Handy wrap is a highly adaptable stretch film designed to secure and protect items in a wide range of settings. Known for its versatility, handy wrap provides a convenient solution for both household and professional use, offering reliable protection for valuables. In residential settings, it’s ideal for securing furniture during moves or bundling loose items for storage. Commercially, handy wrap is widely used in warehouses to stabilize pallets and protect goods. For industrial applications, it’s durable enough to shield machinery and bundle bulky items like pipes or lumber. With its easy-to-use design, handy wrap has become an essential tool for safe and effective packaging across multiple environments.

Handy wrap is a versatile, self-adhering plastic stretch film commonly used to secure, bundle, and protect items across different settings. Made from durable polyethylene material, handy wrap is designed to cling to itself, forming a tight, secure hold without the need for adhesives or tapes. This characteristic makes it ideal for wrapping various items, from household goods to commercial pallets, providing a strong barrier against dust, dirt, and moisture. Handy wrap can be applied manually or with the help of a dispenser, like the Wrapmaster, for more efficient handling. Whether used in the home to organize loose items, in commercial settings for securing packages, or in industrial environments for bundling heavy-duty materials, handy wrap offers an economical, flexible, and effective solution for keeping items stable and protected. Its ability to conform to different shapes and sizes adds to its value, making handy wrap a go-to option for packaging and securing loads in numerous applications.

Handy wrap is available in a variety of sizes to suit different packaging needs. The sizes typically vary in both width and length to accommodate different types of items, from small bundles to larger pallets. Understanding the common sizes of handy wrap can help you choose the right option for your packaging requirements.

Width

Length

Thickness

Core

While handy wrap is a specific type of stretch film, it is important to note that there are other types of stretch film available in the market, including machine stretch film and pre-stretched film. These types differ in size, thickness, and application method, but they also share several common characteristics. Below is a breakdown of how the sizes of handy wrap compare to other stretch film options.

| Factor | Handy Wrap | Machine Stretch Film | Pre-Stretched Film | Impact of the Difference |

|---|---|---|---|---|

| Width | 4 to 8 inches (10-20 cm) | 12 to 20 inches (30-50 cm) | 12 to 20 inches (30-50 cm) | Handy wrap is narrower, suited for manual use; machine stretch film is wider for machine wrapping of larger loads. |

| Length | 500 to 3000 feet (152-914 meters) | 1500 to 6000 feet (457-1829 meters) | 1000 to 2000 feet (305-610 meters) | Handy wrap rolls are shorter, making them ideal for smaller or frequent tasks; machine stretch has longer rolls for bulk packaging. |

| Thickness (Gauge) | 50 to 80 gauge (0.5 to 0.8 mil) | 60 to 120 gauge (0.6 to 1.2 mil) | 50 to 80 gauge (0.5 to 0.8 mil) | Machine stretch films are often thicker, providing more strength for large, heavy loads. |

| Core | Extended core, 1.5 to 2 inches (3.8-5 cm) | Standard 3-inch core | Standard 3-inch core | Handy wrap’s extended core is specifically designed for manual handling; machine stretch films often use larger cores for machine application. |

| Application Method | Manual application | Machine or manual | Manual application | Handy wrap is designed for small, manual wrapping; machine stretch is for industrial use with machines, and pre-stretched film is often used for automated systems. |

Handy wrap is a great solution for smaller-scale, manual wrapping tasks, offering a variety of widths and lengths that cater to different packaging needs. Its narrower width and compact roll sizes make it ideal for individual or small-scale packaging, especially for irregularly shaped items or bundles. In contrast, machine stretch film and pre-stretched film are designed for larger applications and are typically used with machines to wrap pallets or large volumes of items. These films often come in wider rolls and thicker gauges, providing the necessary strength for heavy-duty applications.

By understanding the size differences and the specific uses of each type of stretch film, you can better determine which film will meet your needs based on your packaging volume, application method, and required durability.

Handy wrap offers a range of key benefits that make it an ideal packaging solution for both small and large-scale needs. From its durability and flexibility to its self-adhering properties, handy wrap provides strong protection for items during storage and transit. It acts as an effective barrier against dust, dirt, and moisture, ensuring that your goods remain clean and secure. Additionally, its cost-effective nature makes it an affordable choice, offering significant savings without compromising on performance. This detailed overview explores these advantages in-depth, helping you understand how handy wrap can be a valuable asset for your packaging needs.

One of the most significant advantages of handy wrap is its durability and flexibility. It is designed to provide robust protection for items of varying shapes and sizes. Whether you’re wrapping delicate electronics or bundling irregularly shaped products, handy wrap adapts seamlessly to the contours of the object, ensuring a snug and secure fit. The film’s tear-resistant nature ensures that it won’t easily rip, even when handling sharp edges or heavy objects. This durability reduces the risk of damage during transit, making it an excellent choice for protecting goods in both transportation and storage environments.

Another standout feature of handy wrap is its self-adhering nature. The film has a cling property that allows it to stick to itself without requiring any additional adhesives or tape. This makes wrapping much quicker and more efficient, as you don’t need to rely on external materials that might add to your costs. The self-adhesion creates a strong and secure hold, preventing the wrap from slipping or loosening during handling or transit. This property is particularly useful in situations where quick and efficient wrapping is needed, as it eliminates the need for extra steps in the packaging process.

Handy wrap provides an excellent protective barrier against external contaminants such as dust, dirt, and moisture. This is especially important during storage or shipping, as these elements can potentially damage or degrade the quality of products. Whether it’s preventing dirt from settling on stored items or protecting products from moisture during shipping, handy wrap ensures that the contents remain clean and secure. This makes it particularly suitable for industries where product hygiene and condition are paramount, such as food, electronics, and medical supplies.

Cost-effectiveness is one of the primary reasons businesses and individuals opt for handy wrap. It offers an affordable alternative to other packaging options such as boxes, bubble wrap, or packing peanuts, all of which can be more expensive and require more storage space. Handy wrap is inexpensive per unit, making it an ideal choice for small businesses, startups, and even large-scale operations that need to keep packaging costs low. Moreover, because it’s lightweight and compact, it is easier to store, saving both space and money in warehousing. The reduced need for additional materials like tape or cushioning further enhances its cost-effectiveness.

Handy wrap is a versatile and practical packaging solution that combines durability, flexibility, and affordability. Its self-adhering nature and ability to provide a protective barrier against environmental elements make it a go-to choice for a wide range of industries, offering both efficiency and cost savings. Whether you’re looking to protect your goods during transit or need a reliable, budget-friendly packaging option, handy wrap is a solution that meets a variety of needs effectively.

Handy wrap offers multiple features that make it an essential packaging tool for a variety of needs. From its self-clinging action to its durability, this versatile wrap provides reliable protection across many environments.

Each of these features contributes to handy wrap’s popularity as a versatile, cost-effective, and secure packaging solution, making it indispensable across both personal and professional settings.

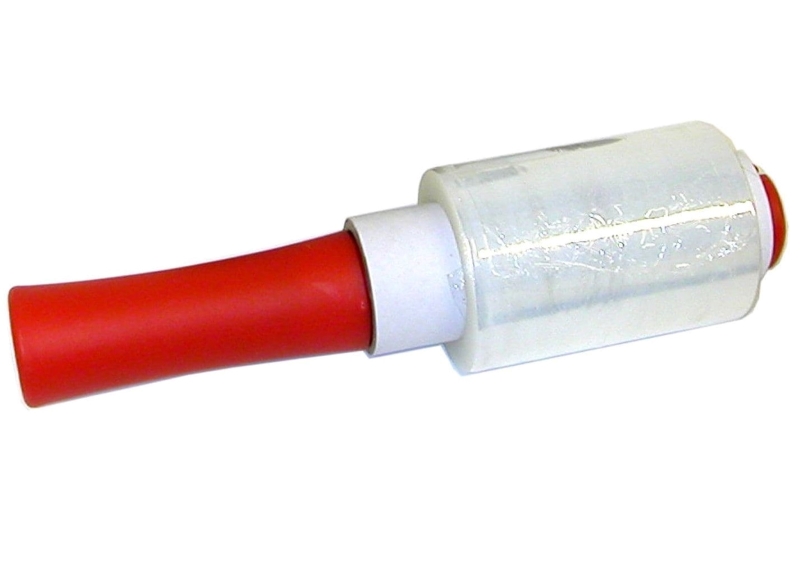

When people refer to handy wrap, the term extended core often comes up as well. The two are closely related, with the extended core playing a crucial role in the ease of use and functionality of handy wrap. This connection is not just about physical design, but also about efficiency, ergonomics, and overall performance. To fully understand the relationship between handy wrap and extended core, it’s essential to explore how the two work together and why the extended core is such a defining feature of handy wrap.

Physical Design and Functionality

The extended core refers to the central tube inside the roll of handy wrap, which extends beyond the edges of the film, providing a handle for easy manual application. This extended core is one of the most distinct features that set handy wrap apart from other types of stretch film. With a standard core, the roll can be difficult to handle, especially in high-volume or fast-paced environments. The extended core solves this problem by giving users something to grip, making it easier to apply the wrap quickly and efficiently.

Ease of Use and Ergonomics

The presence of an extended core makes handy wrap especially user-friendly. The core is designed to be held comfortably in the hand, offering more control over the application of the wrap. This is especially important when wrapping smaller items or bundles, as it allows for a smoother, more controlled wrap. The ergonomic design reduces hand strain and improves the speed and efficiency of the wrapping process, making it ideal for tasks that require precision and speed. For users who need to wrap multiple items in a short period of time, the extended core enables a faster and more effective wrapping process compared to traditional rolls without such a core.

Application Method

Handy wrap with an extended core is primarily used for manual application, making it perfect for small-scale or intermittent wrapping needs. The extended core ensures that even when wrapping by hand, the wrap is applied with the proper tension and control, reducing the likelihood of sloppy, uneven application. This is particularly useful when wrapping smaller packages, boxes, or irregularly shaped items that require a more delicate touch. Without the extended core, it would be much harder to apply the wrap with the same level of consistency and precision.

Increased Efficiency in Low-Volume Operations

Unlike machine stretch film, which is designed for high-volume, industrial applications, handy wrap with an extended core is perfect for low-volume tasks. The roll size and ergonomic design make it ideal for small businesses, retail settings, or for individuals wrapping personal items. The extended core allows users to quickly and easily wrap items without the need for additional tools or equipment, thus increasing productivity in environments where manual wrapping is preferred or necessary.

The extended core also contributes to the compactness of handy wrap rolls. The extended portion of the core provides a sturdy handle while still allowing the roll to remain relatively small and lightweight. This is beneficial for businesses or individuals who have limited storage space or need to carry wrapping materials to different locations. Handy wrap rolls with extended cores are more portable and easier to store compared to larger, bulkier rolls of machine stretch film or those with standard cores.

Cost-Effective Packaging Solution

The cost-effectiveness of handy wrap with an extended core is another advantage. It eliminates the need for additional tools, such as dispensers or tape, which might be required for other forms of stretch film. As a result, businesses can save on both the upfront cost of the wrapping material and the additional expenses associated with packaging equipment. The extended core allows users to manually wrap their products quickly, thus cutting down on labor time and increasing efficiency.

Reduced Material Waste

Another benefit of the extended core is that it helps maintain consistent tension while wrapping. When wrapping manually, the extended core allows users to apply the film at the right level of stretch, reducing the likelihood of over-wrapping or under-wrapping. This results in less material waste, making handy wrap an even more economical choice. Proper tension helps ensure that the items are secured tightly without unnecessary excess film being used.

The relationship between handy wrap and extended core is one of design and efficiency. The extended core plays a critical role in enhancing the usability and functionality of handy wrap, offering a comfortable and practical means of applying the wrap manually. By providing an ergonomic grip, allowing for quicker application, and reducing waste, the extended core is an essential feature that makes handy wrap ideal for smaller-scale and precision wrapping tasks. It also enables a cost-effective, space-saving, and efficient packaging solution for a wide range of users, from businesses to individuals. The combination of handy wrap and the extended core ensures that users get the most out of their wrapping materials with minimal effort.

Handy wrap is an incredibly versatile tool used in a wide range of applications, making it invaluable across household, commercial, and industrial settings. Its self-clinging, durable nature ensures it meets the varied needs of users in these environments.

Handy wrap is a practical solution for numerous household tasks, helping homeowners keep items organized and protected.

In commercial settings, handy wrap is widely used for organizing, securing, and stabilizing items, especially in warehouses, shipping centers, and retail spaces.

In industrial environments, handy wrap plays a crucial role in bundling heavy-duty items, protecting machinery, and simplifying logistics.

Handy wrap’s flexibility and self-clinging design make it indispensable for users across these diverse settings, from securing everyday items at home to stabilizing heavy loads in warehouses.

Handy wrap is highly valued for its broad range of applications. In personal settings, similar to bundling stretch film, it is ideal for bundling loose items, securing furniture, and covering items during storage or transport. Professionally, handy wrap plays a critical role in packaging and shipping, ensuring goods remain intact and stable on pallets. In industrial contexts, it serves as a safeguard for machinery and equipment, helping to bundle and protect materials like pipes and construction supplies.

Its simple, self-cling design and durability make handy wrap film an invaluable tool for maintaining the safety and stability of various items in multiple settings.

When sourcing handy wrap stretch film, understanding the role of reliable factories is essential for ensuring quality and performance. Leading handy wrap stretch film factories have a direct impact on product consistency, durability, and cost-efficiency, making it important for buyers to carefully assess their options.

Selecting a factory with the right standards and capabilities can enhance the quality and longevity of handy wrap products. Here are several factors to evaluate:

The standards maintained by handy wrap stretch film factories significantly affect the end product’s quality, durability, and overall usability. The right factory can ensure a product that not only meets but exceeds market expectations. Below are some ways these standards influence handy wrap performance:

Choosing the right handy wrap stretch film factory is key to ensuring that buyers receive a durable, reliable, and eco-friendly product. By assessing these factors, buyers can select a manufacturer that aligns with their quality and sustainability expectations, securing a dependable supply of high-quality handy wrap for various applications.

Selecting the right handy wrap stretch film manufacturer is essential for obtaining a high-quality, durable product. Leading manufacturers not only provide consistency in performance but also incorporate sustainable practices, adding value for buyers focused on quality and environmental impact.

To ensure you receive a product that meets industry standards and specific usage requirements, evaluate potential manufacturers based on the following factors:

Partnering with a reputable manufacturer ensures that the handy wrap stretch film performs consistently, providing multiple benefits to the end user. Below are some advantages that reliable manufacturers offer:

Choosing a reputable handy wrap stretch film manufacturer helps secure a product that performs effectively across a wide range of applications. For companies focused on both quality and eco-conscious practices, these manufacturers provide an ideal balance, delivering reliable handy wrap solutions that meet high standards.

Handy wrap stands out as a versatile, convenient, and cost-effective packaging solution that meets the needs of both personal and professional users. Unlike many traditional packaging materials, handy wrap offers unique benefits that make it ideal for securing, protecting, and transporting items in diverse settings.

Handy wrap is prized for its ease of use and flexibility, making it suitable for a wide range of applications:

Handy wrap provides a robust barrier against environmental factors, keeping items safe during storage or transport:

Choosing handy wrap as a packaging solution offers significant cost advantages for businesses and individuals:

Handy wrap provides the ideal combination of convenience, protection, and economy, making it a preferred choice over other packaging solutions. Its unique features address a variety of needs, delivering value across both household and commercial applications.

Both hand wrap and stretch wrap are types of plastic films used for securing and protecting items during transportation, storage, and handling. While they serve a similar function, the materials and application methods can differ significantly. Hand wrap is typically used manually and is ideal for smaller, more precise wrapping tasks, whereas stretch wrap is more commonly used for larger-scale, industrial applications and can be applied with machines or manually.

To better understand the key differences between handy wrap and stretch wrap, we will break down several important factors. This will allow you to easily compare the two types of wraps and determine which one is best suited for your needs.

| Factor | Handy Wrap | Stretch Wrap | Impact of the Difference |

|---|---|---|---|

| Application Method | Manual (applied by hand) | Can be applied manually or with machines | Handy wrap is ideal for smaller, more precise wrapping; stretch wrap suits large-scale, industrial uses. |

| Film Thickness | Generally thinner | Generally thicker | Handy wrap is more flexible and suitable for lightweight items; stretch wrap is stronger and better for heavy-duty uses. |

| Stretchability | Less stretchable | Highly stretchable | Stretch wrap provides greater tension, ensuring better hold and security for large, heavy items. |

| Use Case | Small boxes, bundles, and irregular items | Palletizing and large-volume shipping | Handy wrap is ideal for light packaging, while stretch wrap is optimized for bulk and pallet wrapping. |

| Core Type | Extended core with tension control handle | May or may not have an extended core | Handy wrap comes with an easy-to-use core for manual application; stretch wrap may require machine handling for large volumes. |

| Cost | Typically more expensive per unit | More cost-effective in bulk | Handy wrap may be more expensive due to its manual application, while stretch wrap offers bulk savings for larger orders. |

By understanding these key differences, you can determine which type of wrap—handy wrap or stretch wrap—better suits your specific packaging needs. Whether you’re working with small items and need precise wrapping, or you need the strength and stretchability of a larger film for palletizing, each type offers distinct benefits tailored to different applications.

Yes, Wrapmaster is designed with safety and ease of use in mind, making it a reliable choice for various wrapping needs. This dispenser system securely holds handy wrap and allows users to cut the wrap smoothly and safely without the need for sharp tools or scissors, minimizing the risk of accidental cuts. Many Wrapmaster models come equipped with a concealed blade, so there’s no direct contact with any cutting edge, further enhancing user safety. Additionally, Wrapmaster dispensers help users achieve a precise cut each time, which reduces waste and ensures an even application. The Wrapmaster is especially useful for high-traffic environments like kitchens, warehouses, or retail spaces where frequent use of handy wrap is required. When used correctly, Wrapmaster provides a seamless and secure way to handle handy wrap, keeping both the user and the wrapped items safe from damage.

Wrapping food in aluminum foil is generally safe as long as certain precautions are taken. Aluminum foil can effectively preserve the freshness of food and protect it from air, moisture, and contaminants, helping to keep it fresh for longer. However, there are a few things to consider: Avoid wrapping acidic foods, such as tomatoes or citrus, directly in foil, as the acid can react with the aluminum, potentially altering the taste and leading to the release of small amounts of aluminum. Additionally, when heating food wrapped in aluminum foil, it’s important to ensure it’s done safely to prevent foil from reacting to high heat or microwaving, which can cause sparks. For food safety, it’s also essential to avoid using foil to wrap food for extended periods in the refrigerator without proper sealing.

A pareo wrap is a versatile piece of cloth that is commonly used as a garment in tropical and beach settings. Originating from Polynesian culture, it’s a large piece of fabric typically worn as a sarong-style wrap around the waist or over the shoulders. A pareo wrap is made from lightweight materials like cotton, linen, or silk, making it comfortable and breathable. It can be styled in various ways—worn as a skirt, dress, or even a shawl—depending on the occasion. Besides being a beachwear staple, pareo wraps are also popular for their easy-to-wear nature, offering a simple and stylish solution for hot climates. While the word “pareo” is often used to refer to the cloth itself, it can also represent the garment worn using it in the Pacific Islands.

Yes, hand wraps are supposed to be tight, but not excessively tight. The purpose of hand wraps is to provide support and protection to the wrists, knuckles, and fingers during activities like boxing or martial arts. Properly applied wraps help prevent injuries like sprains, fractures, or bruising. They should be snug enough to stabilize the wrist and knuckles, but tight enough to allow for comfort and flexibility. If they’re too tight, it could restrict blood circulation, leading to numbness or tingling. On the other hand, if they’re too loose, they won’t provide adequate protection. The wrap should allow for proper movement while ensuring the hand and wrist are firmly supported. Ideally, hand wraps should cover the knuckles and secure the wrist, while leaving some room for flexibility and natural hand movement.

The durability of hand wraps depends on the material they are made from and the frequency of use. High-quality hand wraps, typically made from cotton or a cotton-blend fabric, can last for years if they are properly cared for. However, after several uses, they may start to show signs of wear, such as fraying or losing their elasticity. To extend the lifespan of hand wraps, it’s important to wash them regularly after each use to remove sweat, bacteria, and odors. Some hand wraps are also made from synthetic materials like polyester or elastic blends, which may be more durable but may not offer the same level of comfort as cotton-based wraps. Ideally, hand wraps should be washed by hand or in a gentle machine cycle to prevent damage. Overall, with proper care, hand wraps can last for a long time.

Cling film and food wrap are both types of plastic film commonly used for wrapping food, but there are some subtle differences between the two. Cling film, also known as plastic wrap or Saran wrap, is a thin, stretchable film designed to cling to surfaces tightly, offering an airtight seal. It’s mainly used for covering bowls, wrapping leftovers, or covering food to keep it fresh. It’s transparent and flexible, making it ideal for preserving the freshness of food while allowing easy visibility. Food wrap, on the other hand, is a broader term that can refer to a variety of materials used for wrapping food, including wax paper, parchment paper, aluminum foil, and cling film. The key difference is that food wrap encompasses multiple types of wrapping materials, while cling film is specifically the stretchable plastic film often used for sealing food tightly.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed