Pre stretched shrink wrap is a highly efficient packaging solution that has gained popularity in various industries. Unlike traditional stretch wrap, pre stretched shrink wrap is already stretched during manufacturing, making it easier to apply and more cost-effective. Its growing use in packaging comes from its ability to stabilize loads with minimal effort, reducing worker fatigue and packaging costs. Whether you’re looking for pre stretched shrink wrap near me or searching for pre stretched shrink wrap for sale, this versatile material offers excellent value. As more businesses switch to pre stretched options, it’s clear that this product is setting new standards for both efficiency and reliability in packaging applications. Pre stretched shrink wrap is a clear, residue-free film pre-stretched to 90%, providing higher performance, lower costs, and less waste.

Pre stretched shrink wrap is a type of packaging material that has been stretched during its manufacturing process, making it different from traditional stretch wrap. This means that the film is already stretched to its maximum capacity before being wound onto rolls, allowing for easier and more efficient application. Products like hand pre-stretch film are particularly useful for manual wrapping tasks, offering improved control and reducing strain during application.

In comparison, traditional shrink wrap needs to be stretched manually during application, often requiring significant effort. Traditional wrap also has more elasticity, meaning it may not provide the same stability as pre stretched shrink wrap, especially for heavy or oddly shaped loads.

In terms of cost, pre stretched shrink wrap cost is generally lower in the long run because it uses less material while offering the same or better stability. Many businesses opt for pre stretched shrink wrap wholesale options to further reduce expenses and ensure they have enough material for large-scale operations.

This type of wrap offers not only a more efficient solution for packaging but also a cost-effective one, making it increasingly popular in various industries.

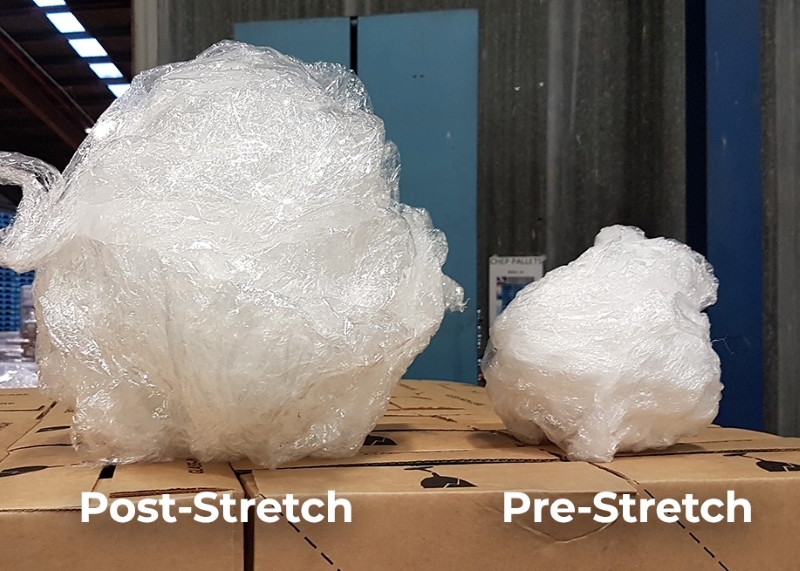

One of the standout advantages of pre-stretched shrink wrap is its material efficiency. The pre-stretching process, part of stretch film production, means that the film is already stretched close to its breaking point at the manufacturing stage, allowing it to cover more surface area with less material. This is in contrast to traditional stretch wraps, which require manual or machine stretching during application.

The thinner yet highly durable nature of pre stretched shrink wrap ensures that less material is needed to secure loads, making it an environmentally friendly option. Companies can reduce their overall consumption of plastic, thereby decreasing their carbon footprint. This benefit is especially important for industries looking to meet sustainability goals without compromising on packaging performance.

Moreover, since pre stretched shrink wrap is designed to stretch less during the wrapping process, workers can wrap loads more consistently and efficiently, resulting in better packaging quality. The pre stretch film vs stretch film comparison clearly shows that pre stretched shrink wrap requires significantly less material to achieve the same or even better load stability.

Another significant advantage of using pre stretched shrink wrap is the cost savings it offers. The pre-stretching process reduces the amount of film required for each load, meaning businesses can purchase less material over time. In addition, pre stretched shrink wrap is lighter, which reduces shipping and storage costs since fewer rolls are needed to secure the same amount of goods.

For companies that use large quantities of wrap, these savings can add up quickly. The pre stretched shrink wrap cost is often offset by the long-term reduction in waste and increased efficiency. Traditional stretch films, on the other hand, tend to result in more waste as they are prone to inconsistent application and breakage, especially when workers fail to achieve the ideal stretch during manual wrapping.

In addition, pre stretched shrink wrap offers more cost-effective load stabilization. Since it requires less force during application, workers are able to wrap loads more quickly and with less physical exertion. This not only reduces labor costs but also minimizes the risk of repetitive strain injuries, which can lead to costly workers’ compensation claims and downtime.

When comparing pre-stretch film vs stretch film, In contrast, pre stretched shrink wrap arrives ready to use, with consistent tension and stretch pre-applied, ensuring that each load is wrapped securely. the advantages of pre-stretched film as an innovative stretch film become more obvious Traditional stretch films rely on the user or machine to stretch the film during application, which can lead to inconsistent coverage and weaker load containment.

The use of pre stretched shrink wrap leads to stronger, more stable loads without the need for extra manual stretching. This results in fewer packaging errors and less film waste due to tears or inconsistencies in application. The enhanced material efficiency and ease of use make pre stretched shrink wrap a superior choice for many businesses.

The X10 pre stretched shrink wrap is a highly efficient and durable packaging solution that is designed to meet the needs of industries requiring strong, stable load containment. This type of wrap combines the benefits of traditional pre-stretched films with enhanced durability, offering superior performance for heavy-duty packaging needs. The X10 pre stretched shrink wrap is engineered to provide consistent tension and coverage, minimizing waste and maximizing cost savings.

One of the standout features of X10 pre stretched shrink wrap is its advanced pre-stretching technology. Unlike traditional shrink wrap, which requires stretching during application, the X10 version is pre-stretched at the factory, which allows it to maintain consistent tension across loads. This results in stronger, more stable packaging that can withstand the rigors of transportation and storage.

The X10 pre stretched shrink wrap excels in a variety of applications, particularly in scenarios where heavy-duty packaging is required. Its superior strength and durability make it ideal for industries such as logistics, manufacturing, and retail, where loads need to be securely wrapped for transportation or storage.

At PWP Stretch Film, we prioritize the safety and integrity of your products during transport, which is why we have become a trusted name in the packaging industry. Our extensive experience—spanning eighteen years—has allowed us to establish a strong reputation as a leading manufacturer and supplier of high-quality stretch films, pallet wraps, and other packaging solutions. What sets us apart is our unwavering commitment to customer satisfaction, supported by a dedicated team of professionals who are always ready to assist you.

Our mission is simple: to deliver top-notch packaging solutions that meet the diverse needs of our clients, both domestically and internationally. Our commitment to excellence is reflected in the products we provide, including our renowned X10 Pre Stretched Shrink Wrap. We offer a range of high-performance films that ensure reliable protection throughout the shipping process. Whether you need a robust, puncture-resistant wrap or a UV-protective solution, PWP Stretch Film delivers products tailored to your specific packaging requirements.

At PWP Stretch Film, we understand that every business has unique packaging requirements. That’s why we offer a wide range of stretch films, including various types of pre stretched shrink wrap. From X10 Pre Stretched Shrink Wrap to other tailored solutions, our flexible options ensure you can find the right film to meet your exact needs.

No matter the size of your order, we provide custom design services and contract packaging options, making us a one-stop shop for all your packaging requirements. We stand by our products and services, ensuring that we offer the best value without compromising on quality.

Choosing PWP Stretch Film means selecting a partner who understands the importance of quality, reliability, and customer support in the packaging industry. Whether you’re interested in X10 Pre Stretched Shrink Wrap or other pre stretched shrink wraps, you can trust us to deliver innovative, high-performance packaging solutions. Let us help you secure your products and streamline your shipping processes with confidence.

For more information, please contact us at pwpstretchfilm@gmail.com.

When it comes to choosing between pre stretched shrink wrap and traditional stretch wrap, there are several key factors to consider. Both have their own advantages and are used in different packaging applications, but a detailed comparison helps highlight where pre stretched shrink wrap excels in terms of application methods, efficiency, durability, and ease of use.

The main difference between pre stretched shrink wrap and traditional stretch film lies in how they are applied. Pre stretched shrink wrap is already stretched close to its maximum potential at the manufacturing stage. This eliminates the need for manual stretching during application, which makes it significantly easier to use. The wrap is simply unrolled and applied to the load with minimal force, maintaining consistent tension.

On the other hand, traditional stretch film requires significant manual or machine stretching during application. Workers or machines must pull the film tightly around the load to achieve the required stretch and stability. This additional stretching step can lead to inconsistency, especially in manual applications where achieving the ideal stretch every time is difficult.

In terms of efficiency, the shrink wrap materials of pre stretched shrink wrap offer clear advantages over traditional stretch film. Since the film is pre-stretched, less material is needed to wrap the same load. This translates to lower packaging costs and reduced material waste. Companies using pre stretched shrink wrap often report up to 25-40% savings on film usage compared to traditional stretch wrap.

Additionally, the consistency of pre stretched shrink wrap ensures that each load receives the same level of protection. In contrast, with traditional stretch wrap, variations in how much the film is stretched during application can lead to unstable loads or wasted material. The pre stretch film vs stretch film comparison reveals that pre stretched wrap requires fewer revolutions around the load, speeding up the packaging process and improving overall efficiency.

Durability is another area where pre stretched shrink wrap shines. During the pre-stretching process, the film is reinforced, especially along the edges, making it more resistant to tearing or puncturing. This added strength means that pre stretched shrink wrap can handle heavier or more irregularly shaped loads without the risk of breaking. The durability of pre stretched shrink wrap also contributes to more stable and secure loads during transportation.

Traditional stretch wrap, on the other hand, is more prone to tears if not stretched correctly or if the load is sharp or irregular. As a result, traditional wrap may require more layers or revolutions to achieve the same level of durability, which increases material usage and labor costs.

In terms of ease of use, pre stretched shrink wrap is the superior option. Since the film is pre-stretched, it requires significantly less effort during application. Workers can apply the film more quickly and efficiently, reducing strain and fatigue. The lightweight rolls of pre stretched shrink wrap are easier to handle, further enhancing worker productivity and reducing the risk of injuries associated with heavy lifting or repetitive motions.

Traditional stretch wrap, however, demands more manual effort or machine adjustments to achieve the desired stretch. This increases the time and labor required for packaging, making it less user-friendly, especially in high-volume environments.

Finding the right supplier for pre stretched shrink wrap is crucial for businesses looking to optimize their packaging processes. There are several purchasing options available, including wholesale and retail, depending on the quantity and specific needs of your operation. Whether you are a small business looking for local suppliers or a large company seeking bulk orders, there are plenty of resources available to ensure you get the best product for your packaging requirements.

When it comes to buying pre stretched shrink wrap, businesses can choose between wholesale and retail options based on their packaging needs. For smaller operations or those just starting to use pre stretched shrink wrap, retail options may be more suitable. Retailers often provide smaller quantities of pre stretched shrink wrap, making it easier to test out different products or order as needed.

On the other hand, wholesale options are ideal for larger businesses or those that require a steady supply of packaging materials. Buying pre stretched shrink wrap wholesale allows companies to save money by purchasing in bulk, often at a lower cost per roll. Wholesale distributors can also provide specialized services, such as custom orders or regular deliveries, ensuring that your business never runs out of the materials needed to keep operations running smoothly.

For those searching for pre stretched shrink wrap near me, many local packaging suppliers carry this product. These local suppliers are often well-stocked with different sizes and strengths of pre stretched shrink wrap, making it easy to find the right product for your packaging needs. Additionally, purchasing from local suppliers can offer advantages like faster delivery times and lower shipping costs, as well as the ability to pick up orders directly from their locations.

Retail options such as hardware stores or specialized packaging stores may also have pre stretched shrink wrap for sale, making it convenient for businesses that need to make last-minute purchases or smaller quantities. Some suppliers even offer online ordering options for local delivery or pickup, making the process even more efficient.

For businesses that require large quantities of packaging materials, buying pre stretched shrink wrap wholesale is often the most cost-effective solution. Wholesale suppliers typically offer a variety of pre stretched shrink wrap products in bulk quantities, providing discounts that lower the overall cost of packaging. In addition to cost savings, purchasing wholesale can also ensure that businesses have a reliable supply of pre stretched shrink wrap, avoiding disruptions in packaging operations.

Many wholesale suppliers also offer additional services such as custom packaging solutions or tailored advice on the best type of pre stretched shrink wrap for your specific needs. These suppliers often have an extensive range of products to choose from, including different thicknesses, strengths, and sizes of pre stretched shrink wrap, making it easy to find exactly what you need. Whether you’re packaging heavy-duty industrial goods or delicate retail products, buying wholesale allows for greater flexibility and more efficient operations.

The use of pre stretched shrink wrap has become widespread across numerous industries due to its efficiency, durability, and cost-saving benefits. From manufacturing to logistics and retail, businesses are increasingly adopting this innovative packaging material to streamline operations and improve load stability. Below, we explore some of the most common industries where pre stretched shrink wrap is making a significant impact.

In the manufacturing sector, packaging efficiency is a key concern. Products of all shapes and sizes need to be securely wrapped and transported, often under challenging conditions. Pre stretched shrink wrap provides an ideal solution for manufacturers, offering a reliable and consistent way to package goods without excessive material usage.

Manufacturers benefit from the material’s ability to securely hold products together, ensuring that loads remain stable during handling and transportation. Since pre stretched shrink wrap requires less force during application, it speeds up the packaging process, allowing manufacturers to wrap more products in less time. Additionally, its durability means that even heavy or irregularly shaped items can be securely wrapped without the risk of the film tearing or breaking during transit. This makes it an ideal choice for wrapping film manufacturer looking to meet high efficiency and reliability standards.

In logistics and transportation, ensuring that goods arrive safely and intact is of utmost importance. Pre-stretched shrink wrap, along with stretch wrap for logistics, is widely used in this sector due to its strength and stability, particularly when wrapping loads for long-distance shipments. The ability of pre-stretched shrink wrap to tightly secure pallets and products reduces the risk of load shifting during transit, which can lead to damage or accidents.

The lightweight nature of pre stretched shrink wrap also contributes to its appeal in logistics. Since it requires less material to achieve the same level of security as traditional stretch wrap, companies can save on packaging costs while still ensuring that their shipments are protected. Furthermore, the ease of application means that logistics workers can wrap goods more quickly, improving overall productivity and efficiency within the supply chain.

Retailers often deal with a large volume of goods that need to be packaged and transported from distribution centers to stores. For this reason, the retail industry has embraced pre stretched shrink wrap for its ability to provide consistent and reliable packaging. Whether wrapping products for shipment or securing items for in-store displays, pre stretched shrink wrap offers retailers the flexibility and durability they need to maintain operational efficiency.

The benefits of using pre stretched shrink wrap in retail packaging extend beyond just protection. Its excellent clarity allows store employees and customers to easily identify the contents of wrapped packages without the need to unwrap them, ensuring quick visual inspections and saving time. In addition, the pre-stretching process ensures that fewer materials are used, aligning with sustainability goals for retailers aiming to reduce their plastic waste.

Across all industries, one of the main advantages of pre-stretch shrink wrap as a reinforced stretch film is its ability to provide superior packaging stability. Since the film is pre-stretched during manufacturing, it maintains consistent tension when applied, reducing the need for manual stretching and ensuring that the load is tightly secured. This is especially important for businesses that need to transport products across long distances or store goods for extended periods.

The stable hold of pre stretched shrink wrap not only prevents load shifting but also minimizes the risk of product damage, ultimately leading to fewer returns or customer complaints. In industries where product integrity is critical, such as food and beverage or pharmaceuticals, the ability to trust in the stability of pre stretched shrink wrap packaging is invaluable.

Pre stretched shrink wrap is an advanced packaging solution designed to offer superior performance, efficiency, and cost savings. Unlike traditional shrink wrap, which needs to be manually stretched during the wrapping process, pre stretched shrink wrap is pre-stretched during its manufacturing. This means the film is already at its optimal tension when it arrives at your facility, which streamlines the application process and saves valuable time.

The process of creating pre stretched shrink wrap involves stretching the film up to 90% of its maximum stretch capacity before it is rolled into a compact, easy-to-handle roll. This pre-stretching ensures that the film is significantly more elastic than standard shrink wrap, allowing it to securely wrap around items with minimal effort. The film conforms tightly to the shape of the product, ensuring that it stays in place and provides excellent protection during storage and transport.

Because the film is already stretched, it is easier to apply, especially in high-volume environments. The tension required during the wrapping process is lower, reducing the risk of the film breaking or tearing. Additionally, pre stretched shrink wrap is designed to shrink with consistent force, ensuring uniform coverage without the need for complicated machinery or additional effort.

One of the primary advantages of pre stretched shrink wrap is its ability to reduce material costs. Since the film is already stretched to its optimal length, less material is required to achieve the same or better load stability than traditional shrink wrap. This translates into lower packaging costs and reduced waste, helping your facility save money over time.

With pre stretched shrink wrap, the wrapping process becomes faster and more efficient. The film’s pre-stretched nature means it is easier to apply, reducing the time needed to wrap each load. Whether you are using manual methods or automated systems, the ease of use improves overall productivity and minimizes downtime in your packaging process.

Even though pre stretched shrink wrap uses less material, it provides excellent load stability. The film tightly conforms to the shape of the product, ensuring that it remains securely wrapped throughout handling, transport, and storage. This is particularly beneficial for products that need to be transported long distances or stored for extended periods, as it prevents shifting and reduces the risk of damage.

Because the film is pre-stretched, it is stretched to its optimal capacity before being applied, which reduces film wastage. Traditional shrink wrap often requires additional stretching during use, which can lead to overuse or film tearing. Pre stretched shrink wrap ensures that the film is used efficiently, without excess waste or material spillage, contributing to a cleaner, more sustainable packaging process.

Pre stretched shrink wrap is typically clear and residue-free, which ensures that the wrapped products remain visible and free from sticky residue. This is important for industries that require product visibility or need to keep goods free from contamination, such as food or electronics. The clear film also provides a professional appearance, improving the presentation of your packaged products.

Pre stretched shrink wrap is available in various sizes and thicknesses to suit different types of products. Whether you’re packaging irregularly shaped items, small consumer goods, or larger industrial products, there’s a pre-stretched shrink wrap solution tailored to your needs. Additionally, many suppliers offer customizable solutions, such as specific stretch levels or film widths, allowing you to optimize your packaging for unique products.

Adopting pre stretched shrink wrap can significantly improve the efficiency, cost-effectiveness, and environmental sustainability of your packaging operations. By reducing film usage, minimizing waste, and enhancing load stability, it helps streamline the packaging process, ensuring products are securely wrapped with minimal effort and cost. Whether you’re dealing with high-volume packaging or need to protect fragile items, pre stretched shrink wrap offers an excellent solution for meeting the demands of modern-day packaging.

Pre stretched shrink wrap is available in various types, each designed to meet specific packaging needs. These different types vary in material thickness, strength, and performance characteristics, making it essential to choose the right one based on the type of products you are packaging. Below are the key types of pre stretched shrink wrap, along with their unique features and advantages.

This is the most common type of pre stretched shrink wrap and is suitable for a wide range of packaging applications. It is pre-stretched during the manufacturing process, which allows it to stretch up to 90% of its maximum capacity during application, resulting in excellent load stability.

Key Features:

Best For: Retail products, food items, and warehouse applications where load stability and visibility are essential.

High-density pre stretched shrink wrap is a thicker and stronger variation of the standard pre-stretched wrap. This film is designed for heavy-duty applications where extra strength and durability are required.

Key Features:

Best For: Heavy machinery, industrial products, and items that need extra protection during transport or long-term storage.

Color-coded pre stretched shrink wrap is available in a variety of colors and is used for applications where visual differentiation is important. The color helps identify different product types, shipments, or inventory.

Key Features:

Best For: Marketing and branding purposes, inventory control, and outdoor storage.

Vented pre stretched shrink wrap is designed with small perforations or holes that allow air to circulate through the wrap. This type is especially useful for packaging perishable items that need to breathe during storage or transport.

Key Features:

Best For: Food products, fresh produce, flowers, and other perishable goods that need controlled moisture levels.

Anti-static pre stretched shrink wrap is treated with special additives that reduce or eliminate static electricity, making it ideal for packaging sensitive electronics or other products that are prone to damage from static discharge.

Key Features:

Best For: Electronics, computer components, and other items susceptible to static damage.

UV-inhibited pre stretched shrink wrap is specifically treated to protect products from the harmful effects of ultraviolet (UV) light. It is ideal for products that will be stored or transported outdoors for extended periods.

Key Features:

Best For: Outdoor storage, items that will be exposed to sunlight, and long-term transport.

The different types of pre stretched shrink wrap offer tailored solutions for various packaging needs, from protecting heavy-duty industrial products to preserving the freshness of perishable goods. By choosing the right type of pre-stretched shrink wrap for your application, you can optimize your packaging process, reduce material costs, and improve product security and visibility. Whether you’re dealing with consumer goods, electronics, or fresh produce, there’s a pre stretched shrink wrap option to suit your specific requirements.

When selecting the right pre stretched shrink wrap, it’s crucial to understand that price alone shouldn’t be the deciding factor. Instead, focus on the specific requirements of your application to ensure that you select the film that best meets your needs. Choosing the right pre stretched shrink wrap involves evaluating various factors that will impact the efficiency of your packaging process and the level of protection your products require. By understanding these key aspects, you can make an informed decision that ensures your products are safely secured while minimizing costs.

The following table outlines the key considerations to take into account when purchasing pre stretched shrink wrap. Each factor plays a crucial role in determining the most suitable film for your packaging needs:

| Consideration | Impact on Choice |

|---|---|

| Load Type (Regular or Irregular) | Irregular loads require stronger, more flexible wrap, while regular-shaped loads can be efficiently wrapped with thinner films. |

| Puncture and Tear Resistance | If your load is fragile, sharp-edged, or transported through rough environments, a film with high puncture and tear resistance is essential. |

| Pre-Stretch Film Requirement | If you don’t use a stretch wrap machine, a pre stretched shrink wrap with a high degree of pre-stretch can eliminate the need for additional stretching, offering convenience and savings. |

| UV Protection | UV-inhibited pre stretched shrink wrap protects products from sun exposure and prevents degradation of sensitive materials, especially for outdoor storage or long-term transport. |

| Film Gauge | The thickness of the film affects its strength and durability. Thicker films offer better protection but are costlier; choose based on the weight and fragility of the load. |

| Clarity and Residue-Free | If visibility or aesthetic appeal is important, a clear, residue-free wrap ensures products remain visible and free from sticky residues. |

| Environmental Considerations | Some films are recyclable or made from environmentally friendly materials. Choose if sustainability is a priority in your packaging process. |

| Cost vs. Efficiency | While price matters, balancing cost with the film’s ability to perform without causing load instability, product damage, or frequent film replacement will ultimately save money in the long run. |

Each of these factors should be considered in light of your specific packaging requirements. For instance, if you’re packaging fragile or irregularly shaped items, you may need a thicker, more puncture-resistant film. On the other hand, if you need to wrap items for outdoor storage, UV protection will be a key feature to look for. By taking the time to assess these considerations, you can select the most effective pre stretched shrink wrap for your needs, ensuring efficient and secure packaging while optimizing your investment.

Pre-stretched shrink wrap is a type of packaging material that has been stretched during the manufacturing process to near its breaking point before it is wound onto rolls. Unlike traditional shrink wrap or stretch wrap, which requires manual or machine stretching during application, pre-stretched shrink wrap is easier to apply because it maintains a consistent tension without the need for additional stretching. This type of wrap is often used in industrial and commercial packaging, where the goal is to stabilize loads more efficiently and with less effort. Pre-stretched shrink wrap is highly valued for its material efficiency. It covers a larger area with less material, reducing waste and contributing to lower packaging costs. Its lightweight nature also makes it easier for workers to handle, decreasing fatigue and increasing productivity. Additionally, the reinforced edges resulting from the pre-stretching process make it more durable, preventing tearing and breakage, even when used on irregularly shaped or heavy loads. This combination of ease of use, cost savings, and durability makes pre-stretched shrink wrap an ideal choice for a wide range of packaging needs.

The primary difference between “shrink wrap” and “stretch wrap” lies in their application processes and purposes. “Shrink wrap” is a plastic film that shrinks tightly around an item when heat is applied. This type of wrap is often used for sealing individual items or bundling multiple items together for retail packaging or protective purposes. Once the heat is applied, shrink wrap forms a tight, tamper-proof seal, making it ideal for protecting items from dust, moisture, and tampering. It’s widely used in the food industry, electronics, and other retail products. Stretch wrap, on the other hand, does not require heat. It is a flexible plastic film that is stretched around products or pallets to secure them during storage or transportation. The elasticity of stretch wrap allows it to cling tightly to the items, holding them in place. This is particularly useful in industrial settings where large pallets or boxes need to be stabilized for safe transport.

Shrink wrapping pre rolls serves several important purposes, primarily centered around protection, freshness, and presentation. Pre rolls are sensitive to environmental factors such as moisture, dust, and air exposure, which can affect their quality and shelf life. By shrink wrapping them, manufacturers and retailers create an airtight, tamper-proof seal that helps preserve the pre rolls’ freshness and protect them from contamination.Another significant benefit is that shrink wrapping pre rolls enhances the visual appeal of the product. The clear, tight wrap gives the pre rolls a professional, well-packaged look that is attractive to customers. It also allows for easy branding, as labels or branding materials can be applied beneath the wrap without affecting the aesthetics of the product. Moreover, shrink wrapping pre rolls ensures tamper-evidence. Once the wrap is broken, it becomes clear that the product has been opened, which builds consumer trust. In summary, shrink wrapping pre rolls helps maintain product integrity, improves presentation, and ensures tamper-evident packaging.

The longevity of shrink wrap depends on various factors such as the quality of the material, environmental conditions, and the way it is applied. High-quality shrink wrap can last anywhere from six months to two years or more, depending on these variables. For instance, when used in outdoor applications, shrink wrap is exposed to elements like UV light, rain, and fluctuating temperatures, which can degrade the material over time. Shrink wrap that is stored or used indoors, away from harsh environmental factors, tends to last longer. The type of shrink wrap used also plays a role—some materials are designed to withstand extreme conditions and have additives that enhance their durability, such as UV inhibitors for outdoor use. Proper installation is also essential; poorly applied shrink wrap can come loose or tear, significantly reducing its lifespan. For specific uses like boat shrink wrapping or outdoor equipment, you can expect shrink wrap to last a full season, typically up to one year. When properly applied and stored, shrink wrap can maintain its protective properties for extended periods.

Shrink wrap and stretch wrap are both commonly used packaging materials, but they operate differently. Shrink wrap is a plastic film that shrinks tightly over an item when exposed to heat. The shrinkage is uniform, conforming to the shape of the product and creating a protective, snug barrier. This makes shrink wrap ideal for single-item packaging or for bundling smaller items together.

In contrast, stretch wrap is a highly elastic film that is stretched around the item during application. It does not require heat to conform to the load; instead, the film stretches to create a tight hold around the product. Stretch wrap is typically used for securing loads on pallets, providing stability and preventing shifting during transport. While shrink wrap is more about creating a tight, sealed cover, stretch wrap is primarily focused on load containment and stability.

An alternative to shrink wrap is stretch wrap, though their applications differ. Stretch wrap is more commonly used for securing larger items, particularly on pallets, during transport and storage. Unlike shrink wrap, stretch wrap does not require heat to apply and is highly elastic, making it ideal for load stabilization.

Another alternative is banding or strapping, which involves using plastic or metal bands to secure a load. This method is often used for heavy-duty applications, such as securing large bundles or products that are less suited to being wrapped with stretch film.

For smaller or delicate items, vacuum-sealing is another option. This technique removes air from a bag and then seals it tightly, ensuring the product is protected from moisture, dust, and damage. Each alternative has its strengths, depending on the product and the intended use.

The gauge of shrink wrap refers to the thickness of the film, and choosing the right gauge depends on the type of product being packaged. For general consumer items, a 60-75 gauge shrink wrap is commonly used. This thickness provides a balance of flexibility and durability, allowing the film to shrink properly while offering sufficient protection from dirt, dust, and damage.

For heavier items or sharp-edged products, a thicker shrink wrap, such as an 80-100 gauge film, is often preferred. This ensures that the film remains intact during the shrinking process and can handle the stresses of packaging heavier loads. However, for lightweight products that don’t require as much protection, 50-60 gauge shrink wrap may suffice, offering better cost efficiency while still providing adequate coverage. The correct gauge will depend on the specific application, balancing strength and flexibility.

Yes, shrink wrap can work with a hair dryer for small-scale or DIY applications. A hair dryer is a good tool for applying heat to shrink wrap around small items, such as gifts, packaged foods, or single products. The heat causes the plastic to shrink and conform to the shape of the item, creating a tight protective seal.

However, it’s important to note that a hair dryer may not provide the same level of control or heat intensity as a professional shrink wrap machine. While a hair dryer is sufficient for small items, larger or more industrial-scale packaging may require a heat gun or shrink tunnel, which offers higher, more consistent temperatures for uniform shrinkage. A hair dryer can work for light use, but for larger or more consistent shrink wrapping needs, specialized equipment is recommended.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed