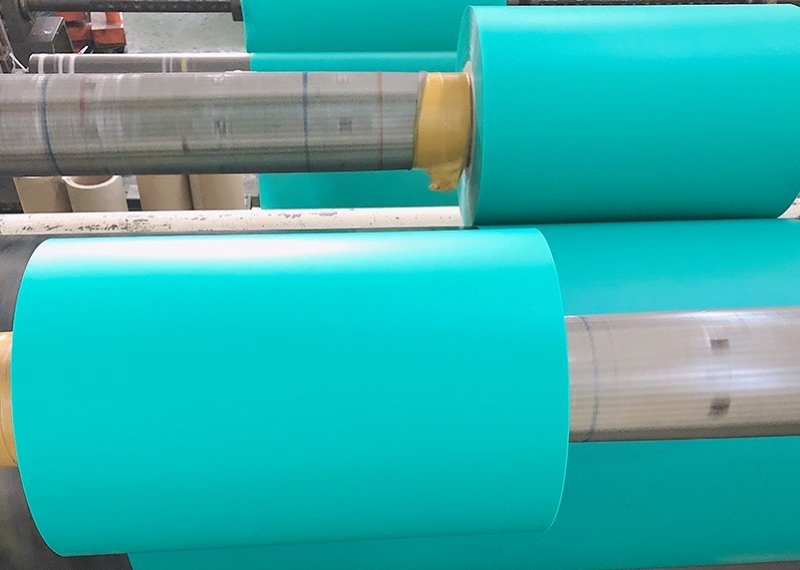

PE stretch winding film is a highly versatile packaging material used to securely wrap items during shipping and storage. Pre-stretch film is a pre-stretched variant of PE stretch winding film, designed for greater efficiency and reduced material usage. Its flexibility and strength make it ideal for securing moving boxes, mailing tubes, and other goods, ensuring they remain safe and protected during transit. OEM PE stretch winding film manufacturers play a crucial role in producing custom stretch films tailored to the specific needs of businesses. As Original Equipment Manufacturers (OEMs), they provide large-scale production solutions, offering high-quality, reliable packaging materials. By working with OEMs, companies can benefit from cost-effective, customized products that are essential for safe and efficient packaging across various industries.

Why Choose Our Stretch Film Over Competitors?

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Product Name | Stretch Film |

| Material | LDPE + LLDPE |

| Size | Customized |

| Thickness | Customized |

| Length | Customized |

| Width | Customized |

| Color | Customized |

| Features | Moisture-proof, Protective |

| Hardness | Soft |

| Logo Printing | Yes |

| Processing Type | Casting, Multiple Extrusion |

| Transparency | Transparent, Translucent, Opaque |

| Surface | Glossy, Smooth, High Gloss |

| Certificate | EU, ROHS, GMC, ISO9001 |

| Packaging | Gift Box, Carton |

| Sales Unit | Single Item |

OEM (Original Equipment Manufacturer) refers to companies that produce products or components that are sold by another company under its own brand. In the context of OEM PE Stretch Winding Film, it means that the manufacturer produces stretch films according to the specifications and branding requirements of other companies, providing a tailored solution for their packaging needs.

PE (Polyethylene) is a widely used plastic material known for its durability, flexibility, and resistance to moisture and chemicals. In the context of stretch films, PE is chosen for its strength, stretchability, and tear resistance, making it ideal for wrapping and securing goods during storage and transportation.PE (Polyethylene) stretch winding film is a stretchable plastic film commonly used in packaging to secure and protect items during transport or storage. It is applied by stretching the film tightly around products, creating a secure barrier that prevents movement, and protects against dust, moisture, and external damage. PE stretch winding film is highly flexible, puncture-resistant, and provides a reliable solution for bundling various items.

Choosing OEM PE Stretch Winding Film Manufacturers like PWP Stretch Film ensures you receive cost-effective, high-quality, and customizable packaging solutions. These manufacturers offer stretchable and tear-resistant films designed to meet unique packaging requirements, providing durability and efficiency for businesses. With the ability to tailor products to your needs, OEM manufacturers offer scalable solutions that improve packaging performance and reduce costs.

| Packaging Material | Properties | Best Uses | Advantages |

|---|---|---|---|

| PE Stretch Winding Film | Stretchable, durable, puncture-resistant, clear or colored | Securing pallets, wrapping large items | High flexibility, strong hold, protects against elements |

| Skid Wrap | Strong, stretchable plastic film | Wrapping boxes, furniture, pallets | Excellent for industrial use, secures items during transit |

| Bubble Wrap | Air-filled cushioning material | Protecting fragile items like glass or electronics | Impact protection, lightweight, shock absorption |

| Plastic Wrap for Furniture | Clingy, thin plastic film | Wrapping furniture and household items for moving | Prevents scratches, protects from dust and dirt |

PE stretch winding film is widely used in industries such as logistics, retail, and manufacturing. Its most common application is wrapping pallets to keep goods stable during transportation. Additionally, it’s highly effective for protecting furniture during moves, ensuring items like couches, tables, and mattresses are safeguarded from dust, scratches, and moisture. PE stretch film can also be used for bundling smaller items together, making it a versatile solution for both commercial and residential packaging needs.

Pallet Wrapping for Transportation

One of the most common applications of PE stretch winding film is for wrapping pallets in logistics and transportation. The film keeps goods securely in place during transit, preventing movement and damage, ensuring that products arrive safely at their destination.

Furniture Protection During Moves

PE stretch film is also highly effective for protecting furniture during moves. Items such as couches, tables, and mattresses are wrapped to shield them from dust, scratches, and moisture, making it an essential tool for moving or storing furniture.

Bundling Smaller Items

In addition to wrapping large items, PE stretch film is ideal for bundling smaller items together. This is especially useful in both commercial and residential packaging, as it allows multiple items to be grouped for easier handling, storage, and transportation.

These versatile applications make PE stretch winding film a go-to solution for a wide range of packaging needs across different industries.

When selecting packaging materials for your business, partnering with OEM PE stretch winding film manufacturers offers a range of significant benefits. These manufacturers specialize in producing high-quality PE stretch films customized to the specific needs of businesses across various industries, from logistics to retail and industrial packaging. Below, we explore the advantages of choosing an OEM manufacturer, focusing on customization, cost-efficiency, scalability, and their role in different sectors.

One of the main benefits of working with OEM PE stretch winding film manufacturers is the ability to customize the product according to your exact requirements. Unlike standard stretch films, OEM manufacturers can create films that are tailored in terms of thickness, strength, color, and size. This level of customization is crucial for businesses with unique packaging needs, such as:

Customization ensures that businesses receive exactly the type of packaging material needed for their operations, improving efficiency, reducing waste, and enhancing the safety and protection of goods.

Another compelling reason to choose OEM PE stretch winding film manufacturers is the potential for cost savings. Since OEMs manufacture products directly, without the need for intermediaries, businesses can benefit from lower production costs. Moreover, OEM manufacturers often offer bulk purchasing options, which can significantly reduce the per-unit cost of stretch film.

As your business grows, your packaging needs will evolve. OEM PE stretch winding film manufacturers are well-equipped to scale production in line with your expanding operations. Whether your company is managing seasonal surges, expanding into new markets, or increasing production volumes, OEM manufacturers have the capacity to adjust their output and meet growing demand.

OEM PE stretch winding film manufacturers are also capable of providing tailored solutions for specific industries, ensuring that their products meet the specialized demands of different sectors. This is particularly important for industries like:

OEMs are adept at working with businesses to develop industry-specific solutions, from lightweight films for smaller goods to high-strength films for industrial applications.

Partnering with OEM PE stretch winding film manufacturers offers a wide range of benefits, including the ability to customize stretch film, cost savings through direct pricing and bulk production, and scalability to meet growing demands. By working with an OEM, businesses can receive tailored packaging solutions that align perfectly with their operational needs, from moving supplies to shipping and retail packaging. Whether you’re looking for specialty films or large-scale production capabilities, OEM manufacturers provide the flexibility, efficiency, and expertise to ensure that your packaging requirements are met with the highest standards of quality and reliability.

Ensuring the production of high-quality stretch film is critical for OEM PE stretch winding film manufacturers, as these films play a crucial role in securing goods during shipping, storage, and transportation. From the manufacturing process to quality control, OEMs focus on maintaining rigorous standards to ensure that their PE stretch films meet the needs of various industries, such as logistics, moving supplies, and industrial packaging. Below is an in-depth look at how OEM manufacturers maintain high quality throughout their production process.

The production process of PE stretch film involves several key stages that OEM PE stretch winding film manufacturers carefully manage to ensure a consistent and high-quality product. These stages include:

To ensure the durability, flexibility, and performance of their stretch films, OEM PE stretch winding film manufacturers implement strict quality control procedures throughout the production process. These measures are crucial in guaranteeing that the final product meets industry standards and customer expectations. Some of the key quality control measures include:

The role of high-quality stretch film is paramount when it comes to securing valuable items during transit or storage. Whether it’s wrapping moving boxes, protecting mailing tubes, or safeguarding fragile goods, using reliable stretch film ensures that products remain intact and damage-free throughout their journey. OEM PE stretch winding film manufacturers are responsible for producing films that provide the strength, flexibility, and durability needed to achieve this.

Through a well-managed production process and stringent quality control measures, OEM PE stretch winding film manufacturers deliver high-quality stretch films that meet the demanding needs of various industries. From ensuring tensile strength and puncture resistance to maintaining consistent thickness and performance under different conditions, OEM manufacturers play a vital role in providing durable, flexible, and reliable packaging materials. By choosing high-quality stretch film from trusted OEM manufacturers, businesses can ensure the safe transport and storage of their valuable goods, from moving boxes to fragile items like mailing tubes.

In today’s global packaging market, there are several OEM PE stretch winding film manufacturers that stand out for their innovation, quality, and capacity to serve diverse industries. These manufacturers provide custom stretch films to businesses in industries like shipping, logistics, retail, and industrial packaging.

PWP Stretch Film is one of the largest OEM PE stretch winding film manufacturers in the world, supplying a wide range of flexible packaging solutions. Known for our innovation in film technology, We provides stretch films with superior durability, puncture resistance, and stretchability. We serve industries such as logistics, e-commerce, and consumer goods, offering customized films that are ideal for securing pallets and protecting goods during shipping.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed