Pallet film is a type of stretch film specifically designed for wrapping and securing pallets during storage and transportation. Pallet film secures and protects palletized goods, ensuring stability, moisture resistance, and packaging for storage and transport. Its significance in logistics and shipping cannot be overstated, as it helps maintain the integrity of loads, preventing shifts and damages during transit. Pallet film is widely used in various industries, providing essential protection against dust, moisture, and unauthorized access. Additionally, it enhances load stability, making it easier to handle and store products efficiently. With its ability to conform to different shapes and sizes, pallet film is an indispensable tool for businesses aiming to optimize their shipping processes and reduce costs. Overall, the use of pallet film contributes significantly to effective supply chain management.

Pallet film plays a crucial role in enhancing the efficiency and safety of logistics operations. Its effectiveness in improving load stability is one of the primary reasons it is widely used across various industries. By tightly securing products on a pallet, pallet wrap film minimizes the risk of shifting during transport, which can lead to damage and increased costs.

Pallet film provides essential protection for products, ensuring they arrive at their destination in optimal condition. The material’s properties contribute significantly to safeguarding goods from environmental factors and unauthorized access.

The uses and benefits of pallet wrap films are numerous and critical for effective logistics management. By improving load stability and offering protection against dust, moisture, and theft, pallet film is an indispensable asset in the shipping industry. Embracing the advantages of pallet film not only enhances operational efficiency but also contributes to long-term cost savings and increased reliability in the supply chain.

Pallet film comes in various types, each designed to meet specific needs in packaging and shipping. Understanding the differences between machine stretch film and hand wrap is crucial for selecting the right option for your logistics operations. Each type offers unique advantages that can enhance efficiency and effectiveness in securing loads.

Machine Stretch Film

Machine stretch film is specifically designed for automated wrapping machines. It is generally thicker and stronger than hand wrap, allowing for faster and more consistent application.

Hand Wrap

Hand wrap, on the other hand, is intended for manual use. It is typically lighter and comes in smaller rolls, making it easier for workers to handle.

Advantages of Machine Stretch Film:

Advantages of Hand Wrap:

Choosing between machine stretch film and hand wrap depends on various factors, including the scale of operations, types of products being wrapped, and budget considerations. Additionally, businesses may consider using recyclable film, which offers an eco-friendly alternative while maintaining performance. By understanding the advantages of each type of pallet film, businesses can make informed decisions that enhance their logistics processes, improve load security, and ultimately contribute to greater customer satisfaction. Embracing the right pallet film solution is key to optimizing efficiency in any supply chain.

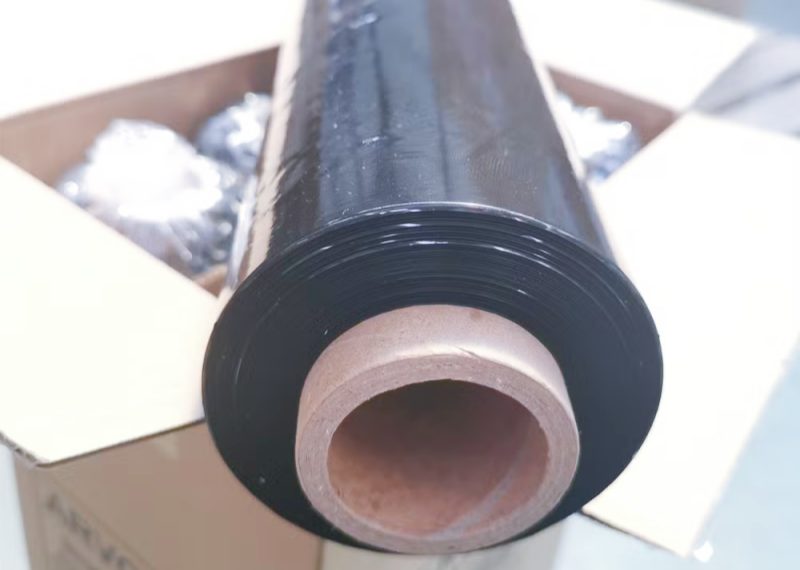

Opaque pallet film is a specialized stretch film designed for securing and concealing palletized loads. Unlike standard clear stretch film, opaque pallet film prevents visibility of the wrapped items, providing enhanced security, privacy, and protection against tampering or theft. It is commonly used in logistics, warehousing, and transportation industries, particularly when shipping high-value or confidential goods.

Opaque pallet film is an essential packaging solution for businesses requiring added security, privacy, and protection for their palletized shipments. With its ability to conceal, stabilize, and safeguard goods, it plays a vital role in logistics, warehousing, and global supply chain operations.

Pallet film, also known as stretch film or stretch wrap, is widely used in various industries for securing and protecting palletized loads. Its primary functions include load stabilization, product protection, and enhanced handling efficiency. Below are some of the key applications of pallet film across different sectors.

Pallet film is a crucial packaging material that enhances logistics, security, and efficiency across multiple industries. Its versatility in load containment, protection, and handling makes it an indispensable tool in modern supply chains.

Finding the right pallet film for your business needs is essential for efficient packaging and shipping operations. Fortunately, there are various options available for purchasing pallet film, including both online and local sources. This guide will help you navigate where to buy pallet film and provide tips for identifying the best deals and reputable sellers.

The internet offers a convenient platform for sourcing pallet film, allowing you to compare prices, features, and customer reviews. Here are some popular online options:

If you need to secure palletized goods or bundle products efficiently, PWP Stretch Film offers a range of stretch film solutions to meet your packaging needs. Our selection includes hand stretch film, machine stretch film, and pre-stretched film, all designed to provide superior load stability and product protection.

We offer stretch films in various widths, lengths, and core sizes to accommodate different packaging applications. Our films come in both transparent and black options, with different thickness levels to match standard and heavy-duty requirements. Black pallet wrap is particularly useful for concealing products and providing additional security during transportation.

Many of our stretch films are made with 30% recycled content, making them exempt from plastic packaging tax. We also provide a stretch film audit service to help businesses optimize film usage, reduce waste, and lower overall packaging costs. By using our solutions, companies can wrap more pallets with less film, improving both efficiency and sustainability.

For businesses requiring large quantities, we offer bulk discounts on hand and machine stretch film rolls when purchasing five or more boxes. Our premium-grade stretch films are ideal for securing industrial and commercial shipments while ensuring cost-effective packaging solutions.

Stretch film is essential for keeping palletized goods stable during storage and transport. By securing products with elastic tension, our stretch films ensure items remain tightly bound, preventing movement and potential damage. Our advanced manufacturing technology produces high-performance stretch films that deliver consistent and reliable wrapping performance.

With 18 years of experience in the packaging industry, PWP Stretch Film has become a leading provider of stretch films, pallet wraps, and industrial packaging solutions. Our commitment to quality and innovation ensures that customers receive the best products for their packaging needs. We work with top-tier suppliers to offer cutting-edge packaging materials without compromising on performance.

Our state-of-the-art production facilities utilize automated palletizing and packaging systems, ensuring efficiency and product consistency. With a team of skilled engineers and packaging specialists, we manufacture stretch films tailored to specific customer requirements. Additionally, we provide contract packaging services and custom packaging solutions to meet diverse industry demands.

For more information about our stretch film products and services, contact us at pwpstretchfilm@gmail.com. Let PWP Stretch Film help you protect and distribute your products with confidence, offering high-quality solutions tailored to your business needs.

When searching for pallet film, consider the following tips to ensure you get the best value and quality:

Purchasing pallet film is a vital aspect of effective logistics and shipping operations. By exploring various online options and following these tips, you can find the right pallet film at a competitive price. My experience with PWP Stretch Film has shown that doing thorough research pays off, leading to informed decisions that enhance operational efficiency. Whether you choose to buy from e-commerce platforms, manufacturers, or wholesale suppliers, ensuring you select reputable sellers will contribute to successful supply chain management.

When selecting pallet film, understanding the specifications of the rolls is essential for ensuring optimal performance in your packaging operations. The right size and thickness can significantly affect the efficiency, safety, and cost-effectiveness of your logistics processes.

Pallet film is available in various sizes and thicknesses, tailored to meet the demands of different applications. Here are some common specifications:

Selecting the appropriate specifications for pallet film is crucial for several reasons:

Understanding the specifications of pallet film rolls is essential for optimizing packaging and shipping operations. By considering factors such as size, thickness, and stretch capabilities, businesses can choose the right pallet film that meets their unique needs. Investing in the right specifications not only enhances load protection and stability but also contributes to overall cost efficiency and sustainability in logistics management.

protection, and cost efficiency. The right choice depends on various factors such as load type, wrapping method, storage conditions, and transportation needs. Below is a guide to help determine the best pallet film for different applications.

Choosing the right pallet film requires evaluating load characteristics, film type, application method, thickness, and environmental factors. By selecting the most suitable film, businesses can improve packaging efficiency, reduce costs, and ensure products are securely transported and stored.

In the ever-evolving world of logistics and packaging, nano pallet wrapping film has emerged as a groundbreaking option for businesses seeking enhanced load protection and sustainability. This innovative film incorporates advanced nanotechnology, which provides unique properties that set it apart from traditional pallet film.

Nano pallet wrapping film is designed with microscopic particles integrated into the film structure. These particles enhance the film’s performance in several ways, offering significant advantages over conventional pallet films. Some of the key properties of nano pallet wrapping film include:

The benefits of using nano pallet wrapping film extend beyond its unique properties. Here are several advantages that this innovative solution brings to logistics operations:

Nano pallet wrapping film represents an innovative solution in the realm of packaging. Its unique properties, driven by advanced nanotechnology, offer significant benefits in load protection and sustainability. By adopting this cutting-edge film, businesses can enhance their logistics processes, reduce costs, and contribute to a more sustainable future. The transition to nano pallet wrapping film can be a game-changer for companies looking to optimize their packaging strategies and improve overall operational efficiency.

Pallet wrap, also known as stretch film, is primarily used to secure and protect goods stacked on pallets during storage and transportation. Its primary function is to maintain the stability of the load, ensuring that the items do not shift or fall off the pallet. Pallet wrap is made from a stretchable plastic material, allowing it to cling tightly to the items being wrapped. This tight wrap not only stabilizes the load but also provides a protective barrier against dust, moisture, and other environmental factors that could damage the products. Additionally, pallet wrap serves as a deterrent against pilfering or tampering, as tightly wrapped pallets can indicate unauthorized access if the wrap is torn or damaged. Overall, pallet wrap is essential for efficient logistics, protecting goods, and ensuring that products arrive at their destination in excellent condition.

The amount of pallet wrap required to wrap a pallet can vary based on several factors, including the size and weight of the pallet, the dimensions of the products on it, and the type of pallet wrap being used. Typically, a standard 4-foot tall pallet might require between 50 to 100 feet of stretch film for adequate coverage. However, for larger or heavier loads, more film may be needed to ensure that the wrap is tight and secure. To calculate the exact amount, you should consider the pallet’s dimensions and the recommended overlap of the wrap layers. A general rule of thumb is to wrap the pallet from the base up to the top, ensuring at least a 50% overlap between layers for added stability. For precise estimates, consulting product specifications and guidelines from the pallet wrap manufacturer can provide better insights into the optimal usage for specific loads.

Pallets are wrapped for several critical reasons that enhance the safety and efficiency of logistics operations. One of the main reasons is to ensure load stability; wrapping helps to hold the products tightly together, preventing any movement during transit. This stability is especially important when goods are transported over long distances or through rough handling conditions. Additionally, wrapping provides protection from dust, moisture, and contaminants, keeping the products clean and intact. Furthermore, pallet wrapping acts as a security measure; it can deter theft and unauthorized access to the goods. If a pallet is tampered with, the film may show visible signs of damage, alerting handlers to potential issues. Finally, using pallet wrap can improve overall operational efficiency, as it simplifies the handling and stacking of goods, making it easier to load and unload shipments in warehouses and transport vehicles.

Cling film and stretch film are both plastic wrapping materials, but they serve different purposes. Cling film, also known as plastic wrap, is primarily used for food preservation and household wrapping. It is thin, lightweight, and has self-adhering properties that help it stick to surfaces without requiring additional adhesives.

Stretch film, on the other hand, is designed for industrial and commercial applications, particularly in packaging and shipping. It is significantly stronger, more elastic, and provides excellent load stability when wrapped around pallets or products. Stretch film requires tension to adhere properly and does not naturally cling in the same way as food wrap. Instead, it tightly conforms to the items being wrapped, ensuring secure transport.

Additionally, stretch film is available in different thicknesses and formulations, such as cast and blown stretch film, which offer varying levels of puncture resistance and stretchability. Cling film is typically made from polyvinyl chloride (PVC) or polyethylene (PE), while stretch film is mainly composed of linear low-density polyethylene (LLDPE). The primary distinction lies in their applications—cling film for food storage and light wrapping, while stretch film is essential for heavy-duty packaging and securing large loads.

Pallet wrappers are machines designed to wrap stretch film around pallets to stabilize and protect goods during storage or transportation. There are several types of pallet wrappers, each suited for different needs and production volumes:

Manual Pallet Wrappers – These require an operator to manually apply and stretch the film around the pallet using a handheld dispenser. This is cost-effective for small businesses or low-volume packaging operations.

Semi-Automatic Pallet Wrappers – These machines require some manual operation but significantly reduce labor compared to manual wrapping. The operator places the pallet on a turntable, and the machine applies the film with consistent tension, improving efficiency.

Automatic Pallet Wrappers – Fully automated machines that require minimal human intervention. They use a conveyor system to move pallets into position, wrap them with precision, and cut the film automatically. These are ideal for high-volume packaging environments.

Rotary Arm Pallet Wrappers – These machines have a rotating arm that moves around the pallet, making them ideal for wrapping unstable or very heavy loads. Unlike turntable wrappers, they do not require the pallet to be spun.

Orbital Pallet Wrappers – Also known as horizontal wrappers, these are used for wrapping long and irregularly shaped products, such as pipes or furniture.

Choosing the right pallet wrapper depends on factors such as production speed, budget, and load stability requirements.

While stretch film is widely used for securing pallets, there are several alternatives that can serve similar purposes depending on the situation:

Strapping (Plastic or Metal) – Straps made from polypropylene, polyester, or metal can be used to hold pallets together. These are commonly used for securing heavy loads and preventing movement during transportation.

Shrink Wrapping – Instead of stretch film, shrink wrap uses heat to form a tight seal around products, offering strong protection against dust and moisture.

Pallet Bands – Reusable rubber or elastic bands can be wrapped around a pallet to hold items in place, reducing plastic waste.

Pallet Netting – A breathable alternative to stretch film, netting allows air circulation, making it ideal for products that need ventilation, such as fresh produce.

Reusable Stretch Wraps – Some companies use reusable fabric or plastic wraps with Velcro or clip fasteners, which can be applied multiple times, reducing waste.

Adhesive Spray or Glue – Some businesses use temporary adhesives or anti-slip sprays to hold items together on a pallet without the need for wrapping.

Each alternative has specific advantages, particularly in terms of sustainability, cost, and load stability.

Pallet wrap, also known as stretch film, is primarily made from linear low-density polyethylene (LLDPE). This type of plastic is chosen for its high stretchability, strength, and resistance to punctures and tears. LLDPE is a flexible and durable material that allows the film to conform tightly to the shape of palletized goods while providing load stability.

There are different formulations of LLDPE used in pallet wrapping, including:

Cast Stretch Film – Produced using a cast extrusion process, this film is clear, quiet to unwind, and offers consistent thickness. It is easier to stretch but has lower puncture resistance.

Blown Stretch Film – Made using a blown extrusion process, this film has higher durability and puncture resistance, making it ideal for wrapping sharp or irregularly shaped loads.

Additionally, some pallet wraps contain additives for UV resistance, anti-static properties, or improved cling. Recyclable and biodegradable options are also becoming more available to reduce environmental impact.

Stretch film is primarily made from linear low-density polyethylene (LLDPE). This material is preferred due to its excellent stretchability, tear resistance, and durability, which ensures that wrapped pallets remain secure during transportation.

The manufacturing process of stretch film typically involves one of two methods:

Cast Stretch Film – Produced by feeding molten LLDPE through rollers to create a thin, uniform film. This type of film is known for its clarity, quiet unwinding, and good stretchability.

Blown Stretch Film – Manufactured by blowing hot LLDPE into a bubble, then cooling and flattening it. This results in a stronger, more puncture-resistant film with higher elasticity, though it is less clear and noisier to unwind.

Other materials, such as metallocene polyethylene (mPE) or ethylene-vinyl acetate (EVA), are sometimes blended with LLDPE to enhance strength, elasticity, or other performance characteristics. Some manufacturers also incorporate biodegradable or recycled content to improve environmental sustainability.

Cling wrap and pallet wrap are both plastic films used for wrapping, but their applications, materials, and properties differ significantly.

Cling Wrap

Used mainly for food preservation, keeping items fresh by preventing air exposure.

Typically made from polyvinyl chloride (PVC) or polyethylene (PE).

Has a natural ability to stick to itself and other surfaces.

Thin, flexible, and easy to tear by hand.

Pallet Wrap (Stretch Film)

Used in industrial settings to secure goods on pallets.

Made primarily from linear low-density polyethylene (LLDPE) for durability and elasticity.

Requires tension to wrap tightly around pallets; does not naturally cling like food wrap.

Comes in different thicknesses for various load stability needs.

The primary distinction is that cling wrap is designed for lightweight wrapping applications like food storage, while pallet wrap is a heavy-duty material used for securing large loads in warehouses and shipping.

Yes, pallet wrap is generally water-resistant rather than completely waterproof. It provides a strong barrier against moisture, rain, and humidity, which helps protect goods from environmental factors during storage and transportation.

Stretch film, which is used for pallet wrapping, is made from linear low-density polyethylene (LLDPE), a plastic that does not absorb water. This makes it effective in keeping pallets dry in most conditions. However, while pallet wrap prevents surface moisture from penetrating, it does not form an airtight or completely watertight seal.

For additional water protection, businesses often use shrink wrap instead of stretch wrap. Shrink wrap requires heat to form a tight, sealed layer around a pallet, offering superior waterproofing compared to regular stretch film. Another option is reinforced stretch wrap with a higher thickness or waterproof pallet covers, which provide extra shielding against rain and extreme weather conditions.

If complete waterproofing is required, combining stretch film with desiccants, shrink wrapping, or plastic pallet covers can help ensure full protection from water damage, condensation, and humidity-related deterioration.

Wrapping pallets quickly while ensuring load stability is essential in warehouse operations. Here are some key techniques to improve efficiency:

Use a Pallet Wrapping Machine

Semi-automatic and fully automatic stretch wrappers significantly reduce the time needed to wrap pallets. A turntable wrapper or rotary arm wrapper can wrap a pallet in under a minute with consistent tension.

Choose the Right Stretch Film

Using pre-stretched film or high-performance stretch film requires less effort and fewer wraps while still securing the load effectively.

Optimize Wrapping Technique (for Manual Wrapping)

Start with a strong base by wrapping the bottom of the pallet multiple times to anchor the film.

Keep constant tension on the film while wrapping. Pulling too tightly can rip the film, while too little tension results in an unstable load.

Overlap each layer by 50% to ensure full coverage.

Wrap from the bottom up to keep the load stable and finish with a firm top wrap.

Use a Dispenser

A handheld stretch film dispenser improves grip and allows for even tension, reducing time and physical strain compared to wrapping by hand.

Position the Pallet Correctly

Ensure the pallet is on a flat surface and that workers have enough space to move around it easily.

Train Workers on Efficient Wrapping

Providing training on proper wrapping techniques ensures consistency and speed while minimizing film waste.

By combining the right equipment, film type, and technique, wrapping pallets quickly can be achieved without compromising the security of the load.

The standard size of pallet wrap varies depending on industry requirements and the type of load being secured. However, the most commonly used sizes are:

Width:

18 inches (45 cm) – The most common width for hand stretch film rolls.

20 inches (50 cm) to 30 inches (76 cm) – Typical for machine-applied pallet wrap.

Thickness (Gauge or Microns):

60-80 gauge (15-20 microns) – Suitable for light-duty loads.

90-120 gauge (22-30 microns) – Used for securing heavy or irregular loads.

Length:

Hand stretch rolls range from 500 to 1500 feet (150-450 meters).

Machine stretch rolls range from 5000 to 9000 feet (1500-2700 meters).

Choosing the right size depends on factors such as load weight, pallet height, and shipping conditions. Heavier or unstable loads require thicker and wider film, while lighter loads can be wrapped with thinner film.

Pallet wrap is known by several names depending on the industry and application. Some of the most common terms include:

Stretch Film – The general term for plastic film that stretches and adheres to itself when wrapped around a pallet.

Stretch Wrap – Another common term used interchangeably with stretch film.

Shrink Wrap – Sometimes confused with stretch film, but shrink wrap requires heat to shrink around a load.

Pallet Stretch Film – Specifically refers to stretch film used for securing pallets.

Plastic Wrap – A broad term that can refer to stretch film, shrink wrap, or food wrap.

Hand Wrap or Machine Wrap – Based on the application method.

While different terms exist, “stretch film” is the most accurate name for the plastic wrap used to secure pallets.

No, pallet wrap is not the same as cling film. While both are made from plastic and are used for wrapping, they have different material properties and applications.

Material Differences

Cling film is usually made from polyvinyl chloride (PVC) or polyethylene (PE) and is designed for food preservation and household use.

Pallet wrap (stretch film) is made from linear low-density polyethylene (LLDPE) and is engineered for industrial packaging and load stabilization.

Stretchability and Cling

Cling film naturally sticks to surfaces due to its static properties.

Pallet wrap stretches under tension and adheres through pressure rather than natural cling.

Usage

Cling film is used for wrapping food and small items.

Pallet wrap is used to secure goods on pallets during transport and storage.

Although both are plastic wraps, they serve entirely different purposes in packaging and storage.

No, pallet wrap does not shrink with heat. It is designed to stretch and conform around a pallet through tension rather than shrinking.

Shrink wrap, on the other hand, is a different type of plastic film that requires heat to shrink tightly around a product. It is commonly used for packaging consumer goods like electronics, beverages, and food items.

While pallet wrap can tolerate some heat exposure, applying heat will not cause it to shrink; instead, it may weaken the film and reduce its effectiveness in securing loads.

The main difference between shrink wrap and pallet wrap is how they function:

Shrink Wrap

Requires heat to shrink tightly around a product.

Used for sealing products like CDs, bottles, and bulk retail items.

Provides strong waterproofing and tamper resistance.

Pallet Wrap (Stretch Film)

Stretches around a pallet using tension, not heat.

Used for securing and stabilizing loads on pallets.

Provides load stability but not an airtight seal.

While both materials are used for packaging, shrink wrap is heat-activated, while pallet wrap is stretch-based.

Pallet wrap is not inherently sticky like adhesive tape, but it does cling to itself due to its material composition. Some types of stretch film have a cling coating on one or both sides, which helps the film stick together after being stretched.

Different stretch films have varying levels of cling:

Single-sided cling – Only sticks on one side to prevent pallets from sticking together during transport.

Double-sided cling – Sticks on both sides for better grip and load security.

Even though it adheres well when wrapped tightly, pallet wrap does not leave a sticky residue.

The thickness of pallet wrap depends on the weight and stability of the load. Thickness is measured in gauge (US) or microns (international).

Light loads (under 1000 lbs / 450 kg) – 60-80 gauge (15-20 microns).

Medium loads (1000-2000 lbs / 450-900 kg) – 90-100 gauge (22-25 microns).

Heavy or unstable loads (over 2000 lbs / 900 kg) – 120-150 gauge (30-38 microns).

Choosing the right thickness ensures load stability, film efficiency, and cost-effectiveness in packaging.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed