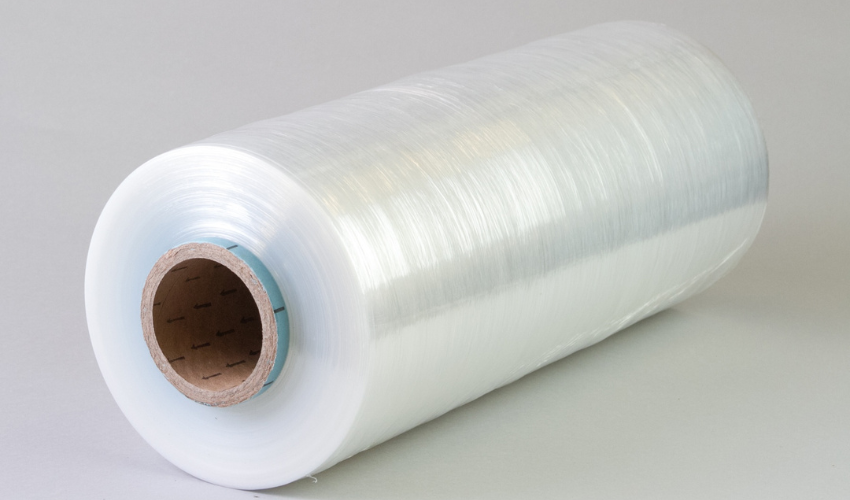

Flame retardant stretch film is a specialized type of protective film designed to reduce the risk of fire. This versatile film incorporates flame-retardant additives that help slow down the spread of flames, making it an essential tool in environments prone to fire hazards. Flame retardant stretch film production involves the careful integration of these additives during manufacturing to ensure optimal performance. Commonly used in industries like shipping and construction, the film provides an extra layer of safety by wrapping and securing items such as boats, marine equipment, and electrical components. Its primary purpose is to safeguard these valuable assets from fire-related risks, ensuring enhanced protection during storage and transportation. This innovative solution is widely appreciated for its reliability and safety benefits.

Flame retardant stretch film is a specialized material designed to provide an added layer of fire protection to the items it covers. Manufactured by a stretch film factory, this unique film is engineered with flame retardant properties, making it highly effective in slowing or halting the spread of fire. When exposed to heat or flames, the film’s additives create a barrier that limits the oxygen supply around the wrapped items, thus reducing the risk of combustion and giving more time for fire control measures to be implemented.

Flame retardant stretch film is a high-performance material designed to protect goods from fire hazards. It is crafted with flame-retardant additives that reduce the risk of combustion by creating a barrier around wrapped items. This innovative film is particularly useful in environments where fire risks are high, ensuring the safe storage and transportation of valuable items. Flame retardant stretch film offers numerous advantages, making it an essential material for industries requiring high safety standards:

One of the key benefits of flame retardant stretch film is its ability to protect wrapped goods by creating an oxygen-poor environment inside the wrapped package. This lack of oxygen reduces the risk of combustion, preventing fires from spreading rapidly. The film forms a protective barrier that slows down fire progress and keeps the contents safe for a longer period.

This film is particularly well-suited for marine environments, construction sites, and logistics operations. In these industries, fire hazards are a significant concern, and using flame retardant stretch film can be a crucial part of fire prevention strategies. Whether used to protect marine equipment or construction materials, the film provides peace of mind by minimizing fire risks.

Flame retardant stretch film meets various fire safety regulations and standards, making it a reliable choice for businesses aiming to comply with safety requirements. Its use in warehouses and during transportation can contribute to lower insurance premiums, as insurers often recognize the added fire protection it offers. By investing in flame retardant stretch film, businesses not only enhance safety but may also reduce operational costs through compliance with safety standards and regulations.

Flame retardant stretch film offers several critical advantages that make it a valuable asset for industries requiring both fire protection and durability. Its unique properties provide reliable safety for goods, especially in environments where fire risks are a concern. Let’s explore the benefits in detail.

One of the most important benefits of flame retardant stretch film is its ability to create an oxygen-poor internal environment around wrapped goods. By limiting the oxygen available within the wrapped package, the film effectively reduces the risk of combustion. This feature is crucial for safeguarding items during storage or transport in fire-prone areas, as it helps slow or prevent the spread of fire if a blaze does occur. This added layer of protection ensures that goods remain safe in high-risk settings.

Flame retardant stretch film is ideal for use in a variety of demanding environments, including marine settings, construction sites, and logistics operations. In the marine industry, for example, the film is frequently used to wrap boats and equipment, providing fire protection as well as resistance to moisture, salt, and UV exposure. Construction sites, where fire hazards are common due to flammable materials and equipment, also benefit from the wrapping film’s fire-resistant properties. Additionally, in logistics, flame retardant stretch film ensures that goods are securely wrapped and protected from both environmental factors and fire risks during long-distance transport.

Another key advantage of flame retardant stretch film is its ability to meet stringent fire safety regulations and standards. Many industries are required to comply with specific fire protection guidelines, and the use of this film helps businesses achieve that compliance. This not only enhances the safety of the operation but also can lead to reduced insurance premiums for warehouses and transportation services. By choosing flame retardant stretch film, businesses are investing in a product that not only protects their assets but also contributes to overall cost savings by lowering potential liabilities and insurance costs.

Flame retardant stretch film plays a crucial role in marine environments, providing superior protection for boats and marine equipment during storage and transportation. Its flame-retardant properties make it the ideal choice for safeguarding valuable assets, particularly in areas where fire hazards are a concern. Here’s a detailed look at how this specialized film is used in the marine industry.

One of the most common uses of flame retardant stretch film in marine applications is for heat shrink wrapping boats and other watercraft. This protective film is perfect for covering vessels when they are in storage or being transported, as it not only shields them from environmental elements like moisture, salt, and UV rays but also offers critical fire protection. Flame retardant stretch film uses help ensure that, in case of an unexpected fire, the film slows the spread of flames, giving more time for fire control measures and minimizing potential damage to the vessel.

To properly wrap boats using flame retardant stretch film, having the right supplies is essential. These supplies typically include a heat gun, shrink wrap tape, and strapping, which help secure the film tightly around the boat. Using flame retardant film adds an extra layer of protection by reducing fire risks during both storage and transport. When done correctly, the film provides a seamless and durable cover that protects the boat from weathering while also complying with fire safety standards.

Choosing the right flame retardant stretch film roll size and thickness is important for marine applications. For boats and larger marine equipment, rolls come in various sizes, ranging from 12 to 20 feet in width, with thicknesses typically between 6 and 10 mils. The thicker the film, the more resistant it is to tears and punctures, offering more robust protection. Thicker rolls are ideal for large vessels, providing not only weatherproofing but also enhanced fire resistance during extended storage periods or long-distance transportation.

When it comes to protecting valuable assets, especially in fire-prone environments, choosing the right material is critical. Flame retardant stretch film offers distinct advantages over regular shrink wrap in terms of fire protection, durability, and cost-effectiveness. Understanding these differences can help in selecting the best option for your needs.

| Feature | Flame Retardant Stretch Film | Regular Shrink Wrap |

|---|---|---|

| Fire Protection | High fire-resistant, prevents flame spread | No fire protection, flammable |

| Durability | Thicker, more durable, better for outdoor use | Less durable in high-risk environments |

| Waterproof/UV Protection | Provides UV and waterproof protection | Provides UV and waterproof protection |

| Tear/Puncture Resistance | More resistant to tears and punctures | Less resistant to tears and punctures |

| Cost-Effectiveness | Higher initial cost, long-term savings in fire-prone areas | Lower cost, but higher risk in fire-prone areas |

The flame retardant stretch film is designed to provide both fire resistance and excellent durability, making it an ideal choice for a variety of applications where safety and performance are critical. Its technical specifications reflect its ability to perform effectively in challenging environments while meeting fire safety standards.

One of the most critical measurements of fire resistance is the Oxygen Limit Index (LOI), which indicates the minimum concentration of oxygen needed to sustain combustion. The flame retardant stretch film has an LOI value of 26.4, as tested by CSI laboratories. This high LOI value ensures that the film is highly resistant to ignition, making it difficult for flames to spread when the film is exposed to fire. This feature is especially important for industries like marine transport, construction, and logistics, where fire risks are heightened.

Flame retardant stretch film is available in two primary forms: flame retardant hand stretch film for manual applications and flame retardant machine stretch film for automated systems. Both types are offered in a range of thicknesses, typically from 6 to 10 mils, to suit varying load requirements. For manual wrapping tasks, flame retardant hand stretch film is commonly supplied in narrower rolls, ranging from 12 to 20 inches in width, ensuring ease of handling and adaptability for smaller-scale operations. On the other hand, flame retardant machine stretch film is engineered for efficiency in high-volume settings, with roll widths extending up to 40 inches to accommodate the wrapping of larger or bulkier loads. This dual offering ensures businesses can choose the right stretch film size and thickness to meet their specific needs.

The flame retardant stretch film is engineered to withstand a range of extreme environmental conditions. Whether exposed to direct sunlight, rain, or harsh chemicals, the film maintains its integrity and protective qualities. It offers strong UV resistance, ensuring that the material won’t degrade under prolonged exposure to sunlight. Additionally, it remains durable in wet conditions, preventing corrosion or water damage to the wrapped goods. The film’s chemical resistance also ensures it can withstand exposure to various industrial substances, maintaining its effectiveness in challenging environments while offering superior fire protection.

Fire retardant film is a specialized material designed to reduce the risk of fire by slowing down or preventing the spread of flames. It is commonly used in industries where fire hazards are a concern, such as construction, logistics, and marine environments. The film is treated with additives that interrupt the combustion process, creating a barrier that limits the amount of oxygen available to fuel the fire. This protective feature makes fire retardant film ideal for wrapping valuable goods or equipment, especially when stored in high-risk areas. In addition to its fire-resistant properties, fire retardant film also provides protection against environmental factors like moisture, UV rays, and chemicals. It’s an essential safety tool for businesses aiming to comply with fire safety regulations and reduce risks associated with fire outbreaks.

Flame retardant fabric is a type of textile material that has been treated with or made from fibers that resist ignition and slow down the spread of fire. These fabrics are designed to prevent flames from spreading and to extinguish themselves after the ignition source is removed. Flame retardant fabrics are commonly used in protective clothing, curtains, upholstery, and other applications where fire safety is a priority. The treatment applied to the fabric helps lower its flammability, making it an important choice for environments such as hospitals, theaters, schools, and industrial settings where fire risks are present. There are two main types of flame retardant fabrics: inherently flame-resistant fabrics, which have fire-resistant properties built into their fibers, and chemically-treated fabrics, which are treated with a flame retardant finish. Both types meet strict fire safety standards and are essential for protecting people and property from fire hazards.

Flame retardant coating is a protective layer applied to surfaces to reduce their flammability and inhibit the spread of fire. This type of coating is used on a wide range of materials, including wood, metal, textiles, and plastics, making it versatile for different applications. The coating works by creating a chemical barrier that reacts with heat and prevents the material beneath it from igniting. In many cases, the coating can also form a layer of char when exposed to fire, which further insulates and protects the underlying material from heat damage. Flame retardant coatings are used in construction, automotive, aerospace, and marine industries to meet safety standards and regulations. By applying these coatings, manufacturers and builders can improve the fire resistance of their products and structures, helping to prevent property damage and increase safety in the event of a fire.

Not all shrink wrap is fire retardant. Regular shrink wrap, which is typically used for packaging and protecting goods, does not have flame retardant properties and can ignite if exposed to fire. However, there are specialized types of shrink wrap, such as flame retardant shrink wrap, that are treated with fire-resistant additives to make them more suitable for environments where fire risks are present. Flame retardant shrink wrap is often used in industries like marine transport, construction, and warehousing, where fire hazards are a concern. This type of wrap is designed to slow the spread of flames and prevent combustion, providing extra protection for the items it covers. If fire safety is a priority, it’s important to choose a flame retardant version of shrink wrap instead of standard packaging materials, as it offers the added benefit of reducing fire risks during storage and transport.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed