Extended core stretch film is a versatile packaging solution designed for securing and stabilizing loads during storage and transportation. This type of stretch film features a unique extended core that serves as a built-in handle, making it easy to use without requiring additional dispensers or tools. The user-friendly design allows for efficient wrapping, saving both time and effort. In the packaging and shipping industries, the importance of extended core stretch film cannot be overstated; it offers excellent load retention and protection against dust, moisture, and other environmental factors. Businesses can rely on this film to enhance their packaging processes, ensuring products remain safe and intact throughout their journey.

Extended core stretch film offers several key features and benefits that make it a preferred choice in packaging solutions. One notable feature is its one-inch diameter inner core, which is designed to provide a built-in handle. This allows for effortless maneuverability while wrapping items.

The price of extended core stretch film can vary significantly based on several factors that influence both the cost of production and market pricing. Understanding these factors can help businesses make informed purchasing decisions.

When evaluating the cost of extended core stretch film, it is crucial for businesses to consider its overall cost-effectiveness and the potential for long-term savings. Properly assessing these factors can lead to more strategic purchasing decisions.

Finding high-quality extended core stretch film for sale is essential for businesses looking to enhance their packaging solutions. There are various avenues to explore when sourcing this product.

Purchasing extended core stretch film wholesale can offer significant advantages for businesses looking to optimize their packaging processes and reduce costs. Buying in bulk allows for strategic savings and ensures a consistent supply of materials.

When selecting extended core stretch film, the choice of extend core stretch film factory plays a critical role in ensuring quality, performance, and reliability. Here, I will highlight some notable extend core stretch film factories in the industry and discuss their production capabilities and offerings.

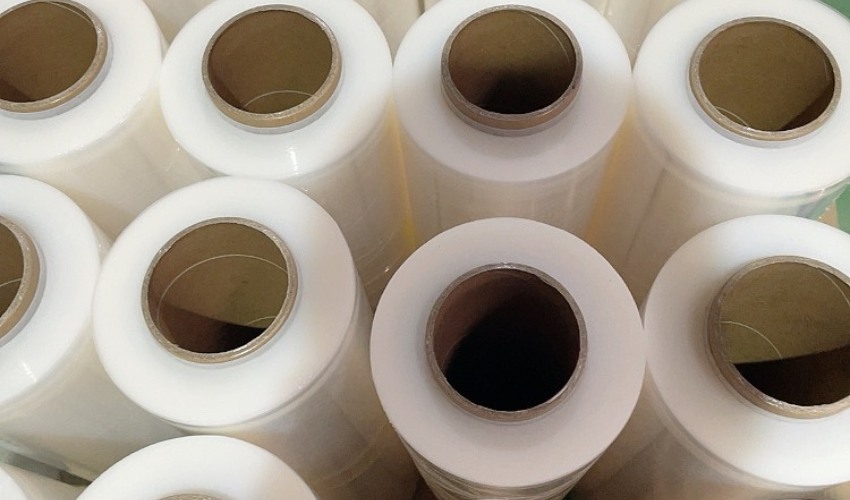

The core in stretch film refers to the cylindrical structure that supports the film and allows for easy handling and application. Typically, this core is made of cardboard or plastic, and its diameter can vary, with one-inch diameter cores being common in extended core stretch film. The core is essential because it provides stability and facilitates the unwinding of the film during use. In the case of extended core stretch film, the core extends beyond the edges of the roll, creating built-in handles that make it easier to use without the need for a separate dispenser. This feature enhances usability and efficiency, especially in fast-paced packaging environments. The design of the core, combined with the film’s stretching capabilities, allows for better load stabilization during transportation and storage, making it an important component of the overall packaging solution.

Stretch wrap and stretch film are terms that are often used interchangeably, but there are subtle differences between them. Stretch film is a broader category that includes various types of films designed for wrapping and securing items, while stretch wrap specifically refers to the material used for palletizing and securing loads during shipping. Stretch film is typically made from polyethylene and is available in different thicknesses, widths, and formulations, such as cast or blown. On the other hand, stretch wrap often implies a thicker, more robust film designed for industrial applications. Both materials serve the purpose of providing load stability and protection, but the choice between stretch wrap and stretch film may depend on specific applications, such as the need for clarity, durability, or environmental considerations.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed