Benefits of Choosing a Plastic Colored Stretch Film Factory

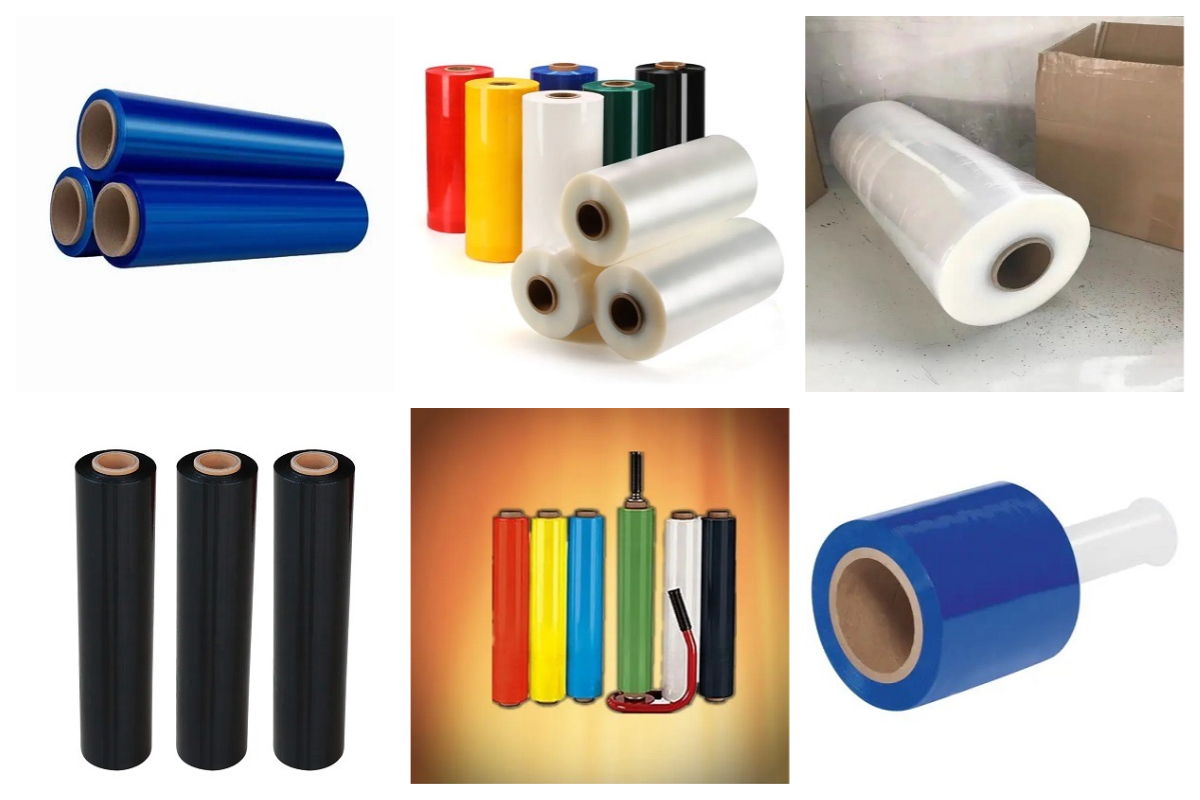

Plastic colored stretch film is a versatile packaging material widely used for securing, bundling, and protecting products during storage and transportation. The use of colored

Home >> Color Stretch Film

Color stretch film is a versatile packaging solution that combines functionality with visual appeal. Ideal for various applications, this film enhances both the security and identification of goods during shipping and storage. Available in a range of vibrant colors, including tinted options, tinted stretch wrap facilitates easy product identification, inventory sorting, and offers a protective barrier against dust and moisture. Color stretch film is particularly useful for color-coding products, making it easier to manage inventory and streamline operations. It also provides an opaque layer to conceal product contents, which is valuable for international shipments and warehouse organization.

By integrating tinted tinted stretch film into your packaging process, you can improve efficiency and ensure your products are well-protected throughout their journey.Shop our in-stock colored stretch wrap in various colors. Enjoy strength、high-quality cast stretch films and pallet wraps.

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Material | Linear Low Density Polyethylene |

| Type | Color Stretch Film |

| Color | Customizable |

| Length | Customizable |

| Width | Customizable |

| Thickness | Customizable |

| Features | Moisture-proof, Anti-static |

| Hardness | Soft |

| Processing Type | Casting, Multiple Extrusions |

| Transparency | Transparent, Translucent, Opaque |

| Size | Customized as per Your Requirements |

| Logo | Customized Logo Accepted |

| Surface | Smooth |

| Advantages | Excellent Performance |

| Use | Pallet Stretch Wrap, Wrapping |

| Grade | Hand Roll, Machine Roll |

Color stretch film comes in various types of wraps, each designed to meet specific packaging needs. Whether you require a manual solution or a more automated approach, colored stretch wrap provide flexibility for different applications. Coloured pallet wrap offers both functional and aesthetic benefits, making it ideal for industries requiring product differentiation, safety enhancements, or branding visibility. Below are the key types of colored stretch films available:

Hand Stretch Wrappers using hand stretch film are ideal for small to medium-sized operations.These films are manually applied using a handheld roll, making them perfect for businesses that need quick and easy packaging solutions. With Hand Stretch Wrappers, operators can easily secure products by wrapping them tightly with the Color Stretch Film. This option is best suited for businesses where labor costs are low and speed is not the top priority, as it offers more control but requires more time to apply low cost stretch film.

For larger-scale operations, Machine Stretch Wrappers using machine stretch film are a more efficient solution. Designed for high-volume environments, machine-applied Color Stretch Film can save time and reduce material usage, thanks to pre-set stretch levels that ensure optimal stretch film tension measurement. Machine stretch wrappers are particularly useful for ensuring consistent and secure packaging, offering enhanced puncture resistance and load stability. With machine wrappers, operators can quickly wrap large pallets, maximizing productivity and minimizing labor costs.

This specialized coloured pallet wrap combines anti-static properties with vibrant color options. Designed for electronics, pharmaceuticals, or environments sensitive to static discharge, it prevents dust attraction and protects sensitive goods. The pre-stretched design ensures consistent tension and reduces material waste. For reliable quality, collaborate with trusted colored pallet wrap film suppliers like PWP Stretch Film, we offers tailored solutions for static-sensitive applications.

PVC-based colored stretch film is known for its durability and clarity, even when tinted. It provides excellent load stability for irregularly shaped items and is often used in food, retail, or lightweight packaging. Available in multiple hues, this film helps categorize shipments or align with corporate branding. Leading plastic colored stretch film manufacturers prioritize UV resistance and tear strength to meet diverse industrial needs.

LLDPE (Linear Low-Density Polyethylene) color stretch film is prized for its elasticity, puncture resistance, and eco-friendly properties. The material’s flexibility makes it suitable for heavy or uneven loads, while colors like blue, green, or red enhance visual organization in warehouses. Partner with colorful LLDPE stretch film suppliers such as PWP Stretch Film to access customizable thicknesses and widths for optimized performance.

There are two main types of Color Stretch Film: opaque and transparent. Opaque colored stretch film is used primarily for concealing products and offering UV protection. It is commonly used in industries that need to hide sensitive shipments or protect products from light exposure. The colors available for opaque films are typically white and black, which provide maximum coverage after just a few wraps.

On the other hand, Transparent Color Stretch Film allows for product visibility, making it easier to identify contents while still providing color-coded organization. Available in a variety of colors such as blue, red, green, yellow, and orange, transparent films help with quick product identification without fully concealing the items. This type is favored for environments where both color coding and product visibility are essential, such as warehouses or retail stores.

12 inches: Suitable for smaller packages or bundles.

15 inches: Ideal for medium-sized loads.

18 inches: Commonly used for a variety of applications.

20 inches: Good for larger loads or pallets.

30 inches: Best for heavy-duty applications and bulk packaging.

50 gauge (0.50 mil): Lightweight, suitable for light to medium loads.

60 gauge (0.60 mil): Offers increased strength for medium loads.

80 gauge (0.80 mil): Provides good puncture resistance for heavier items.

90 gauge (0.90 mil): Ideal for securing heavy and awkwardly shaped loads.

120 gauge (1.20 mil): Heavy-duty option for the most demanding applications.

1,000 feet: Standard length for general use.

1,500 feet: Provides additional film for larger projects.

2,000 feet: Suitable for high-volume operations.

3,000 feet: Best for extensive packaging needs.

Hand rolls: Designed for manual application, easy to handle.

Machine rolls: Compatible with automatic or semi-automatic pallet wrappers.

When sourcing high-quality colored pallet wrap, prioritize suppliers with proven expertise and customization options. PWP Stretch Film stands out among colorful LLDPE stretch film manufacturers, offering a wide range of pre-stretched, anti-static, and PVC-based films. Our products cater to industries requiring color-coded logistics, static control, or enhanced load protection. For bulk orders or specialized requirements, contact PWP Stretch Film directly to ensure your packaging aligns with operational and branding goals.

By selecting the right type of coloured pallet wrap and partnering with reputable suppliers, businesses can improve efficiency, safety, and visual management in their supply chains.

Color Stretch Film offers a range of advantages that make it an essential packaging tool for businesses looking to enhance efficiency and product protection. Compared to traditional wrapping materials like shrink wrap, Color Stretch Film brings unique benefits that streamline operations and safeguard goods.

While both Color Stretch Film and Shrink Wrap are used to secure products, they serve slightly different purposes. Shrink Wrap requires heat to conform tightly around products, offering a more permanent, tight seal. However, Color Stretch Film provides a more flexible and reusable solution, as it doesn’t require heat and can be easily applied by hand or machine. Additionally, Color Stretch Film offers the benefit of color coding, making it ideal for inventory management, while shrink wrap lacks this capability. Businesses that need both security and identification will find Color Stretch Film more versatile, especially in environments with varying packaging needs.

One of the key advantages of using Color Stretch Film is the ability to organize and sort inventory more effectively through color coding. By wrapping pallets or product loads in different colors, businesses can easily identify items based on product type, destination, or date. This system not only streamlines warehouse operations but also reduces the time spent on sorting and finding specific products during shipment or storage. Whether using blue, red, green, or other colors, Color Stretch Film provides an efficient solution for companies aiming to boost productivity and reduce errors in product handling.

Beyond its color coding capabilities, Color Stretch Film offers superior protection for goods during transit and storage. The film acts as a durable barrier against environmental factors like dust, moisture, and even UV light (in the case of opaque films). This added layer of protection ensures that products remain clean and dry, reducing the risk of damage. Color Stretch Film also offers high puncture resistance, helping to prevent accidental tears or holes during handling. This makes it an excellent choice for businesses looking to protect fragile or valuable items without sacrificing ease of use.

Color stretch film is incredibly versatile, suitable for a wide range of applications across various industries. Whether used for securing pallet loads, bundling items, or protecting products during storage, this film adapts to different packaging needs. The ability to choose from various colors and thicknesses allows businesses to customize their packaging according to specific requirements. This versatility ensures that color stretch film can be effectively integrated into diverse workflows, enhancing overall operational flexibility.

Investing in color stretch film can lead to significant cost savings for businesses. The film’s strength and durability help reduce product damage during transit, minimizing the need for costly replacements or returns. Additionally, the enhanced visibility and organization improve inventory accuracy, decreasing labor costs associated with mismanagement. Color stretch film also allows for efficient use of materials, as it can securely hold a variety of shapes and sizes without excessive waste. Overall, its cost-effective nature contributes to improved profit margins.

Packing Tape is a critical companion to Color Stretch Film, particularly for securing the edges and ends of pallets or wrapped items. While Color Stretch Film provides excellent coverage and stability, using Packing Tape ensures that no loose ends or edges are exposed, preventing the film from unraveling during transport or storage. This combination offers an extra layer of security, holding the film in place and reinforcing the packaging to withstand more rigorous handling or long-distance shipping.

For fragile items, pairing Bubble Wrap with Color Stretch Film is essential. Bubble Wrap adds an extra cushion to protect sensitive items from shocks, impacts, or vibrations during transportation. After applying a protective layer of Bubble Wrap around the item, using Color Stretch Film over the wrapped product provides both color coding and a secure external layer. This not only ensures that the items remain safe inside the packaging but also makes the parcels easily identifiable based on the color coding system provided by the stretch film.

Packing Paper serves as a protective inner layer that can be wrapped around products before using Color Stretch Film. It’s particularly useful for filling voids in packaging or wrapping items with irregular shapes. By adding Packing Paper first, the package gains an extra layer of shock absorption, and when combined with color tinted extended core stretch film, the product is fully protected and stabilized. This method is particularly helpful when dealing with glassware, electronics, or other breakable items that need enhanced protection and stabilization.

One of the primary applications of Color Stretch Film is in the organization of shipments and the easy identification of pallets. By using different colored films, businesses can quickly distinguish between products destined for different locations, customers, or departments. This method simplifies the sorting process, enabling warehouse staff to immediately identify the contents of a shipment without needing to inspect the packaging closely. Color-coded pallets also help reduce errors in delivery, ensuring that the right products reach their destination without confusion.

In addition to organizing shipments, color stretch film manufacturers provides a way to conceal sensitive or high-value items while maintaining easy identification through color coding. For example, companies may use opaque black or white films for privacy while applying bright colors to differentiate between product categories or priority shipments. This dual functionality makes Color Stretch Film a versatile tool in any shipping or storage operation.

Logistics Sector:

Plays a crucial role in improving supply chain efficiency.Streamlines the identification and handling of goods.

Allows logistics companies to quickly categorize pallets by destination or delivery urgency.

Makes the sorting and loading process faster and more accurate.

Retail Industry:

Used to protect merchandise while maintaining visibility.

Provides an additional layer of branding through color-coded wrapping.

Helps retailers organize products by season, category, or promotional sales.

Ensures items can be easily located on shelves or in storage.

Manufacturing Industry:

Used to bundle products, parts, or raw materials.

Ensures shipments are well-organized and secure.

Color coding is useful in assembly lines or production areas for quick identification.

Color stretch film plays a crucial role in international shipping by providing protection and visibility to packaged goods. The film’s strong, elastic properties ensure that items are securely wrapped and protected from damage during transit. In international logistics, the use of colored stretch film helps facilitate easy identification and organization of shipments. Different colors can signify specific destinations, customs statuses, or product types, simplifying the sorting and handling process at various points along the supply chain. Additionally, the opaque nature of certain colors can conceal contents, which is beneficial for security and confidentiality during transport. By integrating color stretch film into their packaging processes, companies can enhance the efficiency of their international shipping operations while ensuring that their products arrive safely and in optimal condition.

At the Color Stretch Film Factory, colored stretch wrap suppliers specialize in producing high-performance Color Stretch Film designed to meet a wide range of packaging needs. Our films are not only visually striking but also engineered to provide superior protection and functionality for your products. Whether you’re looking to enhance product visibility, improve inventory management, or ensure secure transportation, our Color Stretch Film is the ideal solution.

High Visibility Colors:

Our Color Stretch Film is available in vibrant colors such as blue, red, and green, making your products stand out on the shelves. The high visibility of these colors ensures that your products catch the eye of customers, giving you a competitive edge in the market.

Puncture and Abrasion Resistant:

Our films are designed to withstand tough handling and transportation conditions. The puncture and abrasion-resistant properties ensure that your products remain safe and secure, even during long-distance shipping or storage in challenging environments.

Extra Quiet Unroll:

Our Color Stretch Film is engineered for extra quiet unrolling, making it easier and more pleasant to use in busy warehouse or production environments. This feature reduces noise pollution and enhances the overall user experience.

Customizable Colors:

While we offer a range of standard colors, additional colors are available upon request. This flexibility allows you to choose the perfect color to match your branding or specific packaging needs.

Eco-Friendly Formula:

We are committed to sustainability. Our Color Stretch Film is made using an eco-friendly formula that ensures no harmful pollutants are released into the environment. This makes our film a responsible choice for businesses looking to reduce their environmental impact.

Hand Stretch Film:

Our colored hand stretch film is easy to use and ideal for smaller packaging tasks. It provides the same high level of protection and visibility as our machine films but is designed for manual application.

Machine Stretch Film:

For larger-scale operations, our colored machine stretch film is the perfect choice. It is compatible with automated packaging systems, ensuring consistent and efficient wrapping of pallets and large loads.

Preferential Quotes and Pricing:

Factors Influencing the Quote:

Content Concealment:

Our colored stretch film is excellent for hiding the contents of packages, providing an additional layer of security and privacy.

Dust, Dew, and Rain Protection:

The film acts as a barrier against environmental factors, keeping your products clean and dry.

Extended Outdoor Lifespan:

When treated with UV inhibitors, our films can last longer outdoors compared to standard clear films, making them ideal for long-term storage or transportation.

Color-Coded Management:

Use different colors to color-code your packages for easy identification and management, streamlining your logistics and inventory processes.

At PWP Stretch Film, we combine advanced manufacturing techniques with innovative design to produce Color Stretch Film that meets the highest standards of quality and performance. Our films are not only functional but also aesthetically pleasing, allowing you to create a unique and attractive packaging that sets your products apart from the competition.

Whether you need color-coded packaging for efficient inventory management, tamper-evident solutions for secure shipping, or simply want to give your products a distinctive look, our Color Stretch Film has you covered. With a variety of colors, widths, and sizes available, we can tailor our products to meet your specific requirements.

Try PWP Stretch Film’s Color Stretch Film today and ensure your products stand out while staying protected!

Contact Us:

For more information or to place an order, please reach out to our team. We’re here to help you find the perfect packaging solution for your needs.

The terms blown film and stretch film can be related but refer to different aspects of plastic film production and application. Blown film is a manufacturing process used to produce various types of plastic films, including stretch films. In this process, molten plastic is extruded through a circular die to form a thin-walled tube. Air is then blown into the tube to expand it, creating a bubble. As the bubble rises, it cools and solidifies into film, which is then collapsed and wound onto rolls. Stretch film, on the other hand, is a type of plastic film used primarily for wrapping and securing palletized goods. Stretch film can be produced using either the blown film process or the cast film process. When stretch film is produced using the blown film method, it is referred to as blown stretch film. Blown stretch film is known for its high strength, puncture resistance, and excellent load-holding capabilities due to the molecular orientation achieved during the manufacturing process. It typically has a more textured surface and a hazy appearance. In contrast, cast stretch film is produced using the cast extrusion process, where molten plastic is extruded through a flat die and rapidly cooled on chilled rollers. Cast stretch film offers superior clarity, a smooth surface, and quiet unwind, making it ideal for applications where visual inspection of the load is important.

Stretch film is also commonly known as stretch wrap. Both terms are used interchangeably in the packaging and shipping industries to describe the elastic plastic film used for wrapping and securing products. Other alternative names include pallet wrap, plastic wrap, or wrapping film, which highlight the film's primary functions of wrapping around items to hold them together and protect them during transit and storage. In some regions or industries, it may also be referred to as cling film, although this term is more commonly associated with food-grade plastic wrap used in kitchens. It's important to note that stretch film differs from shrink wrap, which is a different type of packaging material that requires heat to shrink tightly around products. Understanding these various terms is helpful when selecting the appropriate packaging materials and communicating effectively within the industry. Regardless of the name used, the essential characteristics and uses of the material remain the same: to secure, protect, and stabilize products during handling, shipping, and storage.

The shelf life of stretch film refers to the period during which the film retains its optimal physical and mechanical properties when stored under recommended conditions. Typically, stretch film has a shelf life of approximately 12 to 18 months from the date of manufacture. However, this can vary depending on factors such as the film's composition, storage environment, and exposure to environmental elements. To maximize the shelf life of stretch film, it should be stored in a cool, dry environment, away from direct sunlight and sources of heat. Ideal storage temperatures range from 50°F to 77°F (10°C to 25°C), with relative humidity below 80%. Exposure to high temperatures can cause the film to lose its elasticity and become brittle, while excessive humidity may affect its cling properties. Ultraviolet (UV) light from sunlight can degrade the film, leading to a breakdown of the polymer chains and resulting in reduced strength and performance. Therefore, storing stretch film away from windows or in UV-protected packaging can help prolong its shelf life. It's also important to avoid stacking heavy objects on top of stored rolls, as this can deform the cores and make the film difficult to unwind during application. Rotating stock (first-in, first-out) ensures that older film is used before it potentially degrades. After the shelf life has elapsed, stretch film may still be usable, but its performance could be compromised. Signs of degradation include a loss of elasticity, reduced cling, brittleness, or discoloration. Using degraded film can lead to insufficient load containment, increasing the risk of product damage during transit.

Stretch film is utilized across a wide range of industries due to its effectiveness in securing and protecting goods during transportation and storage. Here are some of the key industries that rely heavily on stretch film: Manufacturing: Producers of consumer goods, electronics, automotive parts, and machinery use stretch film to wrap and stabilize products on pallets. It ensures that finished goods are protected from damage and remain intact throughout the supply chain. Logistics and Distribution: Warehouses, distribution centers, and freight companies use stretch film extensively to consolidate shipments, optimize space, and reduce the risk of product damage during transit. It aids in efficient handling and storage of goods. Retail: Retailers, including supermarkets and department stores, use stretch film to secure merchandise for bulk shipments to stores. It helps prevent tampering, maintains product cleanliness, and ensures that items arrive in good condition. Food and Beverage: The food industry uses stretch film for hygienic packaging solutions, wrapping pallets of packaged foods, beverages, and perishable items. It helps maintain freshness and prevent contamination during transportation. Agriculture: Farmers and agricultural businesses use stretch film to wrap bales of hay, silage, and other fodder, preserving their quality by protecting them from moisture and air exposure. Specialized agricultural stretch films are designed for this purpose. Pharmaceutical and Medical: The pharmaceutical industry employs stretch film to secure sensitive products, medicines, and medical devices, ensuring they are delivered safely without compromising their integrity. Construction and Building Materials: Stretch film is used to bundle building materials such as lumber, pipes, tiles, and metal components. It facilitates easier handling and protects materials from dust and moisture. Chemical and Petrochemical: Companies in these sectors use stretch film to secure drums, containers, and bags of chemicals, preventing spills and ensuring safe transport. Paper and Printing: Producers of paper goods and printed materials use stretch film to protect products like reams of paper, books, and magazines from damage and environmental exposure. E-commerce and Fulfillment: With the rise of online shopping, fulfillment centers use stretch film to consolidate packages and ensure that orders are shipped securely to customers.

Choosing the right stretch film is crucial for ensuring the security and integrity of your palletized loads during transportation and storage. Here are key factors to consider when selecting a stretch film: Load Characteristics: Evaluate the weight, size, shape, and stability of your loads. Heavy or irregularly shaped loads may require a thicker film (higher gauge) with greater tensile strength and puncture resistance. Lighter, uniform loads might be adequately secured with thinner films. Type of Stretch Film: Decide between different types of films: Cast Stretch Film: Offers excellent clarity, making it easy to inspect wrapped goods. It unwinds quietly and has consistent cling, which is ideal for standard loads. Blown Stretch Film: Provides superior puncture resistance and load-holding force, suitable for heavy or sharp-edged loads. It has a higher tear resistance but is less clear than cast film. Application Method: Determine if you'll be applying the film manually or with a machine: Hand Stretch Film: Designed for manual wrapping, it's lighter and easier to handle. Ideal for low-volume operations or when wrapping occurs in various locations. Machine Stretch Film: Formulated for use with stretch wrapping machines, it can handle higher stretch levels and is suitable for high-volume applications. Film Gauge (Thickness): The thickness affects strength and stretchability. Common gauges range from 60 to 120 gauge (15 to 30 microns). Thicker films offer more strength but may be more expensive. High-performance films allow for thinner gauges without sacrificing strength. Pre-Stretch Level: Some films are pre-stretched during manufacturing, reducing the effort required during application and improving efficiency. Pre-stretched films can also reduce material usage and cost. Environmental Conditions: Consider the storage and transit conditions: UV Resistance: If loads are stored outdoors, UV-resistant film prevents degradation from sunlight. Temperature Tolerance: For cold storage or hot environments, select a film designed to maintain performance under extreme temperatures. Special Features: Look for films with specific properties if needed: Colored or Opaque Films: Enhance security by concealing load contents or aid in product identification. Vented Films: Allow airflow for products that need to breathe, such as fresh produce. Cost Efficiency: Balance the cost with the film's performance. While higher-quality films may have a higher upfront cost, they can offer better protection and reduce overall expenses by minimizing product damage and film usage. Supplier Consultation: Work with reputable suppliers who can provide guidance based on your specific needs. They may offer samples for testing to ensure the chosen film meets your performance requirements.

Stretch film can be food grade, but it is important to verify that it meets specific standards for food safety. Food Grade Stretch Film: Food grade stretch film is designed to meet stringent safety and hygiene requirements for packaging food products. This type of stretch film is made from materials that are approved for direct contact with food. The primary material used is typically Linear Low-Density Polyethylene (LLDPE) or Low-Density Polyethylene (LDPE), which are both considered safe for food packaging. Key Characteristics: Compliance with Regulations: Food grade stretch film must comply with regulations set by food safety authorities, such as the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These regulations ensure that the film does not contain harmful substances that could migrate into the food. Hygiene and Safety: Food grade stretch film is manufactured in controlled environments to prevent contamination. It is often produced using additives that are specifically approved for food contact, ensuring that the film remains safe throughout its use. No Harmful Chemicals: Food grade films are free from hazardous chemicals like heavy metals or phthalates, which could potentially leach into food items. The materials used are selected to ensure that they do not negatively impact food safety. Applications: Food grade stretch film is commonly used in grocery stores, food service industries, and households to wrap fresh produce, deli meats, and other food items. It helps to maintain freshness, prevent contamination, and extend the shelf life of food products. How to Verify: To confirm whether a stretch film is food grade, check the product specifications or labels for certifications or approvals from relevant food safety authorities. Manufacturers often provide documentation or certifications that verify their stretch film’s compliance with food safety standards.

The thickness of stretch film wrap is a crucial factor that determines its strength, stretchability, and suitability for different applications. Stretch film thickness is typically measured in microns (µm) or gauge, where one gauge equals 0.254 microns. Common thicknesses range from 8 microns (32 gauge) up to 35 microns (140 gauge). For lightweight applications, such as wrapping small or uniform loads, thinner films ranging from 8 to 12 microns (32 to 47 gauge) are often used. These thinner films are more cost-effective and reduce material usage, making them ideal for securing light packages or boxes. For medium-duty applications, films between 15 to 20 microns (60 to 80 gauge) are commonly utilized. These are versatile and suitable for most general-purpose pallet wrapping, offering a good balance between strength and cost. For heavy-duty applications, where loads are heavy, irregular, or have sharp edges, thicker films ranging from 23 to 35 microns (90 to 140 gauge) are necessary. These thicker films provide increased puncture resistance and load-holding capability, ensuring that the load remains secure during handling and transit. Advancements in stretch film technology have led to the development of multi-layered and high-performance films that offer the same or improved strength at reduced thicknesses. This allows for material cost savings and environmental benefits due to reduced plastic usage. When selecting the appropriate thickness, it is essential to consider factors such as the weight and dimensions of the load, the type of products being wrapped, handling methods, and storage conditions. Consulting with a packaging specialist can help determine the most suitable film thickness for your specific needs, ensuring optimal load security and cost-efficiency.

While both stretch film and cling film are plastic films used for wrapping, they are not the same and serve different purposes. Stretch film, also known as stretch wrap, is primarily used in industrial and commercial settings to secure and stabilize palletized goods. Made from linear low-density polyethylene (LLDPE), stretch film is designed to be stretched around products, providing tension that holds items tightly together during transportation and storage. It offers load containment, protection from dust and moisture, and can be applied manually or with wrapping machines. Cling film, often referred to as plastic wrap or food wrap, is a thin, flexible, and transparent film commonly used in households and the food industry to wrap food items. Typically made from low-density polyethylene (LDPE) or polyvinyl chloride (PVC), cling film is designed to cling to surfaces without the need for stretching, providing an airtight seal that helps preserve food freshness by protecting it from air exposure, moisture loss, and contaminants. Cling film is safe for direct contact with food and is not intended for heavy-duty packaging or securing large loads. Key Differences: Intended Use: Stretch film is used for industrial pallet wrapping; cling film is used for wrapping food items. Material Composition: Stretch film is made from LLDPE; cling film is made from LDPE or PVC. Stretchability: Stretch film is designed to stretch significantly and provide tension; cling film has minimal stretch and relies on adhesion. Application Method: Stretch film is applied by wrapping and stretching around loads; cling film is placed over or around food items and pressed to adhere. Safety for Food Contact: Cling film is food-safe; stretch film is not intended for direct contact with food.

Stretch film rolls are versatile packaging tools used for securing and protecting a wide range of products and materials. Primary Uses: Pallet Wrapping: One of the most common uses for stretch film rolls is to wrap pallets of goods. This helps to stabilize the load during transportation and storage, preventing items from shifting or falling. The film’s cling properties create a tight, secure wrap that holds the goods in place. Product Protection: Stretch film rolls are used to protect individual products from dust, dirt, moisture, and other environmental factors. This is especially useful for items that need to be stored or transported over long distances. The film’s stretchability ensures a snug fit around irregularly shaped products. Tamper Evidence: Stretch film can act as a tamper-evident seal, alerting users if a package has been opened or tampered with. This feature enhances security and helps ensure the integrity of the product. Bundling: Stretch film is also used to bundle multiple items together. For example, in retail settings, it can be used to group similar products or to create multipacks, making handling and transportation more efficient. Wrapping and Protection in Storage: In warehouses and storage facilities, stretch film rolls help to wrap and secure products on shelves or in storage bins. This prevents items from becoming damaged or separated. Benefits: Cost-Effectiveness: Stretch film rolls are relatively inexpensive and provide a cost-effective solution for various packaging and protection needs. Ease of Use: The film is easy to apply using either manual or automatic stretch film dispensers, making it suitable for both small-scale and high-volume applications. Cling and Stretch Properties: The film’s ability to cling to itself without adhesives and its stretchability make it ideal for creating a tight, secure wrap around products. Types of Stretch Film Rolls: Machine Stretch Film: Designed for use with stretch wrap machines, ideal for high-speed and high-volume wrapping. Hand Stretch Film: Suitable for manual application, often used in smaller operations or for wrapping irregularly shaped items.

Black stretch film is a specialized type of stretch film that is commonly used for a variety of specific applications due to its unique properties. Primary Uses: Privacy and Security: Black stretch film is often used to enhance privacy and security. The opaque nature of the film conceals the contents of packages or pallets, making it harder for unauthorized individuals to see or access the items. This can be particularly useful in situations where confidentiality is important, such as in high-value goods or sensitive materials. Protection from UV Light: One of the significant advantages of black stretch film is its ability to block UV light. This makes it suitable for protecting products that are sensitive to light exposure, such as certain chemicals, pharmaceuticals, or sensitive electronics. By shielding these items from UV rays, the film helps prevent degradation and extends their shelf life. Improved Aesthetic Appearance: In some cases, black stretch film is used for aesthetic reasons. For example, it can give a uniform and professional appearance to products or pallets, which may be desirable in retail or promotional settings. Enhanced Durability and Strength: The formulation of black stretch film can sometimes include additives that enhance its strength and puncture resistance. This makes it suitable for securing heavier or more fragile items during transportation and storage. The film’s thickness and tensile strength can help reduce the risk of damage to the contents. Theft Prevention: The opaque color of black stretch film makes it more challenging for thieves to identify and access valuable goods. This added layer of security can help deter theft and improve overall safety in storage areas or during transit. Benefits: Concealment: Provides privacy and prevents the visibility of contents. UV Protection: Shields items from harmful UV radiation. Enhanced Security: Deters theft and tampering. Professional Appearance: Offers a sleek, uniform look for products and pallets. Applications: Black stretch film is used in various industries, including logistics, warehousing, retail, and manufacturing. It is applied to wrap pallets, secure shipments, and protect sensitive materials.

Cling film and stretch film are both used for wrapping and protecting items, but they have distinct characteristics and applications. Cling Film: Composition and Characteristics: Material: Cling film is typically made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE). Its primary feature is its ability to cling tightly to surfaces without the need for adhesive. Cling Properties: As the name suggests, cling film adheres to itself and to various surfaces, providing a tight seal that helps to keep food fresh by minimizing air exposure. Thickness and Stretch: Cling film is usually thinner and more flexible compared to stretch film. It is designed to wrap tightly around food items or containers, offering a secure seal that helps prevent spoilage. Applications: Food Storage: Commonly used in households and food service industries to cover food items, keep them fresh, and prevent contamination. It is ideal for wrapping sandwiches, leftovers, and other food products. Miscellaneous Uses: Cling film can also be used to cover dishes, bowls, or other kitchenware to keep contents fresh. Stretch Film: Composition and Characteristics: Material: Stretch film is primarily made from linear low-density polyethylene (LLDPE). It is designed to stretch and cling to objects with the help of its elastic properties. Stretch Properties: Stretch film is thicker and more robust than cling film, allowing it to stretch significantly while maintaining its strength. This makes it suitable for securing and stabilizing larger items or pallets. Durability: It is more durable and resistant to punctures and tears compared to cling film, which makes it ideal for wrapping and protecting items during transport or storage. Applications: Pallet Wrapping: Widely used in warehouses and logistics to wrap pallets of goods, providing stability and protection during transit. Product Bundling: Used to bundle multiple items together for easier handling and transportation. General Protection: Provides a protective layer against dust, moisture, and other environmental factors during storage or shipment. Key Differences: Thickness: Stretch film is generally thicker and more durable than cling film. Elasticity: Stretch film has higher elasticity and is designed to stretch and conform tightly around objects, while cling film is more about adhering to surfaces without stretching. Primary Use: Cling film is mostly used for food storage and covering, while stretch film is used for wrapping pallets and securing larger items.

While stretch wrap is widely used for securing and protecting palletized goods during transportation and storage, it does have several disadvantages that should be considered. One of the primary drawbacks is its environmental impact. Stretch wrap is typically made from linear low-density polyethylene (LLDPE), a non-biodegradable plastic derived from fossil fuels. This means that discarded stretch wrap contributes to plastic waste in landfills and can take hundreds of years to decompose. Recycling options exist but are not always readily accessible or cost-effective, leading to environmental concerns. Another disadvantage is the potential for insufficient load stability if not applied correctly. Improper wrapping techniques, such as inadequate tension or insufficient layers, can result in unsecured loads that may shift or topple during transit, causing product damage or safety hazards. Over-wrapping, on the other hand, leads to unnecessary material usage and increased costs. Stretch wrap can also pose ergonomic challenges for workers. Manual application requires repetitive motion, which can lead to strain injuries or fatigue if not managed properly. Additionally, the disposal of used stretch wrap can create workplace clutter, increasing the risk of slips, trips, and falls. From a cost perspective, while stretch wrap is generally economical, the expenses can accumulate, especially for businesses with high-volume packaging needs. The cost of materials, equipment maintenance, and labor for application and disposal must be factored into operational budgets.

Stretch film is an essential packaging material used primarily to secure and stabilize products on pallets during transportation and storage. The main reason for using stretch film is its ability to tightly wrap around items, preventing them from shifting, toppling, or becoming damaged. This not only ensures that products arrive at their destination in optimal condition but also enhances overall safety during transit. The elasticity of stretch film allows it to conform to various shapes and sizes, providing a snug fit that holds goods together firmly. Additionally, stretch film offers protection against environmental factors such as dust, dirt, and moisture, which can compromise product quality. It acts as a barrier against contaminants, preserving the integrity of the goods. Stretch film also serves as a deterrent against tampering and theft by concealing the contents of the pallet. From an operational standpoint, using stretch film can lead to cost savings by reducing the need for additional packaging materials like straps or shrink wraps. It streamlines the packaging process, improves load stability, and simplifies handling, making it an efficient and economical solution in the supply chain. Overall, stretch film is indispensable for businesses looking to protect their products, ensure customer satisfaction, and maintain operational efficiency.

Stretch film and shrink film are both used for packaging and protecting products, but they operate on different principles and are suited for different applications. Stretch film is an elastic plastic film that is stretched and wrapped tightly around items, relying on its elastic recovery to hold the load securely without the need for heat. It is primarily used for unitizing pallet loads, providing stability during transportation and storage. The application involves wrapping the film around the load while applying tension, which creates a tight, secure fit as the film tries to return to its unstretched state. Stretch film protects against shifting, dust, and moisture and can be applied manually or with wrapping machines. Shrink film, on the other hand, is a plastic film that is loosely placed around a product or group of products and requires the application of heat to shrink tightly around the items. This is typically done using a heat gun or passing the wrapped products through a heat tunnel. Shrink film provides a tight, tamper-evident seal and is commonly used for retail packaging, bundling products together, and protecting items from dust, moisture, and other environmental factors. It conforms closely to the shape of the product, enhancing its appearance and providing a professional finish. The main differences lie in their application methods, equipment required, and typical uses: Application: Stretch film is stretched and wrapped around the load; shrink film is applied loosely and then heated to shrink tightly around the product. Equipment: Stretch wrapping can be done manually or with stretch wrap machines; shrink wrapping requires heat equipment like heat guns or shrink tunnels. Uses: Stretch film is ideal for securing large loads and pallets; shrink film is suitable for wrapping individual items or smaller bundles, often for retail display.

Stretch wrap film is a versatile and practical material used for securing and protecting items during storage and transportation. Here’s how to use it effectively: 1. Prepare the Film and Area: Choose the Right Type: Select the appropriate stretch wrap film for your needs. Options include hand stretch film for manual use and machine stretch film for automated processes. Clean and Clear the Area: Ensure the area where you will be wrapping is clean and free from debris to avoid contamination of the items. 2. Wrapping Technique: Start from the Bottom: Begin wrapping from the base of the pallet or item. This helps to secure the bottom layer and provides a stable foundation. Wrap in Overlapping Layers: Apply the film in overlapping layers, wrapping around the item or pallet in a vertical or horizontal direction. This ensures a tight and secure wrap. Stretch and Cling: Stretch the film as you wrap to maximize its clinging properties. Ensure that the film conforms tightly to the item or pallet without leaving gaps. Finish Securely: Once you have wrapped the desired number of layers, cut the film and secure the end to prevent it from unraveling. 3. Use Tools if Necessary: Hand Dispensers: For manual wrapping, use a hand dispenser to make the process easier and more efficient. Machine Wrappers: For high-volume applications, use an automated stretch wrap machine to achieve consistent and efficient wrapping.

Stretch film has specific requirements to ensure its effectiveness and performance. Key requirements include: 1. Material Quality: Polyethylene Composition: The film should be made from high-quality linear low-density polyethylene (LLDPE) or similar materials, which offer strength, stretchability, and durability. Thickness and Gauge: Choose a thickness that suits your application. Thicker films provide greater strength and protection, while thinner films are suitable for lighter loads. 2. Stretch Properties: Elongation: The film should have good elongation properties, allowing it to stretch and conform tightly to the items being wrapped. Cling Ability: It should adhere well to itself and to the items without the need for additional adhesives. 3. Environmental Considerations: Recyclability: Opt for films that are recyclable or produced with environmentally friendly practices if possible. 4. Application Method: Compatibility: Ensure the film is compatible with the wrapping equipment you plan to use, whether manual or machine-based.

The number of times you should wrap a pallet with stretch film depends on several factors: 1. Load Stability: Light Loads: For lighter loads, 2-3 full wraps around the pallet may be sufficient. Heavy or Irregular Loads: For heavier or irregularly shaped loads, 4-6 wraps may be needed to ensure stability and prevent shifting during transportation. 2. Film Thickness and Type: Thicker Films: If using thicker stretch film, fewer wraps may be necessary due to its strength. Film Type: Different types of stretch film (e.g., pre-stretched, extended core) may affect the number of wraps needed. 3. Handling and Transport Conditions: Transportation Conditions: Consider factors such as the length of transport and handling conditions. More wraps may be required for longer transport distances or harsher conditions.

The cost of stretch film can vary based on several factors: 1. Film Type and Quality: Material: High-quality films made from LLDPE or other premium materials may cost more than standard options. Thickness and Gauge: Thicker films with higher gauge tend to be more expensive due to their increased strength and durability. 2. Quantity Purchased: Bulk Buying: Purchasing stretch film in bulk or larger rolls can reduce the cost per unit. Wholesale prices are often lower than retail prices. 3. Supplier and Brand: Brand Premium: Well-known brands may charge more due to perceived quality and reliability. Supplier Pricing: Costs can vary between suppliers based on factors such as location, shipping, and supplier policies.

Stretch film, often referred to as stretch wrap, is a versatile plastic film designed to secure and protect items during storage and transportation. It is widely used across various industries, including logistics, manufacturing, and retail. The primary function of stretch film is to wrap pallets, bundles, or individual products to prevent movement and damage while they are being handled or shipped. This type of film is highly elastic, allowing it to stretch and conform closely to the items it wraps, creating a tight and secure hold. This is crucial in minimizing the risk of shifting during transit, which can lead to product damage. Stretch film also protects against dust, moisture, and other environmental factors, making it suitable for both indoor and outdoor storage. Additionally, it is often employed for color-coding items, which aids in inventory management and organization. By consolidating smaller products into larger units, stretch film streamlines the shipping process, ultimately enhancing efficiency in handling and logistics.

Choosing between cast and blown stretch wrap depends on the specific requirements of your application. Cast stretch wrap is characterized by its clarity and smooth surface, which makes it ideal for applications where product visibility is important, such as in retail displays. It offers excellent puncture resistance and has a lower memory, meaning it doesn’t return to its original shape as much as blown film, allowing for a tighter wrap around products. In contrast, blown stretch wrap is known for its superior strength and stretchability. It is more resistant to tearing and can provide better load stability, making it suitable for heavy-duty applications. The blown film also features a higher stretch ratio, enabling it to stretch further without breaking. Therefore, if you need something strong and durable for heavy loads, blown stretch wrap may be the better option. Conversely, for light to medium loads where visibility and tightness are key, cast stretch wrap is often preferred. Ultimately, the choice should be based on the nature of the products, handling methods, and specific application requirements.

Stretch hood and stretch film are both used for securing and protecting products during shipping and storage, but they have distinct differences in their application and characteristics. Stretch film, commonly used to wrap pallets and individual items, is a highly elastic plastic film that adheres tightly to surfaces through its stretchability. It provides a snug fit that minimizes movement and protects against dust and moisture. On the other hand, stretch hood involves using a pre-stretched hood of film that is pulled down over the entire pallet or product. This method offers several advantages, including greater load stability and protection against environmental elements since the film forms a tight, protective cover over the entire package. Stretch hoods are often preferred for taller and bulkier loads as they can provide more comprehensive coverage. Additionally, stretch hoods can be applied using automated systems, making them efficient for high-volume operations. In summary, while both serve to protect products, stretch film is more versatile for various applications, whereas stretch hood is ideal for providing a more secure and stable cover over larger loads.

Don't wait - reach out today to ensure timely delivery and exceptional service.

Plastic colored stretch film is a versatile packaging material widely used for securing, bundling, and protecting products during storage and transportation. The use of colored

Pallet wrap plays a vital role in modern packaging, providing essential protection and stability for products during storage and transportation. When it comes to specialized

Wholesale colored stretch wrap is an essential packaging solution for industries requiring efficient load management and streamlined shipment processes. Available in bulk, this versatile film

Double color stretch film plays an essential role in modern packaging, offering enhanced visibility and product identification. This innovative stretch film, featuring two distinct colors,

Stretch wrap is an essential packaging tool used to secure, protect, and bundle products during shipping and storage. It provides a reliable way to keep

PE stretch film is a versatile packaging material widely used across industries for wrapping, securing, and protecting products during storage and transportation. Known for its