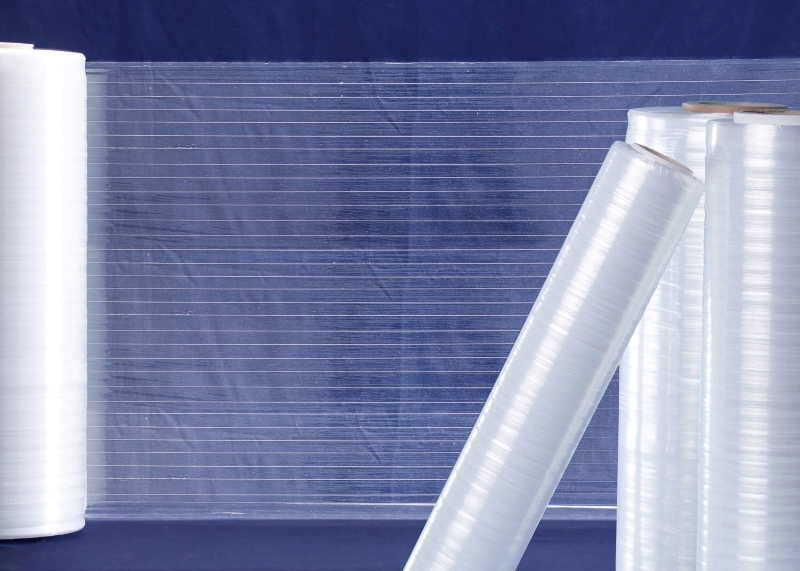

Fiber film stretch is a high-efficiency stretch film that integrates reinforcement fibers, setting it apart from traditional stretch films. These unique fibers make fiber film stretch more tear-resistant and durable, allowing it to maintain stability during the wrapping process. Unlike standard stretch films, fiber film stretch combines strength with flexibility, offering secure and effective wrapping without the risk of tearing. This design, along with the use of bundling stretch film, enables companies to use less film per pallet, effectively reducing material consumption and waste. The purpose of fiber film stretch is to enhance pallet stability and load retention, providing an eco-friendly, cost-effective solution that optimizes wrapping efficiency across a range of industries. Fiber film stretch is a reinforced stretch film with integrated fibers that enhance tear resistance, pallet stability, and cost-efficiency.

Fiber film stretch is a specialized type of stretch film that integrates reinforcement fibers within its structure, offering enhanced strength, durability, and efficiency compared to traditional stretch films. This innovative design makes it a highly effective packaging material for securing and stabilizing loads during transportation and storage, particularly in industries that deal with heavy, irregularly shaped, or delicate items.

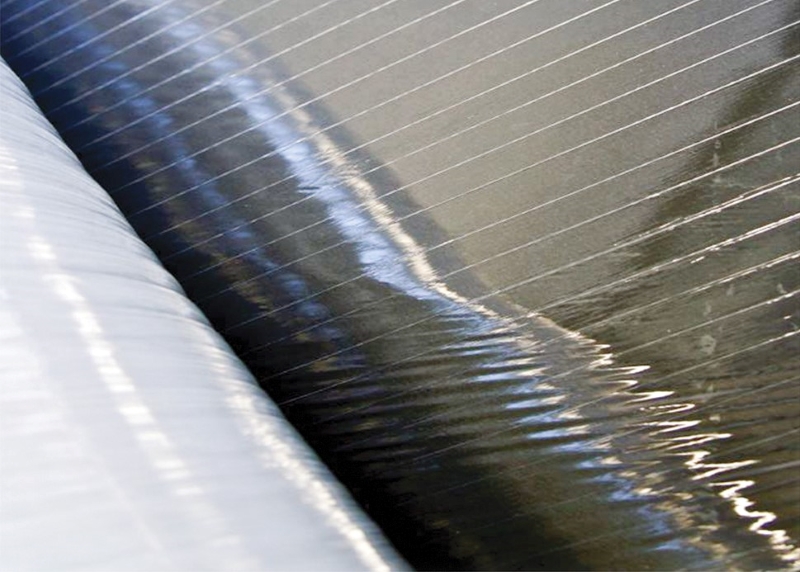

The unique feature of fiber film stretch lies in its construction, where the fibers are embedded into the polymer matrix, improving the film’s tear resistance and load containment capabilities. These fibers act as reinforcement elements, significantly boosting the film’s tensile strength, which allows it to stretch further without losing its integrity. As a result, fiber film stretch provides superior protection, ensuring that products stay securely bound to the pallet, reducing the risk of shifting or damage during transit.

One of the key advantages of fiber film stretch is its ability to reduce material usage without compromising performance. By incorporating reinforcement fibers, the film can achieve the same level of stability and protection with less material, leading to a reduction in packaging costs by up to 30%. This material efficiency also contributes to sustainability efforts, as less plastic is used, reducing waste and the environmental impact associated with excess packaging material.

Additionally, fiber film stretch is well-suited for high-demand applications, such as logistics, manufacturing, and automotive industries, where product stability and strength are critical. The film’s enhanced durability makes it an excellent choice for securing loads that are exposed to rough handling or challenging transportation conditions. Whether it’s securing heavy machinery, large pallets, or irregularly shaped products, fiber film stretch delivers exceptional load containment and stability, ensuring that goods arrive safely at their destination.

Fiber film stretch represents a significant advancement in stretch film technology, offering greater strength, material efficiency, and cost-effectiveness while maintaining a high level of reliability. It is an ideal choice for businesses seeking to improve their packaging process while reducing waste and enhancing the security of their shipments.

Fiber film stretch offers advanced characteristics that set it apart from traditional stretch films, making it a top choice for industries looking to maximize efficiency, security, and cost-effectiveness in their packaging operations. Below are the key features that make fiber film stretch uniquely capable of addressing various packaging needs.

One of the primary strengths of fiber film stretch is its reinforced durability, which is achieved through the integration of special fibers within the film material. These fibers add significant tear resistance, ensuring that the film can endure the rigors of wrapping and transport without breaking or weakening. This durability is especially beneficial in applications where pallets are stacked or subjected to shifting forces during transit. The additional strength from fiber film stretch minimizes the risk of accidental tears, which are common in standard films, and helps maintain the integrity of the wrap.

Fiber film stretch is engineered to offer high elongation without compromising on strength. This means the film can stretch significantly while retaining its durability, which is particularly important for loads that have unusual shapes or heavier weight. The high elongation properties allow fiber film stretch to mold securely around pallets, creating a tight seal that keeps the items securely in place during transit. Unlike traditional films that may stretch only to a limited extent before tearing, fiber film stretch offers enhanced elasticity, allowing users to achieve a reliable wrap with minimal material use.

Fiber film stretch is designed to resist punctures effectively, even when wrapping items with sharp edges or corners. The reinforced fibers enhance the film’s puncture resistance, making it ideal for applications where the packaging may encounter abrasive surfaces or sudden impacts. Puncture resistance is crucial for industries handling products like hardware, machinery, and building materials, where traditional films often fail due to tearing at stress points. The puncture-resistant properties of fiber film stretch ensure that once the load is wrapped, it remains protected throughout the logistics chain.

Optimal pallet stability is one of the most notable benefits of fiber film stretch. This feature helps prevent the load from shifting or toppling during transport, even when subjected to sudden movements or uneven surfaces. The combination of reinforcement fibers and high elasticity ensures that the wrap provides uniform pressure across the pallet, creating a stable and secure environment for the goods. This level of stability is particularly advantageous in high-volume distribution centers and for products that require extra caution during shipment. Industrial wrap adds an extra layer of durability, making it ideal for situations where consistent load stability is essential.

By incorporating these key features, fiber film stretch brings a range of advantages to the table, making it an ideal choice for various industrial applications:

Fiber film stretch stands out as a modern packaging solution that combines strength, flexibility, and efficiency. By offering a reliable way to secure pallets with minimal material use, fiber film stretch proves itself a practical, sustainable option for companies aiming to enhance load stability and reduce costs.

Fiber film stretch is designed with sustainability in mind, offering several significant environmental benefits that make it an ideal choice for companies focused on reducing their environmental impact. By incorporating innovative reinforcement fibers, fiber film stretch minimizes material use, aligns with recyclable packaging practices, and contributes to a lower carbon footprint. Below are the primary environmental advantages of using fiber film stretch.

One of the most impactful benefits of fiber film stretch is its ability to reduce plastic waste. By integrating reinforcement fibers, fiber film stretch achieves greater strength and durability, allowing users to use up to 50% less material than traditional stretch films. This means fewer wraps are required to achieve the same level of stability, resulting in significant reductions in plastic consumption. As industries strive to cut down on single-use plastics, fiber film stretch provides a practical solution to reducing waste.

Fiber film stretch is fully recyclable, making it a responsible choice for companies that prioritize sustainable packaging. Unlike some conventional stretch films that may contain non-recyclable additives, fiber film stretch is designed for complete recyclability. This ensures that after use, the film can be reprocessed and reused, helping companies close the loop on their material usage. PWP Stretch Film has engineered fiber film stretch to be compatible with existing recycling systems, making it easy to integrate into company recycling protocols.

Fiber film stretch also contributes to a reduced carbon footprint due to its lower material consumption and recyclability. By needing less film per pallet and incorporating lighter-weight materials, fiber film stretch reduces CO₂ emissions across the supply chain. Companies benefit from reduced transportation emissions, as less material means lighter loads and fewer trips required for film replenishment. Additionally, the reduced need for replacement wraps minimizes production emissions, making fiber film stretch a more carbon-neutral packaging option compared to traditional pallet film.

The environmental benefits of fiber film stretch provide companies with several tangible advantages, making it an eco-conscious choice in packaging:

Fiber film stretch presents an eco-friendly alternative to traditional stretch films, helping businesses achieve greater sustainability without compromising on performance. With its reduced plastic use, full recyclability, and lower carbon footprint, fiber film stretch is a responsible choice for companies committed to reducing their environmental impact.

Fiber film stretch is a versatile and efficient packaging solution suited to a range of industries that require reliable and durable wrapping with reduced material usage. From manufacturing and logistics to retail and specialized industries, fiber film stretch provides an adaptable solution that ensures stability, efficiency, and cost savings.

Fiber film stretch offers several unique qualities that make it an optimal choice across multiple sectors. The following are some of the industries and applications where fiber film stretch is most effective:

Fiber film stretch is available in various formats, making it adaptable to a wide range of operational needs. Companies can choose from manual and automated options to fit their unique requirements and enhance their packaging processes. Here are some of the versatile options available:

Fiber film stretch provides industries with numerous advantages that contribute to improved packaging efficiency and sustainability. Below are the key benefits across various applications:

Fiber film stretch is a high-performance packaging solution suited for diverse applications across various industries. With its unique combination of durability, flexibility, and eco-friendliness, fiber film stretch helps companies achieve reliable, sustainable, and cost-effective packaging, enhancing their overall efficiency and meeting their operational goals.

When it comes to choosing the right stretch film for pallet wrapping, it’s essential to understand the distinctions between staple stretch film and fiber film stretch. While both serve as protective layers to secure loads during transport, they differ in material composition, durability, and ideal use cases. Below is a detailed breakdown of the key aspects that set these two options apart, helping businesses make an informed decision based on their specific needs.

Staple stretch film is a standard, widely used stretch film designed for basic wrapping applications. It provides general tear and puncture resistance suitable for low to moderate packaging needs. However, unlike fiber film stretch, staple stretch film lacks additional reinforcement, making it less durable in more demanding environments. Staple stretch film is typically chosen for its straightforward application and affordability, fitting operations that do not require heavy-duty wrapping.

| Factor | Staple Stretch Film | Fiber Film Stretch |

|---|---|---|

| Durability | Offers basic tear and puncture resistance | Includes reinforced fibers, providing superior durability |

| Material Composition | Made from standard polyethylene | Engineered with unique fibers for enhanced strength |

| Efficiency | Requires more material to secure heavy or irregular loads | Requires up to 50% less film due to greater strength and stretch |

| Cost | Lower initial cost, economical for basic use | Higher upfront cost but leads to material savings over time |

| Environmental Impact | Non-recyclable versions available, more waste over time | Fully recyclable, with reduced plastic usage for sustainability |

Staple stretch film is suited for general-purpose pallet wrapping in environments that prioritize cost-efficiency over high-performance requirements. It is beneficial for straightforward applications where heavy load stability or extreme durability is not critical. Here are some common use cases where staple stretch film may be the preferred choice:

Fiber film stretch offers distinct advantages, making it the superior choice for industries requiring enhanced durability and efficiency. With its reinforced fibers, fiber film stretch is optimized to reduce material usage while still providing excellent load security. The following are key benefits of choosing fiber film stretch over staple stretch film:

When selecting between staple stretch film and fiber film stretch, consider the durability, cost, and specific needs of your operation. While staple stretch film is an economical choice for simple applications, fiber film stretch offers reinforced security, long-term cost benefits, and a reduced environmental impact for more intensive packaging requirements. Each option has its unique advantages, but fiber film stretch stands out in scenarios where sustainability, material efficiency, and superior load stability are prioritized.

Fiber film stretch offers a range of unique advantages that make it the optimal choice for companies seeking superior pallet stability, durability, and efficiency. From its enhanced load security to its eco-friendly design, fiber film stretch is engineered to address the diverse needs of modern packaging. Below, we delve into the reasons why fiber film stretch stands out as a preferred choice for various industries.

One of the most critical benefits of fiber film stretch is its ability to provide exceptional load security, which is achieved through its optimal holding force and load retention. The integration of reinforcement fibers within the film allows it to maintain tension and withstand external forces, keeping pallets stable even during long-distance transport or rigorous handling. This level of security is essential in reducing product damage and ensuring that loads remain intact. Accurate stretch film tension measurement ensures that the right amount of tension is applied, optimizing the film’s performance and enhancing the overall stability of the load.

Fiber film stretch utilizes a proprietary formula to achieve unmatched durability and performance, setting it apart from traditional stretch films. This exclusive technology enables PWP Stretch Film to deliver a product that combines resilience with flexibility, making it ideal for demanding applications. The reinforced fibers allow the film to achieve higher levels of elongation and puncture resistance, which are essential for high-performance wrapping solutions. This patented technology is a significant factor behind fiber film stretch’s reliability and efficiency in industrial applications.

Fiber film stretch is designed to meet modern environmental standards by using fewer materials without compromising strength. Its eco-friendly composition helps companies reduce their plastic waste, as fiber film stretch requires up to 50% less material than traditional films for the same coverage. Furthermore, the film is a type of recyclable film, ensuring it can be fully recycled, making it a sustainable choice for companies looking to meet environmental goals and lower their carbon footprint.

While fiber film stretch may have a slightly higher upfront cost, it offers long-term savings through reduced material usage, minimized waste, and decreased re-wrapping needs. This cost efficiency benefits companies by lowering the total cost per wrapped pallet, making fiber film stretch a more economical choice over time. Its ability to cover more with less material also means fewer replacements, optimizing supply chain expenses.

Fiber film stretch adapts well to both manual and automated applications, allowing companies to use it in a variety of packaging setups. From smaller operations to large-scale facilities, the versatility of fiber film stretch makes it a valuable solution that can be tailored to fit different operational needs. Its ergonomic design for manual applications and compatibility with automated wrapping machines make it easy to implement across industries.

Fiber film stretch is a forward-thinking packaging solution that offers unique benefits for companies prioritizing load security, sustainability, and cost-effectiveness. With its enhanced load stability, patented technology, and reduced environmental impact, this innovative stretch film is an ideal choice for companies seeking high-performance packaging that aligns with modern business and environmental standards. Whether used in manual or automated applications, fiber film stretch stands out as a versatile, eco-friendly, and efficient packaging material that meets the diverse needs of today’s industries.

Fiber film stretch and traditional stretch film are both used to wrap and secure products during transportation or storage, but they are designed differently to offer unique advantages based on the specific needs of packaging operations. Let’s delve deeper into their features, advantages, and key differences.

Fiber film stretch is a specialized type of stretch film that integrates reinforcement fibers into the film’s structure. These fibers are strategically arranged within the polymer matrix to enhance its tensile strength, tear resistance, and load stability. This design innovation makes fiber film stretch ideal for situations where extra durability is required without compromising on the efficiency of the packaging process.

Traditional stretch film is a widely used packaging material known for its high elasticity and ability to stretch tightly around products and pallets, securing items during transportation or storage. It works by using the inherent stretchiness of the plastic to cling tightly to the load, forming a protective layer.

The key difference between fiber film stretch and traditional stretch film lies in the added strength and stability provided by the integrated fibers in the former. Fiber film stretch not only offers superior performance but also reduces costs, improves pallet stability, and is more durable, making it ideal for high-demand, high-performance packaging needs. Traditional stretch film, while versatile, may be suitable for less demanding applications but is less efficient in terms of material usage and durability when compared to fiber film stretch.

Thus, the choice between the two depends largely on the specific requirements of the load being packaged, the cost considerations, and the desired level of protection during transport.

When purchasing fiber film stretch, it’s essential to take several factors into account to ensure you select the best product for your specific packaging needs.

While fiber film stretch offers superior strength and efficiency compared to other types of stretch films, it’s important to consider the following key aspects to maximize its benefits:

Fiber film stretch is available in different thicknesses, typically measured in mils or microns. The right thickness depends on the weight and fragility of the items being packaged. A thicker fiber film provides more strength and better tear resistance, but it can also increase costs and weight. Conversely, a thinner film may be sufficient for lighter loads but might not offer the same level of stability and durability. Consider your product’s requirements to determine the optimal gauge.

One of the unique benefits of fiber film stretch is its ability to stretch significantly without compromising its strength. The level of pre-stretch, or how much the film has been stretched before application, is crucial. Some fiber films are pre-stretched during manufacturing, which reduces the amount of film required for wrapping. Ensure that the film you choose has the right amount of stretch for your packaging machinery and manual wrapping needs.

Different fiber film products may offer varying levels of stability for different types of loads. If you are packaging heavy, irregular, or unstable items, opt for fiber films with higher tensile strength and tear resistance. Consider whether your packaging requires added load containment features, such as enhanced pallet stability, or if a more standard level of security is sufficient. The fibers in the film play a major role in securing the load, preventing shifting, and minimizing damage during transport.

Consider the environmental conditions in which the film will be used. Fiber film stretch can perform differently under extreme temperatures, humidity, or exposure to UV light. Some films may become brittle in cold temperatures or lose adhesion in humid environments. Make sure the fiber film you select is suitable for your specific shipping conditions to ensure its optimal performance and longevity.

Although fiber film stretch is often more expensive than traditional stretch films, its material efficiency can lead to cost savings in the long run. Fiber films require less material to achieve the same performance as other films, which reduces both material costs and waste. However, it’s still important to balance cost against your packaging needs. Ensure that the increased strength and durability justify the investment based on your load sizes and shipping volume.

Ensure that the fiber film stretch is compatible with the packaging machinery you are using. Fiber film is often used with powered pre-stretch machines, which are designed to optimize the film’s stretching capabilities while reducing material consumption. Check that the film is compatible with your machine’s specifications for best results. In some cases, manual wrapping may also require specific techniques to get the most efficient use from the film.

Many businesses are increasingly focused on sustainability, and fiber film stretch offers environmental benefits by reducing material usage and waste. If sustainability is a priority, check whether the fiber film is made from recyclable materials or has certifications that align with eco-friendly packaging standards. This can contribute to your company’s green initiatives and reduce your overall carbon footprint.

By considering these factors when purchasing fiber film stretch, you can ensure that you select the most suitable product for your specific application. Whether you’re seeking improved load stability, cost efficiency, or sustainability, fiber film stretch provides significant advantages over traditional stretch films when chosen and applied correctly.

When compared with traditional stretch films, fiber film stretch offers enhanced strength and durability, but it still requires careful maintenance to ensure its long-term effectiveness and optimal performance. Proper handling, storage, and use of fiber film stretch can significantly extend its lifespan and improve packaging efficiency. Here are some key considerations and measures to extend the service life of fiber film stretch:

Fiber film stretch should be stored in a cool, dry environment away from direct sunlight, excessive heat, or moisture. Exposure to UV rays and high temperatures can degrade the film, reducing its strength and elasticity. Storing the film in a controlled environment prevents deterioration and ensures it retains its integrity when it’s ready for use. Avoid storing fiber film stretch near sources of chemicals or solvents that could cause the material to break down.

One of the benefits of fiber film stretch is its ability to stretch significantly without losing strength, but overstretching it beyond its recommended limit can cause the film to tear or lose its stretchability. When using fiber film stretch, always ensure that you are operating within the manufacturer’s recommended stretch ratio. Overstretching leads to film breakage, waste, and poor load containment. Proper tension settings should be maintained on both manual and automatic stretch wrapping machines.

The machinery used for applying fiber film stretch must be regularly maintained to avoid any issues that can affect film performance. Dust, dirt, or adhesive build-up on stretch wrapping machines can cause uneven film application or damage to the film itself. Regular cleaning and calibration of the machine, along with inspecting rollers, tensioners, and film dispensers, will ensure that the film is applied smoothly and evenly, minimizing wear and tear on both the film and the equipment.

While fiber film stretch is designed to withstand various conditions, environmental factors such as humidity, temperature fluctuations, and exposure to moisture can affect its performance. High humidity can lead to reduced adhesive properties and make the film less effective at holding loads. Cold environments may cause the film to become brittle. Always monitor and adjust the storage and usage conditions to suit the specific requirements of the fiber film stretch.

Handling fiber film stretch with care during the application process is crucial to avoid unnecessary damage. Abrasive surfaces, sharp objects, or rough handling can cause the film to tear or become scratched. Ensure that operators are trained on how to properly load and apply the film to prevent unnecessary stress on the material. Additionally, avoid unnecessary contact with the floor or dirty surfaces that could introduce contaminants to the film.

Using too much film can waste material, while using too little can result in poor load containment. It is important to use the right amount of fiber film stretch for each load to maximize material efficiency. If you use a powered pre-stretch machine, adjust the settings to achieve the correct tension and stretch ratio. This will reduce film consumption while still providing sufficient strength to secure the load properly.

Before applying fiber film stretch, it’s essential to inspect it for any visible signs of damage such as tears, holes, or weak spots. Any defects in the film can compromise the strength and stability of the wrapped load, leading to shipping issues or damage. Regularly check the film rolls before use and discard any damaged material to prevent further complications.

Finally, to extend the service life of fiber film stretch, consider implementing a waste reduction and recycling program. Excess film or defective rolls can sometimes be recycled or repurposed, depending on the type of fiber film. This not only reduces waste but also helps in maintaining the cost-effectiveness of using fiber film stretch.

By following these maintenance practices, businesses can ensure that fiber film stretch maintains its optimal performance, providing reliable and efficient packaging solutions for longer periods while also reducing waste and unnecessary costs. Proper storage, handling, and machine maintenance are essential steps in maximizing the longevity and effectiveness of fiber film stretch.

Stretch film, also known as stretch wrap, is a plastic film primarily used to secure, bundle, and protect products, particularly on pallets during transportation and storage. Stretch film is applied tightly around items, creating a strong bond that holds them in place, minimizing movement and potential damage. It’s especially valuable in logistics and distribution, where it provides a cost-effective way to stabilize large loads, preventing shifting or tipping during transit. The film’s stretchability allows it to conform to the shape of irregular loads, adding versatility to its use. In addition to providing physical security, stretch film protects items from dust, moisture, and UV exposure, helping to preserve the integrity of packaged goods. Companies in industries such as manufacturing, warehousing, and retail frequently use stretch film for its ability to reduce damage risks, improve load stability, and enhance efficiency in transporting products. Its lightweight design also makes it a popular choice for eco-conscious companies looking to minimize packaging material without sacrificing load protection.

Fiber film is an advanced type of stretch film designed with embedded reinforcement fibers that provide greater strength and durability compared to traditional stretch films. Unlike conventional films, fiber film incorporates these fibers to increase tear and puncture resistance, making it ideal for applications that demand higher load stability and protection. The unique design of fiber film allows it to use less material while maintaining—or even exceeding—the security provided by standard stretch wraps. This material efficiency not only reduces plastic waste but also makes it a cost-effective choice for companies looking to lower their environmental impact without sacrificing performance. Fiber film is fully recyclable, aligning with sustainable packaging practices, and it’s suitable for both manual and machine wrapping applications. This makes fiber film a versatile option across various industries, including logistics, manufacturing, and retail, where it’s used to secure goods on pallets or in bundles with enhanced stability and protection during transport and storage.

Fiber film stretch, including stretch film, and shrink film, are both used in packaging, but they serve different purposes and have distinct properties.

Stretch Film: Stretch film is a highly elastic, stretchable plastic film used to wrap products tightly around a pallet or item. When stretched, it clings to the product, holding it in place and protecting it from external elements like dust, dirt, and moisture. Stretch film is typically used in manual and machine wrapping, providing superior load containment without the need for heat.

Shrink Film: Shrink film, on the other hand, is designed to shrink tightly around a product when heat is applied. Unlike stretch film, shrink film conforms to the shape of the product, offering a tight and secure seal. It is commonly used for individual product packaging, particularly for retail goods.

Key Difference: Stretch film relies on tension to hold products, while shrink film uses heat to shrink tightly around them.

Fiber film stretch includes various specialized films, one of which is carbon fiber film. Carbon fiber film is a high-performance material that combines the lightweight yet strong properties of carbon fibers with the flexibility of film packaging.

Carbon fiber film typically consists of a composite of carbon fiber strands embedded in a polymer matrix, providing enhanced durability and strength compared to traditional films. It is used in industries that require superior strength-to-weight ratios, such as automotive, aerospace, and sports equipment.

The primary advantage of carbon fiber film is its exceptional tensile strength, making it ideal for applications that require high load-bearing capacity or resistance to impact and wear. Additionally, carbon fiber films can have unique aesthetic qualities, with a sleek, matte finish, making them popular in decorative and functional applications.

Carbon fiber films are not commonly used in standard packaging but find specialized applications in high-tech industries.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed