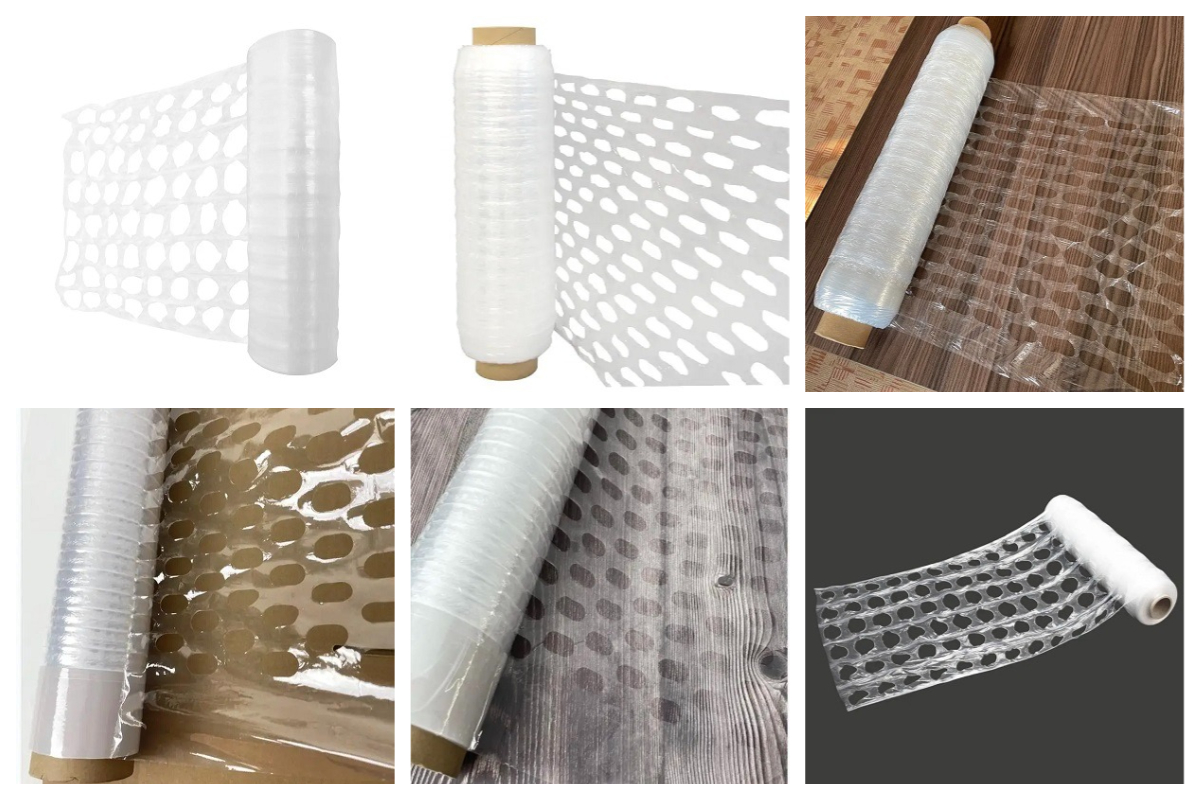

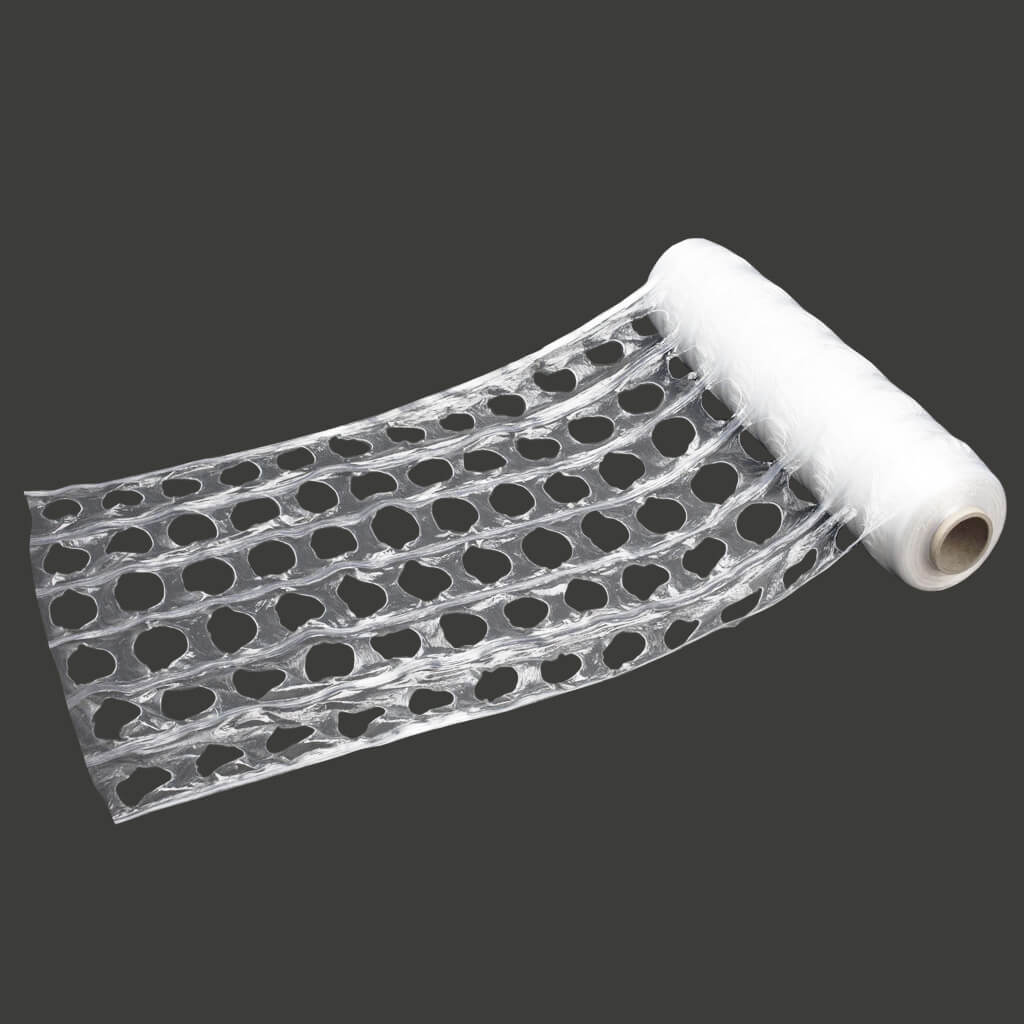

How to Choose the Right Breathable Stretch Film Model for Pallets

Choosing the appropriate ventilated stretch wrap depends on several factors:

Load Type and Moisture Sensitivity:

For highly perishable goods like fresh produce, select a model with smaller perforations to ensure optimal ventilation. For industrial products like cement bags, larger perforations might be sufficient. For more sustainable packaging needs, reusable pallet wrap can also be considered, as it provides breathability while reducing single-use plastic waste.

Pallet Size and Load Stability:

Evaluate the dimensions of the pallet and the weight of the goods. A film with higher elasticity and tensile strength is recommended for heavier loads to ensure secure wrapping without compromising airflow.

Stretchability Requirements:

Check the stretch rate (e.g., 250%). High stretch rates are advantageous for wrapping irregularly shaped pallets while maintaining proper tension and ventilation.

Manual or Machine Application:

If using a pallet wrapping machine, ensure the breathable film is compatible with the equipment. For manual applications, opt for manual breathable stretch film, which is designed with lightweight rolls for easier handling and ensures proper airflow for products requiring ventilation.

Advantages of Using Breathable Stretch Film for Pallets

Breathable stretch film offers numerous benefits for palletized goods:

Prevents Condensation and Mold Growth:

The ventilated design allows moisture to escape, reducing the risk of spoilage, mold, and damage to both perishable and nonperishable items.

Improves Product Freshness:

For food and horticulture products, maintaining airflow ensures goods arrive in peak condition, enhancing customer satisfaction and reducing waste.

Enhanced Load Stability with Ventilation:

Despite its perforations, breathable stretch film provides excellent elasticity and strength, securing the load tightly while ensuring adequate airflow.

Environmentally Friendly:

Most breathable stretch films, such as those made from pure LLDPE resin, are fully recyclable, supporting sustainability goals.

Breathable stretch film for pallets is a specialized solution designed to address the unique needs of ventilated packaging. By carefully evaluating the type of goods, load stability requirements, and application methods, businesses can select the right breathable stretch film model to protect and secure their palletized products effectively. This approach not only enhances product quality but also optimizes operational efficiency and sustainability.