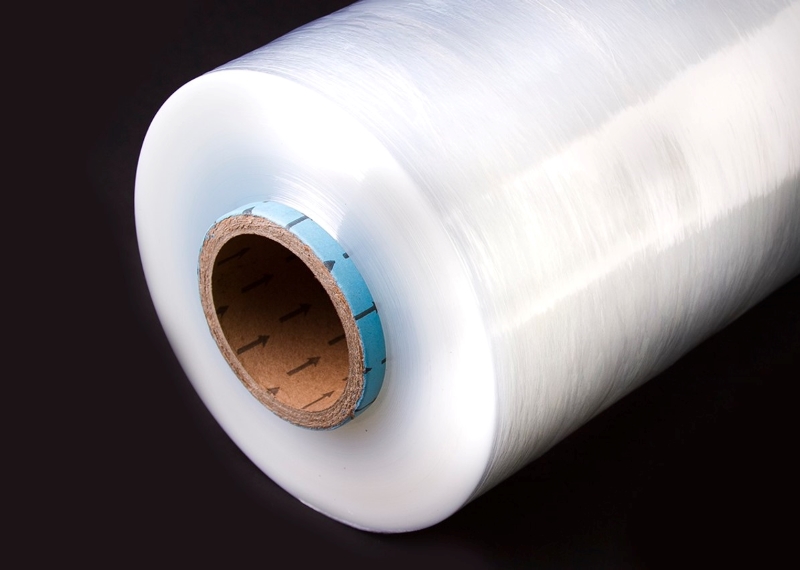

High performance stretch film is a specialized packaging material designed to provide superior strength and elasticity compared to standard stretch films. Made from high-quality polymers, it effectively secures and stabilizes loads during transport and storage. The unique properties of high quality stretch film allow it to conform tightly around products, minimizing the risk of damage from shifting or external elements. Its importance in packaging and logistics cannot be overstated, as it enhances load integrity, reduces material waste, and improves overall efficiency in supply chains. By using high performance stretch film, businesses can ensure that their products arrive safely and in excellent condition, ultimately contributing to customer satisfaction and operational success. High-performance stretch film offers superior elasticity, strength, clarity, and cost efficiency, with reduced material use and excellent puncture resistance.

High performance stretch film offers numerous advantages that set it apart from standard stretch films. These benefits make it a preferred choice for many businesses looking to enhance their packaging processes.

At PWP Stretch Film, we prioritize providing high performance stretch film that not only meets industry standards but also supports our clients in achieving their packaging goals effectively.

High performance stretch film has become an essential tool across various industries, offering versatile solutions for securing and protecting products during transport and storage.

At PWP Stretch Film, we understand the diverse applications of high performance stretch film, which is why we provide tailored solutions to meet the specific needs of various industries.

High performance stretch film stands out from traditional stretch films due to its unique characteristics that enhance its effectiveness in packaging applications.

At PWP Stretch Film, we are committed to providing high performance stretch film that embodies these key features, ensuring optimal performance and reliability for our customers’ packaging needs.

The quality of stretch film plays a crucial role in its performance and reliability, particularly for high performance stretch film, which is designed to meet demanding packaging needs. Understanding the factors that influence this quality can help businesses make informed decisions.

At PWP Stretch Film, we prioritize providing high performance stretch film that meets the highest quality standards, ensuring our customers can rely on our products for their packaging needs.

Selecting the right high performance stretch film is essential for ensuring effective packaging and protection of your products. Several key factors can guide your decision-making process.

Gauge Thickness:

Types of Stretch Film:

At PWP Stretch Film, we provide guidance and a wide selection of high performance stretch film options tailored to meet diverse packaging needs, ensuring you find the best fit for your specific requirements.

To maximize the effectiveness of high performance stretch film, it’s essential to employ proper application techniques and use the right equipment. These practices will ensure secure and efficient packaging, ultimately enhancing product safety during transport and storage.

By following these best practices, PWP Stretch Film can help you ensure that your high performance stretch film is used effectively, providing reliable protection for your products while optimizing your packaging processes.

High-performance stretch film is the ultimate packaging solution, balancing strength, flexibility, and sustainability for optimal load security and cost-effectiveness.

Ultra-high-performance stretch film, often referred to as nano-stretch film, is a game-changer in packaging due to its ability to significantly reduce costs while maintaining superior packaging quality. Here’s an in-depth look at how this material achieves cost savings across multiple dimensions:

Ultra-high-performance stretch film provides exceptional strength and elasticity, allowing it to stretch further while maintaining its load containment properties. This means that businesses can use up to 50% less film compared to conventional stretch films for the same application. Despite using less material, the film offers equal or better protection for loads, reducing the overall cost of packaging materials.

The high tensile strength and resilience of the film ensure that products are securely wrapped, minimizing shifting and potential damage during transport. This improved stability reduces the costs associated with damaged goods, claims, and returns. Additionally, better load security translates into fewer rewraps, saving time and labor costs.

With superior tear and puncture resistance, ultra-high-performance stretch film significantly reduces the risk of film breaks during the wrapping process. This minimizes machine downtime, maintenance requirements, and operational disruptions, leading to improved productivity and cost savings in labor and equipment repairs.

The thinner profile of ultra-high-performance stretch film takes up less space, allowing for more efficient storage and transportation. Reduced bulk not only saves on storage costs but also lowers shipping expenses, as businesses can transport more film in the same shipment or reduce packaging waste volume.

Using less material results in lower environmental impact and waste generation. Many businesses face regulatory requirements or consumer expectations for sustainable practices. By adopting ultra-high-performance stretch film, companies can reduce their carbon footprint, comply with environmental standards, and potentially qualify for eco-friendly certifications or tax benefits.

While ultra-high-performance stretch film may have a higher initial cost compared to standard films, its durability and efficiency lead to long-term savings. Businesses benefit from fewer film rolls purchased, reduced waste disposal costs, and improved operational efficiency, making it a cost-effective solution over time.

Ultra-high-performance stretch film delivers a multi-faceted approach to cost reduction by minimizing material usage, enhancing load stability, improving operational efficiency, and supporting sustainability. These advantages make it an ideal choice for businesses looking to optimize packaging costs without compromising quality or performance.

Stretch wrap and stretch film are often used interchangeably, but there are subtle differences. Stretch wrap typically refers to the broader category of elastic plastic film used for securing and stabilizing items, while stretch film is a specific type of stretch wrap designed for more specialized applications. High performance stretch film is engineered to provide superior strength, elasticity, and puncture resistance, making it ideal for heavy-duty packaging needs. In contrast, standard stretch wrap may not offer the same level of durability or performance under demanding conditions. When choosing between the two, consider the specific requirements of your application, such as load weight and environmental factors.

The strength of stretch film varies significantly based on its gauge and material composition. High performance stretch film is designed to withstand substantial tension without tearing or breaking. Typically, the thickness of stretch film ranges from 35 to 150 gauge, with higher gauges indicating thicker, stronger film. For example, a 70-gauge high performance stretch film is suitable for loads weighing up to 2,400 pounds, providing reliable support during transport and storage. When selecting stretch film, it’s important to assess the weight of your loads and the conditions they will face to ensure you choose the appropriate strength for your needs.

Cling film and stretch film serve different purposes, although both are used for wrapping items. Cling film, often made from polyvinyl chloride (PVC), is a thin, flexible film primarily used in food packaging to maintain freshness by creating an airtight seal. It adheres well to surfaces and itself, making it ideal for wrapping food items. In contrast, high performance stretch film is thicker and designed for securing loads in logistics and shipping. It provides greater durability and puncture resistance, making it suitable for industrial applications. While cling film is focused on food preservation, stretch film emphasizes load stability and protection during transport.

High-performance stretch film is a type of packaging material designed for securing, protecting, and stabilizing products during transport or storage. Unlike traditional stretch films, high-performance variants are engineered to provide superior stretchability, puncture resistance, and load retention while using thinner gauges. This innovation allows businesses to reduce material usage, leading to cost savings and environmental benefits without compromising on performance.

High-performance stretch films are typically made from linear low-density polyethylene (LLDPE) and may include advanced additives or production techniques to enhance durability and stretch capability. They are commonly used in industries like logistics, manufacturing, and retail, where securing large or irregular loads is critical. These films often exhibit excellent clarity, making it easier to identify products while maintaining protection from dust, moisture, and other environmental factors. Overall, high-performance stretch films combine efficiency, sustainability, and robust protection, making them an essential tool for modern packaging solutions.

Blown film and stretch film are two distinct types of plastic films, each with specific production methods and applications. Blown film is manufactured by extruding molten plastic through a circular die and then blowing air into it to form a bubble, which cools into a film. This method gives blown film superior strength, puncture resistance, and a higher level of cling, making it ideal for heavy-duty packaging tasks.

Stretch film, on the other hand, is specifically designed for wrapping and securing loads. It is primarily produced using a cast extrusion process, where the film is cooled rapidly over a chilled roller. This results in a smoother, clearer film with excellent stretchability and uniform thickness. Stretch films are easier to handle and ideal for pallet wrapping or bundling products.

The key distinction lies in their purpose: blown film excels in durability for heavy packaging, while stretch film focuses on elasticity and load stabilization.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed