Pallet shrink wrap is a versatile packaging material commonly used to secure and protect palletized goods during storage and transportation. It is a thin, stretchable plastic film that shrinks tightly around products when heat is applied, creating a secure and tamper-evident seal. This makes pallet shrink wrap an ideal choice for packaging a variety of products, from food and electronics to industrial goods. However, there are also several alternatives to shrink wrap for pallets, such as stretch film made from recycled materials, biodegradable wraps, and paper-based packaging. These alternatives offer businesses more sustainable options for securing their palletized goods while minimizing environmental impact. Choosing the right wrapping solution for palletized goods is crucial, as it ensures that items remain stable and undamaged during transit. Proper use of pallet shrink wrap or its eco-friendly alternatives helps minimize the risk of damage from moisture, dust, and other environmental factors, while also enhancing the efficiency of the packing and shipping process.

Why Choose Our Stretch Film Over Competitors?

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Material | Linear Low Density Polyethylene |

| Type | Stretch Film |

| Length | Customized |

| Width | Customized |

| Thickness | Customized |

| Color | Customized |

| Features | Moisture-proof |

| Hardness | Soft |

| Processing Type | Casting, Blow Molding |

| Transparency | Transparent, Opaque |

| Surface | Smooth |

| Application | Packaging, Industry, Home |

| Sales Unit | Single Item |

Pallet shrink wrap is a highly effective packaging material designed to secure goods stacked on a pallet during storage and transportation. Made from stretchable plastic film, it shrinks when exposed to heat, tightly conforming to the shape of the items it wraps. This provides a strong, protective barrier that keeps products intact and secure. Shrink wrap commercial applications often rely on this type of wrap to ensure that palletized products remain stable and are protected from external elements like moisture, dust, and contamination. For a variety of packaging needs, packing shrink wrap is also a great option, offering similar protection with a more customized fit to the products being wrapped.

Unlike other wrapping materials, pallet shrink wrap has a high level of stretchability, allowing it to tightly wrap around items and conform to their shape, ensuring better protection. This is one key difference between shrink wrap and stretch wrap, as stretch wrap does not shrink when heat is applied but is highly elastic, providing a secure hold by stretching around the items. Shrink wrap, on the other hand, offers a more tight-fitting, protective seal after shrinking. This makes shrink wrap an ideal choice for wrapping a wide range of goods, from delicate electronics to heavy industrial equipment.

Shrink wrap pallets refer to the process of using shrink wrap to secure products stacked on a pallet. The shrink wrap is applied around the goods, and then heat is used to shrink the film, creating a tight and durable seal. This method is commonly used for securing bulk shipments or for long-term storage.

When people refer to shrink wrap pallets, they are discussing the specific technique of applying shrink wrap to products stacked on a pallet. This is done to secure the items during handling, shipping, and storage. Shrink wrap pallets ensure that the goods remain firmly in place, preventing shifting or damage. It’s also commonly used for creating palletized units that are easier to handle and transport.

Factors that make Pallet Shrink Wrap an ideal choice:

Common uses of Pallet Shrink Wrap:

Pallet shrink wrap offers several benefits that make it an essential choice for businesses involved in the shipping and storage of palletized goods. This packaging solution not only ensures that items are securely wrapped but also provides a range of protective advantages that enhance the overall efficiency of the logistics process. In addition to pallet shrink wrap, parcel shrink wrap can be used for smaller shipments to offer similar protection. By using pallet shrink, companies can reduce the risks of damage, improve handling, and ensure goods are kept in optimal condition during transportation.

Pallet shrink wrap is ideal for securing palletized goods, ensuring that multiple items stacked on a pallet remain stable and in place. The shrink wrap film molds tightly to the shape of the products, preventing them from shifting during transit, which can help avoid damage. When palletized products are wrapped with shrink film, they are easier to handle, move, and store, improving efficiency in warehouses and reducing handling errors.

Key benefits of using pallet shrink wrap include:

The process of shrink-wrapping products and loading them onto pallets is essential for ensuring that the goods stay intact during transport. By securing the products with pallets shrink-wrapped, businesses can protect items from potential damage caused by handling or external conditions. Additionally, this method makes it easier to store and organize goods, improving warehouse efficiency and optimizing space utilization.

Additional benefits of using pallet shrink wrap:

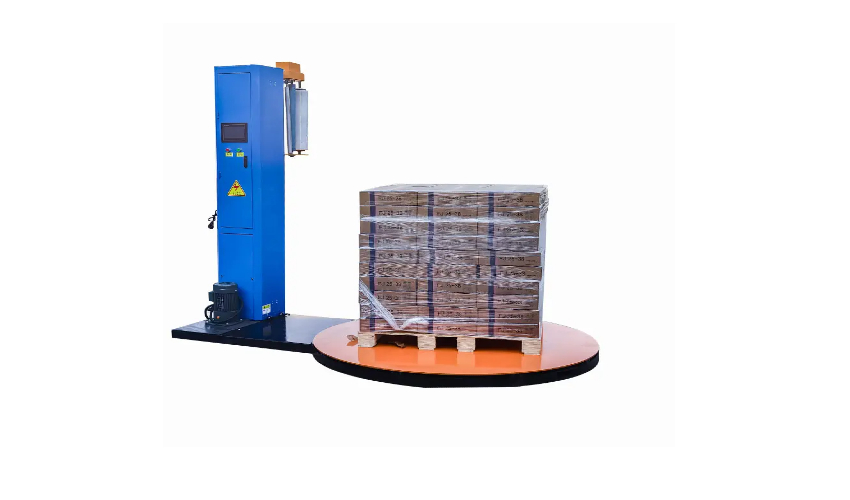

When it comes to applying pallet shrink wrap, the type of machine used plays a crucial role in determining the efficiency and quality of the wrapping process. Different machines are designed to accommodate varying production speeds, load sizes, and levels of automation. For operations that involve frequent movement of goods, a shrink wrap pallet jack can be particularly useful. This device allows for easy transport of palletized loads while they are being wrapped, ensuring that products are securely wrapped in a consistent manner. Selecting the right pallet shrink wrap machine, along with the appropriate tools, is essential for ensuring that products are wrapped securely and efficiently, whether for small batches or high-volume operations.

Pallet shrink wrap machines are specialized tools that apply shrink wrap to palletized goods. These machines come in different configurations, ranging from manual to fully automated systems. The main purpose of these machines is to apply shrink film tightly around the products, which is then heated to shrink and conform to the shape of the load.

There are several types of pallet shrink wrap machines, each suited for different types of packaging needs:

Key benefits of using pallet shrink wrap machines include:

One of the most advanced types of pallet shrink wrap machines is the automatic system with a conveyor. This system combines the power of automation with the flexibility of conveyor belts to move pallets through the wrapping process without requiring manual intervention. The conveyor feeds the palletized products into the shrink wrap machine, where the film is applied and then shrunk using heat.

The benefits of auto pallet shrink wrap with a conveyor system include:

For businesses that require flexibility, mobile pallet shrink wrap machines offer a great solution. These portable units allow operators to move the machine around the warehouse or production floor, wrapping pallets wherever they are located. Mobile shrink wrap machines are ideal for smaller operations or businesses that require flexibility in their packaging processes.

The benefits of mobile pallet shrink wrap machines include:

Key benefits of mobile pallet shrink wrap machines include:

Plastic shrink wrap is commonly used for securing palletized goods to ensure they stay stable and protected during transportation and storage. This type of shrink wrap provides a durable, tight seal around products, offering protection from moisture, dust, and dirt. It is particularly effective for goods that need to be kept safe in transit or while stored in warehouses. Pallet shrink wrap’s flexibility makes it an ideal choice for wrapping a wide range of products, from food to industrial materials, providing reliable protection against external contaminants.

Key benefits of using plastic shrink wrap for pallets include:

Pallet shrink wrap is often used for wrapping household appliances like refrigerators, washing machines, and dishwashers. These products are often large, heavy, and vulnerable to scratches, dents, and other types of damage during handling or transport. By using pallet shrink wrap, these items are securely fastened to the pallet, preventing movement and providing an added layer of protection from dust, moisture, and physical damage. The tight shrink film ensures the appliances remain protected throughout the shipping and delivery process.

Key benefits of using pallet shrink wrap for household appliances include:

Pallet shrink wrap is also commonly used to secure and protect chemical products, including containers of liquids, powders, and hazardous materials. Chemicals often need special care to avoid contamination, leakage, or exposure to the environment, which makes pallet shrink wrap an ideal choice. The shrink wrap film forms a tight seal around the chemical containers, offering an extra layer of protection against external elements such as moisture, dust, and other contaminants. For added protection in environments where moisture is a concern, waterproof shrink wrap can provide an enhanced barrier, ensuring the contents remain secure and dry even in wet conditions.

Key benefits of using pallet shrink wrap for chemicals include:

Portable pallet shrink wrap systems are ideal for businesses that require flexibility and mobility when wrapping products. These machines are designed to be compact and easy to transport, allowing operators to move them between different workstations or locations. Portable systems are often used for smaller-scale operations or in warehouses where space is limited. They offer the convenience of shrink wrapping pallets without the need for a fixed setup, making them a practical solution for industries with varying packaging needs.

Key benefits of using portable pallet shrink wrap include:

Professional shrink wrap pallet machines are high-end, automated systems designed for businesses with high-volume packaging needs. These machines are built to handle larger loads efficiently, ensuring consistent and high-quality shrink wrapping for pallets. Professional machines are typically used in large-scale warehouses or distribution centers where speed and precision are critical. They can accommodate a variety of shrink wrap materials and pallet sizes, making them versatile for different industries.

Key benefits of using professional shrink wrap pallet systems include:

The procedure for shrink wrapping pallets is a step-by-step process that ensures products are securely wrapped and protected. It begins with placing the palletized goods on the wrapping machine. The shrink wrap film is then applied around the load, followed by the use of heat to shrink the film tightly around the products. This method creates a strong, protective seal that helps prevent damage during storage and transportation.

Key steps in the procedure for shrink wrapping pallets include:

Envelope shrink wrap is a method where the pallet is wrapped in a large, pre-formed shrink wrap bag or envelope. This method is often used for irregularly shaped or larger loads that need extra protection. The pallet is simply placed inside the envelope, and the excess film is sealed at the bottom. Once the film is heated, it shrinks to tightly conform to the shape of the load, offering a secure and durable wrap. This method is especially beneficial for protecting large or heavy products that need extra stability.

Key benefits of using envelope shrink wrap for pallets include:

The cost of pallet shrink wrap depends on several factors, including the type of material, machine requirements, and the quantity purchased. These factors also influence the cost of wrapped pallet, as different types of pallet shrink wrap films, such as standard polyethylene shrink wrap or more specialized films with added features like UV resistance or higher tensile strength, come with different price points. The quantity purchased is another significant factor, as bulk orders generally lead to discounts and lower overall costs. Additionally, the choice between manual, semi-automatic, or fully automatic shrink wrap machines can impact the cost, with fully automated systems requiring a larger upfront investment but offering greater efficiency for high-volume operations.

Key factors influencing the cost of pallet shrink wrap:

Choosing the best pallet shrink wrap for your business requires evaluating several factors, such as the level of protection needed, durability, and cost-effectiveness. The best shrink wrap will depend on the specific products being wrapped—whether you’re shipping food, household appliances, or industrial equipment. High-quality shrink wrap films offer excellent puncture resistance, high tensile strength, and the ability to conform tightly to the load. Cost-effective options are available for businesses with budget constraints, while more robust and specialized films are ideal for protecting sensitive or heavy items.

What to look for when choosing the best pallet shrink wrap:

Pallet shrink wrap is readily available for purchase from a variety of suppliers, both online and in physical stores. When looking to buy shrink wrap, it’s important to consider the specific requirements of your business, such as film size, strength, and the type of shrink wrapping machine you plan to use. Suppliers offer shrink wrap in various roll sizes and types, so knowing the right specifications for your packaging needs will help you make an informed decision. Purchasing from reputable retailers ensures that you’re getting high-quality shrink wrap that will perform effectively.

Where to buy pallet shrink wrap:

Finding local suppliers for pallet shrink wrap can be an excellent way to ensure quick availability and minimize shipping costs. Many packaging and shipping supply companies carry shrink wrap in different sizes and material types, so sourcing locally allows businesses to access products faster, especially when they have urgent shipping deadlines. Additionally, local suppliers may offer the opportunity to inspect the quality of the product before purchase, ensuring it meets the specific needs of your business.

Benefits of sourcing pallet shrink wrap locally:

For smaller businesses or DIY projects, shrink wrapping a pallet without specialized equipment can be a simple and effective process. By following a few basic steps, you can quickly wrap products to protect them during storage or shipment. The process typically involves manually applying the shrink film around the pallet and then using heat to shrink it tightly to the load.

Step-by-step tips for easy pallet shrink wrapping:

This method is especially useful for low-volume operations, and even smaller businesses can get the job done efficiently without the need for expensive machinery.

Cement and similar materials like sand or gravel are typically not shrink-wrapped. While shrink wrap offers great protection against moisture and dust, cement pallets require a different approach due to the weight and nature of the material. Shrink wrap is not always the best solution for cement because it doesn’t provide the level of protection needed for heavy or potentially abrasive loads. Additionally, cement bags often require more robust wrapping, like machine stretch film or industrial-grade shrink films that can support the weight.

Why shrink wrapping may not be used for cement pallets:

Shrink wrap plays a crucial role in protecting frozen goods, such as ice cream, during shipping. These products require strict temperature control to maintain their quality and prevent thawing. Shrink wrapping helps ensure that ice cream pallets remain securely wrapped and insulated, protecting them from outside elements such as temperature fluctuations, moisture, and contaminants during transit.

How shrink wrap helps in maintaining the integrity of frozen pallets:

Shrink wrapping is particularly beneficial for keeping ice cream and other frozen foods in optimal condition until they reach their destination.

Shrink wrapping is an effective solution for securing pallets of heavy materials such as stone, bricks, or tiles. These types of loads are typically heavy, rough, and prone to shifting during transport, so proper packaging is essential for their safe delivery. Shrink wrap offers a cost-effective and efficient way to keep such materials stable and protected from environmental factors, such as moisture or dust.

Best practices for shrink wrapping stone pallets:

Shrink wrapping is particularly effective for stone and other heavy materials that need both secure packaging and protection from external elements.

The amount of shrink wrap needed for a pallet will depend on the size and weight of the load. Ensuring that the load is properly wrapped with enough film is essential for providing adequate protection during transit. Typically, more shrink wrap is needed for heavier or irregularly shaped loads, while smaller or lighter loads may require less.

Tips for determining how much shrink wrap to use:

Ensuring you have the right amount of shrink wrap can help improve the security and stability of the pallet load, reducing the likelihood of damage during shipping.

When purchasing pallet shrink wrap in bulk, businesses must consider several factors to ensure cost-effectiveness, product quality, and compatibility with their packaging needs. Wholesale purchases involve evaluating the material type, gauge, size, stretchability, and load containment capabilities to optimize wrapping efficiency and ensure product safety. Additionally, understanding the technical data characteristics of pallet shrink wrap helps buyers select the right film for their specific applications. This guide outlines the key factors to consider when wholesaling pallet shrink wrap, followed by an in-depth look at the crucial technical data characteristics that impact performance and usability.

Buying pallet shrink wrap in bulk requires careful evaluation to ensure the chosen film meets operational requirements while maintaining cost efficiency. Several critical aspects must be assessed when selecting the right supplier and product.

The quality of pallet shrink wrap is directly linked to its durability and effectiveness in securing loads. Buyers should consider:

Wholesale buyers should compare pricing across different suppliers to ensure they receive competitive rates while maintaining quality assurance. Important considerations include:

The shrink wrap must be compatible with existing wrapping equipment to prevent inefficiencies or increased operational costs. Buyers should check:

Different warehouse conditions require specific film properties for optimal performance and longevity. Factors to consider include:

Understanding the technical specifications of pallet shrink wrap is crucial to selecting the right film for load security, efficiency, and cost-effectiveness. The following data characteristics play a significant role in wrap performance.

The gauge determines the film’s durability and load containment capacity. Common gauges include:

Thicker films provide greater protection but may increase costs, so buyers must balance strength vs. efficiency based on their needs.

Stretch wrap films are designed to stretch and conform to the shape of the load while maintaining elasticity. Key stretch properties include:

The wrap’s ability to cling to itself without adhesives ensures load stability. Some films have:

Load containment force refers to the wrap’s ability to hold a load tightly without shifting, which is crucial for transportation.

The dimensions of pallet shrink wrap affect wrapping efficiency and coverage. Standard sizes include:

Longer rolls minimize downtime by reducing the need for frequent roll changes.

Depending on product visibility requirements, pallet shrink wrap comes in different colors:

Some applications require advanced film properties, such as:

Wholesale purchasing of pallet shrink wrap requires careful consideration of quality, cost, equipment compatibility, and environmental factors to ensure maximum efficiency. Additionally, understanding key data characteristics, including gauge, stretchability, cling properties, and roll dimensions, helps buyers choose the right film for their specific needs. By evaluating these factors, businesses can ensure secure, cost-effective, and efficient pallet wrapping solutions for storage and transportation.

Pallet shrink wrap is a crucial packaging material used for securing and stabilizing palletized goods during transportation and storage. While it can be applied manually, using Stretch Wrap Machines significantly improves efficiency, consistency, and load stability. However, machines are not the only tools involved in the pallet shrink wrap process. Several additional products and accessories enhance the wrapping process, ensuring maximum protection, durability, and ease of application. This guide explores whether Stretch Wrap Machines are necessary, their benefits, and other essential tools and accessories used in conjunction with pallet shrink wrap.

Stretch Wrap Machines are highly recommended for businesses that wrap multiple pallets daily, as they improve speed, reduce material waste, and provide even tension for better load containment. These machines come in different types, each suited for various packaging needs:

Using a Stretch Wrap Machine enhances efficiency, reduces labor costs, and minimizes film waste, making it a valuable investment for businesses handling large volumes of palletized shipments.

For small-scale operations or occasional pallet wrapping, manual wrapping with hand stretch wrap is a cost-effective alternative. Manual application is suitable for:

When wrapping manually, proper technique is crucial to ensure even tension and load stability. Workers should use a stretch wrap dispenser to maintain consistent application and reduce hand fatigue. While manual wrapping is flexible, it can be time-consuming and inconsistent compared to machine wrapping.

Beyond Stretch Wrap Machines, several tools and accessories enhance the wrapping process, ensuring efficiency, safety, and durability.

Hand-held stretch wrap dispensers are essential for manual wrapping, providing better control over tension and reducing worker strain. These dispensers come in lightweight plastic models or heavy-duty metal versions for durability.

Pallet covers and top sheets provide an additional layer of dust, dirt, and moisture protection. They are often made from polyethylene plastic and can be applied before or after wrapping for added security.

For pallets with fragile or sharp-edged products, using corner protectors prevents film tearing and protects the load from damage during transit. These are especially useful for wrapping stacked boxes or delicate materials.

When using heat-shrinkable pallet wrap, a heat shrink gun is required to tighten and conform the film around the load. These are typically used for outdoor storage or high-security shipments.

For extra reinforcement, plastic or steel strapping can be applied before shrink wrapping to secure heavy or unstable loads. Strapping tools include tensioners, sealers, and automatic strapping machines.

To maintain clear product visibility, companies use label holders or stretch wrap with label windows. These prevent important information from being obscured by the wrap.

The choice between manual vs. machine wrapping and the selection of accessories depends on:

While pallet shrink wrap can be applied manually, Stretch Wrap Machines significantly enhance efficiency, consistency, and load stability. Depending on the volume and type of shipments, businesses may opt for manual dispensers, strapping tools, heat shrink guns, or additional protective accessories. Understanding the available tools ensures cost-effective, secure, and efficient pallet wrapping, helping businesses maintain product integrity and reduce damage risks during transit and storage.

Pallet shrink wrap is widely used for securing and protecting palletized goods during storage and transportation. While traditional shrink wrap is designed for single-use, increasing environmental concerns and cost-efficiency demands have led to discussions on its reusability. Reusing pallet shrink wrap requires advancements in material technology, application methods, and recycling processes. Below, we explore the feasibility of reuse and the technological innovations needed to achieve it.

To make pallet shrink wrap reusable, materials must be developed to withstand multiple heating and cooling cycles without degrading.

Reusing shrink wrap requires improvements in how it is applied and removed to minimize damage.

If direct reuse is not possible, efficient recycling methods can turn used shrink wrap into new wrap or alternative products.

While traditional pallet shrink wrap is single-use, technological advancements in material science, application techniques, and recycling processes could enable reusability. These innovations can reduce waste, lower costs, and improve sustainability in logistics and packaging.

Pallet wrap and shrink wrap are related but distinct types of packaging films used for different purposes. While they may appear similar at first glance, their functions and characteristics differ. Pallet wrap, often referred to as stretch wrap, is a highly stretchable plastic film used to securely wrap and stabilize loads on pallets. It is typically made of linear low-density polyethylene (LLDPE) and is used primarily for bundling products together during transport or storage.

Shrink wrap, on the other hand, is a plastic film that shrinks tightly around an item when heat is applied. It is used for securing products, protecting them from environmental elements like dust, moisture, and dirt, and often offers a more rigid, tightly-sealed finish. While pallet wrap (stretch wrap) is used to secure the load without shrinking, shrink wrap offers a tighter, more rigid fit, which can be more protective in certain situations.

In summary, pallet wrap (stretch wrap) and shrink wrap serve different purposes. Pallet wrap is ideal for stabilizing and securing palletized goods during transit, while shrink wrap provides a more protective, sealed covering.

Shrink wrapping a pallet is a straightforward process that can be done manually or with the help of shrink wrapping machines, depending on the volume of pallets being wrapped. The goal is to ensure the load is tightly secured and protected from moisture, dust, and other external elements during transport or storage. Here’s a simple guide on how to shrink wrap a pallet:

Prepare the Pallet: Ensure the pallet is stable, and all items are positioned securely. If there are any sharp edges, protect them to avoid puncturing the shrink wrap.

Select the Right Shrink Film: Choose the appropriate shrink wrap for your pallet. The thickness and type of shrink film will depend on the nature of the goods being wrapped. Standard shrink wrap is usually fine for lightweight items, while more robust films are needed for heavier or fragile products.

Wrap the Pallet: Start by placing the shrink wrap around the base of the pallet, ensuring it covers the bottom completely. Then, proceed to wrap the rest of the pallet, moving upwards and around each layer of goods.

Apply Heat: Use a heat gun or shrink wrap tunnel to apply heat to the shrink film. The film will shrink tightly around the items as it is exposed to heat, providing a secure, tight seal.

Check for Secure Wrapping: Once the pallet is fully wrapped, check for any loose areas and reapply heat if necessary. The shrink wrap should be smooth, without any gaps or wrinkles, to ensure the load is secure.

Using shrink wrap to wrap a pallet is an effective way to protect goods during shipping, especially in harsh conditions. Whether for small or large quantities, shrink wrapping offers reliable protection for palletized loads.

The cost of wrapping a pallet depends on several factors, including the type of shrink wrap used, the gauge (thickness), the number of wraps per pallet, and the size of the pallet. On average, the cost can range from $0.50 to $2 per pallet when using standard machine-grade stretch film. If using high-performance stretch wrap, costs might be slightly lower due to better stretchability and coverage. For manual wrapping, costs can vary based on the efficiency of the wrapper and the type of film used. Additional costs may apply for colored or specialty wraps designed for UV resistance or tamper-evidence. The total expense also depends on whether the pallet is wrapped by hand or machine, as automated wrapping machines optimize film usage, reducing waste and costs. Bulk purchasing of wrap rolls can further lower the per-pallet cost, making it a more economical choice for large-scale operations.

The gauge of shrink wrap required for pallets depends on the weight and nature of the load. Common gauges include:

60–80 gauge: Suitable for light loads up to 1,500 lbs. Ideal for standard retail or warehouse shipments.

90–120 gauge: Used for medium-weight loads (1,500–2,500 lbs.), offering enhanced durability.

150+ gauge: Best for heavy or irregular loads (over 2,500 lbs.), preventing punctures and tears.

For high-performance stretch films, lower gauges (e.g., 50-63 gauge) may be sufficient due to advanced strength and stretchability. Pre-stretched wrap (about 50-70 gauge) provides excellent load containment while reducing material use. Machine-grade stretch films often range from 63 to 120 gauge for consistent tension. Choosing the right gauge prevents product shifting and damage while optimizing cost efficiency. The correct selection depends on factors such as transport conditions, pallet weight, and wrapping method (manual or machine).

The number of pallets covered by a single roll of shrink wrap depends on the roll size, gauge, and wrapping technique. Standard 18-inch-wide hand stretch wrap rolls (1,500 feet long, 80 gauge) can wrap approximately 30–50 pallets, assuming five full revolutions per pallet. Higher-gauge films or inefficient wrapping may reduce coverage.

For machine-grade stretch film, a standard 5,000-foot roll can cover between 150 and 250 pallets, depending on film stretch and load type. Pre-stretched films improve efficiency, reducing film usage by up to 50% per pallet. Factors like load size, wrapping pattern, and film overlap impact total coverage. Using a turntable wrapper with consistent tension maximizes film usage. Bulk orders often specify estimated pallet coverage per roll, helping businesses budget wrap costs effectively. Optimizing wrap technique—such as avoiding excessive overlap—ensures maximum pallets per roll, reducing waste and improving cost-effectiveness.

The best shrink wrap for pallets depends on load size, weight, and shipping conditions. High-performance stretch film is ideal for most applications due to its elasticity, durability, and cost-effectiveness.

Hand Stretch Wrap: Used for manually wrapping pallets; typically available in 80 to 120 gauge for secure containment.

Machine Stretch Wrap: Designed for automated pallet wrapping; offers consistent tension and reduces material waste.

Pre-Stretched Wrap: Requires less force when applying and provides excellent load stability with minimal film usage.

Blown Stretch Film: Offers superior puncture resistance and strength, ideal for irregular or heavy loads.

Cast Stretch Film: Provides high clarity for easy product identification and quieter unwinding.

For extreme conditions, UV-resistant, anti-static, or vented stretch films may be necessary. Choosing the right type ensures cost efficiency and protects products during transit.

The standard size of pallet wrap varies based on application needs. The most commonly used hand stretch wrap measures 18 inches wide and comes in rolls ranging from 1,000 to 1,500 feet long. For machine stretch wrap, widths typically range from 20 to 30 inches, with roll lengths from 5,000 to 9,000 feet.

Standard pallet dimensions (40″ x 48″) dictate wrap size requirements. Pallet wrap widths of 12, 15, or 18 inches are common for hand applications, while larger widths (20–30 inches) are best for machine wrapping. The thickness (gauge) also impacts wrap effectiveness, with 60 to 120 gauge being the most used.

Choosing the right size ensures efficient wrapping, proper load containment, and reduced film waste. For irregular loads, specialty wraps such as vented or reinforced stretch films may be necessary.

Yes, pallet wrap is water-resistant but not entirely waterproof. Most stretch films provide an effective barrier against moisture, dust, and dirt, protecting palletized goods during storage and transport.

While standard stretch wrap repels light rain and humidity, it is not fully waterproof in prolonged exposure to water. For enhanced protection, waterproof pallet covers or shrink hood films are used, which offer a tighter seal and superior moisture resistance.

Blown stretch film provides better protection against external elements due to its stronger tensile strength and thicker composition. Some stretch films are designed with UV inhibitors, protecting loads from sunlight damage during outdoor storage.

For maximum water protection, using shrink wrap with heat sealing creates a tight, nearly waterproof covering. Additionally, wrapping pallets with multiple layers and proper overlapping helps reduce water penetration.

The number of wraps required depends on load weight, stability, and transportation conditions. Generally, pallets should be wrapped 4 to 6 times, ensuring sufficient tension and coverage for stability.

Lightweight loads (under 1,000 lbs.): 3 to 4 wraps may be sufficient.

Medium loads (1,000–2,500 lbs.): 5 to 6 wraps provide better containment.

Heavy or irregular loads (over 2,500 lbs.): 6+ wraps or reinforced film ensures maximum security.

For optimal wrapping, start at the pallet base, applying at least two layers around the bottom for stability. Work upwards, overlapping each layer by 50%. Finish with a few additional wraps at the top for extra containment.

Using pre-stretched film reduces the number of layers required while maintaining load security. Machine wrapping also optimizes film usage, applying the right amount for each load.

Shrink wrap is also commonly known as:

Stretch wrap – The most widely used term for wrapping pallets, emphasizing its elasticity.

Pallet wrap – Specifically refers to shrink wrap used for securing palletized loads.

Stretch film – A general industry term for various types of plastic wrapping film.

Shrink film – Refers to film that requires heat to shrink and conform tightly around products.

Plastic wrap – A broad term that may also apply to household and industrial wrapping films.

Cling wrap – Although typically used for food wrap, some industrial films have similar adhesive properties.

Packaging film – Describes film used for securing and protecting goods during transport.

Each term is used differently, depending on the application—stretch wrap is common for pallet wrapping, while shrink film is often associated with heat-sealed packaging.

Pallet wrap is not traditionally sticky but has a clingy or tacky surface that allows it to adhere to itself. This self-clinging property keeps the wrap in place without needing adhesives.

Cast stretch film has a smooth, high-clarity surface with one-sided cling, making it less likely to stick to other objects.

Blown stretch film has a more tacky texture and offers superior load stability due to its high cling properties.

Pre-stretched film has a lighter tack but maintains strong grip due to its elasticity.

While pallet wrap clings to itself, it does not leave residue on products, making it ideal for packaging sensitive items. Some specialty films, like anti-static wrap, have reduced cling to prevent static buildup. For loads that need added friction, high-cling or double-sided stretch film is available.

To determine the correct shrink wrap size, consider:

Pallet Dimensions: Measure width, length, and height of the load.

Shrink Film Width: Choose a film 1.5 to 2 times wider than the largest pallet dimension to ensure full coverage.

Shrink Rate: Most films shrink 30-50% when heated, so factor this into your calculations.

Gauge Selection:Light loads (under 1,000 lbs): 60-80 gauge

Medium loads (1,000-2,000 lbs): 100-150 gauge

Heavy-duty loads (2,000+ lbs): 200+ gauge

Using the right size prevents wasted material and ensures proper load security during transit.

200 gauge shrink wrap is thicker than 100 gauge.

100 gauge = 1 mil (0.001 inches) thick – Used for medium-duty packaging and wrapping.

200 gauge = 2 mils (0.002 inches) thick – Ideal for heavy-duty protection and industrial use.

A thicker gauge provides more strength and puncture resistance, but it is also less flexible and more expensive. Choosing between 100 and 200 gauge depends on pallet weight, shipping conditions, and storage needs.

200 gauge shrink wrap is equivalent to 2 mils (0.002 inches) thick. This is a heavy-duty shrink wrap used for palletized goods, machinery protection, and industrial packaging.

For comparison:

60 gauge = 0.6 mil (thin)

80 gauge = 0.8 mil (standard pallet wrap)

200 gauge = 2 mil (very thick)

200 gauge shrink wrap is resistant to tears, punctures, and extreme conditions, making it ideal for long-term storage and heavy loads.

80 gauge shrink wrap is thicker than 60 gauge. The higher the gauge number, the thicker and stronger the film.

60 gauge: Light-duty shrink wrap, best for small or lightweight items.

80 gauge: Standard strength, used for most general-purpose pallet wrapping.

Thicker gauges offer better durability, puncture resistance, and load stability. However, they also increase material costs. Choosing the right gauge depends on the weight, shape, and fragility of the palletized goods.

To calculate how much shrink wrap you need for a pallet, use this formula:

Measure the pallet dimensions:Width (W), Length (L), and Height (H).

Estimate Film Coverage Per Wrap:Film width should be at least 1.5 times the widest pallet side.

Determine Film Usage:For Hand Wrapping: Estimate 150-300 feet per pallet depending on the number of layers.

For Machine Wrapping: Use 100-200 feet per pallet due to film stretching.

Example: For a 40” x 48” x 60” pallet with 3-5 wraps, expect to use 200-250 feet of film.

Using pre-stretched wrap or optimizing layers helps reduce material waste and costs.

To shrink wrap a pallet without a machine, follow these steps:

Select the Right Shrink Wrap Film – Use polyethylene or PVC shrink wrap that suits your pallet load.

Wrap the Pallet Securely –Unroll the film around the base of the pallet several times for stability.

Cover the entire load with the film, ensuring a snug fit.

Use a Heat Gun or Propane Torch –Start at the bottom and slowly apply heat, moving in even sweeps.

Avoid overheating, as this can cause holes or weak spots in the wrap.

Allow to Cool – Once the shrink wrap tightens, let it set before moving the pallet.

While manual shrinking is possible, using a shrink wrap machine ensures better consistency and efficiency.

To size shrink wrap correctly, consider product dimensions, shrink percentage, and thickness (gauge):

Measure the Load:Measure length, width, and height of the palletized goods.

Choose the Right Shrink Film Size:The film should be 25-50% larger than the item to allow proper shrinkage.

Select the Right Gauge:45-75 gauge: Light-duty items.

100-150 gauge: Medium-weight loads.

200+ gauge: Heavy-duty or sharp-edged products.

Account for Shrink Rate:Most shrink films shrink 30-50% when heated, so select a film that fits when fully shrunk.

Proper sizing ensures secure, tight wrapping without excess material waste.

Shrink wrap and pallet wrap serve different purposes in packaging:

Shrink Wrap: A heat-activated plastic film that shrinks tightly around a product when exposed to heat. Used for securing products for shipping, bundling items, or protecting goods from moisture and dust.

Pallet Wrap (Stretch Wrap): A stretchable plastic film used to wrap and secure pallets. Unlike shrink wrap, it does not require heat—instead, it stretches and clings to itself to hold the load in place.

For palletizing, stretch wrap is preferred since it provides load stability, protection, and ease of application. Shrink wrap is more common for smaller retail packaging, equipment protection, and long-term storage.

The number of times you should wrap a pallet depends on load weight, stability, and transit conditions. As a general guideline:

Lightweight loads (<1,000 lbs): 2-3 layers of wrap.

Medium loads (1,000-2,000 lbs): 3-5 layers, ensuring full coverage.

Heavy or irregular loads (>2,000 lbs): 5+ layers for extra reinforcement.

Start by wrapping the base at least 3-5 times to anchor the load to the pallet. Work upward with overlapping layers, ensuring 50% overlap per wrap. For added stability, wrap back down to the base.

Machine wrapping requires fewer layers due to pre-stretch capabilities, while hand-wrapping needs more passes to maintain tension. Testing different wrapping techniques can help optimize film usage while ensuring pallet security.

Shrink wrap itself does not directly damage wood furniture, but improper application can cause issues. Potential risks include:

Trapped Moisture: If wood furniture is wrapped before it’s completely dry, condensation can form, leading to mold or warping.

Heat Damage: Applying excessive heat during the shrinking process can scorch or deform wooden surfaces.

Adhesion Issues: Some shrink wrap contains chemicals that react with certain wood finishes, causing discoloration or stickiness.

To protect wood furniture, follow these steps:

Wrap the furniture in a soft protective layer (such as moving blankets or foam) before applying shrink wrap.

Avoid excessive heat near delicate wood surfaces.

Leave small ventilation gaps to prevent moisture buildup.

When done correctly, shrink wrap provides excellent dust, scratch, and moisture protection without harming the furniture.

To effectively shrink wrap a pallet, follow these steps:

Choose the Right Film: Use high-quality shrink film suited for pallet loads, typically polyethylene or PVC film.

Position the Film: Place the film around the base of the pallet, ensuring full coverage.

Secure the Wrap: Use heat-resistant tape or tie the film to prevent it from shifting before shrinking.

Apply Heat Evenly: Use a heat gun or shrink tunnel to evenly apply heat around the wrap. Start from the bottom and work upwards to shrink the film tightly.

Check for Gaps: Ensure the wrap fully conforms to the load without weak spots.

Allow Cooling Time: Let the film set before moving the pallet to avoid tears or warping.

Using the correct temperature and technique ensures secure, tamper-proof, and weather-resistant packaging for shipping and storage.

The amount of pallet wrap required depends on pallet size, wrap gauge, and the number of layers used. A typical pallet (40” x 48” x 60”) may require:

Hand Wrapping: ~150-300 feet of stretch film per pallet.

Machine Wrapping: ~100-200 feet per pallet due to pre-stretch capabilities.

A standard 18-inch wide roll of stretch wrap (1,500 feet long) can wrap 5 to 10 pallets, depending on the number of wraps applied. Heavier or fragile loads may require multiple layers, increasing film usage.

Using pre-stretched wrap reduces the amount needed while maintaining stability. Proper wrapping technique also helps minimize waste and ensure cost-effective pallet wrapping.

The time required to wrap a pallet depends on factors like method (manual vs. machine), load complexity, and operator experience. On average:

Manual wrapping takes 3-5 minutes per pallet, depending on the number of layers and wrap quality.

Semi-automatic stretch wrappers can wrap a pallet in 30-60 seconds, making them ideal for high-volume operations.

Fully automatic stretch wrappers can wrap pallets in under 20 seconds, reducing labor costs and increasing efficiency.

For high-volume warehouses, investing in a stretch wrapping machine significantly improves productivity. Manual wrapping, while cost-effective for small businesses, is slower and can lead to inconsistencies in load security.

While stretch and shrink wrap are the most common methods for securing pallets, alternatives exist depending on cost, environmental concerns, and load type:

Strapping (Plastic or Steel Bands): Provides strong hold for heavy or rigid loads but lacks dust and moisture protection.

Pallet Netting: A breathable alternative to shrink wrap, ideal for produce and perishable goods that need air circulation.

Reusable Pallet Covers: Made from durable materials, these covers reduce plastic waste and offer protection for returnable shipments.

Adhesive or Anti-Slip Sheets: Placed between layers to prevent shifting, often used in combination with minimal wrap.

Corrugated Pallet Wraps: Cardboard-based wraps that stabilize loads while being recyclable.

Each method has its benefits and limitations, but shrink wrap remains the most effective and versatile for palletized goods.

Wrapping pallets manually can be challenging, especially for large or irregular loads. It requires physical effort, proper technique, and experience to ensure the pallet is secure. Key challenges include:

Even Tension: Wrapping too loosely leads to unstable loads, while excessive tension can cause film breakage.

Proper Overlap: The wrap must overlap correctly to prevent gaps that could cause shifting.

Bottom Wrapping: Wrapping tightly around the pallet base is crucial for load stability.

Film Breakage: Using the wrong gauge or incorrect wrapping technique can lead to film tearing.

Machine stretch wrappers simplify the process and reduce labor costs, making wrapping more consistent and efficient. However, manual wrapping is still common in smaller operations. Using pre-stretched film can also make the process easier, requiring less effort while providing a strong hold.

Pallet wrap, also known as stretch film, is available in various thicknesses, measured in gauge. The most common gauges used for pallet wrapping are:

60-80 gauge – Ideal for wrapping lightweight loads (under 1,500 lbs).

90-120 gauge – Suitable for medium-weight pallets and provides added puncture resistance.

150+ gauge – Heavy-duty wrap for sharp-edged or very heavy pallets exceeding 2,000 lbs.

A higher gauge means thicker film, offering better durability and load retention. For machine stretch wrapping, 80 to 120 gauge is commonly used, whereas hand wrapping typically uses 60 to 80 gauge for ease of use.

Choosing the right gauge depends on the type of load, transit conditions, and handling requirements. Using the wrong gauge could lead to pallet instability or excessive film use, increasing costs.

Shrink wrap and vacuum packaging are both used for sealing products, but they function differently. Shrink wrap is a plastic film that is wrapped around a product or pallet and then heated to shrink tightly around it. It provides protection from dust, moisture, and tampering while keeping the load stable. Shrink wrap is commonly used in pallet wrapping, retail packaging, and industrial storage.

Vacuum packaging, on the other hand, involves removing air from the package before sealing it. This method is primarily used for food storage, medical products, and electronics, as it prevents oxidation, mold growth, and contamination. Unlike shrink wrap, vacuum packaging requires specialized machines to extract air and seal the bag or film around the product.

For palletizing, shrink wrap is the preferred method since vacuum sealing is not practical for large loads. It keeps pallets secure for shipping and storage.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed