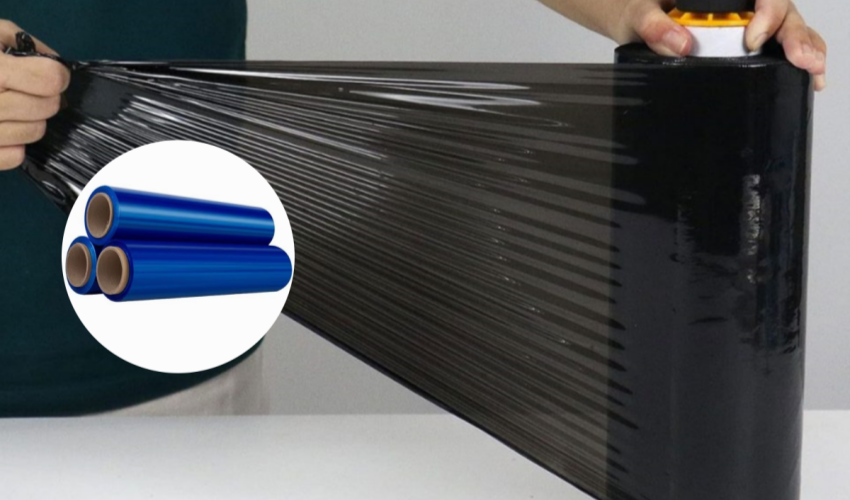

Industrial shrink wrap is a versatile and durable packaging solution widely used across industries for protecting large, valuable items during storage and transport. Unlike standard wraps, industrial shrink wrap provides heavy-duty protection for construction materials, equipment, and even boats, safeguarding them from environmental damage like moisture, dust, and UV exposure. One common alternative, the polyolefin shrink wrap roll, is often used for smaller items; however, industrial shrink wrap’s strength and resilience make it ideal for larger-scale applications. This wrap is applied with heat using specialized machinery, which enables a tight, secure seal that prevents shifting and potential damage. Compared to traditional wrapping methods, industrial shrink wrap is a reliable choice that maximizes safety and durability in challenging conditions.

Industrial shrink wrap encompasses several types specifically designed for heavy-duty applications and large-scale items, offering much greater protection than the more common polyolefin shrink wrap roll. This range includes specialized wraps and equipment for diverse needs, from construction to marine use. Below, we explore some key types of industrial shrink wrap, detailing their features, applications, and benefits.

| Type | Description |

|---|---|

| Industrial Shrink Wrap Machine | Industrial shrink wrap machines streamline wrapping by automating the application process, providing efficiency and precision for large items. Portable and large-scale machines are available, with adjustable heat settings, durable build, and safety features for industrial-grade performance. These machines allow for consistent wrapping and secure seals. |

| Industrial Heat Shrink Wrap | Applied by heat, industrial heat shrink wrap creates a tight, durable seal around objects, offering added stability. Common applications include wrapping construction materials, heavy machinery, and large equipment for protection from dirt, moisture, and UV exposure. Thicker wraps increase strength, making them essential for safeguarding items in demanding environments. |

| Heavy-Duty Heat Shrink Wrap | Designed for extreme conditions, heavy-duty heat shrink wrap is ideal for wrapping large structures, including scaffolding, boats, and vehicles. Its superior durability and weather resistance ensure long-lasting protection, even in harsh weather. The wrap’s high thickness and puncture resistance make it reliable for both transport and storage. |

| Boat Shrink Wrap | Boat shrink wrap is tailored for the marine industry, offering secure protection for vessels against weather damage, dust, and moisture during off-season storage or transport. Marine-specific accessories, such as venting systems and shrink wrap kits, provide added convenience and ensure complete coverage and durability. |

Industrial shrink wrap machines are essential for businesses that require efficiency and consistency in securing large items. These machines, available in portable and large-scale versions, are designed to apply industrial shrink wrap seamlessly, creating a tight seal around products. Key features to consider include temperature control, size, portability, and safety features, which ensure reliable performance for various applications.

Industrial pallet heat shrink wrap is designed to withstand heavy-duty use, offering a protective barrier that prevents environmental damage. Unlike a polyolefin shrink wrap roll, which is typically used for smaller items, industrial heat shrink wrap can handle large equipment and construction materials. Different thicknesses are available to suit specific needs, with thicker options providing greater durability for demanding applications.

Heavy-duty heat shrink wrap is particularly effective in extreme conditions, providing a reliable solution for covering and protecting large structures like scaffolding, boats, and vehicles. This type of wrap is known for its high durability, UV resistance, and puncture resistance, essential for items that may be exposed to harsh weather conditions or require long-term storage.

Boat shrink wrap is a specialized type of industrial shrink wrap, typically utilizing 100 gauge shrink wrap, developed to protect vessels during storage or transport. This robust wrap shields boats from water, dust, and sunlight, making it ideal for off-season storage. Kits and accessories, such as vents and straps, help ensure a secure and customized fit, preventing moisture buildup and preserving the boat’s condition.

In industrial applications, specialized shrink wrap solutions provide robust, tailored protection far beyond the capabilities of a typical polyolefin shrink wrap roll. From securing large machinery and structural materials to wrapping vehicles and construction equipment, industrial shrink wrap solutions are designed to withstand demanding conditions. Among the most critical tools in this domain are large shrink wrap machines, which streamline the wrapping process for oversized items and help ensure a secure, custom fit.

Large shrink wrap machines are specifically engineered to cover massive items that would be impractical to wrap by hand or with standard equipment. These machines are designed for wrapping bulky assets like industrial equipment, shipping containers, construction materials, and even large vehicles, offering a level of durability and precision that smaller machines or handheld tools simply cannot match. Unlike a polyolefin shrink wrap roll, typically used for smaller, lighter items, a large shrink wrap machine handles industrial-grade shrink wrap that can withstand significant environmental stressors, including UV rays, moisture, and extreme temperatures.

Securing the appropriate industrial shrink wrap supplier or service provider is essential for businesses that rely on dependable, high-quality wrapping solutions for protection during storage, transport, and installation. Whether seeking robust materials for construction or marine applications or simply needing an alternative to the polyolefin shrink wrap roll, choosing the right providers ensures durable and reliable shrink wrap protection.

Finding reliable industrial shrink wrap manufacturers begins with evaluating certifications, quality standards, and customer support. A high-quality supplier will offer comprehensive documentation of their materials’ performance, including thickness, durability, and heat-resistance specifications. Certifications such as ISO or ASTM ratings demonstrate adherence to international standards, verifying that the shrink wrap materials meet rigorous quality and environmental guidelines.

Many companies start by searching for “industrial shrink wrap near me” to find local providers who can offer fast delivery, flexible solutions, and in some cases, hands-on support. Working with nearby providers can also mean reduced shipping wrap costs and quicker turnaround times. Reliable manufacturers offer transparent customer service and product guarantees, ensuring that companies receive only the best materials suited for their applications.

Professional industrial shrink wrap services are valuable for businesses that need large-scale or specialized applications beyond typical in-house capabilities. These services bring expertise, industrial-grade equipment, and efficiency, ensuring that items are wrapped securely and professionally. Industrial shrink wrap service providers handle installations on-site, making them ideal for construction projects, large machinery, or marine vessels that require thorough, custom-fitted coverage.

These services include on-site wrapping for construction materials, boats, and transportation needs, ensuring robust protection against the elements. With specialized equipment, including heat guns and heavy-duty wraps, professionals can provide a seamless, secure wrap that maintains durability even in harsh environmental conditions. Companies needing efficient wrapping solutions for oversized or high-value items find significant advantages in outsourcing to trusted industrial shrink wrap providers.

Selecting the appropriate grade of industrial-strength shrink wrap is crucial for meeting the demands of heavy-duty protection. Industrial-strength shrink wrap is formulated to withstand tougher conditions, featuring thicker, more resilient materials designed for long-term durability. When choosing industrial-strength shrink wrap, factors such as material type, thickness, and climate resistance should be carefully considered. While standard shrink wraps may suffice for light protection, industrial-strength shrink wraps are ideal for construction materials, machinery, or items that may face extreme weather or prolonged exposure.

Unlike standard wraps, industrial-strength options offer enhanced puncture resistance, UV stability, and flexibility. An 18 inch shrink wrap roll is a practical choice for securing medium to large items, offering a balance between coverage and ease of handling. In comparison with options like polyolefin shrink wrap roll, which is typically used for smaller packaging, industrial-strength shrink wrap delivers unmatched reliability for large or irregularly shaped items, providing peace of mind that products are well-protected.

Industrial shrink wrap rolls are a staple in heavy-duty packaging and protection solutions, providing durable coverage for large or high-value items that require stability during transport or storage. While a polyolefin shrink wrap roll is commonly used for smaller or lighter items, industrial shrink wrap rolls are specifically designed to handle the demands of industrial applications. These rolls are available in multiple thicknesses, sizes, and material types to ensure that each specific need is met, whether in construction, marine storage, or machinery packaging. Below, we delve into the critical specifications and uses of industrial shrink wrap rolls and supplies, and explore how they differ from lighter options like polyolefin.

Industrial shrink wrap rolls are the foundation of secure, protective wrapping across various industries. Unlike the thinner polyolefin shrink wrap roll, which is generally used for light packaging, industrial shrink wrap rolls are available in thicknesses ranging from 6 to 12 mils. This added thickness provides puncture resistance, making the wrap strong enough to withstand challenging conditions, such as outdoor storage, shipping, and handling in rugged environments. The thicker gauge also ensures that the wrap remains intact over time, preventing tears that could expose items to moisture, dust, or damage.

Key specifications to consider when selecting an industrial shrink wrap roll include:

For businesses needing industrial shrink wrap on a regular basis, finding a local supplier is crucial for maintaining efficiency and minimizing shipping delays. Searching for “industrial shrink wrap near me” can help businesses access reliable suppliers offering quick delivery, support, and possibly customized solutions. Many local suppliers offer a range of materials and thicknesses that can be tailored to specific requirements, along with additional supplies such as tapes, adhesives, and edge protectors to enhance the wrap’s security.

Industrial shrink wrap rolls are essential in industries where secure wrapping is critical:

Industrial shrink wrap rolls are thus designed to provide dependable protection across various applications, offering a more robust solution compared to lighter wraps like polyolefin shrink wrap roll. With the right specifications and a local supplier, industrial shrink wrap rolls can help companies protect their assets effectively, reducing potential damage and extending the lifespan of valuable equipment and materials.

Industrial shrink wrap is a heavy-duty protective film used to securely cover and protect large, high-value, or heavy-duty items in various industrial settings. Unlike standard shrink wraps, industrial shrink wrap is made from thick, durable materials—typically polyethylene (PE) or polyolefin—that are designed to withstand challenging environmental conditions. Industrial shrink wrap is commonly used to cover items like construction equipment, boats, machinery, and large pallets to protect them from moisture, dust, UV rays, and other potential damage during storage or transport. The application process typically involves a heat gun or industrial shrink wrap machine, which helps the wrap form a tight seal around the item, creating a secure, durable barrier. This type of shrink wrap can come in various thicknesses, generally between 6 to 12 mils, providing options for different levels of protection based on the specific needs of the item or industry. Industrial shrink wrap is widely used in construction, marine, transportation, and manufacturing industries due to its effectiveness and strength.

The strongest shrink wrap is generally made from high-density polyethylene (HDPE) or thick-gauge polyolefin, often referred to as heavy-duty shrink wrap. This type of shrink wrap is specifically designed to provide robust protection for large and valuable items, with thicknesses ranging from 9 to 12 mils or more. Strong shrink wraps are particularly useful in industrial applications where items may be exposed to harsh weather, UV rays, or significant wear and tear. For example, a 12-mil industrial-grade shrink wrap is commonly used to cover and protect boats, construction materials, or machinery because it offers excellent puncture resistance, long-lasting durability, and flexibility. Another feature of the strongest shrink wraps is UV resistance, which prevents damage from prolonged sun exposure, making them ideal for outdoor storage. Some types also have flame-retardant properties, offering additional safety in construction or high-risk areas. The strongest shrink wraps provide reliable, secure coverage, ensuring that wrapped items remain undamaged even in extreme conditions.

Shrink wrap comes in various types, each designed for specific applications. The three most common types are polyvinyl chloride (PVC), polyolefin (POF), and polyethylene (PE) shrink wraps. PVC shrink wrap was one of the earliest materials used in shrink wrapping and is often used for retail packaging due to its transparency and high clarity. However, it is less flexible than other options and is more prone to becoming brittle in colder temperatures, making it less suitable for heavy-duty or outdoor applications. Polyolefin (POF) shrink wrap is a versatile, food-safe option that is strong, puncture-resistant, and offers good flexibility. It’s commonly used in applications ranging from food packaging to product bundling and has replaced PVC in many areas because of its durability and safety. Polyethylene (PE) shrink wrap, on the other hand, is often used for industrial shrink wrapping. It comes in different forms—such as low-density (LDPE) and high-density (HDPE)—and can be manufactured in thick gauges, ideal for heavy-duty applications like wrapping large equipment, pallets, boats, and construction materials. Each type of shrink wrap is designed to meet specific needs, offering a range of properties to suit diverse industries.

No, industrial shrink wrap is generally not suitable for direct use on food due to its thickness, chemical composition, and purpose. Industrial shrink wrap, often made from thicker polyethylene (PE) or polyolefin materials, is designed for heavy-duty applications rather than food-grade packaging. It contains properties like UV resistance, flame retardancy, and thick gauges that can make it unsafe or impractical for food contact. The materials used in industrial shrink wrap may not meet the stringent safety requirements of food-grade wraps, which must be non-toxic and approved by regulatory bodies like the FDA. For food-related uses, polyolefin (POF) shrink wrap is a common choice as it is FDA-approved, non-toxic, and designed to be safe for direct contact with food. It provides a safe, hygienic barrier to protect food items without risk of contamination, unlike industrial-grade shrink wrap, which may release chemicals or particles not intended for food use. Therefore, while industrial shrink wrap is ideal for packaging and protecting heavy items in transportation, construction, or storage, it should not be used directly on food products.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed