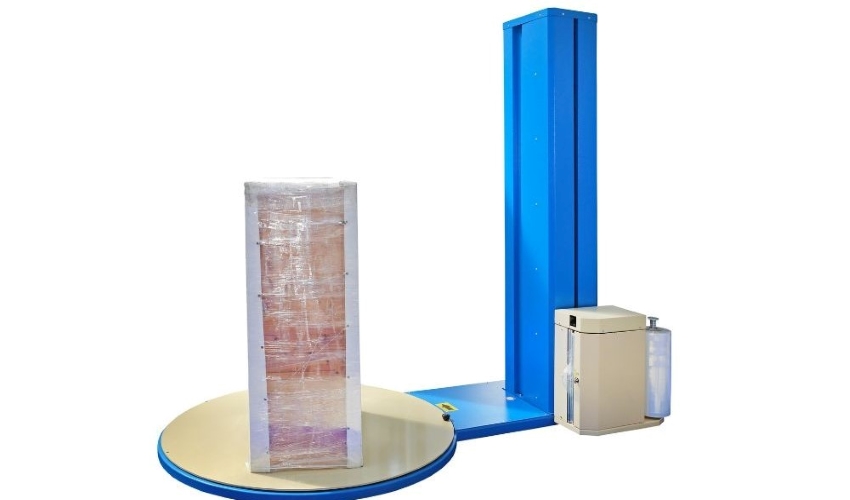

A portable stretch wrap machine is a versatile packaging tool designed to streamline the process of securing loads for transportation and storage. Unlike stationary alternatives, this machine offers flexibility by being mobile, making it ideal for businesses that require on-site pallet wrapping. The portable stretch wrap machine is easy to maneuver, allowing operators to wrap loads in different locations without the constraints of a fixed station. It can also accommodate mini stretch film, providing a more compact and convenient option for wrapping smaller loads or items with specific size requirements. In packaging industries, it plays a vital role in improving efficiency, reducing labor, and ensuring consistent wrapping quality. Compared to stationary pallet wrappers, portable models offer the added benefit of mobility, making them an essential solution for warehouses with diverse wrapping needs. Portable stretch wrap, enhanced by stretch wrappers, offers versatile, weight-unlimited solutions for securing goods during transport and storage.

One of the most significant advantages of a portable stretch wrap machine is its flexibility. Unlike stationary alternatives, the portable model allows you to move the machine to different locations within your warehouse or production floor. This means that it can easily accommodate various pallet sizes and shapes, and wrap loads wherever needed, using machine stretch film to secure the loads effectively. This mobility reduces downtime and bottlenecks caused by stationary wrapping equipment.

A portable stretch wrap machine is designed to optimize film usage, reducing material waste. Compared to manual wrapping, this machine applies consistent tension and stretch, leading to significant savings in stretch film. This cost-efficiency makes it a great investment for businesses looking to cut down on operational expenses while improving packaging quality.

Mobility is a key feature of the portable stretch wrap machine. Its ability to be moved around easily allows operators to wrap pallets at different locations, making it an ideal solution for large warehouses or busy production lines. In addition, the machine is user-friendly, often requiring minimal training for operators, which further reduces labor costs and improves overall productivity.

With a portable stretch wrap machine, businesses can minimize delays in their packaging processes. Being mobile, it can quickly address wrapping tasks without requiring pallets to be moved to a fixed station. This efficient handling of loads helps keep production lines running smoothly and improves throughput.

Another benefit of the portable stretch wrap machine is the consistent wrapping it provides. Unlike manual wrapping, which can be uneven and variable, a portable machine ensures that each pallet is securely wrapped with uniform tension, leading to better load stability and reduced risk of product damage during transportation. This results in a more reliable process for ensuring pallets wrapped and strapped are protected throughout the shipping and handling process.

One of the standout features of a portable stretch wrap machine is its extended battery life, making it highly efficient for businesses with high-volume wrapping needs. The machine is designed to operate for long periods, typically capable of wrapping between 200-250 pallets on a single charge. This longevity reduces the need for constant recharging, which minimizes downtime and maximizes productivity. Additionally, the portable stretch wrap machine can be easily charged using a standard outlet, making it convenient for various warehouse setups.

A portable stretch wrap machine is equipped with the ability to wrap up to 30 loads per hour, ensuring rapid and consistent pallet wrapping. This makes it ideal for businesses that need to process multiple pallets quickly without compromising the security of the load. The machine’s consistent performance in applying the appropriate tension and wrap coverage ensures the goods are securely packaged and protected during transportation.

Another key feature of the portable stretch wrap machine is its versatility. This machine is designed to handle pallets of varying sizes, weights, and shapes. Whether the pallet is large, small, or irregularly shaped, the portable design allows it to wrap loads that may not be compatible with stationary systems. Additionally, the portable shrink wrap machine ensures that even the heaviest loads, with a minimum weight of 200 lbs., can be wrapped effectively.

Operating a portable stretch wrap machine is straightforward, with user-friendly controls that require minimal training for employees. The machine is designed to be intuitive, with automated wrapping settings that adjust to different pallet wrap sizes and wrapping needs. This ease of use not only improves the wrapping process but also reduces the time required for manual adjustments, allowing operators to focus on other tasks within the warehouse.

A portable stretch wrap machine optimizes the use of stretch film by applying consistent pre-stretch and tension throughout the wrapping process. This ensures minimal film waste, which translates into cost savings for businesses. By using less film to secure each load, businesses can reduce their packaging costs without sacrificing the quality of the wrap or the security of the load.

A stationary pallet wrapper is typically a fixed machine that requires pallets to be brought to the wrapping station for packaging. These machines are highly automated and capable of wrapping large volumes of pallets in a uniform and consistent manner. Stationary machines are often favored in environments with high-volume, repetitive wrapping needs due to their ability to process numerous pallets quickly. However, they come with limitations in terms of flexibility and space utilization, as they require a dedicated area for wrapping.

The portable stretch wrap machine offers a different kind of efficiency by bringing mobility and flexibility into the equation. Unlike stationary machines, the portable version allows operators to move the machine directly to the pallets, reducing the time and effort needed to transport loads to a fixed wrapping station. This flexibility is especially useful in warehouses with scattered pallet locations or where space is limited. The portable stretch wrap machine can wrap a wide variety of pallet sizes and shapes without the constraints of a fixed setup.

When it comes to pure efficiency, both stationary and portable stretch wrap machines have their strengths. Stationary machines might have an edge in high-speed, large-volume operations, as they can process multiple pallets in quick succession. However, a portable stretch wrap machine enhances productivity by eliminating bottlenecks and reducing the time needed to move pallets around. This makes the portable option ideal for businesses that need to handle varied pallet sizes and operate in dynamic environments.

Flexibility is where the portable stretch wrap machine truly shines. It allows businesses to wrap pallets in different areas of the warehouse without being confined to a single wrapping station. This is particularly advantageous in settings where pallets are located across different zones, as it reduces the need for additional handling and movement. On the other hand, stationary machines require a dedicated area, which may lead to inefficiencies in environments with limited space.

For businesses focused on high-volume, repetitive wrapping tasks, a stationary pallet wrapper may provide the speed and automation required. However, for businesses looking for flexibility, space efficiency, and the ability to handle diverse pallet sizes and locations, the portable stretch wrap machine offers a significant advantage. Each solution has its own strengths, but for dynamic operations, the mobility of a portable machine can dramatically improve overall efficiency.

Pallet wrapping robots are advanced machines designed to automate the packaging process, offering increased speed, consistency, and efficiency in wrapping pallets. Unlike traditional stretch wrap machines, these robots can move around the pallet, wrapping it seamlessly and with uniform tension. This automation reduces the need for manual labor and improves the overall quality of the wrapped loads, ensuring better protection during transport and storage, all while enhancing the pallet wrap design for optimal security and stability.

The use of pallet wrapping robots in warehouses and logistics centers brings numerous advantages. These robots can wrap loads faster than manual methods, freeing up labor for other tasks. Additionally, they can handle pallets of various sizes, making them ideal for environments with diverse packaging needs. Robots can also reduce material waste by applying the exact amount of film needed with consistent tension, improving both cost efficiency and load stability.

When combined with portable stretch wrap machines, the automation process becomes even more versatile. Portable stretch wrap robots can move easily within warehouse spaces, wrapping pallets in different locations without needing fixed stations. This mobility increases flexibility in packaging operations, especially in large or dynamic environments where pallet locations may vary. By integrating the mobility of portable machines with the automation of robots, businesses can significantly boost productivity and reduce downtime.

One of the key advantages of pallet wrapping robots is their ability to reduce labor costs. With minimal operator involvement, these machines can complete the entire wrapping process automatically, from beginning to end. This leads to a more streamlined workflow and fewer errors, resulting in higher productivity. Additionally, the consistent wrapping ensures that every properly wrapped pallet is securely wrapped every time, reducing the risk of product damage.

Another standout feature of pallet wrapping robots is their ability to adapt to different pallet sizes, shapes, and weights. Whether it’s a standard or irregularly shaped load, these robots can adjust their wrapping technique to ensure optimal protection. This flexibility is especially useful in industries where products come in various sizes, providing a one-size-fits-all solution for pallet wrapping.

The portable stretch wrap machine offers unmatched flexibility in warehouse settings. Unlike stationary machines, the portable version can be easily moved around the warehouse, allowing operators to wrap pallets in multiple locations. This eliminates the need for transporting pallets to a central wrapping station, reducing both time and labor. Whether pallets are stacked in different zones or areas, the portable stretch wrap machine brings the wrapping process directly to the load, streamlining operations and improving workflow efficiency.

A key advantage of the portable stretch wrap machine is its semi-automated operation. Once in position, the machine handles the wrapping process with minimal operator involvement, reducing the need for manual labor. This not only lowers labor costs but also minimizes the risk of errors and inconsistencies. Automated features ensure that each pallet is wrapped with the same tension and coverage, improving load stability and reducing material waste. By integrating automation into a portable format, businesses can enjoy both the efficiency of robotics and the flexibility of mobility.

Another important benefit of the portable stretch wrap machine is its versatility. It is designed to handle pallets of different sizes, shapes, and weights, making it suitable for a wide range of products. Whether dealing with large, heavy pallets or smaller, irregularly shaped loads, this machine can wrap them securely. The portable shrink wrap palletizing machine ensures that pallets of at least 200 lbs. are wrapped consistently, providing optimal load security and reducing the risk of damage during transport.

In warehouse environments where space is often limited, a portable stretch wrap machine offers significant space savings. Instead of dedicating an entire area to a fixed wrapping station, businesses can use the portable machine to wrap pallets wherever they are stored. This flexibility makes it easier to manage operations in busy warehouses where floor space is at a premium. Additionally, the ability to wrap pallets on-site reduces congestion and keeps production lines moving smoothly.

The portable stretch wrap machine enhances operational speed by eliminating the need to move pallets to a fixed location for wrapping. It can quickly wrap multiple loads in different areas of the warehouse, improving throughput and reducing bottlenecks. By wrapping up to 30 loads per hour, the machine significantly boosts productivity, allowing warehouses to handle a higher volume of shipments in less time.

When looking to purchase a portable stretch wrap machine, it’s essential to find a supplier that offers both quality products and reliable service. One of the top suppliers in the market is PWP Stretch Film, known for providing high-quality packaging solutions, including portable stretch wrap machines that cater to diverse business needs. They offer a range of machines that are both durable and efficient, ensuring that businesses can find the right model for their operational requirements.

When selecting a supplier for a portable stretch wrap machine, there are several factors to consider:

Look for suppliers that offer a variety of pallet wrapping machines, ensuring you can choose a model that fits your specific needs. Suppliers like PWP Stretch Film provide multiple options, including machines for different pallet sizes, weights, and wrapping speeds.

A good supplier should offer comprehensive warranties and reliable after-sales support to help with maintenance or repairs. Check that your supplier provides long-term service options for your portable stretch wrap machine, ensuring that your investment is protected.

If your business requires specific features, look for suppliers that offer customizable machines. PWP Stretch Film, for example, provides tailored solutions for companies that need specialized pallet wrapping configurations.

You can purchase portable stretch wrap machines either online or through local distributors. For those preferring online shopping, websites like PWP Stretch Film’s online store provide detailed product information and convenient purchasing options. For businesses that prefer in-person consultations, many suppliers work with local distributors to offer demonstrations and personalized assistance in selecting the right machine.

Before making a final decision, it’s essential to compare prices and features from different suppliers. PWP Stretch Film is known for offering competitive pricing while maintaining high product quality. By comparing different suppliers, you can find the best value for your budget without compromising on the key features your business needs, such as battery life, wrapping speed, and film-saving technology.

If your business requires multiple machines or frequent stretch wrap refills, look for suppliers that offer bulk purchasing options and discounts. PWP Stretch Film often provides special deals on portable stretch wrap machines and related products, making it easier to manage packaging costs effectively. Buying in bulk can lead to significant cost savings, especially for larger operations.

Tools enhance the efficiency and ease of using portable stretch wrap for diverse packaging needs.

Stretch wrappers are essential tools that make the use of portable stretch wrap more efficient and effective, catering to various packaging needs.

| Type | Description | Best For | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Stretch Wrappers | A stand with casters; users rotate film around a stationary pallet manually. | Small-scale wrapping, budget-friendly | Affordable, better tension than hand-wrapping | Labor-intensive, less efficient for large loads |

| Turntable Stretch Wrappers | Rotating base with a mast and film carrier; pallet rotates while film is applied. | Uniform loads on pallets | Consistent wrapping, semi-automated | Requires stable, evenly distributed loads |

| Rotary Arm Stretch Wrappers | A rotating arm wraps around a stationary pallet; automated wrapping and cutting. | Heavy or irregularly shaped loads | High efficiency, handles irregular loads | Larger footprint, higher cost |

| Robotic Stretch Wrappers | Mobile machine wraps around the load; compact and easily portable. | Multiple locations, flexible needs | Portable, flexible, no fixed installation | Less effective on uneven loads or overhangs |

| Orbital Stretch Wrappers | Vertical arm rotates around products like carpets or pipes; no pallets involved. | Long, thin, or irregularly shaped items | Specialized wrapping for non-palletized goods | Limited to specific shapes and sizes |

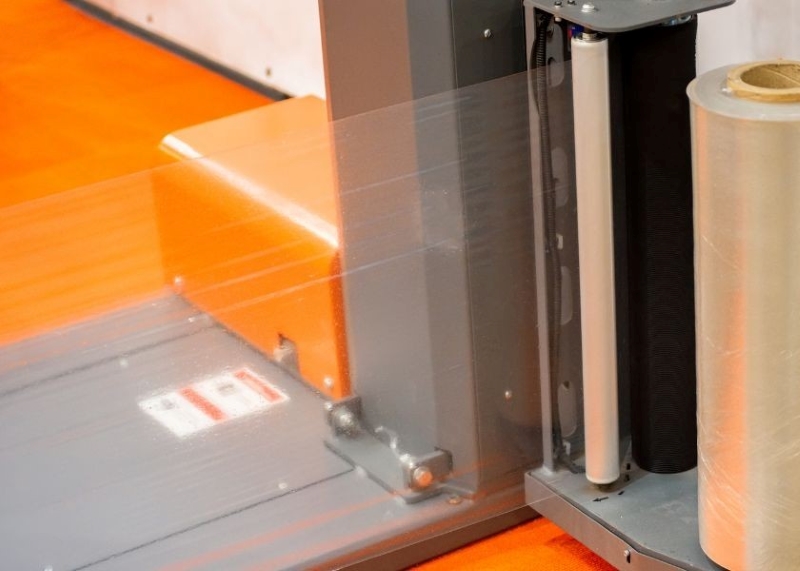

A portable stretch wrap machine consists of several essential parts and accessories that work together to ensure efficient wrapping. Below is a detailed introduction to its components:

These components work together to make portable stretch wrap machines versatile, efficient, and easy to use, catering to diverse packaging needs.

Hand blown and hand cast stretch wraps are both commonly used in packaging, but they differ significantly in terms of their manufacturing processes and performance characteristics. Hand blown stretch wrap is made by blowing heated plastic resin into a thin film. This process gives it a higher level of puncture resistance and cling, making it ideal for irregularly shaped loads or rough handling environments. However, hand blown wrap often lacks the clarity of cast film and can be noisier during application.

On the other hand, hand cast stretch wrap is produced by casting the plastic through rollers, resulting in a smoother, quieter, and clearer film. While it may not have the same puncture resistance as hand blown wrap, it’s easier to stretch, making it more user-friendly for applications requiring consistent, easy handling. Ultimately, the choice between hand blown and hand cast stretch wrap depends on the specific needs of your packaging situation, such as load type and working environment.

Stretch wrappers are specialized machines designed to apply stretch wrap (plastic film) around a pallet or load to secure it for transportation or storage. These machines come in various configurations, including manual, semi-automatic, and fully automatic models, depending on the level of automation required. The primary purpose of a stretch wrapper is to ensure that goods are tightly wrapped with consistent tension, which improves load stability and protection during transit.

Stretch wrappers not only enhance packaging efficiency but also reduce the amount of stretch film used by stretching the film as it is applied, which lowers material costs. This also means a more secure and professional finish compared to manual wrapping. Additionally, stretch wrappers can be used in a variety of industries, from warehousing and logistics to manufacturing, where ensuring the safety and integrity of packaged goods is a top priority. Whether you are using a portable stretch wrap machine or a stationary system, stretch wrappers help streamline packaging operations.

Hand wrap, often referred to as hand stretch film, is a versatile packaging material used to manually wrap pallets, boxes, and other loads for securing them during transportation or storage. It is a vital tool for many businesses, particularly those in logistics, warehousing, and manufacturing. Hand wrap provides stability to the load, preventing items from shifting or becoming damaged during transit. It also offers protection from dust, moisture, and other environmental factors.

Hand wrap is commonly used in situations where the wrapping task is small-scale or the packaging needs are more flexible, such as in environments where pallet sizes and shapes vary. Since it is applied manually, hand wrap is typically used for low to medium volume operations or where a portable wrapping solution is necessary. The flexibility and ease of use make hand wrap an ideal choice for businesses that require a cost-effective, quick, and adaptable packaging solution without the need for machinery.

Yes, hand wraps should be stretchy, as this is what allows them to effectively secure loads by tightly conforming to the shape of the pallet or items being wrapped. Stretchiness ensures that the hand wrap applies even tension across the entire load, providing both stability and protection. This elasticity is key to ensuring that the wrapped goods remain in place during transportation, reducing the risk of movement, shifting, or damage.

The stretchiness of hand wrap also helps in maximizing material efficiency. Most modern hand wraps are designed with pre-stretch capabilities, meaning they can be stretched by hand to cover more surface area, reducing the amount of film required for each load. This not only leads to cost savings but also improves the overall wrapping process by allowing for quicker, easier application. However, the level of stretch in hand wraps should be balanced with the load type to ensure proper load containment without overstretching, which could lead to film breakage or insufficient wrapping.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed