Plastic film waste has become one of the fastest-growing environmental challenges today. Single-use plastic films, such as grocery bags, shipping envelopes, and food packaging, are commonly used but rarely recycled. This growing waste stream contributes significantly to landfill overflow and environmental pollution. The recycling of recyclable film is crucial to alleviating these impacts. By diverting plastic film from landfills, we can reduce the demand for new plastic production, conserve resources, and lower carbon emissions. The concept of recyclable plastic film encompasses many everyday items, such as plastic bags, bread bags, and bubble wrap, all of which can be recycled if properly disposed of. Through the proper collection, sorting, and processing of recyclable plastic film, communities can make a positive impact on waste reduction and the environment. Plastic film suppliers play a key role in providing sustainable alternatives and promoting proper recycling practices to address this growing issue. Recyclable film, made from polyethylene (PE), reduces landfill waste and can be repurposed into products like flooring, building materials, and packaging.

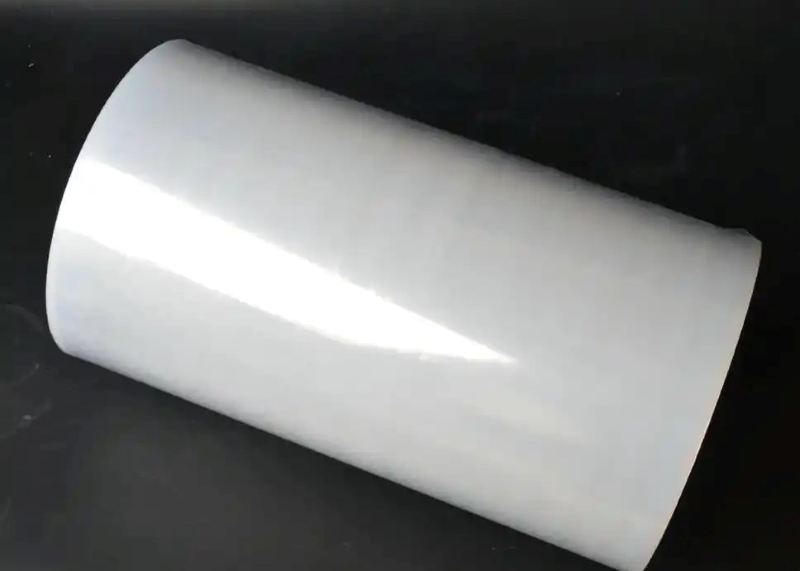

Plastic film refers to thin sheets of plastic, usually less than 10 mils thick, made primarily from polyethylene (PE) resins. These films are flexible, lightweight, and commonly used in packaging. The two most common types of recyclable plastic film are Low-Density Polyethylene (LDPE), and High-Density Polyethylene (HDPE). Products like plastic bags, shipping envelopes, stretch wraps, and mini stretch fil used for packaging small items, are often made from these recyclable materials.

Recyclable films come in various forms and are used in many everyday products. Some of the most common recyclable films include:

For recyclable plastic film to be processed correctly, it must be free from contaminants such as food residue, labels, or tape. Dirty or wet plastic film can clog sorting machines at recycling facilities, making it difficult to process and divert into usable products. Proper preparation, including removing any adhesives or residues, is essential to ensure that the film can be recycled effectively.

Although recyclable film is technically recyclable, it cannot be placed in your regular curbside recycling bin. This is because of the way recycling facilities are designed. Recyclable plastic film is lightweight and flexible, making it prone to getting caught in sorting equipment at recycling plants. When this happens, it causes operational delays and increases the cost of processing recyclables. As a result, most curbside programs do not accept recyclable film.

One of the biggest challenges in recycling recyclable plastic film is its tendency to entangle in recycling machinery. This can cause serious operational issues, as plastic film can wrap around sorting machines, creating bottlenecks and causing downtime at recycling facilities. Additionally, recyclable film often contains contaminants, such as food residue or adhesive labels, which complicate the recycling process even further. For these reasons, many recycling centers prioritize rigid materials and rely on specialized facilities to process recycled plastic wrap, ensuring it is properly handled and reprocessed.

When stretch film is not properly recycled and ends up in landfills, it can take hundreds of years to decompose. Plastic films are lightweight and take up a lot of space in landfills. Since they are typically non-biodegradable, they contribute to long-term waste accumulation.

Improperly disposed plastic films can easily make their way into rivers, lakes, and oceans, either through littering or being blown away by the wind. This exacerbates the growing issue of plastic pollution, which harms aquatic life. Marine animals can ingest or become entangled in plastic, leading to injury, illness, or even death.

The production and disposal of plastic film contribute to greenhouse gas emissions. Stretch film that is not properly recycled often ends up being incinerated or placed in landfills, where it may release methane, a potent greenhouse gas. Additionally, the manufacturing process of plastic films relies on the extraction and processing of fossil fuels, further contributing to carbon emissions. However, using recycled content stretch film can help mitigate some of these environmental impacts by reducing the need for virgin plastic, thus lowering the carbon footprint associated with production and disposal.

As plastic films break down, they can release toxic chemicals such as phthalates, bisphenol A (BPA), and other hazardous substances into the environment. These chemicals can leach into soil and groundwater, posing risks to plant and animal life and potentially even to human health over time.

Contaminating the recycling stream with non-recyclable materials, including improperly disposed stretch film, can cause inefficiencies in recycling plants. Mixed or contaminated plastic waste can clog machinery, slow down processing times, and ultimately reduce the overall effectiveness of recycling efforts.

Finding the right place to recycle stretch film or other types of recyclable film can be a key part of ensuring that plastic waste is properly diverted from landfills. Many local retailers and recycling centers offer designated drop-off locations for stretch wrap and other plastic films. These drop-off programs make it easier for consumers to participate in recycling efforts and keep recyclable materials out of the waste stream. By choosing the best stretch wrap options, which are often designed with sustainability in mind, you can help further reduce waste and contribute to a more eco-friendly approach to packaging materials.

Recycling Apps: Many apps dedicated to sustainability provide information on where you can recycle stretch wrap and other plastic films in your area.

Use Online Resources: Websites or local government recycling programs, can help you locate nearby stretch wrap recyclers and other recyclable film drop-off locations. Simply enter your zip code or city to find a recycler close to you.

Recycling Centers: Specialized recycling centers may also accept stretch film and other recyclable film materials. Some facilities may require you to drop off larger quantities, while others accept smaller amounts.

Stretch wrap, commonly used in packaging and shipping, is often made from low-density polyethylene (LDPE), which is technically recyclable. However, due to its lightweight and clingy nature, it can be challenging to recycle through conventional curbside collection systems. Despite this, there are specific recycling programs that accept stretch wrap. The key is ensuring the material is clean and free from contaminants like dirt or food particles.

Recycling stretch wrap involves specialized processes to melt it down and repurpose it into new products, such as garbage bags, plastic lumber, or new stretch film. Therefore, while stretch wrap can be recycled, it requires a more specific approach than typical recyclables.

To properly recycle stretch wrap, it’s important to locate a nearby recycling facility or drop-off point that accepts it. Many grocery stores or retail locations have designated bins for plastic film, where you can drop off stretch wrap along with other types of plastic bags. If you are using biodegradable plastic stretch wrap, it’s essential to confirm with your local recycling center or waste management service whether it requires special handling. Some specialized facilities focus on processing plastic films, ensuring they are effectively reused and reduced in environmental impact.

Participating retailers make it easy to recycle recyclable plastic film by providing dedicated drop-off bins in store locations. To ensure successful recycling, it’s essential that the plastic film is clean, dry, and free from contaminants like food residue, adhesive labels, or tape. Accepted items typically include grocery bags, bubble wrap, plastic shipping envelopes, and shipping plastic wrap. However, non-recyclable items like multi-layered plastic films or frozen food bags should not be placed in these bins, as they do not meet the recycling standards for recyclable film.

Retailers play a pivotal role in reducing plastic waste by offering recyclable film collection programs. Many of these stores collaborate with national recycling initiatives, ensuring that recyclable plastic film does not end up in landfills. By providing accessible recycling options, retailers help meet their sustainability targets, promote eco-friendly practices, and make it convenient for customers to dispose of recyclable film responsibly.

Once collected, recyclable plastic film is sent to specialized recycling facilities where it is processed and remanufactured into new products. These can include composite decking, new plastic bags, or other items that support sustainable living. Recycling recyclable film helps reduce the demand for new plastic production, conserving natural resources and minimizing environmental impact.

Recycling stretch film is essential for multiple reasons, from environmental protection to resource conservation. Stretch film is widely used in packaging and transportation, but its proper disposal and recycling are often overlooked. This section explores the environmental impact of unrecycled stretch film and the benefits of recycling, detailing its importance for sustainable practices. Below, we will discuss the key reasons why recycling stretch film is so critical, including waste reduction, energy conservation, and economic advantages.

One of the main reasons to recycle stretch film is to reduce the large amounts of plastic waste that accumulate in landfills. Stretch film is typically made from polyethylene, a type of plastic that takes hundreds of years to decompose. By recycling this film, we prevent it from contributing to landfill overpopulation, where it could otherwise sit for centuries. Recycling also reduces the need to create new plastic products from raw materials, conserving natural resources and minimizing waste.

Unrecycled stretch film can end up in oceans and natural habitats, where it poses a serious threat to wildlife. Marine animals, in particular, may mistake plastic film for food, leading to injury or death. Recycling stretch film helps keep it out of ecosystems, reducing the harmful impact it can have on wildlife. Moreover, recycling ensures that the plastic doesn’t fragment into microplastics, which can pollute water supplies and enter the food chain.

Recycling stretch film is far more energy-efficient than manufacturing new plastic from virgin materials. The process of recycling requires less energy and reduces the carbon footprint associated with producing new plastic. When stretch film is recycled, the raw materials, such as polyethylene, can be used to create new products, saving both energy and natural resources like petroleum. This is an important step towards sustainable production practices.

Recycling stretch film also brings economic advantages. The demand for recycled plastic materials is steadily growing, as businesses and industries increasingly prioritize sustainability. By recycling stretch film, companies contribute to the circular economy, where materials are reused rather than disposed of, creating jobs in the recycling industry and driving economic growth. Additionally, recycled stretch film can be repurposed into new products, which can be sold and used for further manufacturing.

Stretch film recycling is vital, but it can only happen effectively if there are accessible recycling programs in place. Specialized drop-off locations for plastic film, such as at grocery stores or recycling centers, are key to making the process easier for consumers. Public awareness of these programs and how to properly recycle stretch film plays a crucial role in ensuring its success. Without effective programs, much of the stretch film ends up in landfills, unable to be recycled.

Recycling stretch film is crucial for environmental protection, resource conservation, and economic growth. Properly handling and recycling this recyclable film prevents pollution, saves energy, and reduces the burden on landfills. Through sustainable practices and improved recycling infrastructure, we can minimize the negative impact of stretch film on the planet.

Recycling stretch film can be made more efficient by adopting certain behaviors during both the purchasing and usage phases. Proper practices ensure that the film is recycled correctly, helping to maximize the value of recycled stretch film. These actions can not only enhance the convenience of recycling but also improve the efficiency of reusing stretch film in other industries. Below, we will explore various ways to make stretch film recycling more effective and how to better utilize recycled stretch film.

The first step toward easier recycling of stretch film begins at the purchasing stage. Choosing the correct type of recyclable film is key to ensuring that the material can be efficiently processed by recycling facilities. Opt for stretch films made from polyethylene (PE), as they are more widely accepted in recycling programs compared to other types of plastic films. Films with minimal additives, like dyes or chemicals, are also preferable, as they can be recycled with fewer complications.

In addition, some stretch films come with labels or certifications indicating their recyclability. This makes it easier for consumers and businesses to identify films that can be properly recycled, further simplifying the recycling process.

One of the most important factors in recycling stretch film is ensuring it is clean and free of contaminants. Plastic film that is covered in food residues, grease, or chemicals becomes difficult to recycle and may be rejected by recycling centers. During use, avoid packaging products that leak or spill, and ensure that stretch film is not exposed to contamination during transportation or storage.

Before sending stretch film for recycling, inspect it to ensure that it is free of sticky residues or contaminants. Some businesses even have designated areas where stretch film can be cleaned before recycling, further ensuring that the plastic remains viable for reuse.

How stretch film is stored before it’s recycled also plays a role in its recyclability. Storing the stretch film in clean, dry environments helps prevent the film from degrading or becoming too contaminated by dirt or moisture. Make sure that stretch film is tightly wound and free from external debris before placing it in the recycling bin. Using proper storage containers for stretch film can also prevent it from becoming tangled or mixed with other waste, making the recycling process more efficient.

Another way to improve the recycling process is by consolidating stretch film before disposal. Instead of leaving it in small, loose pieces, it’s a good idea to collect and bundle the film into larger, more manageable rolls. This makes it easier for recycling centers to process and reduces the chances of the film being lost or misdirected. Companies can use designated containers or bins to store stretch film until it is ready for recycling, keeping it separate from other waste.

Engaging with local recycling programs is essential to making recycling stretch film more convenient. Many areas have designated drop-off locations or in-store collection points where clean stretch film can be recycled. If such programs are not available in your area, consider advocating for them, either through local governments or businesses. Educating others about the importance of stretch film recycling and how to properly participate can significantly increase the amount of film that gets recycled.

Additionally, supporting manufacturers or businesses that use recycled stretch film in their packaging can help drive demand for recycled materials. This creates a more sustainable, circular economy where the use of recycled stretch film becomes a regular practice.

Once stretch film has been recycled, finding ways to maximize its reuse is key to its long-term sustainability. Recycled stretch film can be processed into a variety of new products, including more stretch film, building materials, and other plastic goods. By supporting industries that use recycled plastic, consumers can help drive demand for products made from recycled stretch film.

Furthermore, businesses can also make an effort to purchase products made from recycled materials, thus closing the loop in the plastic film lifecycle. This ensures that the benefits of recycling are realized beyond just the initial process, contributing to a more sustainable future.

Making recycling stretch film more convenient involves taking simple, proactive steps at both the purchasing and usage stages. By selecting recyclable stretch film, ensuring it’s clean, storing it properly, and participating in recycling programs, individuals and businesses can make a significant difference in reducing waste. Additionally, supporting the use of recycled stretch film in manufacturing helps to further enhance the effectiveness of recycling efforts. Through these actions, the recycling process becomes more streamlined, ensuring that stretch film can be effectively reused, reducing its environmental impact.

Once stretch film is recycled, it can be transformed into a wide variety of products that contribute to reducing waste and supporting sustainable manufacturing practices. The recycling process gives the material a second life, allowing it to be reused in different forms while minimizing the environmental impact. This section explores the multiple uses of recycled stretch film and how it can be repurposed in various industries, benefiting both the environment and the economy. From packaging to building materials, there are many ways to make the most out of recyclable film.

One of the most direct ways recycled stretch film is used is in the production of new stretch film. After recycling, the polyethylene material can be reprocessed and turned back into stretch film, closing the loop in the plastic lifecycle. This helps to reduce the demand for virgin plastic, which can be energy-intensive to produce. By using recycled stretch film, manufacturers can produce more eco-friendly packaging solutions, which helps businesses and consumers decrease their overall carbon footprint.

Using recycled material in the production of new stretch film reduces the need for raw plastic resin, conserving valuable resources and reducing pollution. This contributes to a circular economy, where materials are reused rather than disposed of, creating a more sustainable packaging system.

Recycled stretch film can also be used in the manufacturing of durable construction materials. For example, recycled polyethylene can be transformed into products such as plastic lumber, which is used for decking, fences, and other outdoor structures. Plastic lumber made from recycled stretch film is not only durable but also weather-resistant, making it ideal for construction applications.

This repurposing helps to divert plastic waste from landfills while providing a sustainable alternative to traditional wood products. It also eliminates the need for cutting down trees, promoting environmental conservation. As the demand for eco-friendly building materials grows, recycled stretch film will play an important role in reducing the carbon footprint of the construction industry.

In addition to construction materials, recycled stretch film can be utilized to create landscaping products. For instance, recycled film can be turned into mulch film, which is used in gardening and agriculture to control weeds and retain moisture. It can also be used to produce plant pots, trays, and other gardening tools.

These products are beneficial in maintaining the health and sustainability of plants, while also reducing plastic waste. Using recycled materials for gardening helps promote eco-friendly practices among consumers and businesses alike. The ability to turn stretch film into useful landscaping products contributes to the overall reduction of waste in the environment.

Recycled stretch film can be used to manufacture various non-packaging plastic products. For example, recycled polyethylene from stretch film can be used to produce plastic bags, trash can liners, and other consumer plastic products. While these items are often used for packaging, they do not serve the same purpose as stretch film, and thus contribute to reducing the need for fresh plastic production.

This form of recycling reduces the dependence on new plastic, supports the creation of more sustainable products, and keeps stretch film out of landfills. By reusing stretch film in a range of consumer products, the recycling process helps to decrease the overall demand for raw plastic materials.

Recycled stretch film can also be integrated into the creation of stormwater management systems and other infrastructure solutions. For example, recycled polyethylene is sometimes used to produce stormwater detention and retention systems, which help manage water runoff in urban areas. These products are designed to capture and store rainwater, helping prevent flooding and improving water quality.

The use of recycled stretch film in such infrastructure systems not only reduces plastic waste but also supports the development of sustainable urban solutions. This application is particularly beneficial as cities continue to address environmental challenges such as climate change and stormwater management.

Another significant use of recycled stretch film is in the development of new, sustainable packaging solutions. Recycled stretch film can be repurposed into new types of flexible packaging, reducing the need for single-use plastics. This is especially beneficial in e-commerce and retail sectors, where there is an increasing demand for eco-friendly alternatives to traditional plastic packaging.

By using recycled stretch film for packaging, businesses can promote sustainability while reducing waste. This shift towards more sustainable packaging solutions is helping to meet consumer demand for eco-conscious products and contributing to the overall reduction of plastic waste in the environment.

Recycled stretch film has a wide range of potential applications that support sustainability efforts across various industries. From manufacturing new packaging solutions to creating durable construction materials, recycled stretch film helps reduce the environmental impact of plastic while contributing to the circular economy. As recycling programs expand and demand for eco-friendly products increases, recyclable film will play a vital role in promoting resource conservation and reducing plastic waste. By repurposing stretch film in these innovative ways, we can maximize its value and minimize its environmental footprint.

Recyclable film refers to thin plastic sheets that are made primarily from polyethylene (PE) resin, which can be recycled through specific recycling processes. These plastic films are commonly used for grocery bags, bread bags, produce bags, plastic wrap, and shipping envelopes. There are two main types of recyclable plastic film: Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) . These films are flexible, lightweight, and often single-use, which makes them prone to littering and environmental harm if not properly recycled.

To be recyclable, the film needs to be clean and dry. It’s important to remove any labels, tape, or residue before placing the film in designated recycling bins. Plastic films are typically not accepted in curbside recycling bins because they can clog sorting machines. Instead, many grocery stores and large retail chains have drop-off bins where you can deposit recyclable plastic film. Common examples of recyclable plastic film include grocery shopping bags, dry cleaning bags, bubble wrap, and some types of food storage bags.

Yes, old plastic film can be recycled, but it depends on its condition. If the plastic film is clean, dry, and free from contaminants like food residue, labels, or tape, it is recyclable. However, plastic film that has been exposed to contamination, such as greasy packaging or food waste, is generally not accepted by recycling facilities. Additionally, plastic films that are damaged, torn, or excessively crinkled may not be suitable for recycling. The most important factor for recycling old plastic film is ensuring it is free from dirt, liquids, or other debris that could interfere with the recycling process.

To recycle old plastic film, most people need to drop it off at designated recycling drop-off centers rather than curbside bins. Large retail stores, such as Target, Walmart, and Whole Foods, often have drop-off stations at their entrances where you can bring old plastic film. In some cases, manufacturers will offer mail-back programs for specific types of plastic films, such as bubble wrap or product overwrap. It’s essential to check with local recycling programs to ensure that the specific type of plastic film is accepted for recycling.

While many types of plastic film are recyclable, several are not. The general rule is that films made from multiple layers of plastic, or films that contain materials other than polyethylene (PE), are not recyclable in standard plastic film recycling programs. Here are some examples of non-recyclable plastic films:

Frozen food bags: Often made from multi-layer materials that cannot be easily recycled.

Snack bags: Most bags for chips or cookies are made from a mix of materials (e.g., foil, plastic, and paper) that cannot be separated during the recycling process.

Candy wrappers: These are often made from materials that do not have a single resin type, making them difficult to process.

Biodegradable bags: These are designed to break down over time, but they don’t have the necessary chemical properties for recycling.

Flower bouquet wraps: These often contain dyes, metal coatings, or multiple layers of plastic that are not suitable for recycling.

In New York City (NYC), plastic film recycling is not available through curbside pickup, but there are still ways to responsibly dispose of and recycle plastic film. The city offers multiple options for residents to drop off recyclable plastic films at specific locations. Some of the most convenient places to recycle plastic film in NYC include:

Participating Grocery Stores: Major grocery chains such as Whole Foods, Target, and Key Food often have in-store collection bins where customers can drop off plastic bags and film. These stores accept a variety of plastic films, including grocery bags, bread bags, and plastic wraps.

Retail Stores and Shopping Malls: Big-box stores like Walmart, Home Depot, and Kmart frequently have recycling bins near their entrances, where you can deposit your plastic films.

Specialized Recycling Drop-Off Center: Certain recycling centers in NYC are designated to handle specific materials like plastic films. The NYC Department of Sanitation (DSNY) provides a list of locations on its website that accept plastic film for recycling. It’s important to call ahead or check online for the specific drop-off locations as they can vary by neighborhood.

Eco-Friendly Programs: Some programs, such as Wrap Recycling Action Program (WRAP), focus specifically on plastic bag and film recycling. Look for information on these initiatives to find local drop-off points for plastic film.

Before heading to a drop-off location, be sure to clean and dry your plastic film to meet recycling requirements. Always check the recycling guidelines at each location, as some may have restrictions on the types of plastic film they accept.

PVC (polyvinyl chloride) film is technically recyclable, but it is not commonly accepted in curbside recycling programs due to its chemical composition. PVC film is difficult to process because it contains additives, such as chlorine and plasticizers, which can release harmful toxins during recycling. Some specialized recycling centers can handle PVC, but the process is more expensive and complex than other types of plastic. Many types of PVC films, especially those used for packaging or decorations, often end up in landfills instead of being recycled.

Clean plastic film, such as the kind used for food packaging or product wrapping, can be recycled, but it must be free of contaminants like food residue or grease. Clean film made from materials like polyethylene (PE) or polypropylene (PP) is accepted at many specialized recycling centers or drop-off locations, often labeled as “plastic bags and wraps” recycling. Many grocery stores have designated bins for clean plastic film, but curbside recycling programs generally do not accept it. It’s important to check local recycling rules to ensure proper disposal.

To determine if plastic film is recyclable, look for recycling symbols or check the plastic’s resin code. Most recyclable plastic films are made from polyethylene (PE), polypropylene (PP), or sometimes polyolefin, and they are usually labeled with a “1” or “4” resin code. Additionally, you can check with your local recycling center or your community’s waste management program to see if they accept plastic film. The film should also be clean and free of contaminants. Recycling programs that accept plastic film typically have designated bins for it in stores or special drop-off points.

Plastic film can take hundreds to thousands of years to decompose, depending on environmental conditions. Unlike organic materials, plastic film does not break down naturally, and it requires sunlight, heat, and time to degrade, which typically occurs very slowly. During this time, the plastic breaks into smaller pieces called microplastics, which can have harmful effects on wildlife and the environment. Proper recycling and reducing plastic use are key to mitigating its long-term environmental impact.

Only a small percentage of plastic film is recycled, with estimates ranging from 5% to 15%, depending on the region. Plastic film is often excluded from curbside recycling programs due to its lightweight nature and the challenges of processing it. However, some specialized collection programs, like those at grocery stores, help increase recycling rates. The majority of plastic film ends up in landfills or is incinerated, which highlights the need for better recycling infrastructure and consumer education on proper disposal practices.

Nylon film is technically recyclable, but it is not widely accepted in standard recycling programs due to its complexity and the difficulty in separating it from other materials. Nylon film is often used in food packaging, medical products, or textiles, and its recycling process requires specialized equipment to handle the polymer. While it can be recycled in certain industrial settings, it’s important to check with local recycling programs to see if they accept nylon film. Otherwise, it is often disposed of in landfills.

Plastic film, like many types of plastic, can have significant negative impacts on the environment. It is lightweight and often not recycled, leading to large amounts of plastic waste that end up in landfills or the ocean. Plastic film can take hundreds of years to decompose, and as it breaks down, it fragments into microplastics, which are harmful to wildlife and ecosystems. Moreover, plastic film contributes to pollution when it enters water bodies, where it can suffocate marine life or be ingested by animals, leading to health problems.

Polyolefin film, commonly used in packaging and shrink wrap, is recyclable in many regions, provided it is clean and uncontaminated. Polyolefin films, which include polyethylene (PE) and polypropylene (PP), are accepted at many specialized plastic film recycling locations, such as grocery store drop-off bins. These films can be processed into new products, including plastic lumber or new packaging materials. However, it is essential to check with local recycling programs to see if they accept polyolefin films, as some areas do not have the infrastructure to process them.

Printed plastic film can generally still be recycled, but the process can be more complex. The inks and dyes used for printing can contaminate the recycling stream, making it harder to process the film. In some cases, printed films may need to be cleaned or stripped of ink before they can be recycled. If the film is composed of recyclable materials like polyethylene or polypropylene and is free of contaminants, it can be accepted by specialized recycling facilities. It’s best to check with local recycling guidelines for specific rules on printed films.

Styrofoam, or expanded polystyrene (EPS), is not recyclable as a plastic film. While some types of polystyrene can be recycled, Styrofoam is too lightweight and porous to be processed in most recycling systems. Styrofoam can take hundreds of years to decompose, and when it breaks down, it fragments into small particles that are harmful to wildlife. Styrofoam is often disposed of in landfills or incinerated, where it can release toxic chemicals. Many regions have begun to ban or reduce Styrofoam use in packaging and food containers due to its environmental impact.

When plastic film is collected and sent for recycling, it is typically cleaned and processed into smaller pieces. These pieces are then melted down and reformed into new products, such as plastic lumber, new packaging, or recycling bags. However, due to contamination issues and the lack of widespread facilities to process film, much of the collected plastic film is still sent to landfills. To improve recycling rates, more efficient collection systems and technologies are needed to handle plastic film and increase its potential for reuse.

Biodegradable film is made from natural polymers, such as starch, cellulose, or plant-based plastics like polylactic acid (PLA). These materials are designed to break down more quickly than conventional plastic films when exposed to natural environmental conditions, such as heat, moisture, and microbial activity. Biodegradable films are often used in food packaging or agricultural applications where rapid decomposition is desired. However, they still require specific conditions for proper decomposition, and they may not break down as effectively in landfills or the ocean.

Plastic films made from materials such as mixed plastics or those with excessive contamination cannot be recycled. Films that are laminated with multiple types of plastics, such as aluminum or other additives, are difficult to process and usually end up in landfills. Additionally, films with food residue, grease, or other contaminants are not suitable for recycling because they can disrupt the recycling process. Always check local recycling guidelines to ensure the plastic film is clean and accepted for recycling.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed