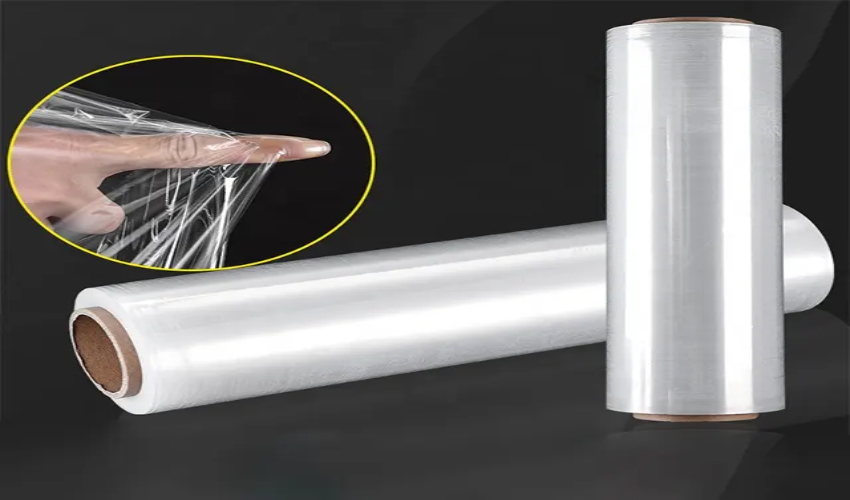

Pallet wrap thickness plays a critical role in ensuring safe and efficient packaging and shipping operations. Selecting the correct thickness is essential for maintaining product safety by securely holding items together, preventing shifts, and minimizing the risk of damage during transit. Additionally, it contributes to cost-efficiency by reducing material waste and ensuring that just the right amount of film is used for each load. Achieving the ideal balance between thickness and performance also improves load stability, reducing accidents and potential losses. A key factor in determining the correct pallet wrap thickness is understanding the stretch wrap gauge, which measures the film’s thickness. This knowledge ensures that businesses choose the optimal film for their packaging needs, enhancing both reliability and efficiency. Pallet wrap thickness, measured in gauge or microns, impacts load security, costs, and wrapping, with 80 gauge standard and 150 gauge needing automation.

Understanding the concept of stretch wrap gauge is essential for making informed decisions about pallet wrap thickness. The gauge refers to the measurement of the film’s thickness, which directly impacts the strength, durability, and performance of the stretch wrap. In practical terms, the higher the gauge, the thicker and stronger the film. Conversely, a lower gauge wrap offers more flexibility and stretch but may lack the necessary strength for heavier or irregular loads.

Gauge serves as the standard unit for expressing the thickness of stretch films. As businesses aim for optimal packaging, it’s crucial to select a pallet wrap thickness appropriate for the type and weight of the load. For instance, wraps used for light items may range from 37-60 gauge, while heavier loads typically require wraps between 80-150 gauge.

When selecting a wrap, it’s helpful to know how gauge values convert into millimeters (mm) or microns (µm) to ensure precise material selection. One gauge is approximately 0.254 microns, or 0.00254 mm. For reference, everyday Saran wrap—commonly used for food storage—has a thickness of around 30-40 microns, which translates to about 1.18-1.57 mils. In comparison, standard 80-gauge stretch wrap is approximately 20 microns or 0.02 mm thick, providing more strength and elasticity for industrial applications.

Choosing the right combination of pallet wrap thickness and gauge ensures secure, cost-efficient packaging, especially when wrapping pallets for transit or storage.

Selecting the correct pallet wrap thickness is critical for achieving load stability, product safety, and packaging efficiency. The stretch wrap gauge, which measures the stretch wrap thickness, plays a key role in determining which wrap is most suitable for different load weights and applications. Choosing the right gauge ensures that loads remain stable during transport while also minimizing the risk of film breakage or excessive material use. Below is a detailed overview of common gauges, their respective load capacities, and ideal applications.

| Gauge | Load Weight Capacity | Application Examples |

|---|---|---|

| 37-Gauge | < 800 lbs (363 kg) | Light loads, small objects |

| 47-Gauge | ~1,800 lbs (816 kg) | Box bundling, lighter cases |

| 60-Gauge | ~1,800 lbs | Small boxes, manual wrapping |

| 80-Gauge | ~2,200-2,400 lbs | Standard loads, industry standard |

| 90-Gauge | ~2,400-2,600 lbs | Heavy boxes with more tension |

| 100-Gauge | ~2,800-3,000 lbs | Heavy loads or irregular objects |

| 120-Gauge | ~3,000-3,200 lbs | Heavy product sets, higher durability |

| 150-Gauge | > 3,000 lbs | Heavy-duty, irregular, or sharp-cornered loads |

Understanding the relationship between stretch wrap gauge and pallet wrap thickness helps businesses optimize their packaging process. Lower gauge films are more economical for lightweight or uniform products, while higher gauge wraps are essential for heavy, irregular, or sharp-edged loads. Using the appropriate film reduces the risk of load shifting, product damage, and excessive material waste.

By referring to the chart above, companies can quickly identify the right pallet wrap thickness based on the weight and type of their products, ensuring they achieve both operational efficiency and cost savings.

When selecting the correct pallet wrap thickness for your operations, it is essential to compare the two most commonly used gauges—60-gauge and 80-gauge stretch wraps. Each offers unique strengths and is suited for specific applications based on load size, handling methods, and cost-efficiency. Understanding the differences between these gauges helps businesses make informed decisions, ensuring optimal load security, efficient material use, and minimized packaging costs.

| Gauge | Load Capacity | Application Type | Advantages | Disadvantages |

|---|---|---|---|---|

| 60-Gauge | Up to 1,800 lbs | Manual wrapping | Lightweight, good stretchability | Less durable, not suited for heavy loads |

| 80-Gauge | 2,200 to 2,400 lbs | Manual & machine wrapping | Stronger, more versatile, industry standard | Slightly higher cost per roll |

The 60-gauge stretch wrap is an excellent option for smaller loads and applications where manual wrapping is preferred. It provides moderate containment force and allows for easy stretch, making it ideal for bundling small boxes or lightweight products that do not require heavy-duty securing. The 60-gauge film is commonly used for products with smooth surfaces and uniform shapes, as it offers flexibility while maintaining sufficient tension.

This gauge is favored by operations focused on minimizing material waste since its thinner profile requires less film to achieve adequate stretch. However, 60-gauge wrap is not recommended for heavier or irregular loads because it lacks the necessary puncture resistance and containment force for long or challenging shipments.

The 80-gauge stretch wrap is the industry standard and is suitable for pallet loads between 2,200 and 2,400 lbs. It offers a balance of strength, flexibility, and cost-efficiency, making it the most popular choice for both manual and machine wrapping. This gauge provides superior containment force, ensuring that loads remain stable even during long-distance transportation.

Because 80-gauge film is thicker than 60-gauge, it delivers greater puncture resistance, making it ideal for irregular or sharp-edged loads. It also performs well with automatic and semi-automatic wrapping machines, improving efficiency in high-volume operations. Despite its slightly higher cost, 80-gauge stretch wrap ensures better load stability, reducing the likelihood of product damage during transit.

When deciding between 60-gauge and 80-gauge stretch wrap, consider the following:

Choosing the correct pallet wrap thickness between 60-gauge and 80-gauge will enhance both the security and cost-efficiency of your packaging operations. While 60-gauge offers a lightweight, flexible solution for smaller tasks, 80-gauge remains the go-to choice for most businesses due to its versatility and durability.

When businesses look for ways to optimize packaging processes, pallet wrap thickness becomes a critical factor. One effective strategy is downgauging, which involves using thinner, high-performance stretch films in place of thicker films without compromising load security. Downgauging not only helps reduce material waste but also lowers overall costs. For smaller or irregularly shaped items, mini stretch film provides a flexible and efficient solution, further enhancing packaging efficiency while maintaining high standards.

Downgauging refers to the process of switching from thicker stretch films to advanced, thinner films that provide the same or even better performance. Modern stretch wraps are designed with enhanced elasticity, puncture resistance, and containment force, allowing thinner films to be just as effective as their thicker counterparts. This approach ensures that businesses maintain load stability without relying on excess pallet wrap thickness.

For example, instead of using a traditional 80-gauge film, businesses might opt for a 47- or 60-gauge high-performance film that offers similar containment force. This transition helps minimize the amount of material used, supporting more sustainable packaging practices.

By using thinner films that offer high strength and elasticity, downgauging allows companies to wrap pallets securely with less material. Reducing pallet wrap thickness directly contributes to minimizing packaging waste, which aligns with environmental sustainability goals. Lower film usage also reduces the amount of stretch wrap required for each pallet, enhancing material efficiency.

Downgauging is a cost-effective solution, as thinner wraps typically cost less per roll and result in fewer material purchases over time. Although downgauged films are thinner, they maintain sufficient containment force, ensuring that loads remain stable throughout transport. This enables companies to lower packaging expenses without compromising product safety or risking load damage.

Using thinner, more flexible stretch films improves the efficiency of both manual and machine wrapping operations. Thinner films require less force to stretch, making them easier to apply and reducing strain on wrapping machinery. In high-volume settings, downgauging speeds up the wrapping process, helping to boost productivity and lower labor costs. Additionally, reduced film usage decreases the frequency of roll changes, which minimizes downtime during operations.

Choosing the correct pallet wrap thickness is essential when implementing downgauging strategies. While downgauging offers multiple benefits, it is important to ensure that the thinner film selected matches the load’s weight, size, and shape to maintain stability. For example, downgauging to a 60-gauge film may work well for light-to-medium loads, but heavier or irregularly shaped pallets might still require an 80- or 90-gauge wrap.

Businesses should carefully evaluate their load requirements, environmental conditions, and operational goals before selecting a downgauged film. When implemented correctly, downgauging not only reduces packaging costs but also enhances sustainability and operational efficiency, all while ensuring that pallet wrap thickness remains optimized for every shipment.

Accurately measuring pallet wrap thickness is essential for selecting the right stretch film for your packaging needs. Ensuring the correct thickness guarantees optimal load stability, prevents product damage, and reduces material waste. While stretch films, like pallet wrap, are measured in gauges, comparing their thickness to other familiar films, such as Saran wrap, helps provide a better understanding of these measurements. Proper tools and methods are necessary to measure the thickness of shrink and pallet wraps with precision, ensuring that businesses can make informed decisions when selecting the right film for their operations. Additionally, for efficient shrink wrap palletizing, it’s crucial to consider the film’s thickness to ensure secure wrapping and stability during storage and transportation.

| Type of Wrap | Typical Thickness (Microns) | Thickness (Millimeters) | Application |

|---|---|---|---|

| Saran Wrap | 30-40 microns | 0.03-0.04 mm | Used for food storage and lightweight packaging. |

| 80-Gauge Pallet Wrap | 20 microns | 0.02 mm | Secures standard pallet loads up to 2,400 lbs. |

| 100-Gauge Pallet Wrap | 25 microns | 0.025 mm | Provides extra strength for heavier, irregular loads. |

When working with various stretch films, it’s important to measure pallet wrap thickness accurately to ensure you are using the appropriate film for the job. A micrometer tool is the most reliable way to measure the thickness of shrink and pallet wraps. Micrometers are designed to provide precise measurements in microns or millimeters, ensuring that businesses can verify the actual thickness of their film rolls.

Using micrometers helps confirm that the actual film thickness matches the specified gauge, which is crucial for maintaining load stability and packaging quality. Businesses that use the right pallet wrap thickness can avoid issues like load shifting, film breakage, and unnecessary waste.

Understanding and measuring pallet wrap thickness is not just about ensuring product safety—it also helps improve cost efficiency and optimize material usage. Using thinner films for lighter loads reduces waste, while thicker films provide extra durability for heavier or more challenging applications. With precise thickness measurements, companies can confidently choose the best film for each task, ensuring both performance and savings.

Pallet wrap thickness is more than just a technical specification; it’s a critical factor that directly impacts the security of goods, operational efficiency, cost control, and sustainability. Whether you’re shipping heavy industrial equipment or lightweight consumer products, the thickness of the pallet wrap determines how effectively your goods are secured during transit, how much material is used, and how well your packaging operations perform. Selecting the wrong thickness can lead to higher costs, damaged goods, or inefficient processes, while the right choice ensures optimal performance. This article explores the key reasons why understanding pallet wrap thickness is crucial, delving into its impact on load security, cost-effectiveness, operational ease, and environmental sustainability.

Pallet wrap serves as a protective shield, and its thickness determines how well it safeguards your goods.

Optimizing pallet wrap thickness is essential for achieving cost-efficiency without compromising product security.

The thickness of pallet wrap influences the ease and efficiency of packaging operations.

The environmental implications of pallet wrap usage are increasingly important in today’s eco-conscious business landscape.

By exploring the relationship between pallet wrap thickness and its impact on load security, costs, efficiency, and the environment, businesses can make more informed decisions that optimize their packaging processes, reduce costs, and enhance sustainability.

Pallet wrap thickness varies significantly across different types of stretch films due to their unique applications and characteristics. Each type is designed with specific purposes in mind, whether it’s for hand wrapping, machine operations, or specialized needs like color coding or ventilation. These variations in thickness ensure optimal performance, protection, and efficiency for the intended application. This guide explores how pallet wrap thickness differs among various stretch film types, offering insights into their specific uses and advantages.

Hand stretch film is designed for manual application, making ease of use and manageability essential.

Machine stretch film is used with automated or semi-automated stretch wrappers, requiring higher tensile strength.

Color stretch film offers a practical way to differentiate or conceal palletized loads.

Bundling stretch film is used for securing smaller items or holding multiple products together.

Mini stretch film, like bundling film, is used for small, lightweight packaging tasks.

Pre-stretch film is stretched during manufacturing, requiring less material while maintaining strength.

VCI (Vapor Corrosion Inhibitor) stretch film is used to protect metal products from corrosion.

UVI (Ultraviolet Inhibitor) stretch film protects against sun damage during outdoor storage or transport.

Breathable stretch film is designed with perforations to allow air circulation, ideal for fresh produce or temperature-sensitive items.

Pallet wrap thickness across these stretch film types ensures optimal selection for specific needs, balancing strength, flexibility, and cost-effectiveness while addressing unique application requirements.

The appropriate pallet wrap thickness depends on the type of load you need to secure. For lightweight products or uniform items, 37-47 gauge wrap is usually sufficient. Mid-range loads, such as small boxes or packaged items, often require 60-gauge wrap to provide moderate containment force. For heavier or bulkier pallets, 80-gauge film is recommended, as it offers greater strength and is suitable for loads up to 2,400 lbs. Extremely heavy or irregular items may need 100-150 gauge wraps to ensure stability and prevent punctures. Matching the thickness to the load ensures optimal security and reduces material waste.

Pallet wrap gauge refers to the film’s thickness, measured in hundredths of a mil (one mil equals 0.001 inches). Common gauges include 60-gauge, 80-gauge, and 100-gauge, each offering different levels of strength and elasticity. The industry-standard 80-gauge wrap is widely used for most applications, balancing flexibility and containment force. Higher gauges like 100 or 120-gauge are typically used for heavy-duty loads, while thinner wraps such as 47 or 60-gauge are preferred for lighter items. Understanding gauge helps businesses choose the correct pallet wrap thickness to prevent product damage while optimizing material use.

Standard pallet wrap sizes refer to both width and length. The most common widths are 15 to 18 inches for hand wrap and 20 to 30 inches for machine wrap. Hand rolls typically offer 1,000 to 1,500 feet of film, while machine wraps can range from 5,000 to 9,000 feet per roll, depending on thickness. These dimensions allow operators to easily wrap around a standard pallet, which measures 48 x 40 inches. Using appropriately sized wrap ensures quick, efficient wrapping and reduces film waste.

The thickness of plastic wrapping varies based on its application. Household Saran wrap used for food storage is typically 30 to 40 microns (0.03-0.04 mm). In contrast, 80-gauge pallet wrap measures around 20 microns (0.02 mm) thick. Plastic wrapping for industrial or packaging use ranges from 60-gauge to 150-gauge, depending on the load’s weight and shape. Thicker films like 100 or 150-gauge offer better puncture resistance for irregular or sharp-edged loads, while thinner films, such as 47-gauge, are ideal for light-duty tasks. Understanding pallet wrap thickness helps ensure the right film is used for each application, balancing security and cost-efficiency.

80 gauge shrink wrap translates to 0.080 inches in thickness. The gauge number is a way to represent the thickness of plastic wrap, with each gauge value corresponding to a specific measurement in inches. In this case, an 80 gauge plastic film is 0.080 inches, or 80 thousandths of an inch thick. To convert gauge to inches, one can use the formula that 1 gauge equals 0.001 inches. This thickness is typically used for applications requiring robust durability, offering better puncture resistance and protection for palletized goods. It is a popular choice for securing and protecting goods in storage or transport. For reference, thinner wraps, like 60 gauge, would be 0.060 inches thick, while wraps with higher gauges, such as 100 gauge, would be 0.100 inches thick.

14 microns is equivalent to 0.014 millimeters or 0.00055 inches in thickness. In the context of shrink wrap, microns are commonly used to measure the thickness of the plastic film, especially for more precise and smaller scale applications. One micron is 1/1,000th of a millimeter, which makes 14 microns a very thin layer of film, primarily used for lighter packaging needs. While 14 microns of shrink wrap may be sufficient for smaller, lighter items, it would not provide the same level of puncture resistance and protection as thicker wraps. In the case of pallet wrapping, films with thicknesses ranging from 50 to 200 microns (or higher) would be more common for securing larger, heavier loads.

200 gauge shrink wrap is equivalent to 0.200 inches in thickness. Gauge is a measure used to define the thickness of plastic films such as shrink wrap, and a higher gauge number means a thicker material. In this case, 200 gauge indicates a substantial thickness, which offers excellent strength, puncture resistance, and protection for heavy-duty applications, including large or bulky palletized loads. The 200 gauge wrap is particularly beneficial for securing industrial equipment, large machinery, or items that need robust protection against environmental factors during shipping or storage. It can also provide a higher level of security against tampering. For comparison, thinner gauges like 60 or 80 would be suitable for lighter items, but for highly sensitive or heavy loads, 200 gauge is a preferred choice.

70 gauge plastic is 0.070 inches thick. Gauge is a unit of measurement used for plastic films like shrink wrap, and the higher the gauge, the thicker the plastic. The 70 gauge shrink wrap is a popular choice for medium-duty applications and offers a balance between strength and flexibility. It is often used to wrap palletized goods that are not excessively heavy but still require strong protection from environmental factors such as dust, dirt, and moisture. It provides more durability than thinner wraps like 60 gauge, and while it is not as heavy-duty as 80 or 100 gauge, it is still sufficient for many general packaging needs. The 70 gauge wrap can protect goods during storage or transport while maintaining a relatively affordable cost.

A thickness of 20 mils is equal to 0.020 inches or 0.508 millimeters. The term “mil” is commonly used to measure thickness, particularly in packaging and shrink wrap materials. One mil equals one-thousandth of an inch. In terms of shrink wrap, a 20 mil thickness is typically used for applications requiring moderate strength and durability. It is suitable for packaging medium to large-sized items or pallet loads that need extra protection against punctures, tears, and moisture. While not as thick as higher mil options (like 40 or 80 mil), a 20 mil film provides sufficient protection for lighter to moderate-duty uses, such as wrapping furniture, machinery, or non-fragile goods. It is also more flexible than thicker wraps, making it easier to handle and apply.

No, 6 mil is not thicker than 12 mil; 12 mil is thicker than 6 mil. Mil is a unit of thickness measurement used in plastic films, where 1 mil is equal to 1/1,000th of an inch. Therefore, a 12 mil thickness is twice as thick as a 6 mil thickness. Specifically, 6 mil is equal to 0.006 inches, while 12 mil is equal to 0.012 inches. The thicker 12 mil film provides more strength, durability, and puncture resistance, making it ideal for heavy-duty applications such as pallet wrapping for large or industrial items. In contrast, 6 mil is more appropriate for lighter packaging needs, offering some protection but not as much as the thicker films.

The amount of shrink wrap required to wrap a pallet depends on the size of the pallet and the film’s thickness, as well as the wrapping method used. Typically, a 1,000-foot roll of 20-inch wide shrink wrap will cover about 60-70 standard pallets (48” x 40” size), assuming a single layer of wrap is applied. If you’re wrapping with multiple layers or using a thicker film, such as 80 gauge or 100 gauge, the amount of shrink wrap needed may decrease, as thicker wraps tend to cover more surface area. To determine the exact amount of shrink wrap, measure the height and circumference of your pallet load, then calculate based on the film width and the number of layers. For example, a pallet with 60” in height and a 40” width would require around 6-7 linear feet of shrink wrap for each layer.

Stretch film wrap thickness varies, but it typically ranges from 15 to 100 gauge (0.015 to 0.100 inches) for most common applications. The stretch film’s thickness plays a significant role in its strength and its ability to hold items securely on a pallet. Thicker stretch films, such as 80 gauge or 100 gauge, are used for heavier loads that require greater durability, while thinner stretch films, like 20 or 30 gauge, are used for lighter loads. Stretch film is designed to stretch and conform to the shape of the wrapped object, allowing for a tight, secure hold. Its stretchability makes it highly versatile, providing protection against dirt, moisture, and damage during transportation or storage. The specific thickness needed depends on the weight and type of goods being wrapped, as well as the level of protection required.

Vinyl wraps, commonly used for vehicle wrapping, are typically between 2 mils (0.002 inches) and 4 mils (0.004 inches) thick. While not directly used for pallet wrapping, this range reflects the flexibility and durability desired in protective wraps. Pallet wraps, however, are thicker, starting from around 12 microns (47 gauge) to 23 microns (92 gauge), depending on the application. Thicker wraps provide increased durability and resistance to tearing during transport. For comparison, pallet wrap thickness is often measured in microns or gauge, where 1 micron equals 3.94 gauge. Vinyl wraps are thinner because they are designed to adhere to smooth surfaces, while pallet wraps prioritize strength and stretch.

Plastic wrap for pallets typically ranges from 47 gauge (12 microns) to 120 gauge (30 microns). The choice of gauge depends on the weight and stability of the load. Lightweight loads often use 47 to 63 gauge wrap, while medium-weight loads benefit from 80 gauge, the most common thickness. For heavier or irregularly shaped loads, wraps between 100 and 120 gauge provide extra strength and puncture resistance. Gauge directly influences durability: a higher gauge is thicker and better suited for demanding conditions. When selecting pallet wrap, consider the stretch capacity and type of material, as cast stretch films differ from blown films in their performance under tension.

While wire isn’t a primary material for pallet wrapping, it can sometimes be used to secure or reinforce loads. For wrapping purposes, 16 to 20-gauge wire is common. Thicker wire, like 16 gauge, is ideal for heavy loads, offering high tensile strength, while 20-gauge wire is better for lighter applications. Unlike pallet wrap, wire wrapping lacks the elasticity of plastic film but provides rigid support, especially for bulky items. To combine these materials effectively, wire is often used in tandem with plastic wraps to stabilize loads, especially during transit. Always ensure the wire does not damage or puncture the plastic wrap when used.

Shrink wrap for pallets is typically between 75 gauge (19 microns) and 100 gauge (25 microns). Heavier loads or items with sharp edges require thicker gauges for added durability. The best gauge depends on the load’s weight and fragility: lightweight items can use 60 to 75 gauge, while industrial applications often demand 100 to 120 gauge. Shrink wrap differs from stretch wrap because it forms a tight seal after heat application, providing excellent load stability. For palletized goods, opt for thicker shrink wraps for better puncture resistance and load security. Balancing gauge and stretchability ensures optimal performance.

For pallet wrap, the most common width is 18 inches to 20 inches, offering adequate coverage for various load sizes. However, smaller hand-held rolls are available in widths of 5 to 12 inches for compact wrapping needs. Core sizes typically measure 3 inches in diameter for compatibility with standard dispensers. The length varies: machine-grade rolls can be 5000 feet or more, while hand-grade rolls average around 1000 feet. Wrap size impacts efficiency; wider wraps reduce application time, while narrower rolls suit irregular or small items. The “best” size depends on the pallet dimensions and wrapping method, balancing coverage and ease of use.

Shrink wrap thickness for pallets usually ranges between 15 microns (60 gauge) and 30 microns (120 gauge). Standard applications use 19 to 23 microns for balanced strength and flexibility. Thicker shrink wrap enhances puncture resistance, making it suitable for irregularly shaped or heavy loads. Measured in microns or gauge, thickness is critical for determining the shrink wrap’s durability after heat application. Palletized goods benefit from thicker shrink wrap to withstand stress during transportation, ensuring the load remains intact. The right thickness balances shrink performance and cost-effectiveness, tailored to the load’s specific needs.

Pallet wrap widths typically range from 12 to 20 inches for hand-applied rolls, with 18 inches being the most popular. Machine-applied wraps can extend up to 30 inches or more for faster and more efficient coverage. Wider wraps reduce the number of layers needed to secure a load, saving time and material. Narrower rolls, often 5 to 12 inches, are ideal for bundling smaller items or reinforcing specific sections of a palletized load. The width impacts application efficiency: selecting the appropriate size ensures optimal coverage, reducing waste and improving load stability.

The core of a pallet wrap roll is typically 3 inches in diameter. This standardized size fits most manual and machine dispensers, ensuring compatibility across various equipment types. Core lengths vary depending on the wrap’s application: hand-grade rolls often have shorter cores for easy handling, while machine-grade rolls feature longer cores to support automated dispensers. Core size is crucial for maintaining tension and control during wrapping, enabling smooth application and minimizing film wastage. Always confirm core size compatibility with your wrapping tools to avoid operational inefficiencies.

Pallet wrap is primarily made from low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE). These materials provide excellent stretchability, puncture resistance, and durability, essential for securing loads during transport. LLDPE is commonly used due to its superior stretch and tear resistance, ideal for heavy-duty applications. Depending on the wrap type, manufacturing processes like cast or blown film extrusion affect clarity, strength, and elasticity. LDPE and LLDPE are both recyclable, making them environmentally friendly options when properly disposed of. Understanding the material composition ensures optimal performance for various load conditions.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed