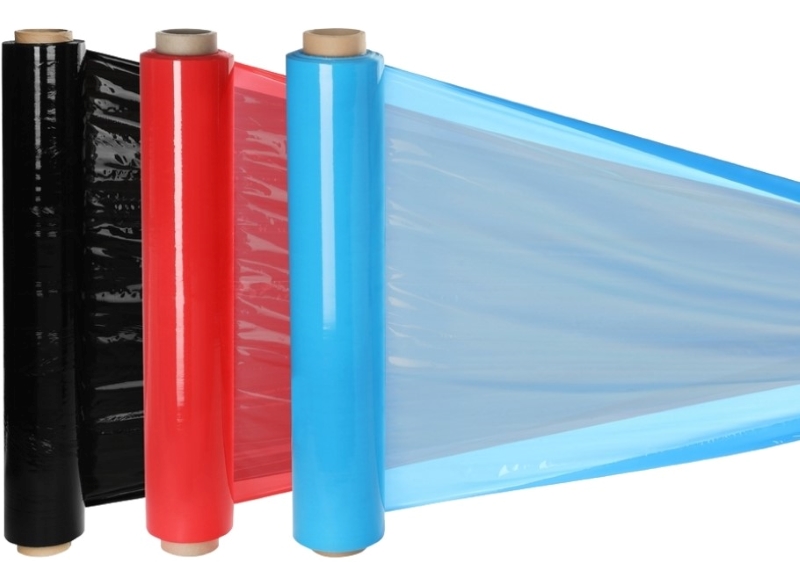

Pallet wrap plays a vital role in modern packaging, providing essential protection and stability for products during storage and transportation. When it comes to specialized applications like framing, using pallet wrap colors on frame offers significant advantages beyond simple containment. Colored pallet wrap helps businesses streamline operations by enabling quick product identification and efficient inventory management. For framing-related applications, these wraps not only safeguard delicate frames from dust, scratches, and moisture but also enhance organization by marking different products or shipment priorities. By integrating pallet wrap colors on frame into their processes, companies can boost productivity and ensure smooth workflows. This method simplifies sorting, improves production tracking, and offers tamper-evident security—delivering both operational efficiency and product protection in one cohesive solution. Pallet wrap colors on frame enhance scheduling, handling, and efficiency, ideal for color coding, product ID, and tamper-proofing in vibrant hues.

Why Choose Our Stretch Film Over Competitors?

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Product Name | Pallet Wrap |

| Material | Polyethylene |

| Features | Moisture-proof, Waterproof |

| Hardness | Soft |

| Processing Type | Casting, Blow Molding |

| Transparency | Transparent, Opaque |

| Color | Customized |

| Thickness | Customized |

| Length | Customized |

| Width | Customized |

| Size | Customized |

| Weight | Customized |

| Surface | Smooth |

| Elongation | 300% to 500% |

| OEM | Avaliable |

| Logo Printing | Customized Logo Accepted |

| Certificate | ISO |

| Use | Machine/Hand Pallet Wrap |

| Packaging | Standard Carton Packaging |

| Sales Unit | Single Item |

| Supply Capacity | 1600 Tons/Month |

Pallet wrap, also referred to as stretch film, is a versatile plastic material used to secure and protect items during storage and transportation. In framing applications, pallet wrap colors on frame offer more than just basic containment—they provide an added layer of efficiency and protection. This type of wrap tightly clings to objects, ensuring that fragile frames, legs, and edges are safeguarded against dust, moisture, and physical damage.

Colored pallet wrap is particularly useful in framing, as different colors can be used to distinguish products by size, material, or priority. Unlike standard clear wrap, colored wraps make it easier to identify and manage inventory. For example, an art gallery might use blue wrap for wooden frames and green for metal ones. Color stretch film can also help to differentiate between production batches, streamlining sorting and tracking. Using pallet wrap colors on frames simplifies the production process by clearly marking batches or orders, reducing confusion and improving workflow. These wraps function just like standard stretch film but offer the added benefits of better organization and tamper resistance, which is especially important for valuable or fragile frames.

The use of pallet wrap colors on frame brings numerous advantages to businesses, especially those involved in framing or handling delicate products. Beyond securing items, colored pallet wrap provides a powerful tool for identification, organization, and process management. Let’s explore two key areas where this strategy offers significant benefits.

One of the primary reasons to use pallet wrap colors on frame is to improve the organization of frames by assigning specific colors to different categories. Businesses can mark frames based on priority levels, material types, or delivery schedules. This color-coded system makes it easy for workers to sort and identify products at a glance, preventing mix-ups and saving time. For instance, an art distributor might use blue pallet wrap for delicate photo frames and green wrap for sturdy wooden frames. This method ensures quick and accurate identification, especially in fast-paced environments where shipments need to be organized efficiently.

In addition to organizing inventory, pallet wrap colors on frames also simplify production and shipping management. Assigning colors to orders or shipments allows businesses to track priorities and manage workflows effectively. For example, red-colored wrap can indicate urgent shipments, ensuring they receive priority handling, while yellow wrap might be used for non-priority or standard deliveries. This color-coding helps prevent delays, improves tracking accuracy, and ensures that production and shipping processes remain smooth and well-organized. The integration of stretch film production in this process also contributes to efficiency, as businesses can synchronize the use of different wrap colors with production schedules. Whether used in warehouses or shipping facilities, colored wraps streamline operations, reduce errors, and boost overall productivity by providing clear visual cues for employees, while also supporting consistent material usage across the supply chain.

Utilizing pallet wrap colors on frame offers several critical benefits beyond basic packaging. This strategy not only secures products but also optimizes protection, enhances tamper resistance, and improves inventory management. These advantages are particularly valuable for businesses that handle fragile frames, high-value items, or complex shipping schedules.

Colored pallet wraps provide the same durability, elasticity, and performance as standard stretch films, making them effective for securely wrapping and protecting frames. They prevent external factors such as scratches, dust, and moisture from damaging sensitive items during storage or transport. Wrapping delicate frame edges or legs in color-coded film also minimizes the risk of accidental damage when products are moved or stacked. Whether used in art galleries, furniture stores, or shipping facilities, pallet wrap colors on frame ensure that frames arrive at their destination in perfect condition.

Using colored or opaque pallet wraps makes tampering more visible, providing an extra layer of security. When customers or staff can easily notice if a wrap has been altered, it helps prevent unauthorized access or theft. In some cases, businesses may use black pallet wrap for added UV resistance and privacy, protecting sensitive or high-value items from both sunlight and prying eyes. This feature is particularly beneficial for industries that handle valuable artwork or fragile frames, where maintaining product integrity is crucial. Pallet wrap colors on frame not only protect the product but also signal tampering, ensuring customer trust.

Color-coding frames with pallet wrap simplifies inventory management and product tracking. Assigning different colors to batches based on priority, production schedules, or day of manufacturing ensures that frames are easily identified and organized. For instance, employees can quickly spot a high-priority order wrapped in red wrap film or identify products for routine shipment in blue or green wrap. By using pallet wrap colors on frame, businesses can streamline inventory checks, improve efficiency, and avoid costly errors, ensuring that production and shipping workflows remain smooth and effective. This system saves time, reduces confusion, and boosts overall productivity.

Selecting the appropriate pallet wrap colors on frame is essential for businesses aiming to enhance efficiency, organization, and brand consistency. The choice of colors should align with specific business needs, including product type, production schedules, and branding efforts. Let’s explore the key factors to consider when deciding which colored wraps to use for your framing operations.

Using pallet wrap colors on frame based on product type ensures better categorization and faster identification. Assigning specific colors to different frames allows employees to distinguish between materials or finishes quickly. For example, blue stretch wrap might be used for glass or delicate photo frames, while green wrap could indicate wooden or metal frames. This strategy helps prevent mix-ups, especially when working with large inventories, and ensures that the correct frames are shipped to the right clients. Color-based categorization also speeds up packaging processes and minimizes the risk of shipping errors.

Another practical way to use pallet wrap colors on frames is to assign colors to specific days or production batches. This method makes it easier to track frame production schedules and monitor the age of products in inventory. For instance, a business could use yellow wrap on Monday’s production batch and orange stretch wrap for Tuesday’s frames. This simple but effective approach ensures that older inventory gets shipped out first, reducing waste and maintaining product freshness. Additionally, businesses can efficiently manage the shavings of stretch film left over after wrapping, as color-coding makes it easier to identify and sort waste materials by batch or production day. Day-based color coding also improves accountability by allowing businesses to trace issues back to specific production days or batches, and helps in managing both product inventory and stretch film waste more effectively.

Incorporating company colors into pallet wrap colors on frame provides a great opportunity to enhance brand identity and consistency. Using wraps in custom colors that align with brand aesthetics can leave a lasting impression on customers, especially when products are delivered or displayed in stores. Additionally, branded pallet wraps offer a unique way to stand out from competitors, particularly in industries where presentation matters. Businesses can even take it a step further by printing logos or slogans directly on the wrap, reinforcing brand recognition throughout the supply chain. This strategy creates a polished and professional look, building customer trust and loyalty.

Choosing the right pallet wrap colors on frame ensures that businesses achieve both practical and aesthetic goals, leading to smoother operations and a stronger brand presence.

The strategic use of pallet wrap colors on frame is helping various industries enhance their operational efficiency and product management. In real-world applications, businesses have discovered that color-coded wraps not only improve organization but also minimize errors and streamline complex workflows. Below are two practical examples demonstrating how specific industries effectively leverage pallet wrap colors on frame to manage their processes.

Art galleries often handle delicate and high-value frames, making careful packaging a priority. To avoid confusion and improve order management, some galleries have implemented a system of pallet wrap colors on frame to categorize and prioritize different types of framing orders. For example, a gallery may use blue wrap for photo frames that require extra care during shipment and green wrap for sturdy metal or wooden frames intended for quick installation. This method ensures that employees can immediately identify the type of frame and its associated care level, reducing the chance of damage and enhancing customer satisfaction. Additionally, the color-coded wraps help the gallery manage multiple framing orders efficiently, ensuring that urgent pieces are prioritized and shipped on time.

Furniture manufacturers deal with numerous components that require precise identification and assembly. Many companies use pallet wrap colors on frame and furniture parts, such as legs and edges, to streamline their assembly process. For instance, they may assign red wrap for legs intended for chairs and yellow wrap for table legs, ensuring that components are correctly identified and assembled without delays. This system not only simplifies the assembly process but also minimizes errors by making it easy for workers to sort parts at a glance. When shipping large furniture sets, manufacturers use the same pallet wrap colors on frame to group related items, preventing mismatches and ensuring that all pieces arrive organized and ready for assembly.

These case studies highlight how pallet wrap colors on frame provide practical solutions to real-world challenges, improving organization, reducing errors, and boosting efficiency across various industries. Whether in art galleries or furniture manufacturing, color-coded wraps have proven to be a valuable tool in managing production, assembly, and delivery processes.

Purpose:

User Experience:

Purpose:

User Experience:

Colored pallet wrap simplifies production workflows by assigning specific colors to product batches or stages in the process. This visual coding helps teams quickly identify the production status or destination of a load, improving efficiency and reducing errors.

Using multiple colors (e.g., blue, red, green, yellow, orange) allows easy differentiation between products, categories, or destinations. This is especially useful in large warehouses or during transit, ensuring seamless sorting and handling.

Pallet wrap colors are ideal for tracking inventory based on dates, enabling quick recognition of older or newer stock. This system enhances inventory rotation and minimizes waste from expired or outdated products.

Opaque or colored wraps provide a level of concealment, making it harder to identify or tamper with pallet contents. This feature is crucial for high-value or sensitive shipments.

Pallet wrap colors can mask the base of pallets, presenting a cleaner and more professional appearance for case stacks, particularly in retail or showroom environments. It aligns with branding needs while enhancing the overall display.

Businesses can use specific colors to align with their brand identity, adding a cohesive look to their packaging. This not only improves aesthetics but also reinforces brand recognition during shipping or storage.

By reducing the time spent identifying products or loads, color-coded wraps streamline operations. Employees can quickly identify the right pallet based on its color, speeding up processes like picking, packing, and shipping.

Pallet wrap colors are suitable for diverse applications, from food and beverage to electronics and pharmaceuticals. Their adaptability makes them an essential tool in various sectors.

Pallet wrap colors on frame provide more than just physical protection—they offer organizational advantages, security, and a polished aesthetic. This makes them indispensable for businesses seeking efficiency and a professional edge in handling and packaging.

The pallet wrap colors on frame sizes are designed to cater to a wide range of applications, ensuring that businesses can choose the most suitable dimensions based on their specific needs. From compact and portable widths to industrial-grade lengths and thicknesses, these options provide flexibility, efficiency, and cost-effectiveness in packaging operations.

At PWP Stretch Film, we are committed to exceeding our customers’ expectations by providing premium packaging solutions that ensure the safe and secure distribution of their products. We understand that your goods are just as important to you as they are to us, which is why we supply high-quality stretch films designed to protect your merchandise throughout the entire transportation process. With a focus on reliability and innovation, we offer a range of solutions tailored to meet the diverse needs of our customers.

Our mission is to deliver superior, dependable packaging products that provide effective protection and security for your items. Whether you are shipping small packages or large shipments, our stretch films are engineered for optimal strength, durability, and flexibility. At PWP Stretch Film, we recognize that every product is unique, which is why we offer a wide variety of options to ensure your packaging needs are met with precision and care.

At PWP Stretch Film, we specialize in providing a diverse range of high-quality stretch films, including Colored Stretch Film options tailored to meet the unique needs of our clients. Our commitment to excellence ensures that all our products deliver superior protection, durability, and security for your goods during transit and storage. Whether you are looking for a specific color to improve branding or need a specialized solution for particular packaging requirements, we have you covered.

Our Colored Stretch Film offerings come in a variety of vibrant hues, providing both functional and aesthetic benefits. Colored films help with easy product identification, enhanced security, and brand differentiation. They also serve as a deterrent to tampering, making them a smart choice for high-value or sensitive products. Additionally, we offer the flexibility for customers to select from a wide range of colors to suit specific needs.

Understanding that every business has unique packaging needs, PWP Stretch Film also offers customization options for Colored Stretch Film. We provide tailored solutions that can align with your brand, product, or logistical requirements. Whether you need specific dimensions, thicknesses, or even custom colors, our team is ready to help you design the perfect stretch film for your packaging needs.

To explore the full range of Colored Stretch Film products or to request a custom solution, simply reach out to us. Our team is always ready to assist with product inquiries or special requests. You can send us an email detailing your needs, and we will work closely with you to deliver a solution that meets your exact specifications. Your satisfaction and the protection of your products are our top priorities.

When considering pallet wrap colors on frame, the correct way to wrap a pallet depends on the type of wrap and the color-coded strategy used in your warehouse. Start by securing the wrap to the bottom of the pallet, ensuring that it binds tightly to the base for stability. Use the chosen color of pallet wrap based on its specific purpose—transparent for visibility, opaque for privacy, or color-coded for quick identification. Wrap the pallet from the bottom to the top, ensuring each layer overlaps by at least 50% for strength. Use additional layers if the pallet contains irregularly shaped or heavy items. A final layer at the top ensures stability. Consistent tension is key to avoid slack or tearing. Colored pallet wrap can also be used to differentiate between product types, storage zones, or shipment destinations, streamlining warehouse operations.

Shrink wrap and pallet wrap serve different purposes but can overlap in function. Shrink wrap is a thin, clear material applied loosely and then heated, causing it to shrink tightly around items, forming a secure, tamper-evident seal. It is often used for retail or product-specific packaging. Pallet wrap (also called stretch wrap) is a flexible plastic film designed to stretch around and secure pallets. Unlike shrink wrap, it does not require heat to work. When addressing “pallet wrap colors on frame,” the difference extends to functionality: pallet wraps are more likely to be color-coded, assisting in quick identification of contents, handling instructions, or shipment priorities. Pallet wrap offers flexibility for reusable applications and customization, whereas shrink wrap is more permanent. Using pallet wrap with specific colors can help categorize products or match brand themes in warehouse settings.

The number of times you wrap a pallet depends on the weight, height, and fragility of the load, but for secure wrapping, 3 to 5 layers are typically sufficient. When focusing on “pallet wrap colors on frame,” use layers strategically to ensure color visibility while maintaining load security. For example, the first two layers should tightly secure the base to the pallet, followed by successive layers to stabilize the items. If using opaque or colored wrap, ensure it doesn’t obstruct important labels or safety markers. For heavy or uneven loads, additional layers may be necessary, especially at stress points or corners. Overlapping the wrap by at least 50% each time strengthens the load and provides tear resistance. Finally, consider using a visible color-coded wrap to signal content type or urgency for easy handling.

A pallet wrapper is commonly referred to as a pallet wrapping machine or stretch wrap machine. These machines automate the wrapping process, improving efficiency and consistency. When incorporating “pallet wrap colors on frame,” pallet wrappers with programmable settings are especially useful. They can be adjusted to apply wrap at specific tension levels and patterns, ensuring consistent visibility of color-coded wraps. Machines vary in type, such as semi-automatic, fully automatic, and turntable models, and some are specifically designed to handle colored wraps for sorting or branding purposes. Using a machine reduces waste, maintains uniform application, and supports faster throughput in busy warehouse environments. Pallet wrapping machines also allow integration of pre-stretch mechanisms to save material and enhance security while highlighting frame color codes critical for inventory or shipping identification.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed