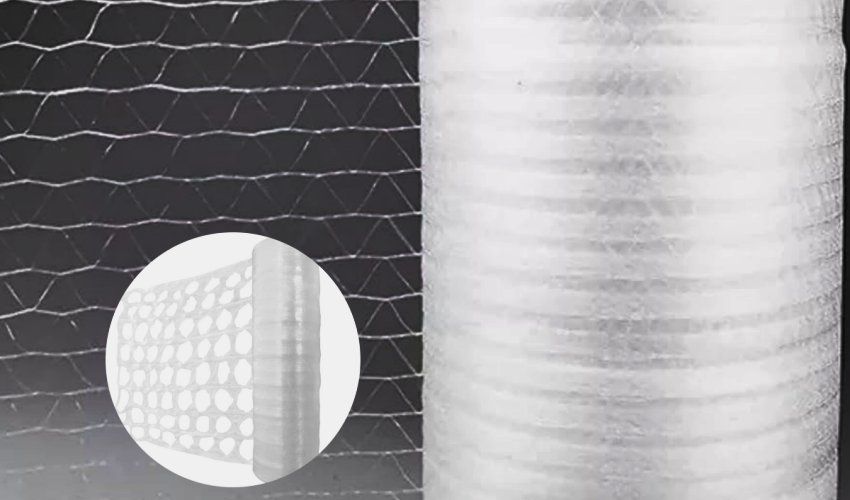

Perforated PE film, or perforated polyethylene film, is a specialized material designed with small holes to allow controlled airflow. This feature makes it essential in various industries, particularly in packaging and protective coverings. The perforations enable better breathability, which helps maintain the freshness of perishable goods like fruits, vegetables, and meats. Perforated PE film is also used in hygiene products and agricultural applications for its flexibility and ability to promote air circulation. In addition to its functional benefits, the film is recyclable, making it a more environmentally friendly option compared to other packaging materials, contributing to its growing popularity in sustainability-focused markets.

Perforated PE film is an incredibly versatile material used across various industries due to its unique ability to promote airflow and offer protective coverage. Below are the key applications of perforated PE film and pe perforated film in different sectors:

Perforated PE film plays a critical role in the food packaging industry. Its perforations allow air circulation, helping to maintain the freshness of perishable goods such as fruits, vegetables, meats, and baked products. By enabling controlled oxygen exchange, perforated PE film prevents spoilage, reduces condensation, and extends the shelf life of food. Unlike pvc shrink wrap rolls, which are used for tight, sealed packaging, perforated PE film ensures that fresh produce remains protected while preventing moisture build-up.

In the hygiene sector, perforated PE film is used in products like feminine hygiene pads, baby diapers, and medical supplies. The breathable nature of the film improves comfort by allowing air to circulate, reducing skin irritation. Additionally, perforated PE film helps maintain the integrity of the product, ensuring durability and reliability in sensitive applications.

Perforated PE film is highly valued in agriculture for its ability to maintain temperature control in greenhouses and crop protection covers. The film allows for adequate ventilation while still protecting plants from harsh environmental conditions like frost or extreme heat. This is particularly important for crops that require a regulated microclimate to thrive.

In industrial settings, perforated PE film is used as a protective wrap for delicate products such as ceramics, electronics, and other fragile goods during storage or transportation. The perforations ensure the products are cushioned and shielded from damage while also allowing any trapped moisture to escape. Compared to pvc shrink wrap rolls, which provide a sealed barrier, perforated PE film offers a breathable alternative, making it ideal for items sensitive to humidity.

Perforated PE film is produced by a variety of global manufacturers, each offering specialized solutions to meet the unique demands of various industries. Below are some of the top suppliers in the market, along with insights into the customization options they provide.

Several well-established companies are recognized for their high-quality perforated PE film products, serving industries ranging from food packaging to agriculture. One such leading supplier is PWP Stretch Film, known for producing durable and breathable packaging films that extend the shelf life of perishable goods. Other notable manufacturers include PWP Stretch Film, which specializes in flexible packaging materials. The company have a global reach and deliver reliable solutions to both large-scale operations and smaller businesses.

Top perforated PE film suppliers offer a variety of customization options to cater to specific industrial needs. Customers can request films with custom perforation patterns, sizes, colors, and thicknesses to meet the exact requirements of their products or packaging. Whether it’s increasing airflow for fresh produce or creating a tailored wrap for delicate industrial goods, these manufacturers ensure flexibility and adaptability in their offerings. For instance, PWP Stretch Film provides films with adjustable perforation diameters and spacing to optimize the product’s ventilation needs.

When discussing alternatives to perforated PE film, it’s essential to mention PVC film roll suppliers. These suppliers focus on providing high-quality PVC films, which are widely used for packaging applications that require airtight sealing and strong durability. PVC film roll suppliers, such as PWP Stretch Film, offer a range of products that are suitable for shrink wrapping, labeling, and protective packaging in industries like food service, electronics, and construction. Additionally, perforated stretch film can be considered as another alternative, especially for applications requiring breathability while maintaining strength and flexibility. Although PVC film offers different properties compared to perforated PE film and perforated stretch film, all these materials play significant roles in the packaging industry, addressing diverse requirements for breathability, protection, and durability.

Perforated PE film is widely available for sale, catering to industries ranging from food packaging to agriculture. The film’s unique characteristics, such as breathability, flexibility, and recyclability, make it highly sought after. Below is a breakdown of typical pricing, specifications, and purchasing options.

When it comes to perforated PE film for sale, prices vary based on factors like material quality, thickness, and customization. Typically, the price range for perforated PE film is between $2.00 to $3.50 per kilogram, depending on the supplier and the specific product specifications. Some common attributes include:

Many suppliers offer perforated PE films in bulk, often requiring minimum orders of 1,000 kilograms or more, which is ideal for large-scale industrial applications.

The convenience of purchasing perforated PE film has increased significantly with the availability of online platforms. B2B marketplaces like PWP Stretch Film and TradeIndia feature listings from suppliers worldwide, offering an extensive range of film types, including micro-perforated options. Additionally, many manufacturers have their own websites where customers can request samples, obtain detailed product specifications, and place direct orders. Buyers can easily compare product options, read reviews, and select the right perforated PE film based on their specific industry requirements.

Locating perforated PE film suppliers near you is essential for reducing shipping costs and ensuring quick delivery. Whether for food packaging, industrial use, or agricultural applications, sourcing locally can help streamline your supply chain. Below are some tips for finding reputable suppliers and understanding the logistics of purchasing perforated PE film.

Finding perforated PE film from local suppliers offers the advantage of quicker lead times and more accessible customer service. To locate reliable providers near you, start by exploring local B2B directories or contacting regional manufacturing associations. Many established suppliers like PWP Stretch Film and others specialize in perforated PE film, providing custom options such as varying thickness, width, and perforation patterns to meet industry-specific needs.

When choosing a local supplier, it’s crucial to verify their reputation by checking customer reviews, product certifications, and industry experience. Establishing a partnership with a trusted local provider can help ensure consistent quality and timely deliveries, especially for large-scale or ongoing projects.

When purchasing perforated PE film, the choice between buying locally or importing depends largely on delivery speed and costs. Local suppliers often offer faster delivery times and more flexible shipping options, which can be crucial for businesses with tight production schedules. Importing, on the other hand, may offer lower unit costs for bulk orders but could incur longer lead times and higher shipping fees.

It’s important to factor in total delivery costs, including customs and potential delays, when deciding whether to source locally or import. Many local suppliers now provide competitive pricing with the added benefit of fast and affordable shipping, making them a preferred choice for businesses looking to optimize both cost and time.

For those looking for solutions to protect electrical wiring, PVC stretch film roll for electrical wire is a popular option. This type of PVC film provides excellent insulation and protection against environmental elements such as moisture, dust, and chemicals. Commonly used in electrical installations, PVC stretch film roll for electrical wire ensures that wires remain organized and safe during transportation or storage.

This film is also highly flexible, allowing it to conform to irregular shapes, making it ideal for wrapping wires and cables of varying diameters. Many suppliers of perforated PE film also offer PVC stretch film roll for electrical wire, making it easier for businesses to source both products from a single provider.

Perforated PE film plays an increasingly important role in industries ranging from food packaging to agriculture. As environmental concerns grow, understanding its sustainability and recyclability is crucial. While perforated PE film is a synthetic material, its environmental impact can be mitigated through effective recycling and responsible usage, offering some advantages over less sustainable alternatives.

Polyethylene (PE) film, including perforated PE film, is considered one of the more sustainable plastic options due to its potential for recyclability and lower production energy requirements compared to other plastic types like PVC or PET. The manufacturing process of PE film generates fewer emissions and uses less energy, making it a somewhat more environmentally friendly choice for industries that require durable, flexible, and breathable materials. The perforations in the film enhance air circulation, reducing the need for additional, non-biodegradable materials to achieve the same breathability in packaging, which is especially important in industries like agriculture and food packaging.

In terms of recyclability, perforated PE film can be recycled into new products if properly processed. The film can be melted down and repurposed into items like new packaging materials, plastic bags, or even construction materials. This recyclability makes it a favorable option for businesses seeking to minimize their carbon footprint and reduce waste. However, to ensure that perforated PE film remains a sustainable option, proper recycling systems must be in place, both at the industrial level and for consumers.

When compared to alternatives like multi-layer films or composite materials that combine plastics with other non-recyclable substances, perforated PE film stands out for its ability to be reintroduced into the production cycle. Many multi-layer films, such as those combining aluminum or other polymers, are not easily recyclable because the layers cannot be separated. In contrast, PE film’s uniform composition simplifies the recycling process, further supporting its environmental advantages.

While perforated PE film is recyclable, many consumers and businesses are not fully aware of the proper methods to recycle this material, leading to improper disposal that can cause environmental harm. Below are some tips on how businesses and consumers can contribute to a more sustainable recycling process.

Perforated PE film offers significant environmental advantages due to its recyclability and relatively low environmental impact during production. By following proper recycling practices and choosing eco-conscious suppliers, businesses and consumers can help minimize the environmental footprint of this versatile material. Though plastic waste remains a global issue, perforated PE film provides a more sustainable alternative to non-recyclable materials, especially when recycled responsibly.

Perforation film is a type of thin plastic film that has been punctured with a pattern of holes. These holes can vary in size and can be uniformly or randomly spaced depending on the intended use of the film. The process of creating these perforations allows for increased airflow, moisture transmission, or the ability to tear the film more easily along the line of holes. The purpose of perforation may be functional, such as enabling breathability or simplifying the usage, or it can be for aesthetic reasons in packaging to create a visual or tactile effect.

Perforated films have a variety of applications across different industries. Commonly, they are used in the medical field for sterile packaging that allows sterilization gases and steam to penetrate while maintaining a barrier to microbes. In the agricultural sector, perforated films are used as mulch to facilitate water and nutrient flow to plants while still deterring weeds. Consumer goods often leverage perforated films for packaging, allowing consumers to open products easily. They are also crucial in the production of sanitary products, where breathability is essential for comfort and hygiene.

PP (polypropylene) and PE (polyethylene) films are both types of plastic films used in various applications, but they have distinct properties. PP film is known for its excellent clarity, high melting point, and good chemical resistance, making it suitable for packaging that requires a transparent window or that will be subjected to higher temperatures. PE film, on the other hand, is known for its flexibility, strength, and resistance to tearing. PE film is softer and more pliable than PP, which makes it a popular choice for shrink wrap, stretch film, and in the case of perforated film, for sanitary products where comfort is important.

In the context of film, PE stands for polyethylene. Polyethylene is the most commonly produced plastic globally and is known for being versatile, affordable, and recyclable. In film form, PE is used for a wide range of applications including plastic bags, films, containers, and as mentioned earlier, various packing and packaging materials. It is favored for its combination of properties such as durability, transparency options, and ease of processing, along with its low cost. PE can be made into films of various densities, offering different levels of rigidity, strength, and protection, making it suitable for many industries.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed