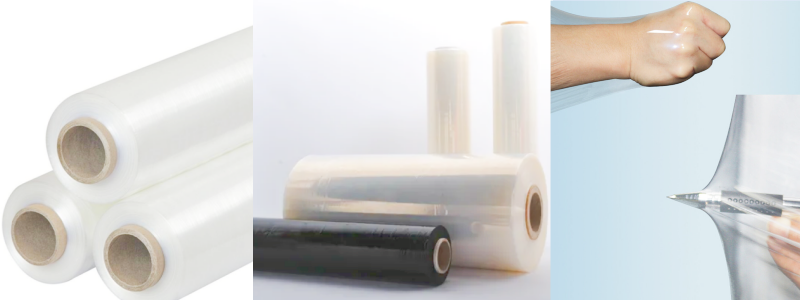

PE winding stretch film is an essential packaging solution used across various industries to secure products during transportation and storage. Known for its stretchability, transparency, and moisture-proof properties, this versatile material is widely employed in sectors like manufacturing, agriculture, and logistics. Companies use PE winding stretch film to protect goods from damage, enhance stability, and reduce packaging costs. PO stretch winding film due to its added durability and clarity offering an alternative for PE winding stretch film. In this blog, we will explore top suppliers and the best deals from leading PE winding stretch film sale company options. We will provide insights into pricing, key features, and how these companies help businesses choose the right film to meet their specific needs efficiently.

Why Choose Our Stretch Film Over Competitors?

| Attribute | Description |

|---|---|

| Place of Origin | Fujian, China |

| Material | LLDPE , HDPE, PE |

| Type | Stretch Film |

| Processing Type | Multiple Extrusion, Blow Molding, Casting |

| Transparency | Transparent |

| Surface | Smooth, Plain, High Gloss, Glossy |

| Hardness | Soft |

| Feature | Moisture Proof, Anti-Static, Durable, Eco-Friendly, Customizable |

| Certification | ISO9001:2008, ROHS, BV, CTI, SGS, Green Leaf |

| Thickness | 6mic to 35mic |

| Elongation | 250% to 400% |

| Grade | Manual and Automatic |

| Industrial Use | Packaging, Chemical, Business & Shopping, Industry Products, Gift & Craft |

| Applications | Hand Roll, Machine Roll, Pallet Wrapping, Packaging for Supermarkets, Grocery Stores, Exhibitions, Logistics |

| Color Options | Transparent, Clear, Black, Blue, Green, Red, White, Custom |

| Customizable Features | Size, Color, Logo, Thickness, Printing |

| MOQ (Minimum Order) | 200kg |

| Packaging | Standard Exported Carton |

| Printing Options | Silk Screen Printing, Customized Logo |

| Product Grades | 5-Layer Multiple Extrusion, Post Consumer Recycled (30% PCR), Environmentally Friendly |

| Tensile Strength | 0.0-50.0 MPa |

| Usage Examples | Packing for cartons, pallets, logistics, chemical products, and eco-conscious business applications |

| Brand Name | PWP Stretch Film |

| Special Features | Anti-static, High Gloss Finish, Eco-Friendly Certification, Competitive Pricing |

PE (Polyethylene) winding stretch film is a highly versatile and essential packaging material widely used in various industries to wrap, secure, and protect goods during storage and transportation. As a key product offered by any PE winding stretch film sale company, it provides reliable pallet wrapping solutions that are indispensable in industries like logistics, agriculture, food packaging, and manufacturing. Its ability to stretch and tightly adhere to itself without any adhesive makes it a cost-effective solution for bundling and stabilizing items on pallets or wrapping products individually.

PE winding stretch film is made from polyethylene (PE), a plastic polymer known for its flexibility and resilience. The film is specifically designed to stretch and cling to objects, forming a secure layer around them. This ability to stretch significantly enhances its load-holding capacity, ensuring goods remain in place and protected throughout the handling process. Unlike bundling stretch film, which is usually used to secure smaller items, PE winding stretch film is usually used for larger pallet loads. Whether it’s in warehouses or during long-distance shipping, the film plays a critical role in keeping products intact and protected from external elements.

PE winding stretch film is commonly used in a variety of sectors. In logistics, it is employed to stabilize and protect shipments on pallets, ensuring that products do not shift or become damaged during transport. In agriculture, it is often used to wrap produce or protect equipment from moisture. The food packaging industry uses it to maintain the freshness of perishable items by wrapping them in moisture-proof layers. Lastly, in the manufacturing sector, PE winding stretch film is used to protect parts, equipment, and materials from dust, dirt, and moisture during both storage and shipping.

One of the primary reasons for the widespread use of PE winding stretch film, especially by companies specializing in its sale, is its extensive range of benefits:

When it comes to purchasing PE winding stretch film, finding the right supplier is crucial. A reliable PE winding stretch film sale company, particularly one that also serves as an on-sale PE winding stretch film exporter, offers high-quality products that meet the needs of various industries. These companies provide films that are moisture-proof, durable, and transparent, ensuring they can handle the demands of shipping, storage, and product protection. Additionally, these suppliers often offer films with superior stretchability, which reduces the overall cost of packaging by allowing for fewer layers to achieve the same level of product protection.

Moreover, a trustworthy PE winding stretch film sale company will offer competitive pricing, bulk purchase options, and tailored solutions to meet the specific requirements of different industries. Whether it’s small-scale orders for retail packaging or large-scale shipments for industrial use, the right supplier ensures timely delivery, quality assurance, and customization options. For businesses looking to cut packaging costs without compromising product security, PE winding stretch film is an optimal choice, and working with a reputable sale company guarantees the best results.

PE winding stretch film is a vital packaging material that offers numerous advantages, from moisture protection and durability to superior stretchability. A PE winding stretch film sale company plays a key role in ensuring businesses receive high-quality film that meets their packaging needs, helping them protect their products efficiently and cost-effectively.

A China PE Winding Stretch Film Sale Company refers to a business entity based in China that specializes in the production, sale, and distribution of polyethylene (PE) winding stretch films. These stretch films are widely used for securing goods, bundling products, and providing protection during transportation and storage. Here is a detailed description of PWP Stretch Film:

PWP Stretch Film is a leading supplier and manufacturer of high-quality polyethylene (PE) winding stretch films based in China. We specialize in providing durable and reliable stretch film solutions that are designed to protect your goods during transport, storage, and handling. As a certified enterprise, PWP Stretch Film is committed to offering top-tier products that combine innovation, diversity, and excellence in packaging solutions.

PWP Stretch Film offers a wide variety of PE winding stretch films, designed for different packaging applications. Whether you’re wrapping products manually or using machines, we provide optimal solutions to meet your needs.

PWP Stretch Films are used extensively across various industries:

As a China PE Winding Stretch Film Sale Company, PWP Stretch Film stands out as a trusted partner for businesses seeking high-performance packaging solutions. Our range of stretch films provides optimal protection, cost efficiency, and versatility for all your packaging needs. Choose PWP Stretch Film for top-quality products, exceptional service, and sustainable packaging solutions tailored to your specific requirements.

PWP Stretch Film is a prominent China-based company specializing in the sale and production of PE Winding Stretch Films. As a leading provider, we offer a variety of processing types to suit different packaging needs, whether for manual use, machine wrapping, or specialized pallet applications. Here’s a breakdown of the key processing types for PE Winding Stretch Films:

PWP Stretch Film understands the importance of providing high-quality, cost-effective packaging solutions, and one of the key ways we achieve this is through factory direct sales. By eliminating intermediaries and offering direct sales from our production facility, we pass on significant benefits to our customers. Below, we outline the key advantages of buying PE Winding Stretch Film directly from the factory:

Choosing to purchase PE Winding Stretch Film directly from PWP Stretch Film provides numerous benefits, from cost savings and improved quality control to better lead times and superior customer support. By bypassing third-party distributors, you can ensure your business has direct access to the best stretch films at competitive prices, tailored to your exact needs. With PWP Stretch Film, you gain a trusted partner committed to delivering high-quality, reliable packaging solutions that keep your products safe and secure.

When looking for the best deals on PE winding stretch films, it’s important to compare prices and features offered by different PE winding stretch film custom suppliers. A reliable PE winding stretch film sale company typically provides competitive pricing, bulk order options, and various features that meet the demands of industries like logistics, agriculture, and manufacturing. Below, we explore current price ranges, minimum order quantities (MOQ), and offer a comparison of deals from top suppliers.

PE winding stretch film is commonly priced based on weight, typically per kilogram (kg) or per roll. The current sale prices for PE winding stretch film vary depending on the supplier, the thickness of the film, and the volume ordered. Most PE winding stretch film sale companies offer a range of products to suit different customer needs, from small-scale retail applications to large-scale industrial packaging.

Prices generally range from $1.5 to $3 per kg, depending on the quality, thickness, and additional features of the film, such as moisture resistance or UV protection.

The minimum order quantity (MOQ) can also influence the pricing. For smaller orders, prices may be higher, while bulk orders often come with discounts and reduced per-unit costs.

Key features to consider when selecting a PE winding stretch film sale company include:

By considering the price, MOQ, and production capabilities of different suppliers, businesses can find the best deal that suits their packaging needs. Whether for small-scale packaging operations or large industrial applications, choosing the right PE winding stretch film sale company is essential for optimizing costs and ensuring reliable packaging solutions.

When purchasing from a PE winding stretch film sale company, it’s essential to consider shipping and packaging options to ensure timely and secure delivery of your products. Proper shipping and packaging solutions play a crucial role in maintaining the integrity of PE winding stretch film during transit, especially when dealing with large-scale or bulk orders. Here’s what to keep in mind when exploring shipping and packaging options.

Using high-quality shipping boxes and moving supplies is critical for ensuring that PE winding stretch films arrive undamaged. Since the films are often produced in large rolls, secure packaging must be employed to protect them from moisture, dust, or other environmental factors that could compromise their quality.

These boxes should be durable enough to withstand potential rough handling during transport. Reinforced packaging is recommended, especially for international shipments where handling conditions may vary.

For large-scale shipments, moving boxes or crates designed for industrial use can help ensure that the stretch films are adequately supported. They prevent deformation of the rolls and maintain the product’s integrity during long shipping periods.

Leading PE winding stretch film sale company suppliers often utilize efficient transport methods such as palletization. This involves wrapping entire pallets with stretch film to secure the load, ensuring that multiple rolls are delivered safely and efficiently. Proper packaging reduces the risk of damage and makes unloading easier upon delivery.

Another critical aspect of shipping involves selecting the right ports and understanding delivery options. A PE winding stretch film sale company will typically offer multiple shipping options depending on the buyer’s location and the size of the order.

Ports such as Qingdao, Ningbo, and Shanghai are frequently used for exporting PE winding stretch films due to their proximity to major manufacturing hubs. These ports offer efficient services and are well-connected to international shipping routes, ensuring faster delivery times.

To optimize shipping costs, it’s essential to work closely with the supplier. By contacting the PE winding stretch film sale company directly, buyers can often negotiate better rates, especially for bulk orders. Choosing the most cost-effective shipping method—whether by sea, air, or rail—can also reduce expenses. For instance, sea freight is usually the most economical option for large orders, while air freight may be preferable for smaller or time-sensitive shipments.

When exploring PE winding stretch film sale options, it’s important to look for a company that provides not only competitive prices but also reliable shipping solutions. A good supplier should offer transparent pricing, including details on delivery fees, and provide guidance on selecting the most appropriate shipping method based on your order size and location.

Whether you are ordering a small quantity or a large bulk shipment, leading PE winding stretch film sale company suppliers will offer flexible sales packages to meet your needs. They may provide discounts for bulk purchases or promotional pricing during peak sale periods.

Some suppliers can also arrange for custom shipping options based on the buyer’s preferences, such as expedited shipping or specialized handling requirements. This level of customization ensures that the product arrives on time and in perfect condition.

A PE winding stretch film sale company should be evaluated not only based on product quality but also on its shipping and packaging capabilities. Efficient and secure delivery, combined with the right shipping boxes and supplies, ensures that your PE winding stretch film is delivered safely and cost-effectively, ready for immediate use in your business.

A PE winding stretch film sale company offers a product that is highly valued for its impressive range of features and benefits, making it a popular choice across various industries. From protecting goods to reducing packaging costs, PE winding stretch film provides both practical and financial advantages. Below are some of the key features and benefits that make it an essential packaging solution.

One of the standout features of PE winding stretch film is its moisture-proof properties. This is particularly important in industries like food packaging, agriculture, and logistics, where protecting goods from moisture is critical to maintaining quality and preventing damage. The moisture-proof characteristic of the film ensures that products remain dry and secure during both storage and transportation, even in humid or damp environments.

A major advantage of using PE winding stretch film is its superior adhesion and stretchability. When applied, the film can stretch up to five times its original length without tearing, which allows for a tight, secure wrap around products. This elasticity not only provides excellent load stability but also helps businesses save on material costs.

In response to growing environmental concerns, many PE winding stretch film sale company suppliers now offer eco-friendly versions of their products. These environmentally friendly PE films are designed to be recyclable, providing businesses with sustainable packaging solutions that align with their environmental goals.

A PE winding stretch film sale company often emphasizes how these features can directly benefit businesses by improving packaging efficiency and reducing costs. By using less material, companies can cut down on both the volume of film needed and the overall packaging expenses. The film’s ability to provide moisture protection and superior stretchability also helps businesses avoid damage-related costs, such as product spoilage or the need for additional protective packaging.

In summary, PE winding stretch film is an indispensable packaging solution due to its moisture-proof properties, transparency, superior adhesion, and stretchability. By partnering with a reliable PE winding stretch film sale company, businesses can enjoy the advantages of high-quality film that not only protects goods but also promotes sustainability through eco-friendly options.

The shelf life of stretch film typically ranges from 12 to 18 months, depending on the storage conditions and the quality of the film. Factors like temperature, humidity, and exposure to direct sunlight can significantly impact the film’s durability. When stored in a cool, dry place away from UV light and extreme temperature fluctuations, stretch film can maintain its stretchability and adhesion for up to a year or more. Over time, stretch film may lose its ability to cling properly and its elasticity may degrade, resulting in reduced performance. Therefore, it’s important to monitor the age of the stretch film and use it within its recommended shelf life for optimal results in securing and protecting goods during transportation or storage.

Stretch film is also commonly referred to as “stretch wrap.” Both terms describe the same product: a highly elastic plastic film that is used to wrap goods tightly to secure them for transport or storage. The term “stretch wrap” highlights the method by which the film is applied—by stretching it around items to hold them in place. Other related terms include pallet wrap or plastic wrap, though these may be used in more specific contexts. Stretch wrap is widely used across industries such as logistics, manufacturing, and retail to ensure that goods are tightly bundled together, protecting them from damage or shifting during handling.

The terms “stretch wrap” and “stretch film” are often used interchangeably, but they both refer to the same material used for packaging. Technically, there is no difference between stretch wrap and stretch film. Both terms describe a plastic film that is highly stretchable and used to wrap around items to secure them for transport or storage. Stretch wrap emphasizes the process of wrapping goods tightly with the material, while stretch film refers to the physical product itself. Whether referred to as stretch wrap or stretch film, it serves the same purpose of protecting items by bundling them securely and providing stability to stacked goods, especially on pallets.

Blown film and stretch film are both types of plastic films, but they differ in their production processes and applications. Blown film is made by melting plastic and extruding it through a die to create a tube, which is then expanded with air and cooled. This process gives blown film superior strength and durability, making it ideal for heavy-duty packaging applications. It is also more resistant to punctures and tears compared to stretch film. Stretch film, on the other hand, is designed specifically to be highly elastic and is typically used for wrapping and securing goods. It is often produced using a cast extrusion method, which results in a thinner, smoother film with excellent cling properties. The primary use of stretch film is to tightly wrap and secure items on pallets, while blown film is often used for packaging food or creating protective barriers in various industries.

PE stretch film, or Polyethylene stretch film, is a type of plastic film commonly used for wrapping and securing products. It is made from low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) and is known for its stretchability, which helps it cling tightly around items. This film is used to bundle or protect goods during storage and transportation, preventing them from shifting or getting damaged. It is available in various thicknesses, and its ability to stretch and conform to different shapes makes it a popular choice for packaging.

The price of Signode stretch film varies based on factors like thickness, width, length, and the type of film (machine or hand stretch film). On average, the price can range from $0.02 to $0.10 per linear foot for basic films. Signode, a well-known manufacturer of packaging materials, offers different grades of stretch film designed for high performance, which may cost more due to additional features like enhanced stretchability or UV resistance. Bulk purchases or specialized films may affect the price, so it’s best to request quotes based on your needs.

Stretch film is used across a wide range of industries, including manufacturing, logistics, food packaging, and retail. Common applications include wrapping pallets of products for shipment in the logistics industry, securing consumer goods in the retail sector, and protecting products like electronics or furniture during transport. Food packaging industries use stretch film to wrap items such as fresh produce, meats, and prepared meals, as it keeps products fresh. Other industries, including pharmaceuticals and automotive, also use stretch film for packaging and protecting parts and products.

Yes, PE (Polyethylene) film is inherently waterproof, as polyethylene is a moisture-resistant material. PE stretch film creates a barrier that prevents water, dust, and contaminants from affecting the items it wraps. This makes it ideal for protecting goods during storage or transit in various environmental conditions. However, it is not a perfect vapor barrier and may not be suitable for long-term outdoor exposure without additional protective layers. When used correctly, PE film can significantly reduce the risk of water damage to goods, especially in short-term storage or transportation.

Stretch film can be recycled, though the process is often more challenging compared to other plastics due to its thinness and potential contamination with dirt or residues. The film is typically made from low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), both of which are recyclable. In the recycling process, the stretch film is collected, cleaned, and melted down to be reformed into new products, such as trash bags, plastic lumber, or new stretch film rolls. To ensure proper recycling, it’s important to remove contaminants like food or adhesive residues before recycling.

Yes, stretch film can be food grade, provided that it meets the necessary regulations for food safety. Food grade stretch film is typically made from polyethylene that is free from harmful chemicals and additives. It is commonly used in the food packaging industry to wrap fresh produce, meats, cheeses, and other perishable items. Food-grade films are designed to keep food items fresh by providing a barrier to moisture, air, and contaminants. When selecting stretch film for food use, it’s important to confirm that it is certified for food contact by relevant authorities like the FDA.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed