach includes sample testing, transparent pricing, and dedicated account management for repeat buyers.

Thinner yet durable, 23-micron stretch film is a popular choice for lightweight to medium-weight loads, balancing cost efficiency with reliable containment. PWP Stretch Film sources this specialized product directly from leading manufacturers with ISO-certified production facilities, guaranteeing films that resist punctures, tears, and elongation failures. These manufacturers utilize advanced resin blends and controlled extrusion processes to achieve consistent thickness and cling properties. By partnering with pallet wrap builders – PWP Stretch Film, buyers gain access to technical datasheets, eco-friendly options (such as recycled-content films), and custom-width rolls for automated machinery. Whether for warehouse distribution or export packaging, PWP ensures 23-micron films meet rigorous performance standards while reducing material waste and overall costs.

Red pallet wrap serves both functional and organizational purposes, such as color-coding shipments, enhancing visibility, or branding high-priority loads. PWP Stretch Film collaborates with the largest pallet wrap supplier of colored films, offering vibrant red options with UV stabilization to prevent fading during outdoor storage. These films maintain the same tensile strength and puncture resistance as standard wraps, ensuring secure palletization even under harsh conditions. For businesses requiring specialized formats, PWP also acts as a pallet shrink wrap roll supplier, providing red shrink films compatible with heat guns or automated sealing systems. Custom printing (e.g., logos, warnings) and anti-static variants are available for industries like electronics or pharmaceuticals. By centralizing procurement through PWP, buyers simplify sourcing, ensure color consistency across batches, and benefit from bulk-order incentives tailored to large-scale operations.

PWP Stretch Film streamlines the entire purchasing process, from product selection to doorstep delivery. Their platform features detailed product comparisons, case studies, and 24/7 support to address technical queries. By eliminating third-party sellers, PWP guarantees authentic, factory-fresh materials with traceable lot numbers and compliance certifications (e.g., FDA, REACH). For businesses prioritizing efficiency and reliability, PWP is the definitive solution for all stretch wrap needs.

The cost of shrink wrapping a pallet can vary widely based on several factors, including the type of film used, the labor involved, and the equipment necessary for the wrapping process. Shrink wrap costs are determined by the following considerations:

Film Type: Different types of shrink wrap film, such as standard PVC, PE (Polyethylene), or crosslinked films, come at varying price points based on their quality and performance. Films designed for high durability, puncture resistance, or UV protection tend to cost more.

Labor: If wrapping is done manually, labor costs will contribute to the overall expense. However, automated wrapping systems can reduce labor costs significantly over time, though the initial investment in machinery can be expensive.

Equipment: The type of equipment used—whether manual tools like a handheld shrink wrap gun, or more advanced machinery for high-volume wrapping—will also influence the price. Manual methods are cheaper upfront, but may be less efficient compared to automated solutions.

Shrink Wrap: The cost of shrink wrap generally ranges from $0.05 to $0.30 per square foot depending on the thickness, quality, and type of film. For larger volumes, bulk pricing can reduce the pallet wrap price significantly.

Stretch Wrap: Pallet stretch film with low price, ranging from $0.04 to $0.20 per square foot. It is widely used for securing loads and offers superior load containment without needing to shrink or heat the film.

Reusable pallet wrap tends to have a higher initial cost compared to disposable options due to its durable nature. However, over time, the investment in reusable wrap can result in long-term savings. Reusable wraps generally cost between $50 and $200 per roll, depending on the material and thickness. While the upfront cost is higher, it can be reused multiple times, leading to savings in the long run.

Disposable Wrap: Disposable wraps are generally cheaper per roll, but they must be replaced after each use. These wraps are designed for one-time use, and their cost can add up quickly for businesses that wrap pallets regularly.

Reusable Wrap: Reusable wraps can be used for multiple cycles, making them more cost-effective for high-volume applications. Though the initial purchase price is higher, the cost per use decreases with each subsequent wrapping.

By investing in reusable wraps, businesses can save on recurring costs of disposable wraps over time. For example, if a business uses 100 rolls of disposable wrap annually, but switches to reusable wrap that costs more initially but can be used 50 times, the ROI can be significant. In addition to the savings on material costs, businesses may also benefit from reduced waste disposal costs and environmental benefits.

Extended core pallet wrap is a variation of stretch film that has an extended handle, making it easier to apply by hand. The main benefits of extended core pallet wrap include:

Easier Handling: With an extended core, the user can handle the wrap more easily and apply it without the need for additional equipment. This can reduce physical strain and speed up the wrapping process.

Reduced Waste: The extended core design also allows for better control over the film’s application, reducing the likelihood of over-application and minimizing waste.

Extended core pallet wrap features a specially designed core that extends beyond the standard roll, providing an easy-to-handle feature for manual wrapping. This design allows users to grip the wrap more comfortably, reducing strain and improving efficiency during the wrapping process. It’s ideal for applications where speed and control are important, and it helps minimize waste by allowing more precise control over the amount of film used.

Extended core wrap is ideal for manual wrapping, as it offers better control and ergonomics compared to standard rolls. It’s a great option for smaller businesses or applications where wrapping needs to be done quickly without sophisticated equipment. However, it can also be used in combination with machines for added efficiency in high-volume environments, as it allows operators to quickly load the film into automated systems without the need for a traditional roll setup.

Not all pallet wraps have an odor, but some may emit unpleasant smells due to the materials used in their production. The causes of odor can include:

Resins and Additives: Some films contain certain resins or additives that can produce a strong odor, especially in warmer environments or when exposed to heat.

Manufacturing Process: The way the film is processed can also affect its smell. For example, films that are produced using certain chemicals during extrusion might have a lingering scent.

To address concerns about smell, manufacturers have developed odor-free stretch films. These films use alternative materials or advanced additives that don’t release unpleasant odors during storage or handling. Businesses that are sensitive to odors—such as those in food or pharmaceutical industries—can choose odor-free or low-odor films to maintain product quality and safety.

The difference between 70 and 80 gauge pallet wrap lies in their thickness and durability. Here’s a breakdown:

70 Gauge: A 70-gauge wrap is thinner and generally suited for lighter loads or situations where less puncture resistance is needed. It is often cheaper but may not provide the same level of protection for heavy or irregularly shaped items.

80 Gauge: An 80-gauge wrap is thicker and more robust, providing greater puncture resistance and durability. It is ideal for heavier loads and applications that require extra strength.

70 Gauge: While less expensive, the thinner film may not offer the same level of protection and can be prone to tearing or puncturing. It is suitable for lighter loads where cost efficiency is a priority.

80 Gauge: The thicker film provides stronger load security but comes at a higher price point. Businesses that regularly handle heavier or bulkier items may find the extra cost worth it for the added protection and load stability.

In the context of pallet wrap, the term “65g” typically refers to the weight of the film per square meter in grams. When converting to microns (a common unit for thickness in the film industry), the conversion depends on the specific material and density of the film. Typically, for stretch film, 1 micron equals approximately 0.92 to 1 gram per square meter. Therefore, 65g in terms of thickness would be roughly equivalent to around 65-70 microns, depending on the specific film formulation.

This metric helps to assess the overall thickness and durability of the film, which can be useful for selecting the right wrap for the application.

Design Features and Compatibility with Cylindrical Goods

Cylinder packaging systems are designed to handle stretch film rolls and other cylindrical goods efficiently. These systems ensure even tension and secure wrapping, reducing film waste.

Case Studies of Integrated Automated Production Lines

Many industries now integrate cylinder packaging with automated production lines, using stretch wrap rolls to streamline operations and improve consistency.

Technical Parameters (Width, Tension Control)

Roll slitters are used to cut large stretch film rolls into smaller stretch wrap rolls or custom-sized stretch rolls. Precision width and tension control are critical to maintaining film quality.

Custom Slitting Services and Efficiency Improvement

Custom slitting services allow businesses to tailor stretch film rolls to specific needs, optimizing material usage and reducing costs.

Equipment Functions and Safety Operation Standards

Roll cradles support stretch wrap rolls during use, ensuring smooth unwinding and minimizing the risk of film breakage. Proper safety standards must be followed to prevent accidents.

Mechanical Design to Reduce Film Roll Wear

Advanced roll cradles are designed to reduce wear on stretch rolls, extending their lifespan and maintaining consistent performance.

Characteristics of High-Performance Film (Puncture Resistance, High Adhesion)

Pro series stretch wrap rolls are engineered for heavy-duty applications, offering exceptional puncture resistance and high adhesion to secure even the most challenging loads.

Suitable Industries (Heavy Industry, Cold Chain Logistics)

These stretch rolls are ideal for industries like heavy manufacturing and cold chain logistics, where load integrity is critical.

Economic Analysis and Warehouse Compatibility

Large stretch film rolls provide cost savings by reducing the frequency of roll changes and are compatible with high-capacity warehouse systems.

Compatibility Requirements for Automated Equipment

When selecting large stretch wrap rolls, it is essential to ensure compatibility with automated wrapping equipment to maximize efficiency.

Product Protection

Stretch film securely wraps and holds items together, preventing damage from dust, moisture, or scratches.

It provides a protective barrier against external elements during storage or transit.

Load Stability

It tightly binds products to pallets, reducing movement and minimizing the risk of shifting or toppling during transportation.

Ensures safer handling and reduces the likelihood of accidents.

Cost-Effective

Stretch film is an affordable packaging solution compared to other materials like strapping or shrink wrap.

Its lightweight nature also reduces shipping costs.

Versatility

Suitable for a wide range of industries, including food, logistics, manufacturing, and retail.

Can be used to wrap items of various shapes and sizes.

Space Efficiency

By compacting items together, stretch film reduces the overall volume of loads, optimizing storage and transportation space.

Transparency

The clear nature of stretch film allows for easy identification of wrapped products without unwrapping.

Enhances inventory management and reduces errors.

Durability

High-quality stretch film is resistant to punctures and tears, ensuring long-lasting protection.

Can withstand varying temperatures and weather conditions.

Root Cause Analysis (Uneven Tension, Equipment Wear)

If a stretch film roll stops rolling, it may be due to uneven tension or worn equipment components. Regular maintenance can prevent such issues.

Solutions and Preventive Maintenance

Implementing preventive maintenance schedules and using high-quality stretch rolls can minimize downtime and improve operational efficiency.

Insufficient adhesion in stretch wrap rolls can result from improper storage or low-quality film, while film breakage often stems from excessive tension or mechanical faults.

When it comes to balancing affordability with premium quality, PWP Stretch Film leads the industry as a trusted provider of customized stretch wrap cost-effective solutions. We understand that businesses prioritize stretch wrap best price without sacrificing performance, and our pricing strategies are designed to meet diverse budgetary needs while ensuring exceptional value.

In an era of stretch film price increases driven by raw material costs and supply chain dynamics, PWP remains committed to transparency and competitive pricing. Our stretch film wrap price is structured to provide clarity, whether you’re purchasing small batches or bulk orders. Below, we break down our pricing framework and product-specific rates to help you make informed decisions:

Stretch Wrap Film Quotes: Stretch Wrap Roll Price Range

Hand Stretch Film: ¥1.2 – 5 rolls (ideal for small businesses)

Machine Stretch Film: ¥2.8 – 8 rolls (heavy-duty pallet wrapping)

Colored Stretch Film: ¥1.8 – 15 rolls (visibility and branding)

Bundling Film: ¥0.9 – 12 rolls (lightweight securing)

Mini Stretch Film: ¥0.5 – 4 rolls (compact packaging)

Pre-Stretched Film: ¥1.2 – 9.6 rolls (reduced material usage)

VCI Stretch Film: ¥0.9 – 8 rolls (corrosion protection)

UVI Stretch Film: ¥0.8 – 12 rolls (UV-resistant for outdoor storage)

Breathable Stretch Film: ¥0.98 – 13 rolls (ventilated packaging)

Our stretch film price per kg remains highly competitive, averaging 20–30% below industry benchmarks due to optimized production processes and economies of scale. Whether you’re comparing stretch wrap price across suppliers or evaluating long-term partnerships, PWP ensures consistent affordability even during market volatility.

Volume Discounts: Larger orders unlock significant savings on stretch wrap film price.

Price Stability: We mitigate stretch film price increases through strategic sourcing and lean manufacturing.

Custom Quotes: Share your requirements for tailored stretch film prices based on custom stretch wrap type, thickness, and order size.

By prioritizing both stretch wrap best price and unmatched quality, PWP Stretch Film empowers businesses to streamline packaging costs while maintaining load integrity. Contact us today to request a quote or discuss strategies to navigate pricing challenges in your industry!

In the competitive landscape of packaging solutions, PWP Stretch Film stands out as a globally recognized leader and trusted partner for businesses seeking high-performance stretch film products. As one of the most honored stretch film suppliers, our commitment to innovation, quality, and customer-centric service has solidified our reputation among top-tier stretch wrap manufacturers and end-users worldwide.

Whether you’re searching for stretch film manufacturers near me or a global supplier, PWP Stretch Film caters to both local and international markets. Our advanced manufacturing facilities produce premium-grade stretch wrap films designed for durability, load stability, and cost efficiency. From lightweight hand wraps to heavy-duty machine-grade films, our product range addresses the needs of industries like logistics, agriculture, food and beverage, and e-commerce.

Innovation-Driven Production: Leveraging cutting-edge technology, we develop films with superior cling, tear resistance, and elongation properties.

Sustainability Focus: As environmentally conscious stretch wrapping companies, we offer recyclable and thin-gauge films that reduce material waste without compromising strength.

Customization: Tailored solutions for unique packaging challenges, including UV-resistant films, pre-stretched options, and specialty widths.

For businesses prioritizing proximity, searching for “stretch film manufacturers near me” often leads to regional partners like PWP. With strategically located distribution hubs, we ensure fast delivery and responsive support. Simultaneously, our global network positions us as a go-to supplier stretch film for multinational corporations requiring consistent quality across borders.

PWP’s recognition as a top stretch film company stems from decades of expertise and certifications in safety and sustainability. Collaborating with renowned stretch wrap suppliers ensures clients receive not only products but also value-added services like technical training, packaging audits, and 24/7 customer care.

Whether you’re evaluating stretch wrapping companies for reliability, innovation, or ethical practices, PWP Stretch Film exemplifies excellence. Explore our offerings and discover why industries worldwide honor us as a pioneer in stretch film solutions.

When it comes to purchasing large rolls of stretch wrap, there are various reliable sources to consider, depending on your specific needs and business requirements. Stretch wrap, also known as stretch film, is essential for securing and protecting products during transportation and storage. Finding the right supplier ensures that you can obtain high-quality products at competitive prices.

Specialized packaging companies are excellent sources for large rolls of stretch wrap. Packaging suppliers usually offer a comprehensive selection of stretch films in various thicknesses, including both manual and machine stretch wrap. Also typically have multiple roll sizes to cater to both small and large businesses.

Example: Stretch Wrap Rolls for Sale platforms often provide a wide range of options for those who need to purchase stretch wrap in bulk.

Many packaging suppliers also offer flexibility in pricing and the option to customize stretch films based on your requirements.

For businesses needing to buy stretch wrap in large quantities, wholesale distributors are a great option. These distributors often provide large roll options at lower prices due to their bulk pricing structure. Wholesale suppliers tend to have substantial inventory and can deliver large orders quickly.

Example: Wholesale stretch film wrapping roll suppliers may offer competitive rates for bulk purchases, often including additional services such as free delivery for large orders.

Buying from a wholesale supplier often ensures a steady supply and can significantly lower overall packaging costs.

A direct route to purchasing large rolls of stretch wrap is through stretch film roll manufacturers. These manufacturers produce high-quality films that can be custom ordered to fit specific needs, such as different thicknesses or UV-resistant features. Buying directly from a manufacturer may offer the best pricing for large orders and provide more flexibility in terms of customization.

Example: PWP Stretch Film stretch wrap rolls for sale, you can directly source the film from the manufacturers, ensuring a more competitive price.

Online platforms such as PWP Stretch Film are convenient options for businesses looking to buy stretch wrap rolls. These marketplaces often feature a wide variety of stretch films, including bulk pricing and competitive offers from multiple suppliers. You can compare different brands, sizes, and prices in one place, making it easier to find the best option for your needs.

Searching for a stretch roll manufacturer on these platforms can lead to several choices of suppliers with options for large rolls of stretch wrap available for fast delivery.

If you prefer a more personal approach or need immediate access to large rolls of stretch wrap, local packaging and supply stores may be a good choice. These stores often carry a selection of stretch film products in different sizes, allowing for a quick purchase without waiting for shipping. Local suppliers can also offer personalized service and advice on which type of stretch wrap would be most suitable for your packaging needs.

Purchasing directly from a stretch film wrapping roll factory is another efficient method, particularly for large-volume needs. Factories that produce stretch wrap often offer competitive pricing for bulk orders and may also provide the option for customized films. These manufacturers typically offer a variety of film types, from basic options to more specialized products like UV-resistant or heavy-duty stretch wraps.

Example: Many manufacturers that produce stretch wrap rolls for sale offer bulk pricing and direct stretch film for sale to companies needing large quantities of film.

There are numerous places to buy large rolls of stretch wrap, ranging from industrial supply stores to direct purchases from stretch film roll manufacturers or stretch wrap rolls for sale online. Depending on your business’s needs—whether you’re looking for bulk pricing, custom sizes, or quick delivery options—there’s a supplier that can meet your requirements. Be sure to compare prices, delivery times, and product options to find the best deal for your stretch wrap needs.

Don't wait - reach out today to ensure timely delivery and exceptional service.

In an era where supply chain efficiency and cost control are non-negotiable for industrial operations, wholesale machine stretch film has emerged as a strategic lever

Driven by the global supply chain and high-frequency logistics turnover, large-scale cling film has broken through the scope of traditional food packaging and evolved into

Imagine carefully stacking boxes for shipment, only to discover upon arrival that goods have shifted, collapsed, or been damaged by moisture and debris. For businesses

Stretch film is a critical component in modern packaging, offering protection, stability, and cost efficiency for a wide range of industries. Among the various thickness

Stretch wrap, also known as stretch film, plays a critical role in ensuring the safety and stability of goods during storage and transportation. From securing

Clear stretch film is an essential packaging material widely used across various industries for securing and protecting goods during transit and storage. Its versatility makes

LDPE (Low-Density Polyethylene) is a versatile and widely used plastic material known for its flexibility, durability, and lightweight properties. In the packaging industry, LDPE is

Polyethylene stretch film is a highly versatile and widely used material in the packaging industry. It is a type of plastic film that stretches over

Pallet shrink wrap is a versatile packaging material commonly used to secure and protect palletized goods during storage and transportation. It is a thin, stretchable

From sealing leftovers in home kitchens to securing pallets in industrial warehouses, plastic wrap rolls have become an indispensable tool across industries. But with countless

Pallet wrap, also known as stretch film, plays a critical role in the logistics and transportation industries. It is used to secure products on pallets,

LDPE (Low-Density Polyethylene) film is a highly versatile plastic material widely used across various industries due to its unique properties. As a flexible and durable

LLDPE stretch film plays a crucial role in the packaging industry, offering flexibility, strength, and excellent performance for a wide variety of applications. LLDPE (Linear

Stretch films are a critical packaging material widely used in industrial applications. Their role is to ensure products remain secure and stable during transit and

What type of damage do you worry about most when moving? Please tell us: The day of moving should be a fresh start — but