Stretch wrapping technology plays a crucial role in modern packaging by securing loads for transport and storage. This method ensures stability, protection, and cost efficiency, making it an essential process across various industries. Entry level stretch wrapping is designed for businesses looking to automate their packaging operations without the complexity or cost of high-end machines. These machines, such as entry-level pallet wrappers and stretch wrap machines, are ideal for low to medium-volume operations. They help reduce manual labor, improve packaging consistency, and save on material costs. By investing in entry level stretch wrapping, companies can enhance both safety and productivity, making it an attractive solution for small and growing businesses. While there are advantages and disadvantages stretch wrapping, entry level stretch wrapping offer a good balance between cost and efficiency, automating wrapping for small to medium operations, boosting efficiency, reducing costs, and wrapping up to 20 pallets daily.

Why Choose Our Stretch Film Over Competitors?

| Attribute | Details |

|---|---|

| Material | LLDPE, polyethylene |

| Type | Stretch Film |

| Place of Origin | Fujian, China |

| Features | Moisture-proof, waterproof, durable, tear-resistant, versatile, flexible |

| Hardness | Soft |

| Processing Type | Casting, injection molding |

| Transparency | Transparent |

| Surface | Smooth, glossy |

| Elongation | 300% to 500% |

| Applications | Packing, shipping, logistics storage, wrapping irregularly shaped items, protecting fragile products |

| Certificates | ISO 9001:2015, MSDS, ROHS |

| Brand Names | PWP Stretch Film |

| Packaging | Carton, standard exported carton |

| MOQ | 1000Kg |

| Advantages | High durability, moisture resistance, easy to use, cost-effective, eco-friendly |

| Customizable Options | Logo, width, length, thickness, printing |

Entry level stretch wrapping refers to machines specifically designed for businesses that require a basic yet effective solution for packaging their products. These machines are tailored for low to medium-volume operations, providing essential functionality without the high cost or advanced features found in premium models. An entry-level stretch wrapper typically includes a simple turntable design that allows operators to secure loads with stretch film efficiently.

While high-end models often come with advanced features such as automatic film cutting, advanced pre-stretch capabilities, and programmable wrap cycles, entry level stretch wrapping machines focus on the core features required for basic packaging tasks. They provide reliable load stability, easy operation, and cost-effectiveness, making them an ideal choice for businesses that don’t need the complexity of fully automatic or high-volume wrappers.

Investing in entry level stretch wrapping machines, which are designed to work seamlessly with machine stretch film, provides several significant advantages for businesses, particularly those involved in low to medium-volume operations. These machines not only streamline the packaging process but also enhance safety, reduce material costs, and improve overall efficiency. Machine stretch film, with its superior stretch strength and elasticity, makes it the ideal choice for these machines, allowing businesses to achieve better load security while minimizing waste. Below are the key benefits that make entry level stretch wrapping an excellent choice for many businesses.

One of the most important benefits of entry level stretch wrapping machines is the increased safety they offer by reducing the need for manual labor. Traditionally, workers would manually walk around pallets to apply stretch film, which can be both time-consuming and physically strenuous. This manual process increases the risk of workplace injuries, especially repetitive strain or accidents related to moving around heavy loads. With an entry-level stretch wrapper, the machine automates much of the process, allowing the operator to remain in a fixed position, significantly improving workplace safety.

Another significant advantage of using entry level stretch wrapping machines is the boost in productivity. These machines allow operators to wrap pallets faster and more efficiently than manual methods. By automating the process, businesses can wrap more pallets in less time, leading to quicker turnaround times in packaging operations. Additionally, the consistency provided by the machine ensures that each pallet is wrapped to the same standard, reducing the chances of improper load securing, which can lead to product damage during transport.

Entry-level stretch wrapping machines are also designed to prevent pyramiding during stretch wrapping, a common issue where the load shifts and forms a pyramid shape due to uneven tension or improper wrapping techniques. This problem can compromise load stability and increase the risk of product damage during transit. By using precise tension control and consistent film application, these machines ensure that the load remains evenly wrapped and secure, eliminating the risk of pyramiding. This not only enhances load stability but also improves the overall integrity of the packaged goods, ensuring they arrive at their destination in perfect condition.

One of the key features of entry level stretch wrapping machines is their ability to optimize film usage. Many of these machines come with pre-stretch capabilities, which stretch the film before it is applied to the pallet. This means that less film is required to achieve the same level of load security, resulting in significant cost savings over time. Additionally, the use of high-quality stretch film resins in the wrapping film further improves performance, ensuring better stretchability and durability. By reducing material waste, businesses can also contribute to more sustainable packaging practices while cutting down on operating costs.

Entry level stretch wrapping machines are best suited for businesses with low to medium-volume packaging needs. These machines provide just the right balance of efficiency and affordability, making them ideal for operations that don’t require the advanced features or capacity of high-end models. For small to mid-sized companies looking to upgrade from manual wrapping methods, these machines offer a practical solution that improves overall productivity without the need for a large investment.

An entry level stretch wrapping machine comes equipped with essential features that make it a valuable investment for small to medium-sized businesses. These machines are designed to offer the key functionalities required for efficient packaging without the high cost and complexity of advanced models. Here are the main features that set entry-level models apart:

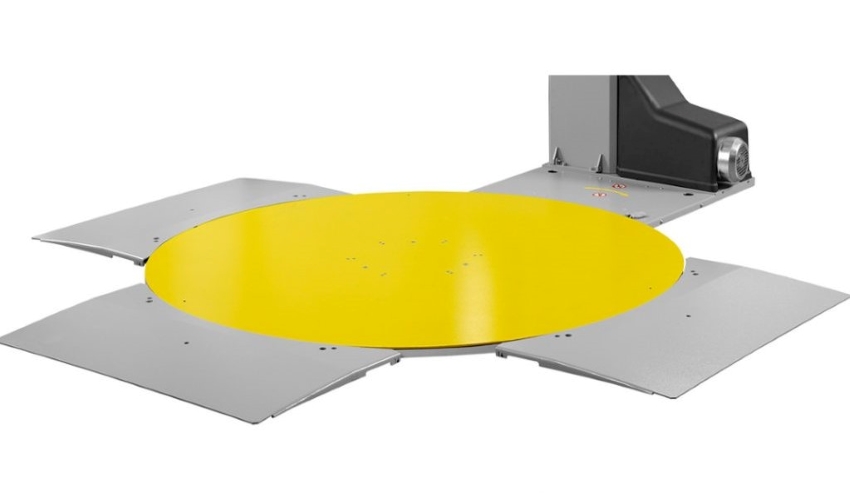

One of the standout features of entry level stretch wrapping machines is the turntable-powered design. This allows for easy loading of pallets onto the machine, enabling the turntable to rotate the load while the film is applied evenly around it. This mechanism is ideal for businesses that handle low to medium volumes, ensuring that the pallets are wrapped securely and consistently.

Depending on the needs of the business, entry level stretch wrapping machines offer manual and semi-automatic operation modes.

Despite being entry-level, these stretch wrappers often include advanced features like film tension control, which allows the operator to adjust the tightness of the film applied around the load. This ensures that the correct tension is used, preventing damage to the products while maintaining load stability. Pallet height sensors automatically detect the size of the load, ensuring that the wrapping process is tailored to the specific dimensions of each pallet. Additionally, customizable wrap cycle settings enable operators to adjust parameters such as the number of top and bottom wraps, further optimizing the wrapping process for different types of loads.

For small businesses, entry-level stretch wrapping machines offer an excellent return on investment. They streamline the packaging process, improve load security, and reduce film waste, including minimizing the shavings of stretch film that often accumulate during manual wrapping. This ultimately saves time and resources. Furthermore, these machines enhance safety by minimizing manual labor and the risks associated with manually wrapping pallets.

When considering the benefits of using an entry-level stretch wrapping machine, such as improved safety, productivity, and cost savings, these features make entry-level models a practical and effective solution for businesses looking to optimize their packaging operations.

When it comes to entry level stretch wrapping, several models stand out in the industry for their cost-effectiveness and ease of use, especially for small businesses and startups. These machines are designed to provide essential features at a budget-friendly price, making them accessible to operations with moderate packaging needs. Below are some of the key specifications and benefits that highlight why these models are popular choices.

Most entry level stretch wrapping machines come equipped with a turntable capable of handling loads ranging from 1,500 to 4,000 pounds. This versatility allows businesses to wrap a variety of pallet sizes and weights, offering flexibility in pallet wrap sizes to match different product dimensions. In addition, many entry-level models include a pre-stretch function, which can range between 150% and 300%, allowing the film to stretch efficiently while maintaining load security. This feature not only reduces film consumption but also enhances load stability, providing significant cost savings in material over time.

Another key feature of entry-level stretch wrapping machines is their ability to accommodate different load heights. Most machines can wrap pallets height up to 80 inches, making them suitable for a wide range of product sizes. This flexibility is especially useful for businesses that deal with varying load dimensions, ensuring that all pallets are securely wrapped and ready for transport.

The benefits of using an entry-level stretch wrapping machine are evident, particularly when it comes to cost savings and efficiency. Entry-level models offer a low-cost solution for businesses looking to upgrade from manual wrapping without the need for complex automation. These machines provide essential wrapping capabilities while remaining affordable, making them the perfect choice for small businesses or startups with limited budgets.

One of the biggest advantages of entry level stretch wrapping machines is their user-friendly design. These models are often equipped with simple controls that allow operators to easily adjust wrap settings, such as the number of wraps, turntable speed, and film tension. This flexibility ensures that new users can quickly learn how to operate the machine, making the transition from manual to automated wrapping seamless. Additionally, the machines’ compact design and straightforward functionality make them a practical choice for businesses with limited floor space.

Selecting the best entry level stretch wrapping machine for your specific needs requires careful consideration of several factors. These machines come in a variety of configurations, so understanding your business’s packaging requirements is crucial. Below are key points to guide your decision-making process.

When deciding on the right machine, it’s important to weigh the benefits of semi-automatic vs. manual models. Semi-automatic machines automate much of the process, including film cutting, starting, and stopping, which reduces operator involvement and speeds up the workflow. This is especially useful for businesses with higher packaging volumes.

On the other hand, manual models require more operator input but come at a lower cost. These are ideal for small businesses with limited budgets or lower packaging demands. By choosing the right model, you can optimize the balance between cost and efficiency in your operations.

Accessories can further enhance the functionality of your entry level stretch wrapping machine. For example, loading pallets onto the machine can be made easier with the addition of ramps, especially for businesses using pallet jacks. Turntable options, such as different speeds and rotation controls, provide flexibility in handling different load types and wrapping requirements.

When it comes to purchasing entry level stretch wrapping machines, businesses have several options available to them. These machines can be found through various channels, each offering its own set of benefits and considerations. Whether you’re looking for convenience, personalized service, or local support, it’s important to choose a supplier that meets your specific needs.

One of the most accessible places to find entry level stretch wrapping machines is through online retailers. Many websites specialize in packaging equipment and offer a wide variety of models suitable for different businesses. Online retailers often provide detailed product descriptions, user reviews, and comparison tools, which make it easy to evaluate different machines based on their specifications and features. Shopping online also allows for a quick and convenient purchasing process, with options for home or business delivery.

However, when buying online, it’s crucial to ensure that the retailer is reputable and offers reliable after-sales support. Look for vendors that provide clear warranty terms, as well as responsive customer service to help with any technical issues that may arise after the purchase.

For businesses that prefer a more hands-on approach, local equipment suppliers are an excellent option for finding entry level stretch wrapping machines. By visiting a local supplier, you can often see the machines in action, get expert advice from sales staff, and even arrange for demonstrations to better understand how the equipment fits your specific packaging needs. Local suppliers may also offer installation and training services, ensuring that your team knows how to operate the machine efficiently.

Working with a local supplier can also have long-term benefits, especially when it comes to technical support and maintenance. You’ll have quicker access to repairs or spare parts, minimizing downtime and keeping your operations running smoothly.

Whether you choose to buy your entry level stretch wrapping machine online or from a local supplier, it’s essential to evaluate the quality of warranties and after-sales service. A solid warranty provides peace of mind, ensuring that the machine is covered for repairs or replacement if something goes wrong. Look for warranties that cover both parts and labor, and ensure that the duration of the warranty is sufficient to protect your investment.

Additionally, after-sales service plays a critical role in maintaining the performance of your machine. Good suppliers will offer technical support, either remotely or on-site, to help with any operational issues. They should also provide access to training resources, such as user manuals, tutorials, or even hands-on training for your staff.

Entry level stretch wrapping comes in various forms, offering tailored solutions for different packaging needs. Below are the three main types:

Semi-Automatic Turntable Pallet Wrapping Machines

These machines are designed to enhance the efficiency of pallet wrapping by reducing the time spent compared to manual wrapping. With a turntable rotating the pallet while the operator feeds the stretch film, these machines automate the process, leading to faster wrapping and increased productivity.

Automatic Stretch Wrapping Machines

Automatic stretch wrapping machines take the automation process further by fully handling the wrapping process. Ideal for businesses looking to reduce labor costs and increase output, these machines offer cost-effective solutions, higher production rates, and improved packaging consistency.

Mobile Robotic Stretch Wrapping Machines

These machines are perfect for wrapping large, heavy, or unstable palletized cargo in various locations. With mobility and flexibility, the robotic machines can be deployed to different areas and put away once the wrapping is complete, offering an efficient and versatile solution for challenging wrapping needs.

These types of entry level stretch wrapping machines cater to different operational needs, from small businesses to larger production environments.

Understanding the terminology related to entry level stretch wrapping is essential for optimizing your packaging process. Here are the key terms that will help you navigate stretch wrapping systems:

Understanding these terms will help ensure you make the most of your entry level stretch wrapping machine, enhancing productivity and load stability during transport and storage.

A good entry level stretch wrapping machine is one that provides a balance between cost-effectiveness, efficiency, and ease of use, making it ideal for small to medium-sized businesses looking to automate their pallet wrapping processes without the complexity or high costs of more advanced systems. Here are the key aspects to consider when evaluating an entry level stretch wrapping machine:

Ease of Use

A good entry level stretch wrapping machine should be user-friendly, with intuitive controls and minimal setup. Machines that offer simple, adjustable settings for parameters like bottom wrap, top wrap, and film tension will make the wrapping process faster and more efficient.

Cost-Effectiveness

Entry level stretch wrappers are designed to offer value without sacrificing essential features. A good machine should offer competitive pricing while ensuring reliable performance and durability. It should help reduce manual labor and stretch film costs, making it an affordable option for businesses.

Efficiency and Speed

While entry level machines are typically slower than advanced models, they should still offer the ability to wrap up to 20 pallets per day. Look for machines that have adjustable wrapping speeds and can handle the throughput required by your operation.

Film Pre-Stretch Capability

Pre-stretching is an important feature that allows the film to be stretched before being applied to the load, increasing its strength while reducing the amount of film used. A good entry level stretch wrapper will have a pre-stretch carriage with adjustable ratios, allowing you to maximize efficiency and minimize waste.

Load Security and Stability

A good machine should provide consistent film tension (film load force) to ensure the wrapped load is secure and stable during transport. Machines that allow you to adjust film tension to match load weight and type can help improve load integrity.

Adjustable Parameters

A flexible machine that allows you to adjust the wrapping parameters, such as the number of wraps at the bottom, top, and sides, is crucial for adapting to various load types. This feature helps ensure that different products are securely wrapped according to their specific needs.

Durability and Reliability

Even at the entry level, the machine should be built to last and capable of handling daily use in a warehouse or production environment. A good stretch wrapper will be robust enough to withstand wear and tear without compromising performance.

By considering these factors—ease of use, cost-effectiveness, efficiency, and versatility—you can find an entry level stretch wrapping machine that meets your business’s needs. Whether you need to wrap smaller, lightweight loads or more substantial palletized goods, choosing the right machine will ensure your packaging process is both effective and efficient.

When it comes to entry-level stretch wrapping, the gauge of the stretch wrap refers to its thickness. For most basic applications, such as wrapping lightweight pallets or bundling products, a 60-80 gauge stretch wrap is sufficient. This range strikes a balance between ease of use and durability. If you’re working with lighter products that don’t require extensive protection, a 60 gauge stretch wrap will provide enough strength and elasticity. For slightly heavier loads or products that need more stability, 80 gauge is a better choice. For heavier-duty applications or items with sharp edges, you may need a 100 gauge wrap, but this is typically more suitable for intermediate to advanced wrapping operations.

As an entry-level user, start with a 60-80 gauge stretch film. It’s versatile, affordable, and can be used with hand dispensers or simple machines, offering good stretchability without compromising on strength.

Stretch wrap and shrink wrap are both used for packaging, but they have distinct characteristics. Stretch wrap is a highly elastic plastic film that is stretched around products, tightly securing them. It relies on its ability to stretch and cling to the product, providing a secure wrap with minimal shrinkage. Stretch wrap is commonly used for bundling and securing items on pallets.

Shrink wrap, on the other hand, is a plastic film that shrinks when heat is applied. This film is typically used when you need a tight, shrink-wrapped covering around the item, often for retail packaging. The main difference is that shrink wrap requires a heat source to activate the shrinkage, while stretch wrap does not. For entry-level stretch wrapping, stretch wrap is more versatile and easier to use, as it requires no heat.

Hand wrap refers to stretch film that is manually applied around items or pallets, typically using a simple hand-held dispenser. This process is more labor-intensive but ideal for small-scale or entry-level operations. Hand wraps are often used for lighter or smaller loads and offer flexibility in wrapping irregularly shaped products.

Stretch wrap, in contrast, refers to the film itself, which can be applied either by hand (as hand wrap) or using a machine (machine wrap). The key difference is in the method of application. While hand wrap is commonly used for manual operations, machine stretch wrap is more efficient for larger volumes of products. As an entry-level user, hand wrapping is likely your first step before transitioning to more automated wrapping solutions.

While stretch wrap and plastic wrap are both types of plastic films, they serve different purposes. Stretch wrap is designed to be highly elastic and stretchable, making it ideal for securing and stabilizing products during storage and transportation. It is typically used in industrial and logistics settings for bundling goods, securing pallets, or protecting items from dust and moisture.

Plastic wrap (commonly known as food wrap or cling film) is thinner and often used for wrapping food items to keep them fresh. While both wraps cling to surfaces, stretch wrap is stronger, thicker, and more durable, with the ability to stretch up to 400% of its original size. As an entry-level user, it’s important to recognize that stretch wrap is more suited for packaging and logistics than the thinner plastic wraps typically used in kitchens.

When choosing wrist wraps for stretch wrapping, you are typically looking at options for added support during manual wrapping tasks. Wrist wraps help prevent strain and injury, especially during extended periods of hand wrapping with stretch film. For entry-level users, a standard wrist wrap size (typically 12 to 18 inches) should suffice. This size provides adequate support for wrist stability while wrapping items, allowing for easy movement without restricting circulation.

For those who require more support due to a history of wrist injuries or more intense manual labor, opting for longer wrist wraps (18 to 24 inches) may be beneficial. Make sure the wrist wraps are adjustable to fit securely but comfortably around your wrist. Proper wrist support will help minimize discomfort and increase efficiency when performing stretch wrapping tasks manually.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed