Manual stretch film is a highly versatile packaging material widely used in various industries to secure and stabilize products during transit. It is a stretchable plastic film that adheres tightly to the load without the need for additional adhesives, offering cost-effective protection against dust, moisture, and minor damage. In modern packaging, manual breathable stretch film has become an essential variant, providing ventilation to prevent moisture build-up while maintaining the durability and flexibility of traditional manual films. The importance of manual stretch film factories cannot be overstated, as these facilities produce high-quality films, including manual breathable stretch film, to meet the diverse needs of businesses globally. A reliable manual stretch film factory ensures consistent product quality, sustainability, and the ability to customize films for specific applications, making it an essential part of the global supply chain. PWP Stretch Film is a top manual stretch film factory, offering premium LLDPE film to stabilize products for domestic and international markets.

Manual stretch film is an essential packaging material used worldwide to secure and stabilize loads during transit and storage. In the context of manual stretch film factories, this product is crafted to offer a versatile, cost-effective solution for various industries. It is ideal for packaging items of different sizes and shapes, ensuring goods stay intact while in storage or transit. With its growing demand in sectors such as logistics, retail, and food industries, manual stretch film has evolved to meet the unique needs of customers, providing a combination of durability, flexibility, and ease of use. In this detailed guide, we’ll explore what manual stretch film is, its key characteristics, and how it functions across industries, offering insight into the production processes at manual stretch film factories.

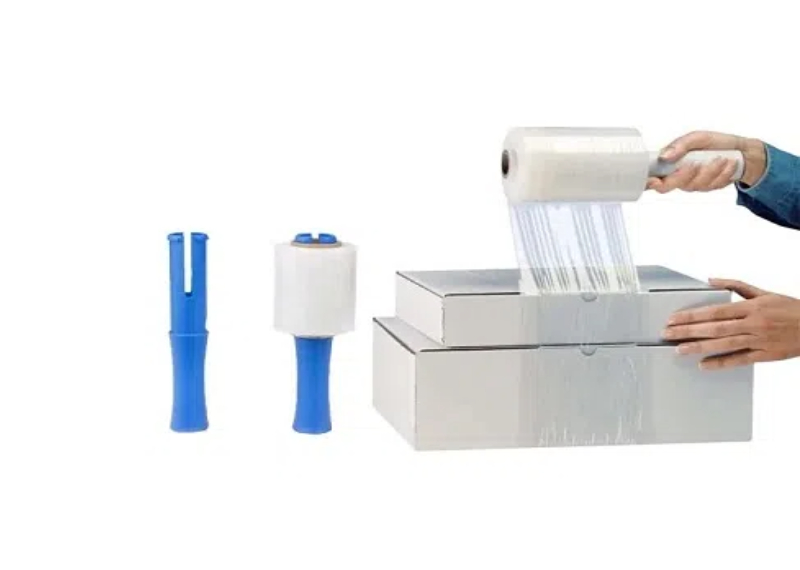

Manual stretch film is a type of polymer-based packaging material designed for hand application, primarily used to wrap and secure palletized goods during shipment or storage. Unlike machine stretch films, which require automated machinery to apply, manual stretch film is applied manually using handheld dispensers. It is predominantly made from linear low-density polyethylene (LLDPE), a plastic material that exhibits excellent stretch, strength, and flexibility.

Manual stretch film factories produce different grades of film based on thickness, stretch capacity, and environmental resistance, allowing businesses to choose the best options for their needs.

Manual stretch film is known for its distinct features that make it effective in various packaging applications. These characteristics include its elasticity, puncture resistance, and versatility in handling different loads.

One of the defining qualities of manual stretch film is its ability to stretch up to 200-300% of its original length without breaking. This exceptional elongation capability ensures tight and secure wraps, which enhance load stability.

At manual stretch film factories, the film is engineered to stretch effectively while maintaining its strength and flexibility, enabling secure packaging.

The film is highly resistant to punctures and tears, even when wrapping sharp-edged products.

Manual stretch film factories focus on producing high-quality films with these properties to meet the needs of industries that require high strength and reliability.

Manual stretch film is lighter compared to other forms of packaging film, which makes it easier for workers to handle.

At manual stretch film factories, films are designed with ergonomic considerations in mind, ensuring that the product is user-friendly and highly functional for all operators.

The versatility of manual stretch film makes it applicable across various industries, ranging from logistics to food packaging. Here’s a closer look at its widespread applications:

Manual stretch film is predominantly used in the logistics industry for securing palletized goods. It stabilizes products during shipping, preventing items from shifting or being damaged. The stretch film provides load containment, reduces the risk of damage during transport, and helps with stacking efficiency.

In retail settings, manual stretch film is often used for bundling products, ensuring they remain intact during handling and storage. It helps businesses stack items neatly and securely, enhancing the efficiency of their inventory systems.

Manual stretch film is used in the food and beverage industry to wrap perishable goods. Food-grade stretch films are produced under stringent guidelines to ensure they do not contaminate the products they are wrapping.

Manual stretch film factories ensure that the stretch films they produce meet various regulatory and industry standards, offering tailored solutions for different market needs.

As sustainability becomes increasingly important, many manual stretch film factories are producing environmentally friendly stretch films made from recyclable materials like LLDPE. Some factories offer options with post-consumer recycled content or biodegradable films, addressing the growing concern about plastic waste in the packaging industry.

By offering these environmentally conscious options, manual stretch film factories are helping businesses reduce their carbon footprint while maintaining efficient packaging solutions.

Manual stretch film is an essential tool in packaging, offering a combination of strength, flexibility, and cost-efficiency. Produced by manual stretch film factories, this material serves a wide range of industries, providing secure, stable, and protective packaging solutions. The unique characteristics of manual stretch film, such as its elasticity, tear resistance, and lightweight nature, make it ideal for various applications, from logistics and transportation to food packaging. With an increasing focus on sustainability, the future of manual stretch film includes more eco-friendly options that will meet the evolving needs of businesses worldwide.

In a manual stretch film factory, efficient use of a manual stretch film wrapping machine is critical to ensure consistent packaging, minimize material waste, and enhance worker productivity. This guide provides a detailed overview of how to use such machines, structured into key aspects: preparation, operation, safety considerations, and maintenance. Each section delves into specific details, empowering workers and managers with practical knowledge to optimize machine performance and prolong its lifespan.

Before using a manual stretch film wrapping machine, proper preparation ensures smooth operation and reduces errors. This phase involves selecting the appropriate film, configuring the machine, and preparing the load.

The operational phase is where the manual stretch film is applied to the load. Proper technique ensures secure and consistent wrapping.

Safety is a top priority in a manual stretch film factory. Following these guidelines minimizes risks during machine operation.

Routine maintenance helps to keep the manual stretch film wrapping machine functioning effectively and extends its service life.

In a manual stretch film factory, proper use of a manual stretch film wrapping machine is crucial for efficient operations. By following the outlined steps in preparation, operation, safety, and maintenance, workers can ensure high-quality results while minimizing costs and risks. This structured approach enhances productivity and ensures optimal use of both the machine and the stretch film.

Manual stretch film offers numerous benefits, making it a popular choice in various industries for securing loads. These advantages are often the result of the efficient production processes in a manual stretch film factory, which ensures that the film maintains high standards in quality and functionality.

Manual stretch film plays a vital role in modern packaging, providing businesses with a flexible and cost-effective solution for securing products during storage and transit. The importance of manual stretch film factories lies in their ability to produce films that meet industry standards and cater to diverse packaging needs across various sectors. These factories are integral to the global supply chain, as they ensure the consistent production of high-quality stretch films and support the widespread use of manual wrapping solutions. However, it’s crucial to understand when not to use stretch film, such as for packaging heavy or sharp objects, where alternative materials may offer better protection.

Manual stretch film production is not limited to one region; instead, manual stretch film factories are located worldwide, allowing businesses to access high-quality films regardless of their geographic location. The global network of pallet wrapping factory locations ensures that manufacturers can meet the needs of industries across continents, from Asia to Europe to the Americas.

Proximity to industrial hubs is a key factor for ensuring the efficient distribution of manual stretch films. Factories located near major shipping ports or manufacturing centers can reduce transportation costs and delivery times, making it easier for businesses to get the materials they need quickly. In particular, the pallet wrapping factory USA has emerged as a leading market, given the country’s strong manufacturing base and the high demand for stretch films across various sectors, including logistics, food, and retail.

Selecting the right manual stretch film factory and manufacturer is essential to ensure high-quality products, reliable supply, and competitive pricing. This decision impacts your packaging efficiency, costs, and sustainability efforts. To make an informed choice, consider factors such as product quality, manufacturing capability, customization options, customer support, and compliance with environmental standards. Below is a detailed guide, divided into multiple aspects, to help you navigate this selection process effectively.

The quality of manual stretch film directly affects its performance and the security of your packaged goods. Evaluating the manufacturer’s quality standards is the first step.

The factory’s manufacturing capabilities determine its ability to meet your needs, especially during peak demand periods. Analyze their production scale and technology.

Customization is vital to align the film’s specifications with your unique packaging requirements. Evaluate the factory’s ability to offer tailored solutions.

Reliable customer support ensures smooth communication and prompt resolution of issues. This aspect reflects the manufacturer’s commitment to customer satisfaction.

Choosing a manufacturer committed to environmental responsibility aligns with modern sustainability standards and reduces your carbon footprint.

Selecting the ideal manual stretch film factory and manufacturer requires a thorough evaluation of several factors, including product quality, manufacturing expertise, customization capabilities, customer support, and environmental responsibility. By following these guidelines and performing due diligence, you can build a long-term partnership with a manufacturer that meets your operational and sustainability needs, ensuring consistent and high-quality packaging solutions.

At PWP Stretch Film, we are committed to providing high-quality packaging solutions that ensure the safe distribution of your products. With 18 years of experience in the industry, we have built a reputation for delivering effective, reliable, and consistent packaging products that protect your merchandise throughout the transportation process. We understand the importance of your goods, which is why our dedicated team of professional sales representatives, customer account specialists, and marketing experts are always here to assist, ensuring a seamless experience.

As a leading manufacturer and supplier of Stretch Film, Pallet Wrap, and Stretch Wrap, we specialize in offering cutting-edge solutions tailored to meet the specific needs of various industries. Our state-of-the-art automated systems and highly trained experts enable us to produce high-performance stretch films, including custom designs and contract packaging services. We take pride in our strong partnerships with premium suppliers, ensuring that we consistently deliver the latest packaging innovations without compromising on quality.

Additionally, we also support the production and customization of Manual Stretch Film, designed to offer flexibility and convenience for various packaging applications. Whether you need standard or tailored stretch film solutions, we are your trusted partner in delivering the best products for your packaging needs.

For more information or to discuss your custom requirements, please feel free to reach out to us at pwpstretchfilm@gmail.com. Let us help you protect and distribute your products with confidence, offering exceptional customer service and reliable packaging solutions.

In the world of packaging, there are different types of manual stretch film factories that cater to various industrial needs. These factories are specialized in producing specific kinds of stretch films, each designed to address distinct packaging challenges. From pallet wrapping to hand applications, these factories ensure that businesses have access to the right kind of film for their specific requirements.

A manual stretch film factory that specializes in pallet stretch film production is dedicated to creating films optimized for wrapping pallets. These films are essential for securing products on pallets during storage and transit. The main features of pallet stretch films produced by these factories include superior cling properties, excellent stretchability, and strong load containment. The films are designed to tightly wrap around the palletized goods, ensuring that the products remain secure and intact during handling, transport, and storage. The ability to stretch the film to a high percentage allows businesses to reduce material costs while providing the necessary strength to protect goods.

Manual stretch film factories focused on plastic stretch films for hand applications specialize in creating easy-to-use films for businesses that do not require machinery for packaging. These films are designed to be simple to apply by hand, making them perfect for small businesses, retail stores, or companies that need to manually wrap items. The key selling points of these films include high durability, flexibility, and ease of use. Retail stores, moving companies, and e-commerce businesses are some of the primary users of manual use plastic stretch films. These factories provide different options in terms of thickness, ensuring that customers can select the most suitable film based on their specific application.

A manual stretch film factory dedicated to producing stretch wrap films offers versatile solutions suitable for both industrial and manual applications. These factories focus on creating a wide range of stretch films with varying thicknesses, colors, and special additives to meet different packaging needs. For example, some films might be enhanced with UV protection to safeguard goods from sunlight exposure, while others may feature anti-static properties for electronics packaging. The flexibility of these films makes them ideal for diverse industries, including logistics, retail, and agriculture. These factories provide the ability to customize the films to fit the unique requirements of various clients, enhancing the value they offer.

Some manual stretch film factories go a step further by offering dual capabilities in both stretch wrap and shrink wrap film production. These factories produce films that provide flexibility in packaging solutions for different types of load requirements. Stretch wrap films are ideal for securing items that need a tight hold without additional shrinkage, while shrink wrap films are used to provide a tighter, more protective layer around products. This dual capability makes these factories highly adaptable to the needs of businesses that require both types of films for different packaging applications. Whether it’s securing a load on a pallet or providing a shrink-wrapped seal around an individual product, these factories provide comprehensive solutions to meet a wide range of needs.

92ga manual stretch film factories specialize in producing high performance stretch films with specific thickness and strength characteristics. These films are designed to provide excellent load stability for heavy-duty applications, such as wrapping large and bulky items or securing goods that require a high level of protection during transportation. The precise thickness and strength offered by 92ga films make them the ideal choice for industries where load containment is critical, such as the construction, logistics, and manufacturing sectors. These films provide a superior solution for businesses that need to ensure their goods are securely wrapped and protected from external factors during transit.

A manual stretch film factory that specializes in producing 70ga hand stretch films focuses on providing cost-effective solutions for light-duty applications. These films are perfect for industries that prioritize efficiency and cost savings without compromising on quality. The 70ga film is designed to be lightweight and easy to handle, making it ideal for businesses that need to wrap smaller items or less heavy products. These factories provide an economical option for companies that need stretch films for hand wrapping while maintaining adequate performance and durability. These films are commonly used in retail environments, small-scale distribution centers, or for individual items requiring minimal protection.

In the production of manual stretch films, manual stretch film factory plays a crucial role in enhancing efficiency, consistency, and quality. While manual stretch film factories primarily focus on providing manual packaging solutions, the integration of various machines allows for a streamlined production process, ensuring that the stretch films produced are of high quality and meet the diverse needs of customers. From semi-automatic to fully automatic machines, each type serves a specific purpose in optimizing production workflows, thus making the process faster and more cost-effective.

In manual stretch film factories, semi-automatic stretch wrap machines are used to bridge the gap between manual and fully automated solutions. These machines allow operators to wrap products efficiently while still maintaining a level of hands-on control. Semi-automatic machines are ideal for medium-scale operations that need a balance between manual effort and automation. They can wrap a variety of loads with consistent tension and stretch, ensuring uniformity in packaging. These machines are easy to operate and typically require less labor than manual wrapping, making them an attractive option for businesses looking to scale up their packaging process without a full investment in automation. By utilizing semi-automatic stretch wrap machines, manual stretch film factories can increase throughput while minimizing the risk of operator fatigue and errors.

In a larger manual use stretch film factory or those focusing on high-volume production, automatic pallet wrapping machines are a vital asset. These machines can wrap pallets at a significantly faster rate compared to manual or semi-automatic solutions, making them perfect for high-volume packaging needs. Automatic pallet wrapping machines use advanced technology to wrap stretch film around pallets with precise control, ensuring that the load is tightly secured and stable. These machines are designed to reduce labor costs by requiring minimal human intervention, which boosts overall productivity. Furthermore, automatic machines can be integrated with other systems in a factory, such as conveyors and shrink tunnels, to create an efficient, fully automated packaging line. As a result, they are ideal for manual stretch wrap factories that need to meet the demands of large-scale operations while maintaining quality standards.

For a manual stretch wrap factory, integrating used or refurbished pallet wrapping machines into their operations offers a cost-effective and sustainable alternative to purchasing new equipment. Used machines can provide the same performance and functionality as new ones but at a fraction of the cost. Refurbished machines are thoroughly tested and restored to meet factory standards, offering a reliable solution for businesses that want to save on capital expenses while still benefiting from enhanced production capabilities. In addition to being more budget-friendly, used pallet wrapping machines also contribute to sustainability efforts by reducing waste and promoting the reuse of equipment. This makes them an excellent choice for manual stretch film factories looking to balance cost-efficiency with environmental responsibility.

Polyvinyl alcohol (PVA) films are made by dissolving PVA resin in water and casting the solution onto a surface to form a thin layer. This layer is then dried and processed into sheets or rolls. PVA films are biodegradable and water-soluble, making them suitable for eco-friendly applications like detergent pods or agricultural uses. At a manual stretch film factory, PVA films may be offered as part of their sustainable packaging solutions, diversifying their product range. The factory typically uses specialized equipment to ensure uniform thickness and consistent quality for industrial and commercial use.

Stretch films are produced using polymer resins like LLDPE (linear low-density polyethylene). The manufacturing process involves melting the resin, extruding it through a die, and cooling it into a thin film. Stretch films are either cast or blown, with manual stretch film factories commonly using both methods depending on the required film properties. Cast films offer clarity and tear resistance, while blown films provide strength and flexibility. The factory ensures precise control over the film’s thickness, elasticity, and cling to meet diverse packaging needs.

Blown stretch film is produced by melting LLDPE resin and extruding it through a circular die to form a tube. The tube is inflated with air, forming a bubble, which is cooled and flattened into rolls. This process results in a film with superior strength and puncture resistance. At a manual stretch film factory, blown films are often manufactured for demanding applications like securing heavy or irregularly shaped loads. The process is slower than casting but yields films with excellent durability, ideal for manual wrapping.

Stretch film recycling involves collecting used films, cleaning them to remove contaminants, and melting them into pellets. These recycled pellets are then used to create new stretch films or other plastic products. Manual stretch film factories contribute to sustainability by incorporating recycled content into their products or offering closed-loop recycling programs. Proper segregation and cleaning of the film during the recycling process are crucial to maintaining the quality of the final product, reducing waste, and promoting environmental responsibility.

Stretch film thickness typically ranges from 8 to 30 microns, with variations depending on the application. Manual stretch film factories produce thinner films for lightweight loads and thicker options for heavy-duty or high-security needs. Advanced manufacturing technologies allow factories to create films with thinner gauges while maintaining strength and performance, reducing material usage and costs. Customers can select thicknesses based on their specific load requirements, ensuring optimal performance in transportation and storage.

Yes, certain stretch films are food-grade, made from FDA-approved LLDPE resins to ensure safety for direct contact with food. These films are often used for wrapping perishable goods or protecting food items during transport. Manual stretch film factories may produce specialized food-grade stretch films with added features like anti-fog or UV protection. The factory ensures compliance with regulatory standards, making these films safe for use in food packaging applications.

Stretch film and cling film are different. Stretch film is primarily used for securing and stabilizing pallets, while cling film is a thinner, more elastic material used for food wrapping. At a manual stretch film factory, stretch film is designed for industrial use, offering high tensile strength and load-holding capabilities. Cling film, by contrast, is focused on sealing food containers and preserving freshness.

Stretch film is typically made from LLDPE (linear low-density polyethylene) due to its superior stretch and puncture resistance. LDPE (low-density polyethylene) is occasionally used for specific applications requiring softer films. Manual stretch film factories predominantly use LLDPE to manufacture films, ensuring high-performance packaging solutions for various industries.

LLDPE film grade is used for applications requiring flexibility, durability, and strength. This includes stretch wrapping, agricultural films, and liners. Manual stretch film factories rely on LLDPE to produce films with excellent elongation properties, making them ideal for securely wrapping pallets and reducing material usage.

LDPE films are softer and more flexible, while HDPE (high-density polyethylene) films are rigid and stronger. LDPE is used for applications like shrink wrap, while HDPE is often used for heavy-duty bags or liners. Manual stretch film factories focus on LDPE or LLDPE for stretch films due to their stretchability and resilience.

PE stretch film refers to stretch film made from polyethylene, primarily LLDPE. It is used for securing and stabilizing loads during transport. Manual stretch film factories manufacture PE stretch film with varying properties to suit specific industrial needs, such as enhanced puncture resistance or higher clarity.

Stretch wrap, while widely used, has certain disadvantages. First, it is not biodegradable, contributing to environmental pollution unless recycled properly. Second, manual application can be labor-intensive and may result in inconsistent wrapping if not applied correctly. Overuse of material during hand wrapping can also increase costs. Furthermore, improper storage or exposure to UV light can degrade the film, reducing its effectiveness. Stretch wrap may also not provide sufficient protection against moisture or extreme temperature changes. Lastly, manual application can lead to physical strain for workers, such as repetitive motion injuries, especially in factories where large volumes of stretch wrap are used daily.

Stretch film is primarily made from linear low-density polyethylene (LLDPE). The LLDPE is derived from ethylene and octene or butene copolymers, which give the film its elasticity and strength. In a manual stretch film factory, additives such as UV stabilizers, colorants, or tackifiers may be included to enhance specific properties, like UV resistance or cling capability. High-density polyethylene (HDPE) can also be blended to modify the film’s mechanical attributes. The raw materials undergo extrusion processes to produce the thin, stretchable film that is commonly used for hand wrapping.

Another name for stretch film is pallet wrap or stretch wrap. In the context of manual stretch film factories, the term “manual stretch wrap” is often used to distinguish it from machine-applied films. The name “pallet wrap” originates from its primary application in securing goods on pallets for transport and storage. Other informal names include “cling wrap” or “plastic wrap,” though these are less precise and may refer to similar materials used for different purposes.

Hand stretch film is a type of stretch wrap designed for manual application rather than machine use. It is typically produced in smaller rolls, making it easier for workers to handle. In a manual stretch film factory, hand stretch film is manufactured with properties like enhanced stretchability and cling to ensure it securely wraps goods without the need for specialized equipment. It is commonly used in small to medium-scale operations where automation is not feasible or cost-effective. Hand stretch film is ideal for wrapping irregularly shaped items or pallets in tight spaces.

Alternatives to stretch film include strapping, shrink wrap, reusable pallet wraps, or netting. Strapping uses metal or plastic bands to secure items, while shrink wrap, applied with heat, offers a tight fit around goods. Reusable options, such as fabric-based pallet wraps, provide an eco-friendly solution but may have higher upfront costs. Netting is another alternative, particularly for items needing ventilation. Manual stretch film factories may also explore bio-based stretch films, which are more environmentally sustainable but may not yet fully replicate the properties of traditional stretch film.

Blown film refers to a method of production where molten resin is extruded and air-blown to form a thin film, whereas stretch film describes a product used primarily for wrapping. Blown film often exhibits higher tensile strength and puncture resistance but may have less clarity compared to other production methods. Manual stretch film factories may opt for blown stretch film for heavy-duty applications due to its durability, even though its production process differs significantly from cast stretch film.

Cast stretch film is made through a flat die extrusion process, resulting in a film with excellent clarity and uniform thickness. It unwinds quietly and is easier to stretch, making it popular for manual applications. In contrast, blown stretch film is produced by blowing air into the molten resin, leading to a film with higher puncture resistance and superior strength. However, it is less clear and noisier when unwinding. Manual stretch film factories might choose between these types based on desired application and budget.

Cast film is a type of extruded film made by cooling molten resin on a chill roll, which produces a smooth, clear, and uniform surface. Extruded film, on the other hand, is a broader term encompassing various methods, including blown and cast techniques. Cast films are particularly suited for applications requiring high clarity and quiet unwinding, making them a preferred choice for manual stretch film factories.

Stretch film is applied by stretching it around goods and relies on its elastic recovery to secure items. Shrink film, however, is applied loosely and shrinks tightly when heat is applied. In a manual stretch film factory, stretch films are more popular for quick and cost-effective applications, while shrink films are used for tamper-evident packaging or items requiring a tight, heat-shrunk seal.

The price of polyamide film varies widely based on factors like thickness, grade, and application. Typically, it ranges from $4 to $12 per kilogram. Manual stretch film factories may not directly use polyamide films but could incorporate them in specific high-barrier applications, such as packaging for goods requiring moisture or oxygen protection.

The shelf life of stretch film is typically 12 to 24 months when stored under optimal conditions, such as in a cool, dry, and UV-free environment. Over time, exposure to heat, light, or humidity can degrade its properties, such as elasticity and tackiness, making it less effective. Manual stretch film factories must ensure proper storage to maintain product quality and reduce waste.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed