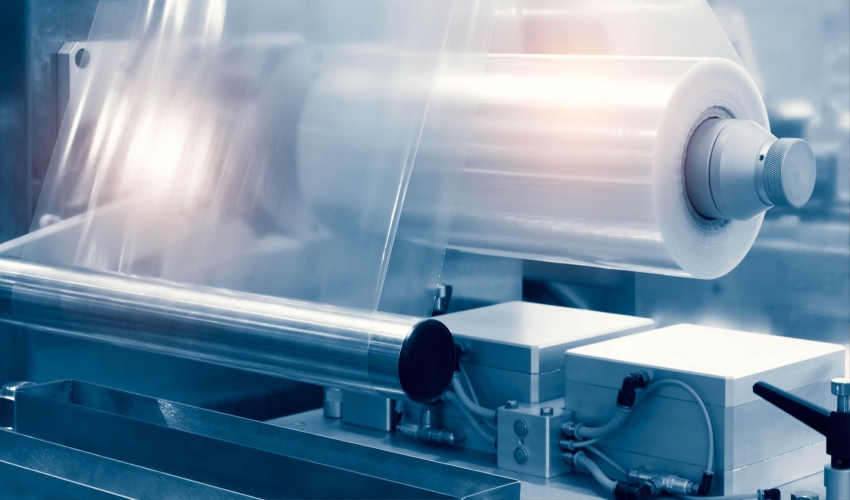

MDO stretch film, or machine direction orientation stretch film, is a specialized polyethylene film engineered through a precise stretching process. This process involves heating the film to a specific temperature and stretching it in the machine direction, a technique commonly used in the production of machine stretch film. The result is a film with significantly enhanced strength, flexibility, and durability, making it ideal for high-performance applications. When compared to traditional raw material stretch film, MDO stretch film is especially valued for its sustainability and recyclability, as it uses fewer raw materials and can be produced in mono-material form. This makes it a practical choice for companies aiming to reduce their environmental footprint while maintaining product quality. By enhancing mechanical properties, MDO stretch film offers reliable, lightweight packaging that supports eco-friendly initiatives. MDO stretch film is a recyclable, uniaxially stretched film offering precise thickness control, improved properties, and reduced material usage.

MDO stretch film refers to a Machine Direction Oriented polyethylene film that undergoes a specialized production process to enhance its properties. By heating the raw polymer (e.g., polyethylene) to just below its melting point and stretching it longitudinally on an MDO machine, the film achieves uniaxial orientation. This stretching process optimizes the film’s strength, clarity, barrier properties, and recyclability while reducing material usage.

Unlike biaxially stretched films, MDO stretch film is engineered for applications demanding high performance, particularly in flexible and sustainable packaging solutions. It can be laminated into 100% polyethylene flexible packaging, solving the recycling challenges of traditional multi-material composites. Its features, such as transparency, glossiness, and printability, make it ideal for food and pharmaceutical packaging, including lidding films, pillow bags, and gusseted bags. Additionally, MDO stretch film excels in hygiene product applications like baby diapers and adult care products due to its adaptability to diverse packaging machinery.

MDO stretch film offers numerous advantages that make it a preferred choice in various packaging applications. Its enhanced mechanical properties, cost-effectiveness, and environmental benefits all contribute to its growing popularity in the packaging industry. Below are the key benefits of using MDO stretch film.

MDO stretch film provides improved strength and durability, thanks to its unique machine direction orientation process. This production technique optimizes the film’s physical attributes, allowing it to withstand demanding conditions without compromising flexibility.

One of the major benefits of MDO stretch film is its ability to reduce costs associated with raw materials and logistics. This efficiency is achieved through the film’s thinner yet stronger structure, which minimizes material usage without compromising performance.

The environmentally friendly nature of MDO stretch film is a primary reason for its widespread use in sustainable packaging solutions. As companies strive to reduce their environmental impact, MDO stretch film provides an ideal alternative to conventional materials.

Each of these benefits showcases how MDO stretch film aligns with industry trends focused on sustainability and resource efficiency.

MDO stretch film offers a combination of performance and environmental advantages, making it an increasingly popular choice for businesses focused on quality and sustainability. Whether for product protection, cost savings, or environmental initiatives, MDO stretch film meets various industry needs while contributing positively to the packaging sector’s goals for a greener future.

MDO stretch film is essential for sustainable and durable packaging solutions, and suppliers play a significant role in meeting the growing demand for this advanced material. This section outlines notable suppliers of MDO PE films and the innovations they bring to the market.

Several suppliers have established themselves as leaders in MDO stretch film, offering high-quality products tailored for various packaging needs. These suppliers are known for their emphasis on sustainable solutions, high-volume production capabilities, and advanced manufacturing techniques.

To meet the ever-evolving demands of the packaging industry, leading suppliers continue to introduce innovations in MDO stretch film production. The following advancements enhance product quality, sustainability, and operational efficiency, making MDO PE films more versatile and accessible for a range of applications.

To illustrate the advantages provided by top MDO stretch film suppliers, here’s a breakdown of factors that make their offerings valuable:

Selecting an MDO PE film supplier depends on the specific needs of a business, including factors such as customization requirements, sustainability goals, and production volume. Suppliers like PWP Stretch Film and others provide industry-leading MDO stretch film solutions, contributing to a more sustainable and efficient packaging landscape. By partnering with the right supplier, businesses can enhance their packaging operations with high-quality, eco-friendly, and reliable MDO stretch film that meets both performance and environmental standards.

In the packaging industry, both MDO PE (Machine Direction Oriented Polyethylene) and BOPE (Biaxially Oriented Polyethylene) films are widely used due to their unique properties and suitability for various applications. While they share some common traits, they differ in areas like film strength, stiffness, clarity, and overall application suitability. Below, we explore the differences between MDO PE and BOPE, helping you determine the best choice for stretch wrap needs.

When comparing MDO PE and BOPE films, several factors come into play, each impacting their effectiveness for specific applications:

The table below provides a direct comparison of MDO PE and BOPE films based on key performance factors:

| Performance Factor | MDO PE (Machine Direction Oriented) | BOPE (Biaxially Oriented) |

|---|---|---|

| Film Strength | High in the machine direction; ideal for linear applications | Balanced in both directions, suitable for broader packaging needs |

| Stiffness | Higher in the machine direction, providing stability | Balanced stiffness, offering flexibility without shape loss |

| Clarity and Gloss | High clarity and gloss; ideal for consumer visibility | Moderate clarity; less glossy due to biaxial stretching |

| Application Suitability | Optimal for stretch wrap and other single-direction force applications | Suitable for lidding, sachets, and applications needing uniform strength |

| Customization | Easier to tailor properties for specific directional performance | More limited customization due to balanced properties |

MDO stretch film offers specific advantages in stretch wrap applications where directional force and film customization are critical. Here are some reasons why MDO PE is a preferred option for certain packaging needs:

While MDO PE has its unique strengths, BOPE films also offer valuable benefits in packaging applications where uniform strength and flexibility are needed. Here’s why BOPE might be preferred in certain cases:

Selecting the right film depends on the specific packaging needs:

By understanding these differences and assessing the advantages of each, businesses can choose the optimal film type, whether MDO stretch film for linear strength or BOPE for balanced flexibility, to meet their unique packaging requirements.

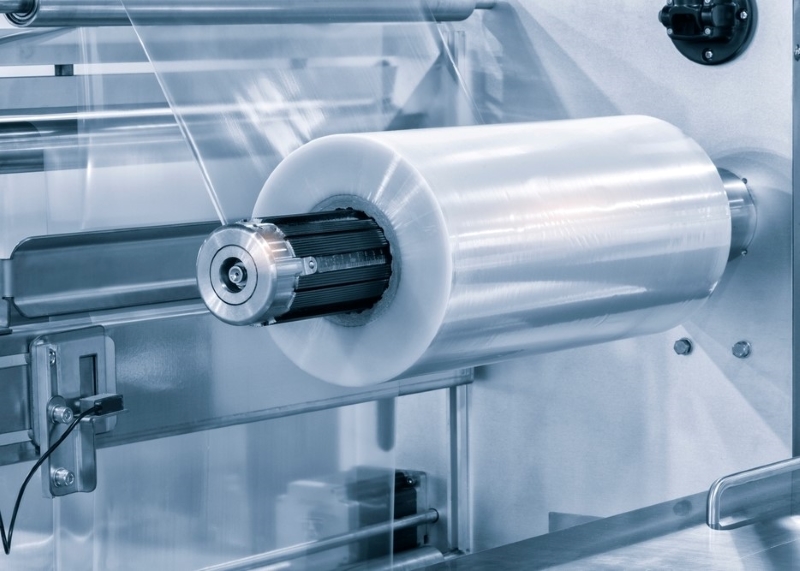

The MDO extrusion line process is a crucial part of producing MDO stretch film, involving a series of meticulously controlled steps to enhance the film’s strength, durability, and flexibility. The process enables the creation of a high-performance product tailored for various packaging needs, from lightweight stretch wraps to durable protective films. Below is a detailed look at the step-by-step process of the MDO extrusion line, illustrating how each stage contributes to the film’s final properties.

The MDO extrusion process consists of four primary stages: preheating, stretching, annealing, and cooling. Each step is essential for achieving the unique characteristics of MDO stretch film.

Modern MDO extrusion lines, especially those developed by industry leaders like PWP Stretch Film and W&H MDO equipment, provide several advantages that enhance the precision, quality, and efficiency of MDO stretch film production. Here are some notable benefits of using advanced MDO extrusion lines:

The unique MDO extrusion process endows MDO stretch film with specific benefits, including:

The MDO extrusion line process is instrumental in transforming raw polyethylene into a high-quality MDO stretch film, meeting the specific demands of industries that prioritize strength, clarity, and eco-friendliness in packaging materials. By leveraging advanced MDO equipment, stretch film producers can produce films that are consistent, customizable, and sustainable. This process is the foundation of reliable, high-performance MDO stretch films used across various sectors today.

MDO stretch film has gained widespread use across various industries due to its durability, clarity, and lightweight properties. Its versatility allows it to meet the specific demands of multiple sectors, including food and beverage, hygiene, and consumer goods, making it a go-to choice for reliable packaging. Below are some of the most popular applications of MDO stretch film, demonstrating its suitability across a range of packaging solutions.

MDO stretch film’s properties make it adaptable to numerous packaging formats. Here’s a breakdown of some common applications and the benefits they provide.

The diverse applications of MDO stretch film reflect its benefits in various industries. Below are some key advantages and the ways different sectors utilize MDO stretch film:

When considering MDO stretch film for various packaging applications, it’s important to evaluate the specific factors that make it suitable for each use:

The adaptability of MDO stretch film makes it a valuable asset across a range of packaging applications. Its unique combination of moisture resistance, mechanical strength, and visual appeal offers manufacturers a flexible solution that enhances product protection and presentation. Whether in food, hygiene, consumer goods, or medical industries, MDO stretch film provides reliable, efficient packaging that aligns with today’s needs for high-performance and sustainable materials.

MDO stretch film is a highly versatile and efficient flexible polyethylene packaging material with exceptional properties, making it a preferred choice across industries. Its key characteristics include:

MDO stretch film combines rigidity with elasticity, ensuring it can handle high weights and temperatures without breaking. This makes it suitable for industrial applications.

Its smooth surface and lightweight design provide an ideal medium for branding, allowing companies to easily print logos and designs for effective packaging solutions.

With superior transparency, gloss, and readability, the film enhances the visibility of printed materials, making it ideal for branding and product presentation.

The film offers exceptional mechanical properties, including high strength and low elongation, making it durable and reliable in demanding applications.

Unlike many other films, MDO stretch film performs excellently in cutting processes, ensuring efficient production without defects.

Its shrinkage can be customized based on application needs, offering flexibility in packaging solutions.

With a glossy and smooth finish, it enhances the aesthetic appeal of packaged products.

These properties collectively position MDO stretch film as a superior material for packaging, offering strength, durability, and excellent processability for various applications.

The production of MDO stretch film primarily involves various types of polymers and additives, each contributing to the film’s performance, functionality, and sustainability.

Each of these materials is carefully selected and processed during the MDO stretching process to create a film with optimized performance, making MDO stretch film a leading choice in modern packaging solutions.

The price of MDO stretch film plays a crucial role in its market acceptance and sales performance. Below is a detailed analysis of the factors affecting its price and how price influences sales volume:

Raw Material Costs

The price of polymers such as polyethylene (PE) and polypropylene (PP) significantly impacts the overall cost of production. Fluctuations in crude oil prices, a key input for these polymers, can directly affect MDO film pricing.

Manufacturing Technology

The advanced MDO process requires specialized machinery and precise control systems, which can increase production costs. However, its efficiency often leads to cost savings over time by reducing material usage.

Additives and Customization

Incorporating UV stabilizers, antistatic agents, or other functional additives increases the film’s price. Additionally, customized solutions tailored for specific industries, like food or pharmaceuticals, can elevate costs.

Market Demand and Supply

High demand, especially during peak seasons or for specialized applications, can drive prices up. Conversely, oversupply may lead to competitive pricing.

Recyclability and Sustainability Features

Films made with recycled content or featuring enhanced recyclability often command higher prices due to the cost of sustainable materials and certifications.

Logistics and Distribution

Transportation and storage costs, particularly for bulk orders, also influence the final price offered to customers.

Price Sensitivity

For cost-sensitive industries, even small price changes can impact purchase decisions, leading to fluctuations in sales volume.

Value Proposition

A higher price is often justified by superior properties such as transparency, strength, and sustainability. Customers willing to pay for quality and long-term benefits drive sales in premium segments.

Competition

Competitive pricing is crucial in markets with multiple suppliers. An excessively high price may reduce market share, while a competitive price can attract bulk orders and repeat business.

Market Trends

Rising demand for eco-friendly packaging can support higher prices for sustainable MDO stretch films, leading to stable or increased sales volumes in such segments.

The pricing of MDO stretch film is a delicate balance of production costs, market dynamics, and perceived value. Strategic pricing ensures competitiveness while maintaining profitability and driving sales.

Producing MDO stretch film involves several technical and operational challenges that stem from the complexity and precision required in the manufacturing process. Here are the key challenges:

The equipment used for MDO film production allows for nearly infinite setup variations, which is both a strength and a challenge. This high degree of flexibility requires operators to have extensive knowledge and experience to manage variables effectively. Mismanagement of these settings can lead to defects, inconsistencies, or reduced film quality.

The choice of raw polymer significantly impacts the film’s performance. The stretch ratio and resulting tensile strength depend heavily on the material’s composition. Certain polymers are unsuitable for MDO orientation due to their inability to maintain structural integrity when stretched, limiting production versatility.

Producing high-quality MDO stretch film demands skilled professionals who deeply understand both the machinery and the material properties. Insufficient expertise can lead to suboptimal film performance or production inefficiencies.

While MDO technology reduces material usage and shipping costs, maintaining this balance while achieving desired mechanical and optical properties can be challenging. For example, excessive cost-cutting on materials may compromise film strength or clarity.

As the industry evolves, integrating new materials and advanced technologies into existing MDO processes requires significant investment and adaptation. Keeping up with advancements while ensuring cost-effective scalability remains a challenge for manufacturers.

Despite these hurdles, MDO stretch film continues to be a groundbreaking innovation, offering reduced material consumption, enhanced properties, and sustainable solutions. Overcoming these challenges will further solidify its dominance in the packaging and industrial sectors.

MDO film stands for Machine Direction Oriented film, a specialized type of polymer film created through a precise stretching process that enhances its properties. During manufacturing, the film is heated close to its melting point and stretched in the machine direction. This stretching process aligns the molecular structure of the film, improving its mechanical strength, clarity, and flexibility. MDO films are widely used in packaging applications where durability, visibility, and lightweight material are essential. Common applications include packaging for food, hygiene products, and consumer goods, as MDO film offers enhanced puncture resistance and a glossy finish that showcases products well. MDO films are also popular for their sustainability benefits, as the process reduces material usage, making them more eco-friendly and often recyclable. Overall, MDO films provide a cost-effective, high-performance solution for industries that require efficient, lightweight, and sustainable packaging options.

The primary difference between TDO (Transverse Direction Oriented) and MDO (Machine Direction Oriented) films lies in the direction of the stretching during their production process. MDO film is stretched in the machine direction, or lengthwise, while TDO film is stretched in the transverse direction, or widthwise. This difference in orientation affects the properties and applications of each film type. MDO films have high tensile strength and stiffness in the machine direction, making them ideal for applications where linear strength is needed, such as stretch wraps and flexible packaging. TDO films, on the other hand, have uniform strength across the width, which provides balanced dimensional stability and flexibility. TDO films are often used in applications like labels and certain types of shrink wraps where multidirectional strength is required. The choice between TDO and MDO depends on the specific requirements of the application, as each offers unique benefits suited to different packaging needs.

Blown film and stretch film differ primarily in their production methods and applications. Blown film is produced using the blown film extrusion process, where molten plastic is extruded through a circular die, inflated into a bubble, and then cooled. This method creates a film with high strength, puncture resistance, and excellent barrier properties. Blown film is commonly used in packaging applications like food bags, agricultural covers, and industrial wraps.

Stretch film, on the other hand, is specifically designed for wrapping and securing goods on pallets. It is typically made through the cast extrusion process, which produces a smoother and more transparent film. Stretch film is highly elastic and clings tightly to objects without adhesives. MDO (Machine Direction Oriented) stretch film is a subtype, engineered to have enhanced tensile strength and stretchability. While blown film excels in durability, stretch film focuses on flexibility and ease of application.

MDO stands for Machine Direction Oriented plastic. It refers to a film manufacturing process where the material is stretched in the machine direction during production. This orientation aligns polymer chains, resulting in a thinner, lighter, and stronger film. For stretch film applications, MDO technology enhances the film’s tensile strength, tear resistance, and barrier properties, while reducing material usage and overall environmental impact.

MDO stretch film is widely used in pallet wrapping and bundling applications due to its excellent load containment and stretchability. Additionally, it offers greater clarity and uniform thickness compared to traditional films, which improves presentation and visibility. This process not only optimizes film performance but also contributes to sustainability by enabling downgauging — producing films with reduced thickness while maintaining or improving mechanical properties. MDO plastic represents an advanced solution for industries prioritizing performance and sustainability in their packaging materials.

Yes, MDO stretch film can get wet and is generally water-resistant, making it suitable for outdoor applications and environments with moisture exposure. The plastic materials used, such as polyethylene (PE), are inherently hydrophobic, which means they repel water. This property ensures that MDO stretch film maintains its structural integrity even when exposed to rain, humidity, or damp conditions.

However, while MDO stretch film is resistant to water, its performance might be impacted by prolonged exposure to extreme wet conditions. For example, excessive moisture could reduce the cling or holding force in certain stretch films. Specialized additives or coatings can further enhance water resistance for specific applications, such as outdoor storage or transport.

In summary, MDO stretch film performs well in wet environments, but it’s essential to consider the specific use case and environmental conditions to ensure optimal performance.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed