Stretch film is an essential component in the packaging industry, providing a reliable solution for securing and protecting products during storage and transportation. Its flexibility and strength make it ideal for various applications, ensuring that items remain intact and undamaged. Among the different types of stretch film, LLDPE (Linear Low-Density Polyethylene) is a popular choice due to its excellent stretchability and clarity. This material offers superior load-holding force, making it suitable for a wide range of products. In this article, we will focus on manual LLDPE stretch film, exploring its unique features, advantages, and best practices for use, particularly in small to medium-sized operations where manual wrapping techniques are often employed. Manual LLDPE stretch film, produced in a high-quality manual LLDPE stretch film factory, is a durable, stretchable wrap for manual use, ideal for bundling and securing items with excellent stability and protection. The expertise and technology used in these factories ensure that the film maintains its high performance, offering reliability in a variety of packing scenarios.

Manual LLDPE stretch film offers a range of advantages that make it a valuable choice for businesses, particularly small to medium-sized operations. Its unique characteristics and application methods contribute to its growing popularity in the packaging industry.

At PWP Stretch Film, we recognize the importance of these advantages for our customers. Our lldpe manual stretch film is designed to empower businesses to achieve efficient, effective, and cost-saving packaging solutions. By utilizing manual LLDPE stretch film, companies can enhance their operational capabilities while maintaining high-quality standards.

Manual LLDPE stretch film is widely used across various industries due to its versatility and effectiveness in securing products for storage and transportation. Understanding the common applications can help businesses leverage this material for optimal packaging solutions.

Manual LLDPE stretch film finds applications in several key sectors, including:

Logistics and Warehousing

Furniture and Appliance Retail

Food and Beverage

Construction and Manufacturing

Manual LLDPE stretch film is suitable for a variety of products, including:

Pallets

Furniture

Electronics

Construction Materials

Utilizing manual LLDPE stretch film offers several advantages in various applications:

Versatile Protection

Cost Efficiency

Easy Handling

Enhanced Visibility

At PWP Stretch Film, we are committed to delivering high-quality hand warp lldpe stretch film that meets the diverse needs of our customers. By employing this versatile film, businesses can improve their packaging processes and ensure their products remain safe and secure during transport and storage.

Using manual LLDPE stretch film effectively requires some basic steps and techniques to ensure that products are securely wrapped. Proper application not only enhances protection but also improves the efficiency of the packing process.

Prepare the Work Area

Position the Product

Begin Wrapping

Overlap Each Layer

Secure the Film

To achieve optimal results when using manual LLDPE stretch film, consider the following tools and equipment:

Hand Dispenser

Safety Cutter

Gloves

Level Surface

Achieving the right tension and coverage is crucial when using manual LLDPE stretch film. Here are some helpful tips:

Maintain Even Tension

Adjust Tension as Needed

Check for Gaps

Practice Makes Perfect

At PWP Stretch Film, we emphasize the importance of proper application techniques to maximize the benefits of our hand stretch film LLDPE. By following these steps and tips, businesses can effectively secure their products for transportation and storage, ensuring they remain protected throughout the process.

Manual LLDPE stretch film plays a crucial role in the efficient and secure packing of pallets, ensuring that goods are protected during transportation and storage. This type of film is specifically designed for hand application, making it versatile for various pallet sizes and shapes, with wide stretch film applications.

LLDPE manual stretch film serves as a protective layer that binds products together on a pallet, preventing shifting and damage during transit. Its unique composition allows for significant stretching, which helps to wrap around items tightly, securing them in place. The film’s transparency also allows for easy identification of products without needing to unwrap the pallet.

Utilizing manual LLDPE stretch film for palletizing products offers numerous advantages, including:

To maximize the effectiveness of manual LLDPE stretch film when wrapping pallets, follow these best practices:

At PWP Stretch Film, we are dedicated to providing high-quality manual LLDPE stretch film tailored for pallet packing. By following these guidelines and utilizing our film, businesses can enhance their packing efficiency, ensuring their products remain secure and protected throughout the supply chain.

Selecting the appropriate manual LLDPE stretch film is essential for optimizing your packaging process. With various options available, understanding the key factors can help you make an informed decision that meets your specific needs.

When choosing manual LLDPE stretch film, consider the following factors:

Understanding the specific requirements of your products is crucial in selecting the right manual LLDPE stretch film. Take into account:

Finding reliable manual LLDPE stretch film suppliers is essential for ensuring quality and consistency. Here are some recommendations:

At PWP Stretch Film, we are committed to helping our customers choose the right manual LLDPE stretch film tailored to their unique needs. By considering these factors and understanding your specific product requirements, you can enhance your packaging efficiency and effectiveness.

When selecting a manufacturer or supplier for manual LLDPE stretch film, careful evaluation is essential to ensure product quality, reliability, and compatibility with your needs.

Below are key factors to consider and guidelines to help you choose a suitable provider:

By thoroughly evaluating these factors, you can confidently select a reliable and suitable manual LLDPE stretch film manufacturer or supplier that aligns with your operational and business goals.

The 125mm manual lldpe stretch film is a specialized variant designed for manual application, catering specifically to the needs of businesses requiring efficient wrapping solutions. This width is particularly popular due to its versatility and effectiveness in a range of packaging scenarios.

125mm hand use LLDPE stretch film offers several unique characteristics that make it a favorable choice for manual wrapping:

The 125mm hand use LLDPE stretch film is versatile and suitable for various applications, including:

The advantages of using 125mm hand use LLDPE stretch film include:

At PWP Stretch Film, we offer high-quality 125mm hand use LLDPE stretch film that meets the diverse needs of our customers. By choosing the right size for your specific applications, you can optimize your packaging process and ensure that your products remain secure and protected throughout their journey.

The production process of manual LLDPE stretch film involves multiple steps that ensure the film is durable, flexible, and suitable for hand wrapping. Below is a detailed breakdown of the production process:

The process begins with high-quality linear low-density polyethylene (LLDPE) resin, which forms the primary raw material. Additives such as tackifiers (to enhance cling), UV stabilizers, and color pigments (if needed) are mixed with the resin to achieve specific performance properties.

The LLDPE resin and additives are fed into an extruder, where they are heated to high temperatures (typically between 200-250°C) to form a molten polymer. This molten material is then pushed through a flat die in a controlled manner to create a thin sheet of film.

The molten sheet is immediately passed over chilled rollers to cool and solidify the film. This rapid cooling, characteristic of the casting method, ensures that the film has excellent clarity, a smooth surface, and uniform thickness. Casting also reduces the presence of imperfections such as gels or uneven areas, which are common in other production methods.

After cooling, the film undergoes a stretch orientation process, where it is stretched in both the machine direction (lengthwise) and transverse direction (widthwise). This stretching aligns the polymer chains, enhancing the film’s strength, elasticity, and puncture resistance, which are critical for manual wrapping applications.

If the film requires cling properties, a tackifier layer is applied during or after extrusion. This layer enables the film to adhere to itself securely without adhesives, making it ideal for bundling and securing items.

The cooled and stretched film is slit into rolls of various widths and lengths based on customer requirements. These rolls are then wound onto cores, ensuring proper tension and alignment for easy manual application.

Each batch of manual LLDPE stretch film undergoes rigorous quality checks to ensure consistent thickness, stretchability, and cling properties. Samples are tested for tensile strength, tear resistance, and clarity to meet industry standards.

Finally, the rolls of stretch film are packaged and labeled according to specifications and distributed to end users or retailers.

This meticulous production process ensures that manual LLDPE stretch film offers excellent performance, reliability, and versatility for hand-applied packaging tasks.

Casting manual LLDPE stretch film is a popular choice for hand-wrapping tasks due to its unique manufacturing process and versatile properties. Below is a comprehensive exploration of its characteristics from multiple perspectives, highlighting why it stands out as an effective packaging solution.

Casting manual LLDPE stretch film is produced using the casting method, where molten LLDPE resin is extruded through a flat die and rapidly cooled on chilled rollers. This process creates a film with superior clarity and uniform thickness. The uniformity ensures consistent wrapping performance, while the clarity allows for easy identification of packaged goods, making it ideal for applications where visibility is crucial.

The film exhibits excellent stretchability, allowing it to stretch up to 150-300% of its original length. This high elasticity ensures tight bundling and load stability. Additionally, it features reliable cling properties on one or both sides, enabling it to stick to itself without adhesives, ensuring secure wrapping during manual application.

Casting manual LLDPE stretch film is suitable for a wide range of packaging needs, including securing pallets, bundling items, and protecting goods during storage or transit. Its flexibility makes it a great option for irregularly shaped loads, small-scale packaging, and operations without automation equipment.

This stretch film offers excellent puncture and tear resistance, ensuring that it remains intact even when wrapped around sharp or uneven surfaces. This durability helps protect goods from damage during handling and transportation.

Casting manual LLDPE stretch film is lightweight and easy to handle, making it suitable for operators of all skill levels. It requires no specialized equipment, and its smooth surface reduces friction during application, minimizing fatigue for manual users.

The casting method minimizes material waste during production, making the film more eco-friendly compared to blown films. Additionally, its efficient performance and lightweight nature reduce material usage and shipping costs, making it a cost-effective choice for manual packaging tasks.

These perspectives demonstrate how casting manual LLDPE stretch film combines performance, durability, and cost-efficiency, making it an invaluable tool in a variety of industries.

When selecting the right stretch film for packaging needs, understanding the differences between manual LLDPE stretch film and automatic stretch film is essential. These two types of stretch film are designed for different applications, methods of use, and operational scales. Manual LLDPE stretch film is applied by hand, making it ideal for smaller operations or irregularly shaped items. In contrast, automatic stretch film is applied using a machine, providing higher efficiency for large-scale packaging tasks. The table below highlights the key differentiating factors between the two, explaining how these aspects influence their applications.

| Factor | Manual LLDPE Stretch Film | Automatic Stretch Film | Impact on Use |

|---|---|---|---|

| Application Method | Hand-applied, requiring manual effort and precision | Applied using machines, ensuring uniform wrapping | Manual is suitable for low-volume or irregular shapes, while automatic suits high-volume, repetitive tasks. |

| Efficiency | Slower, dependent on operator speed | High-speed application, reducing time and labor | Automatic film increases productivity for large operations; manual is better for small-scale use. |

| Film Thickness | Typically thinner, easier to stretch manually | Can handle thicker films for heavier loads | Thinner manual films save cost but may not suit heavy-duty packaging like automatic ones. |

| Cost | Lower upfront cost, no equipment needed | Higher initial investment for machinery | Manual is cost-effective for small operations, while automatic is economical for long-term, large-scale needs. |

| Precision | Depends on operator skill | Ensures consistent tension and wrap | Automatic provides uniform results; manual may vary based on user technique. |

| Load Type | Best for light to medium loads | Ideal for heavy and uniform loads | Manual works for versatile, smaller loads, while automatic is optimized for pallets and heavy goods. |

This table provides a clear overview of the distinctions, helping users determine which type of stretch film is best suited to their specific packaging requirements.

LLDPE (Linear Low-Density Polyethylene) stretch film is widely used for packaging and securing products during storage and transportation. Its primary application is to wrap pallets of goods, ensuring that items remain stable and secure during handling. This type of film is particularly effective in logistics and warehousing, where it provides protection against dust, moisture, and shifting. LLDPE stretch film is also employed in various industries for bundling smaller items, such as boxes, tools, and furniture, making them easier to manage and transport. Additionally, it is used in retail environments for packaging products, as its transparency allows for visibility while keeping items intact. The film’s excellent stretchability and cling properties enable it to conform tightly to the products, ensuring a secure hold without the need for adhesives. Overall, LLDPE stretch film is an essential tool in ensuring the integrity and safety of items throughout their journey from production to end-users.

Cling film and stretch film serve different purposes and are made from distinct materials, which influence their applications. Cling film, often made from PVC or polyethylene, is primarily used in food packaging. It has a high cling property, allowing it to stick tightly to itself and the surfaces of food items. This property helps preserve food by providing an airtight seal, which keeps moisture in and prevents contamination. On the other hand, stretch film, particularly LLDPE stretch film, is designed for securing loads and providing stability during transport. It is thicker and more durable than cling film, allowing it to withstand the rigors of shipping and handling. While cling film is best suited for home use, particularly in wrapping food items, stretch film is more suitable for industrial and commercial applications where securing larger and heavier loads is necessary. Understanding these differences can help users choose the appropriate film based on their specific packaging needs.

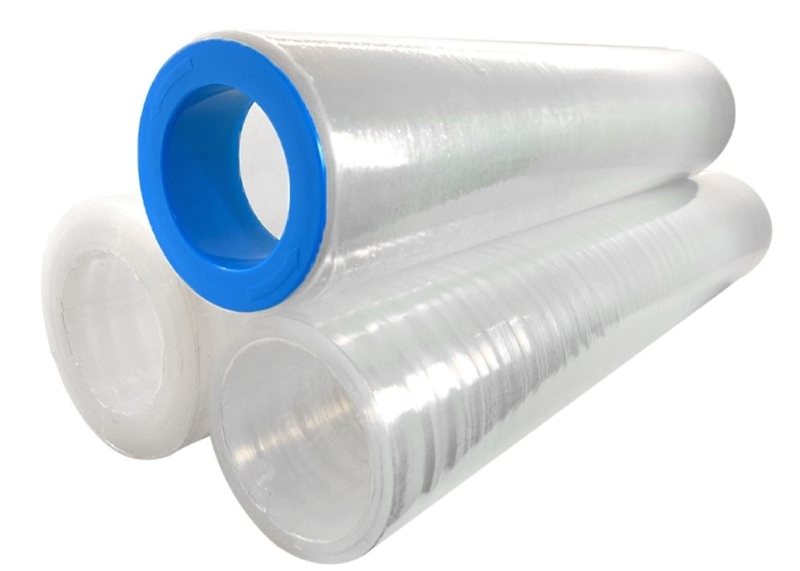

LLDPE (Linear Low-Density Polyethylene) stretch film is a highly flexible and durable plastic material commonly used for packaging and pallet wrapping. It is made from LLDPE resin, which gives it superior stretchability, puncture resistance, and cling properties compared to traditional polyethylene films. Manual LLDPE stretch film is specifically designed for hand application, making it ideal for low-volume packaging operations or where automation is not feasible. The film adheres tightly to products without using adhesives or heat, providing a secure, moisture-resistant barrier to protect goods during storage and transportation. Its elasticity allows it to conform to various shapes, minimizing product movement and reducing the risk of damage. Manual stretch films are lightweight, easy to handle, and come in different thicknesses and roll sizes to accommodate various applications, making them a versatile choice for packaging tasks.

While both shrink wrap and stretch film are used in packaging, they serve distinct purposes and function differently. Shrink wrap is a heat-activated film that shrinks tightly around a product when exposed to heat, forming a protective seal. It is primarily used for bundling items together, protecting individual goods, or creating tamper-evident seals.

On the other hand, stretch film relies on its elastic properties to wrap and secure items without the need for heat. Manual LLDPE stretch film is applied by pulling and stretching it around products or pallets, creating tension that holds items securely. Stretch film is ideal for stabilizing pallets, bundling items, and protecting goods during transit, while shrink wrap is better suited for retail packaging and sealing smaller items. Stretch film offers faster application and is more cost-effective for manual packaging operations.

Manual LLDPE stretch film comes with specific specifications tailored to various packaging needs. Key specs include:

Material: LLDPE resin for elasticity and durability.

Thickness: Ranges from 8 to 30 microns (µm), with thinner films used for light loads and thicker ones for heavy-duty applications.

Roll Width: Common widths are 12 to 20 inches (300 to 500 mm), ideal for manual application.

Stretchability: Can stretch up to 150-300% of its original length, ensuring optimal coverage and load stability.

Cling: Offers one-sided or two-sided cling for secure wrapping.

Color: Clear for visibility or opaque for privacy and UV protection.

Load Capacity: Suitable for light, medium, or heavy loads depending on thickness and film grade.

These specifications make manual LLDPE stretch film versatile for hand wrapping tasks, ensuring goods are securely packaged and protected.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed