Pre-stretched breathable thin stretch film is a specialized packaging material designed to offer both high efficiency and optimal performance. This type of film has been pre-stretched during the manufacturing process, making it easier to handle and apply while maintaining uniform tension. Its breathable nature, featuring micro-perforations or a vented structure, is essential for applications where moisture control is critical. Industries such as food, agriculture, and pharmaceuticals rely on pre-stretched breathable thin stretch film to prevent condensation, reduce spoilage, and maintain product quality during transportation and storage. This innovative film ensures secure load stability and helps protect goods by allowing air circulation, making it an ideal choice for sensitive packaging needs. Pre-stretched breathable thin stretch film reduces waste, lowers costs, ensures load stability, and prevents moisture, perfect for high-volume applications.

The pre-stretched breathable thin stretch film is a highly effective packaging solution that enhances operational efficiency. Unlike traditional stretch films, this film undergoes a pre-stretching process during manufacturing, ensuring it can be applied easily while maintaining consistent tension. Similar to manual breathable stretch film, it provides even coverage and is designed to reduce manual effort during application. The breathable quality of this film, achieved through micro-perforations or a vented structure, plays a crucial role in preventing moisture build-up, making it ideal for products requiring ventilation to maintain quality and stability.

Pre-stretched breathable thin stretch film offers several key advantages. It is designed to be user-friendly, allowing operators to handle and wrap products more swiftly and with less physical strain. For tasks that require manual wrapping, hand pre-stretch film provides added convenience by reducing the effort needed to secure loads while still ensuring uniform application and better load stabilization. The breathable nature of the film helps regulate moisture and prevent condensation, making it ideal for sensitive products.

Pre-stretched breathable thin stretch film and traditional stretch film have distinct characteristics that make them suitable for different packaging needs. These differences primarily affect the film’s efficiency, cost-effectiveness, load stability, and functionality, especially when dealing with moisture-sensitive or high-volume packaging requirements. Below is a table summarizing the key differences between the two, highlighting how each factor influences their suitability for specific applications.

| Factor | Pre-Stretched Breathable Thin Stretch Film | Traditional Stretch Film |

|---|---|---|

| Material Thickness | Thin, lightweight film that uses less material for the same or higher stability. | Thicker, heavier material which may result in higher costs. |

| Breathability | Perforated to allow air flow, preventing moisture buildup. | No breathability; can trap moisture, leading to condensation. |

| Load Stability | Higher load stability with less film used, reducing packaging time. | Lower stability for lighter loads; more film is needed. |

| Cost Efficiency | More cost-effective due to less material usage and reduced waste. | Generally more expensive due to thicker material usage. |

| Application Speed | Faster to apply in high-volume settings due to pre-stretching. | Slower application process, especially in high-volume settings. |

| Environmental Impact | Lower environmental impact due to reduced film usage and waste. | Higher environmental impact due to more material being used. |

Max pre-stretched breathable stretch film is an advanced packaging solution designed for optimal load protection while allowing for essential airflow. This innovative stretch film is manufactured by pre-stretching the material to a specified elongation during production, ensuring that it maintains its integrity and strength while being applied with minimal effort. The breathable properties of this stretch film are achieved through a unique perforation or venting design that facilitates moisture release, preventing condensation buildup around packaged goods. This feature is especially beneficial for industries such as food, pharmaceuticals, and agriculture, where product freshness and quality are paramount.

One of the key advantages of max pre-stretched breathable stretch film is its ability to provide consistent tension and secure wrapping around various product shapes, ensuring load stability during transport. By reducing the amount of film needed for wrapping, it not only lowers material costs but also minimizes waste, making it an environmentally friendly choice. Additionally, the ease of use associated with this film reduces strain on workers, enhancing productivity in packaging operations. Overall, max pre-stretched breathable stretch film stands out as an effective and efficient solution for businesses looking to optimize their packaging processes while maintaining product quality and safety.

One of the standout features of pre-stretched breathable thin stretch film is its ability to facilitate airflow through the packaging. This is achieved through strategically placed perforations or a vented design that allows moisture to escape. By preventing condensation, the film effectively protects the contents from damage due to moisture accumulation, which can be especially critical for sensitive goods such as fresh produce, pharmaceuticals, and other moisture-sensitive items. This breathable quality ensures that products remain in optimal condition during storage and transit, reducing the risk of spoilage and maintaining product integrity.

The ultra-thin nature of pre-stretched breathable thin stretch film is another significant advantage. Despite its thin profile, the film is engineered for exceptional strength and tear resistance. This combination allows for effective wrapping while using minimal material, leading to reduced packaging waste and lower overall costs. The thin yet durable structure means that less film is needed to achieve the desired hold, contributing to more sustainable packaging practices and making it an economical choice for businesses aiming to cut down on expenses without compromising quality.

A critical aspect of pre-stretched breathable thin stretch film is its ability to provide consistent load security. The pre-stretching process ensures that the film maintains uniform tension during application. This uniformity is key to securing loads tightly and evenly, minimizing movement during transport and enhancing stability. The strong hold achieved through this process protects products from shifting or toppling, which is essential for safe and efficient shipping. When combined with the added strength of reinforced stretch film, this feature not only bolsters safety but also prevents potential damage and the associated costs, making the film a dependable solution for industries that prioritize secure transport.

In the food and beverage sector, the importance of using pre-stretched breathable thin stretch film cannot be overstated. This film serves as an effective barrier that helps maintain product freshness while preventing spoilage. The breathable nature of the film allows for moisture release, which is crucial for items such as fresh fruits, vegetables, and prepared meals that are sensitive to humidity. By minimizing condensation, the film helps extend shelf life and preserve the quality of perishable goods during storage and transit. This ensures that products reach consumers in optimal condition, which is vital for maintaining brand reputation and customer satisfaction.

The pharmaceutical industry has stringent packaging requirements, particularly for moisture-sensitive products such as medications and vaccines. The pre-stretched breathable thin stretch film is ideal for these applications, as it not only protects the integrity of the products but also allows for necessary air circulation. This ventilation helps prevent moisture accumulation, which could compromise the efficacy of pharmaceutical items. Furthermore, the film’s ability to provide secure wrapping minimizes the risk of contamination and ensures compliance with industry regulations, making it a trusted choice for pharmaceutical packaging.

In agriculture and floriculture, pre-stretched breathable thin stretch film plays a crucial role in safeguarding crops and floral products. The film effectively protects against excessive moisture buildup, which can lead to mold and decay while still allowing for adequate air circulation. This is particularly important for freshly harvested produce and cut flowers that require a stable environment to maintain their quality during transportation. By utilizing this specialized film, growers and distributors can ensure that their products arrive at market in peak condition, thereby enhancing their marketability and reducing waste.

Beyond these primary sectors, pre-stretched breathable thin stretch film finds applications in various other industries that require ventilated packaging solutions. For example, it is used in the packaging of textiles, where moisture control is necessary to prevent damage during shipping. Additionally, manufacturers in the automotive and electronics industries utilize this film to protect components that could be adversely affected by humidity. The versatility of perforated pre-stretch film for aeration makes it an invaluable tool across multiple sectors, meeting diverse packaging needs while promoting product integrity and sustainability.

One of the most significant advantages of pre-stretched breathable thin stretch film is its user-friendly nature. The film’s pre-stretched design allows for effortless application, making it ideal for both manual and semi-automated operations. Users can quickly wrap products without the need for excessive force, reducing fatigue and increasing productivity. This ease of handling not only speeds up the packaging process but also minimizes the likelihood of errors, ensuring that loads are wrapped securely and consistently. As a result, businesses can operate more efficiently, enhancing overall workflow and throughput.

Pre-stretched breathable thin stretch film also offers notable cost savings for companies looking to optimize their packaging processes. By reducing overall material consumption, this film provides a more economical solution compared to traditional stretch films. Since the film is designed to achieve maximum coverage with minimal material, businesses can use less film while still ensuring effective load containment. This reduction in material usage not only translates to lower packaging costs but also minimizes waste, aligning with cost-saving strategies and improving the bottom line.

Sustainability is an increasingly important consideration in today’s packaging landscape, and pre-stretched breathable thin stretch film addresses this concern effectively. Many options available on the market are recyclable, contributing to environmentally friendly practices within industrial settings. By choosing this film, companies can support their sustainability initiatives, reducing their carbon footprint and promoting a circular economy. Additionally, the film’s reduced material consumption aligns with efforts to minimize resource use and waste generation, making it a responsible choice for environmentally conscious businesses. These benefits make it ideal for various stretch film applications, where efficiency and sustainability are key priorities.

The advantages of pre-stretched breathable thin stretch film extend to enhanced load stability and safety during transportation. The film’s ability to maintain consistent tension throughout the wrapping process ensures that products remain securely fastened and protected from shifting. This secure wrapping is crucial in minimizing the risk of damage during transit, which can lead to costly losses and diminished product quality. Furthermore, the breathable design of the film helps prevent moisture-related issues, further enhancing the safety of the load. As a result, businesses can rely on this film to ensure that their products reach their destinations intact and in optimal condition, reinforcing customer satisfaction and trust.

Pre-stretched breathable thin stretch film is a highly versatile packaging material that can be used in both manual and machine applications. This flexibility makes it an ideal choice for a variety of industries, from small-scale operations to large, high-volume packaging environments. Whether applied by hand or through automated machinery, the pre-stretched breathable thin stretch film offers benefits such as ease of use, reduced material consumption, enhanced load stability, and moisture control. Below, we will explore the advantages and considerations of using this film in both manual and machine-based applications, highlighting its unique features in each context.

Manual application of pre-stretched breathable thin stretch film is commonly used in smaller operations or for packaging irregularly shaped products that require more flexibility. The pre-stretching of the film during manufacturing allows for easier handling and wrapping, reducing the effort needed compared to traditional stretch films. The breathable nature of the film is particularly beneficial when wrapping perishable items like fruits or vegetables, as it prevents condensation buildup that could lead to spoilage.

Using pre-stretched breathable thin stretch film manually is straightforward and does not require specialized equipment. The film’s reduced thickness makes it easier to apply by hand, reducing user fatigue and increasing efficiency. The film’s pre-stretched nature also ensures that the right amount of tension is applied, which helps secure the load without over-wrapping or wasting material.

When used with automated machinery, pre-stretched breathable thin stretch film is highly effective in high-volume packaging environments. The pre-stretched properties of the film make it more suitable for machine use, as the film is easier to handle and requires less force to stretch. This results in faster wrapping speeds, higher throughput, and reduced strain on the wrapping machines.

The film’s breathability is also a key advantage in machine applications, especially for industries that require moisture-sensitive packaging, such as food or pharmaceuticals. The perforations allow air to circulate, helping to maintain the freshness of wrapped products. Machine application of this film allows for precise tension control, ensuring a consistent and secure wrap with minimal waste.

One of the main benefits of using pre-stretched breathable thin stretch film, whether manually or with a machine, is its cost efficiency. Due to the pre-stretching process, the film is thinner and lighter than traditional stretch films, reducing material costs and lowering the environmental impact. This is especially noticeable in high-volume machine applications, where the reduced material usage translates into significant savings over time. In manual applications, users can wrap items more quickly and with less film, which also results in savings on packaging costs.

In both manual and machine applications, the ability to use less material while maintaining high load stability helps to optimize packaging efficiency and reduce overall expenses. This makes pre-stretched breathable thin stretch film an attractive option for businesses looking to streamline their operations and reduce packaging waste.

Pre-stretched breathable thin stretch film is highly adaptable to different industries, offering benefits for a wide range of products. In the food industry, the film’s breathability helps to preserve the freshness of perishables, while its thin and pre-stretched properties make it ideal for wrapping goods securely with less material. In the logistics and distribution sectors, the film’s ease of use, whether applied manually or through machines, ensures efficient packing and shipping of various products.

Its ability to be used in both manual and machine applications makes it ideal for businesses that need flexibility in their packaging processes. Whether in a small warehouse or a large distribution center, pre-stretched breathable thin stretch film provides the performance and efficiency needed across different scales of operation.

Pre-stretched breathable thin stretch film offers significant advantages for both manual and machine applications. Its pre-stretched nature makes it easier to use, while its breathable design ensures optimal moisture control. The film’s versatility, cost efficiency, and adaptability to various industries make it a highly effective packaging solution for businesses of all sizes. Whether applied manually for smaller, flexible operations or used in high-volume machine-based systems, it provides consistent, reliable performance across different packaging needs.

When selecting a supplier for pre-stretched breathable thin stretch film, it’s essential to consider several key qualities that ensure you receive a high-quality product tailored to your industry’s specific needs. A reputable supplier will offer films that meet rigorous standards of durability and performance, ensuring that they can withstand the demands of various applications. Look for suppliers with a proven track record of delivering reliable, high-quality stretch films that not only protect your products but also enhance your packaging efficiency. Pre stretch wrap wholesale options from trusted suppliers can often provide cost-effective solutions for businesses requiring larger quantities, without sacrificing film quality. Quality assurance processes, including testing for strength, elasticity, and breathability, should be part of their operational protocols to guarantee that their films perform optimally in real-world conditions.

The importance of customizable options cannot be overlooked when choosing a supplier for pre-stretched breathable thin stretch film. Different industries have unique requirements, and a one-size-fits-all approach may not yield the best results. A reputable supplier should offer a variety of customizable film sizes, gauges, and perforation patterns to meet diverse application needs. For instance, businesses in the food and beverage industry might require films with specific venting patterns to ensure optimal airflow for perishables, while other sectors may prioritize different attributes. By partnering with a supplier that provides these customization options, you can optimize your packaging solutions to enhance product protection and reduce material waste.

In addition to product quality and customization, strong customer support and expertise are vital factors in choosing the right stretch wrap supplier. A knowledgeable supplier, such as top stretch film manufacturers, should be able to offer guidance on selecting the most appropriate pre-stretched breathable thin stretch film for your specific needs, helping you make informed decisions that align with your operational goals. Their expertise can assist in troubleshooting any issues that arise during the application process and provide insights into best practices for using stretch film effectively. Reliable customer support also means that you can count on them for timely assistance, whether it’s answering queries, processing orders, or addressing any concerns you might have. Partnering with a supplier that prioritizes customer relationships and offers comprehensive support will ultimately enhance your packaging operations and contribute to your overall success.

The production of pre-stretched breathable thin stretch film involves several key steps that differentiate it from traditional stretch film production. The process is designed to optimize film quality, reduce material usage, and incorporate breathability for moisture-sensitive packaging needs. It combines advanced extrusion techniques with pre-stretching methods to ensure the film performs well in high-volume applications while maintaining cost-efficiency and environmental friendliness. Below, we will outline the stages of production, what to pay attention to during manufacturing, and how this process differs from traditional stretch film production.

The production process of pre-stretched breathable thin stretch film begins with the extrusion of base film, followed by stretching, perforation for breathability, and winding. Each step is critical to ensuring the film achieves the right balance of strength, flexibility, and breathability. Unlike traditional stretch films, pre-stretched breathable thin stretch films go through an additional pre-stretching process, which enhances load stability with less material. The perforation step introduces tiny holes in the film to allow air to circulate, making it ideal for applications where moisture control is essential.

The first step in the production of pre-stretched breathable thin stretch film is the extrusion of the base film. During this stage, polymer resins, such as LLDPE (Linear Low-Density Polyethylene), are heated and melted to form a continuous sheet of film. This film is then cooled and solidified into a thin, flexible layer that serves as the foundation for the pre-stretching process. The key to successful extrusion lies in controlling the temperature, pressure, and the extrusion speed to ensure the film maintains uniform thickness and smoothness, which is essential for the subsequent stretching and perforation processes.

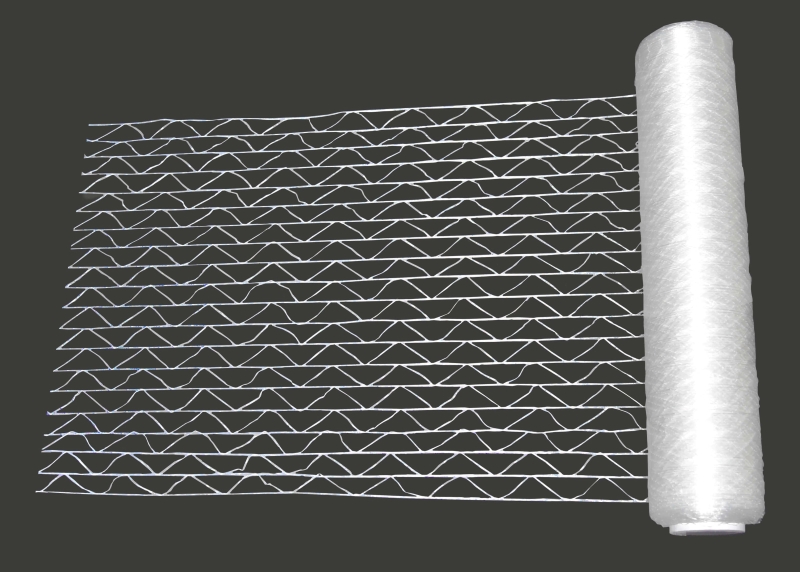

Once the base film is created, it undergoes a pre-stretching process. Pre-stretching refers to the process of stretching the film mechanically to a predetermined elongation, which reduces the force required during the wrapping process and helps to enhance load stability. This step is crucial for making the film thinner while still providing strength and resilience. The pre-stretching process is typically done in a controlled environment, where tension and stretch ratios are carefully monitored to ensure consistency across the entire production batch. The final result is a film that provides better performance with reduced material use compared to traditional stretch films.

One of the defining features of pre-stretched breathable thin stretch film is its breathability. To achieve this, tiny perforations are created in the film to allow air to flow through. These perforations prevent condensation from building up when the film is used to wrap moisture-sensitive items like fruits and vegetables. The perforation process must be finely controlled to ensure the right amount of air flow while not compromising the film’s strength. Excessive perforation can weaken the film, while too little may not offer enough breathability. Specialized machinery is used to ensure precision in this step.

After the pre-stretching and perforation stages, the film is wound into rolls for packaging. The winding process is crucial to maintaining the film’s integrity and ensuring it can be efficiently used in wrapping machines or by hand. The rolls are carefully measured and packed to ensure they maintain consistent thickness and tension, which is important for uniform application during packaging. Quality control measures are implemented at this stage to check for defects, ensuring that the final product meets the required standards for load stability, breathability, and stretch capacity.

During and after production, the pre-stretched breathable thin stretch film undergoes rigorous quality control and testing. This includes checks for material consistency, thickness uniformity, perforation accuracy, stretch ability, and load stability. Testing ensures that the film performs as expected under different conditions, such as temperature variations and moisture levels. These tests are critical to ensuring that the film provides optimal performance in real-world packaging situations, especially for moisture-sensitive products.

The production process of pre-stretched breathable thin stretch film differs from traditional stretch film production in several key aspects:

The production of pre-stretched breathable thin stretch film involves a series of carefully controlled steps that optimize its performance for specific packaging needs, such as moisture-sensitive products and high-volume applications. The pre-stretching and perforation processes set it apart from traditional stretch film production, offering significant advantages in cost efficiency, environmental impact, and performance.

Pre-stretch stretch film is a type of packaging material that has been mechanically stretched during the manufacturing process to a predetermined elongation. This pre-stretching reduces the amount of force needed to apply the film, making it easier to wrap products securely. It is designed to provide optimal load stability and protection during transportation and storage while minimizing material usage. The film is highly elastic, allowing it to conform to the shape of the products being wrapped, ensuring a snug fit. Pre-stretch stretch film is commonly used in various industries, including food and beverage, pharmaceuticals, and logistics, where securing goods effectively is crucial. Its ability to maintain tension and provide breathability also helps prevent moisture buildup, protecting sensitive items from damage. By utilizing pre-stretched stretch film, businesses can enhance their packaging efficiency and reduce costs associated with material waste.

Stretch wrap and stretch film are terms that are often used interchangeably, but there are subtle differences between the two. Stretch wrap refers to a broader category of plastic films that are used to wrap around items to secure them for storage or transport. It can include both manual and machine application films. Stretch film, on the other hand, specifically denotes a type of stretch wrap that is designed for wrapping items tightly and securely using elastic properties. While all stretch films can be classified as stretch wraps, not all stretch wraps may have the same elasticity and cling properties that are characteristic of stretch film. Stretch films are generally more specialized for load stabilization, providing a tight grip on the products, whereas stretch wraps might vary in thickness, strength, and intended use. Understanding these distinctions helps businesses select the right material for their specific packaging needs.

Cling film and stretch film serve different purposes and are made from different materials, although they both involve the concept of wrapping. Cling film, often referred to as plastic wrap or food wrap, is a thin, transparent plastic film made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE). Its primary function is to cling to surfaces and keep food fresh by preventing air and moisture from entering. Cling film is typically used in household settings for wrapping food items. Stretch film, on the other hand, is thicker and more robust, designed primarily for industrial applications to secure and stabilize products on pallets during shipping and storage. Stretch film is often made from linear low-density polyethylene (LLDPE) and has higher elasticity, allowing it to stretch around objects without breaking. In summary, cling film is primarily for food preservation, while stretch film is intended for securing goods in logistics and packaging.

Blown film and stretch film refer to different aspects of film manufacturing and application. Blown film is a type of plastic film produced using the blown film extrusion process, which involves melting plastic resin and inflating it into a bubble to create thin, continuous sheets of plastic. This method can produce various thicknesses and is often used for creating bags, liners, and other types of packaging materials. Stretch film, on the other hand, is a specific application of film that has been engineered for elasticity and strength, allowing it to stretch significantly while maintaining its integrity. While stretch film can be made using the blown film process, it is primarily characterized by its unique properties that allow for high elongation and excellent load stabilization when wrapping products. Therefore, while all stretch films can be categorized under the umbrella of blown films, not all blown films possess the same performance characteristics as stretch films. Understanding these differences is essential for selecting the right material for specific packaging needs.

There are several types of stretch film, each designed for specific packaging needs. The main types include:

Hand Stretch Film: This is used manually and is typically applied with a hand roller. It’s great for smaller packaging needs and provides flexibility in use.

Machine Stretch Film: Designed for use with automatic or semi-automatic stretch wrapping machines, this film is ideal for high-volume packaging. It ensures consistent tension and application for efficient packing.

Pre-Stretched Stretch Film: This type of film has already been stretched during the manufacturing process, reducing the amount of effort required for wrapping. It’s often used for lighter, easier-to-wrap loads.

Breathable Stretch Film: This variant allows air circulation through its tiny perforations, making it ideal for wrapping perishable items like fruits and vegetables.

Thin Stretch Film: It provides the same stretch capabilities as thicker films but with reduced weight, ideal for reducing shipping costs and waste.

Pre-Stretched Breathable Thin Stretch Film combines the benefits of pre-stretching, breathability, and reduced thickness. Pre-stretching the film before use allows it to be applied with minimal force, making the wrapping process quicker and easier. This results in lower energy consumption and reduced material usage. The breathable aspect comes from tiny perforations in the film, which allow air to circulate, keeping wrapped products like produce fresh for a longer time. At the same time, the thin nature of the film reduces its weight compared to regular stretch films, providing cost savings on both material and shipping. This type of stretch film is particularly effective in industries where maintaining product freshness is critical, such as food and agriculture, while still providing strong and secure packaging for transportation and storage.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed