Pallet wrap is an essential tool in the warehousing, shipping, and storage industries. Security Pallet Wrap provides tamper-evident protection, high strength, excellent cling, and up to 250% stretch for secure pallet wrapping. It is commonly used to secure goods on pallets, providing stability and pallet protection during transit and while in storage. The most common type of pallet wrap is stretch film, which is designed to stretch and cling tightly around products, preventing them from shifting or becoming damaged. One specialized form of this product is security pallet wrap, which not only offers the typical benefits of standard stretch film but also enhances security by adding tamper-evident features. This makes security pallet wrap particularly valuable when transporting high-value or sensitive items, as it helps prevent theft and tampering. Ensuring the safety of goods with security pallet wrap is crucial for businesses aiming to protect both their products and their reputation.

Security pallet wrap is a specialized type of stretch film designed to provide additional protection for goods during storage and transportation. Here’s a breakdown of its key features and importance:

Security pallet wrap is an essential tool for protecting palletized goods during storage, handling, and transportation. It offers a variety of features and benefits that make it an ideal choice for businesses seeking efficient, secure, and cost-effective packaging solutions. Here’s a detailed look at the key features and benefits of security pallet wrap:

Security pallet wrap provides a visual indicator if the pallet has been tampered with. This feature is crucial for safeguarding valuable or sensitive goods, as it discourages theft and unauthorized access. When the wrap is broken or damaged, it clearly signals potential tampering, enhancing overall security during transit.

Made from high-strength, bi-oriented polypropylene (BOPP) material, security pallet wrap is engineered for maximum durability. It resists punctures, tears, and abrasions, ensuring that your products remain secure and protected even in rough handling or transportation conditions. This toughness helps prevent damage to the goods and reduces the risk of product loss.

The wrap features a high-cling inside face that ensures it sticks securely to itself, creating a tight and stable wrap around the pallet. This eliminates the need for additional strapping or securing methods, saving time and costs. The strong cling also helps prevent the film from unraveling during transit, offering better protection for your goods.

One of the standout features of security pallet wrap is its ability to stretch up to 250% without tearing. This high stretch ratio means that you can secure more with less material. It helps improve efficiency by reducing material usage, which results in cost savings. Additionally, the ability to stretch the film without compromising its strength enhances the security of your load.

The outer face of the security pallet wrap has low cling properties, making it easier to remove the wrap from adjacent pallets. This reduces the chance of pallets sticking together, which can cause complications during handling and transportation. The low cling design ensures that wrapped pallets can be easily separated, improving the overall efficiency of warehouse operations.

Security pallet wrap comes in a range of variants tailored to different needs. Whether you require Heavy Duty, Airforce Max, or a recycled version, the flexibility of these wraps makes them suitable for a variety of industries, including food, retail, and logistics. You can use the wrap to secure a wide range of products, including boxed goods, bulk items, and heavy-duty loads.

Black security pallet wrap is particularly useful for concealing the contents of a pallet. This is valuable when shipping sensitive, high-value, or confidential items that need to remain hidden from view. Load concealment also adds an extra layer of security by reducing the risk of theft or tampering.

For businesses focused on sustainability, some types of security pallet wrap are made from up to 27% recycled materials. These recycled wraps maintain the same high level of performance while helping reduce environmental impact. By choosing recycled options, businesses can contribute to reducing waste and promoting eco-friendly practices.

Security pallet wrap is available in vented versions that include die-cut holes to allow air circulation. This is especially useful for wrapping perishable goods such as fresh produce or temperature-sensitive items. The ventilation helps maintain the freshness of the products, preventing mold growth and spoilage during cold storage or transport.

With rolls that offer up to 1000 feet of stretch film per roll, security pallet wrap provides ample coverage, making it a cost-effective option for wrapping multiple pallets or large loads. The wrap’s high stretchability means less material is needed to secure each pallet, further enhancing cost savings.

Security pallet wrap is designed for both manual and machine application, making it easy to use in a variety of settings. Whether using simple hand-held tools or more advanced pre-stretch machines, the wrap offers consistent and reliable performance. This ease of application helps reduce labor time and increases productivity in warehouses and distribution centers.

Security pallet wrap provides a protective barrier against moisture, dust, dirt, and other environmental contaminants. This is particularly beneficial for goods that need to be protected from the elements, such as electronics, food products, or pharmaceuticals. The wrap ensures that your goods stay clean and dry, reducing the risk of damage or contamination during transportation or storage.

The wrap’s high stretchability and strong cling properties reduce the amount of time and effort required to secure pallets. This can lead to significant labor savings, as workers can wrap pallets more quickly and efficiently. The simplicity of application also reduces the need for specialized training, allowing for faster onboarding of staff.

By tightly securing goods to the pallet, security pallet wrap helps prevent shifting or toppling during transit. This stability is critical for preventing product damage and ensuring that items arrive at their destination in the same condition they were packed.

Security pallet wrap provides a comprehensive range of features that make it a highly effective solution for protecting goods during transit, storage, and handling. With its combination of strength, stretchability, and versatility, it enhances security, reduces costs, and improves efficiency, making it an essential tool in modern logistics and packaging operations.

Security pallet wrap comes in various types to meet the diverse needs of businesses across different industries. Each type of pallet wrap offers unique features and benefits, allowing companies to choose the most suitable option for their specific requirements. Below are some of the common types of security pallet wrap:

Standard stretch wrap is the most commonly used type of security pallet wrap. It offers a strong, reliable barrier to protect goods during transportation and storage. This type of wrap is ideal for general-purpose use and provides excellent cling properties to keep the wrap securely in place. It is suitable for both manual and machine application, making it a versatile and cost-effective solution for everyday packaging needs.

Heavy duty stretch wrap is designed for more demanding applications. It is thicker and stronger than standard stretch wrap, making it ideal for securing heavier loads and more fragile or valuable items. This type of wrap offers superior puncture resistance, tear strength, and durability, providing an extra layer of protection during rough handling or transportation. It is commonly used in industries such as automotive, construction, and logistics where heavy or high-value products are involved.

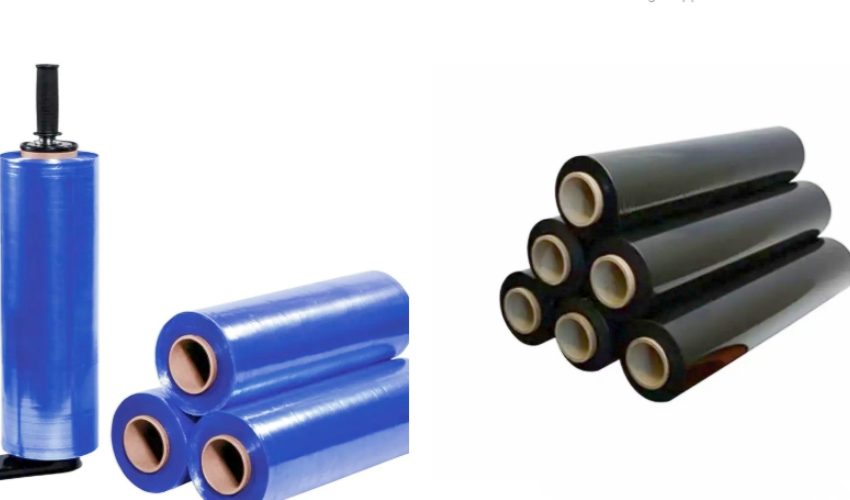

Black stretch wrap is specifically designed for load concealment. It offers the same strength and performance as other types of stretch wrap but provides a black color that hides the contents of the pallet. This feature is beneficial when shipping or storing sensitive or high-value items, as it prevents theft, tampering, or accidental damage. Black stretch wrap is often used in retail, security-sensitive shipments, and for protecting confidential goods.

Vented stretch wrap features perforations or die-cut holes that allow air to circulate through the wrap. This is especially important when shipping or storing perishable goods, such as fresh produce, flowers, or temperature-sensitive items. The ventilation helps to prevent mold growth, spoilage, and moisture buildup, ensuring the freshness and longevity of the products. Vented stretch wrap is commonly used in the food industry and cold storage facilities.

Recycled stretch wrap is made from a blend of post-consumer and post-industrial plastic, helping to reduce environmental impact. This type of wrap offers the same performance as non-recycled alternatives but is a more sustainable option. It is suitable for businesses that prioritize eco-friendly packaging practices and want to reduce their carbon footprint. Recycled stretch wrap is commonly used in industries that emphasize sustainability, such as retail and manufacturing.

Pre-stretch film is a type of stretch wrap that is pre-stretched during the manufacturing process. It is highly efficient because it requires less material to achieve the same strength and stretch as regular stretch wrap. Pre-stretch film is often used in automatic or semi-automatic stretch wrapping machines, as it helps improve productivity and reduce material waste. This type of wrap offers better load retention and improved stretch consistency, making it ideal for use in high-volume environments.

Air Force Max stretch wrap is a high-performance film designed for heavy-duty applications. It features a higher stretch capacity than standard wraps, with the ability to stretch up to 250% without tearing. This type of wrap provides excellent load retention and ensures a secure, tight wrap even on irregularly shaped loads. It is commonly used for securing large or bulky items in logistics, shipping, and warehouse environments.

Colored stretch wrap comes in a variety of colors, such as red, blue, green, and yellow. While it offers the same protective qualities as clear stretch wrap, it also helps with color-coding and load identification. Businesses can use colored stretch wrap to distinguish different types of products, indicate priority shipments, or manage inventory more efficiently. It is commonly used in warehouses and distribution centers for better organization and visual management.

Shrink wrap, though similar to stretch wrap, differs in its application. Shrink wrap is applied over the pallet and then heated to form a tight, protective seal. It provides superior protection against moisture, dirt, and debris, making it ideal for long-term storage or for products that require extra protection. Shrink wrap is commonly used for securing products during shipping or protecting items that need to be kept tightly sealed, such as electronics, food, or pharmaceuticals.

Gusseted pallet top covers are used to protect the top of a palletized load. They are often used in combination with stretch wrap to provide complete coverage for items that need additional protection. These covers are designed to be placed over the top of a wrapped pallet, ensuring that the contents are shielded from dust, dirt, or moisture. They are particularly useful for protecting fragile items or materials that are susceptible to contamination.

Pallet shrink wrap bags are large bags that fit over a pallet and shrink when heat is applied. These bags create a tight, protective seal that provides excellent security and moisture protection for the contents. They are ideal for wrapping bulky or irregularly shaped items that cannot be easily wrapped with traditional stretch film. Pallet shrink wrap bags are commonly used in industries such as food packaging, pharmaceuticals, and furniture.

Coreless stretch wrap is a type of wrap that does not require a cardboard core for its structure. This type of wrap is lightweight and environmentally friendly, as it reduces the amount of waste generated from the core. Coreless stretch wrap is ideal for use in automated packaging systems and for businesses looking to minimize packaging waste while still maintaining the strength and security needed for their loads.

The various types of security pallet wrap offer a range of features tailored to different industries and applications. Whether you’re looking for eco-friendly options, load concealment, or specialized protection for perishable goods, there’s a security pallet wrap that fits your needs. By selecting the right type of wrap, businesses can ensure that their products are securely protected while optimizing efficiency and reducing costs.

Security pallet wrap offers several advanced features that make it highly effective for securing goods during storage and transportation. Here’s a detailed look at the key characteristics that distinguish it from pallet wrapping standards:

Pallet shrink wrap is designed to provide a tight, secure wrap around products, ensuring that items remain in place and are protected from external damage. Security pallet wrap takes this a step further by incorporating tamper-evident properties, which help ensure that any unauthorized access to the pallet is immediately noticeable.

This extra layer of security is particularly beneficial for businesses that ship valuable or sensitive items, where even small signs of tampering can be costly.

One of the standout features of security pallet wrap is its ability to reduce the visibility of the contents of a pallet. Black stretch wrap is commonly used for this purpose. By using opaque or dark color stretch film, the contents of the pallet become less visible to the outside world, providing an additional layer of security.

This is ideal for high-value goods or sensitive products that may be at risk of theft or unwanted attention during transportation or in storage. Black stretch wrap ensures that only authorized personnel can easily access and inspect the goods, further reducing the chances of theft.

For businesses looking for high efficiency in wrapping large quantities of pallets, security pallet wrap is fully compatible with pallet wrapping machines. Whether using automatic or semi-automatic machines, these wraps allow for faster and more consistent application.

This compatibility enhances productivity in warehouses and distribution centers, where wrapping efficiency is essential for meeting tight deadlines. Additionally, pallet wrapping machines ensure that the film is stretched properly and applied with the right tension, maximizing the effectiveness of the security pallet wrap.

Security pallet wrap is a versatile and essential packaging material used across various industries to secure goods during storage, transportation, and handling. Its wide range of applications ensures that products are protected from damage, tampering, and environmental factors. Below are some of the key applications of security pallet wrap:

One of the most common applications of security pallet wrap is securing goods on pallets for shipping. The wrap ensures that the products stay in place during transit, preventing them from shifting or toppling over, which could cause damage. It also helps to keep products tightly bound together, reducing the risk of product loss or theft. Whether for domestic or international shipping, security pallet wrap ensures that the cargo is stable and protected from the elements.

In warehouse settings, security pallet wrap is used to secure items stored on pallets. This helps maintain load stability and prevents the contents from shifting during storage. It is particularly useful in high-traffic environments where pallets are moved frequently by forklifts or other machinery. The wrap also helps to optimize warehouse space by ensuring that items are safely secured and can be stacked or stored more efficiently.

Security pallet wrap is ideal for protecting fragile and high-value items during storage or transportation. Its strong and durable nature helps prevent damage to sensitive products, such as electronics, glass, or pharmaceuticals. The wrap shields these items from impacts, abrasions, and environmental factors like dust, moisture, and dirt. For valuable shipments, such as electronics or expensive machinery, the wrap adds an extra layer of protection, reducing the risk of damage and ensuring that products arrive at their destination in optimal condition.

Security pallet wrap provides an effective barrier against moisture, dust, dirt, and other contaminants. It is commonly used to protect products that are sensitive to these environmental factors, such as food, paper products, textiles, and chemicals. The wrap helps to maintain the cleanliness and quality of the goods, especially when they are exposed to humid or dusty conditions during storage or transit.

Black security pallet wrap, in particular, is used for load concealment, ensuring that the contents of a pallet are hidden from view. This is particularly useful for shipping sensitive items, such as confidential documents, high-value goods, or proprietary products. By concealing the contents, businesses can reduce the risk of theft or tampering. It also helps protect against accidental exposure to unauthorized individuals, providing added security.

Vented stretch wrap is used for temperature-sensitive products that need to breathe during storage or transportation, such as fresh produce, flowers, and certain pharmaceuticals. The die-cut holes in the wrap allow air to circulate around the products, helping to maintain their freshness and prevent moisture buildup. When paired with thermal pallet wrap, which offers added insulation to maintain a stable temperature, this combination ensures that products stay fresh and are protected from both environmental factors and temperature fluctuations, making it especially important in industries like food distribution.

Security pallet wrap is also used to bundle smaller items together for easier handling, storage, or transportation. Whether it’s securing tools, hardware, or other small products, the wrap ensures that the items stay together and are not scattered or lost. Bundling helps streamline the packing and shipping process, saving time and reducing the risk of items being misplaced or damaged.

In the cold storage and refrigerated shipping industries, security pallet wrap plays a key role in protecting goods that require consistent temperature conditions. The wrap helps to keep the products sealed and secure, reducing exposure to temperature fluctuations and contaminants. Vented stretch wrap is particularly useful in this application, as it ensures proper airflow while maintaining temperature control for perishable goods.

Recycled stretch wrap is used by companies that prioritize sustainability and eco-friendly packaging solutions. This type of security pallet wrap, made from recycled plastic materials, provides the same level of performance as traditional wraps but with a lower environmental impact. It is commonly used in industries that are committed to reducing waste and supporting green initiatives, such as retail, logistics, and manufacturing.

For unique or custom loads, security pallet wrap can be tailored to meet specific requirements. For example, certain items may need extra-heavy-duty protection, or the wrap may need to be pre-stretched for efficiency in automated systems. Security pallet wrap can also be used for wrapping irregularly shaped products, such as furniture or large machinery, to ensure they are tightly secured and protected during transport.

For international shipments, security pallet wrap is often used in conjunction with other protective packaging methods to ensure that goods arrive safely and securely. The wrap helps prevent damage from rough handling during transit and protects the products from external factors like moisture or temperature changes. This is especially important when goods are being shipped long distances or to locations with unpredictable weather conditions.

Security pallet wrap is also used to protect goods that are stored outdoors, such as building materials, machinery, or equipment. The wrap shields the products from the elements, including rain, snow, and sunlight, ensuring that the items remain in good condition even when exposed to harsh outdoor conditions. It is a cost-effective solution for protecting materials stored in open-air environments or temporary storage areas.

Security pallet wrap has a wide range of applications across various industries. It is an essential tool for protecting goods, ensuring load stability, maintaining product quality, and improving the efficiency of storage and transportation. Whether for everyday shipments or specialized needs, security pallet wrap provides a reliable and versatile solution to meet the unique requirements of modern logistics and packaging operations.

When using security pallet wrap in industrial environments, safety is of utmost importance. Pallet wrapping, whether performed manually or with a pallet wrapping machine, involves handling stretch films and machinery that can present safety risks if not properly managed. Ensuring compliance with OSHA guidelines helps mitigate these risks and ensures that workers are protected from potential injuries during the wrapping process.

When using a pallet wrapping machine, proper training is essential. Operators should be thoroughly educated on the specific model of machine they are working with, including safety features, settings, and emergency procedures.

OSHA guidelines also emphasize the importance of using equipment that meets safety standards. Machines should have proper safeguards to prevent contact with moving parts, and all equipment should be inspected regularly to ensure that it functions as intended.

Training should also cover safe loading and unloading practices to prevent accidents during the wrapping process.

Whether using security pallet wrap manually or with a pallet wrapping machine, it’s important to follow safe handling procedures. Stretch wrap rolls can be heavy, and improper lifting or handling can cause back injuries or strains.

Workers should be trained on proper lifting techniques when handling large rolls of security pallet wrap, and ergonomic workstations should be set up to minimize strain. Additionally, workers should be instructed on the correct methods for threading and operating pallet wrapping machines to avoid accidental injuries.

Personal protective equipment (PPE) plays a vital role in maintaining safety when using security pallet wrap. OSHA guidelines recommend PPE such as gloves, safety shoes, and eye protection when working with stretch film and machinery.

Gloves should be worn to protect against cuts and abrasions from the shrink wrap materials and sharp edges of the machinery. In environments where there is a risk of flying debris or chemicals, eye protection is essential. For tasks involving heavy lifting or movement, safety shoes can protect against foot injuries.

Additionally, it’s advisable to wear hearing protection if working with loud machinery, especially in large-scale operations where pallet wrapping machines may generate high noise levels.

When using security pallet wrap for packaging or shipping automotive parts and vehicles, it’s important to consider the potential impact of the wrap on delicate surfaces like automotive paint. Although stretch wrap is commonly used in industries for securing loads, its application on painted surfaces requires careful attention to avoid damage.

Pallet wrap is designed to cling tightly to surfaces, which can sometimes be too aggressive for delicate finishes like automotive paint. If security pallet wrap is applied too tightly or left on for too long, it can cause the paint to peel or develop imprints where the wrap was in direct contact with the surface. This can be especially problematic for high-gloss finishes or custom-painted vehicles.

Additionally, the heat generated by the wrap, particularly in warmer climates, can cause the film to adhere too strongly to the paint, making it difficult to remove without leaving residue or damaging the paint job. For this reason, extra caution is needed when using security pallet wrap on painted surfaces.

Prolonged exposure to security pallet wrap can cause “ghosting” or marks on the paint, which are visible imprints left by the film. This is particularly a concern with black stretch wrap, as the dark color can trap more heat and increase the likelihood of damage.

There is also the risk of moisture becoming trapped between the wrap and the paint, leading to mold or rust if the vehicle or parts are exposed to moisture. Security pallet wrap can create a sealed environment that doesn’t allow the surface to breathe, causing condensation to build up, especially when transporting goods in humid or wet conditions.

To minimize the risk of damaging automotive paint, it’s important to apply security pallet wrap loosely, ensuring that it clings securely without applying too much pressure. This can be achieved by using machines that allow for controlled tension when wrapping, or by wrapping manually with extra care.

One effective practice is to use protective materials between the security pallet wrap and the paint. For instance, soft protective covers, blankets, or foam sheets can be placed over the painted surfaces before wrapping. These protective layers act as a buffer, preventing direct contact between the wrap and the vehicle’s paint, reducing the risk of damage.

Security pallet wrap should only be used for short periods and in controlled environments to prevent any adverse effects. Additionally, using UV-resistant wrap can help protect the car finish from prolonged sun exposure, which could otherwise cause fading or degradation of the paint.

One of the advantages of using security pallet wrap on automotive parts is its ability to protect against UV rays and moisture. Security pallet wrap often comes with UV-resistant properties, which can help shield the painted surfaces from sun damage while in transit or storage. This is particularly important when shipping vehicles or parts to areas with intense sunlight or outdoor storage conditions.

Moisture protection is another benefit. Security pallet wrap helps shield vehicles from rain, dust, and dirt during transportation, particularly in open-air shipping methods. However, as mentioned earlier, it’s essential to ensure there’s proper air circulation, as trapped moisture can be harmful over time.

While security pallet wrap offers some benefits for automotive protection, there are alternatives to consider for preserving paint finishes. For instance, using protective plastic sheeting or bubble wrap instead of stretch film provides an additional layer of cushioning that reduces the risk of paint damage.

Additionally, some companies offer specially designed vehicle wraps that are softer and more suitable for long-term contact with painted surfaces. These wraps are made from materials designed to protect against scratches, dents, and environmental factors while being easy to remove without causing damage.

Security pallet wrap plays a crucial role in preventing theft during the transportation and storage of goods. With its tamper-evident properties and ability to secure loads tightly, security pallet wrap offers visible indicators of tampering, making it an essential tool for safeguarding high-value items. Here’s a detailed breakdown of how security pallet wrap helps in theft prevention:

One of the primary features of security pallet wrap is its tamper-evident nature. This means that any unauthorized attempts to access the contents of a pallet will leave visible signs, such as stretch marks, tears, or breakage in the wrap. The wrap’s strong cling and stretch properties make it difficult for unauthorized individuals to remove without leaving traces of tampering.

These tamper-evident characteristics act as a deterrent to thieves. They are less likely to attempt to steal or tamper with goods if they know that any tampering will be immediately noticeable, providing an added layer of security during transit and storage.

Security pallet wrap is typically made of high-quality stretch film with a noticeable tear resistance, meaning any unauthorized access will cause visible damage to the film. This damage can include visible holes or tears in the wrap, which are easily detected by security personnel or workers during routine checks.

In addition, some security pallet wraps are designed with perforations or printed security messages. For instance, the film might display a “VOID” or “OPENED” message if tampered with, making any tampering immediately evident. These types of security pallet wrap are commonly used to wrap high-value items such as electronics, pharmaceuticals, or luxury goods, where security is paramount.

Black stretch wrap is often used in industries where high-value or sensitive products need to be transported or stored. The opaque nature of black stretch wrap makes it harder to visually inspect the contents without unwrapping, which adds an extra layer of security. Thieves are less likely to target goods that cannot be easily identified, and the lack of visibility discourages theft.

For example, in a case involving a large electronics shipment, security pallet wrap with black stretch wrap was used to securely wrap pallets containing expensive devices. The wrap provided not only physical security by keeping the goods tightly bound but also prevented visual inspection, making it more difficult for thieves to assess the contents during transit. As a result, the shipment arrived at its destination without any incidents of theft or tampering.

Security pallet wrap can also be integrated with advanced security features like barcodes, serial numbers, and RFID tags. These features allow businesses to track and monitor the movement of goods, adding another layer of protection against theft.

Barcodes and serial numbers printed directly on the security pallet wrap allow for easy scanning and tracking of pallets throughout the supply chain. This makes it easier for security personnel to verify the integrity of the load and identify any discrepancies in case of theft.

In addition, the use of RFID (Radio Frequency Identification) tags in conjunction with security pallet wrap enables real-time tracking of goods. RFID technology provides a more sophisticated level of monitoring, ensuring that any unauthorized movement or tampering with wrapped pallets is detected promptly. For example, if a pallet is moved outside of its designated area or opened without authorization, the RFID system can trigger an alert, allowing immediate intervention to prevent theft.

Proper use of security pallet wrap is critical to ensuring the safety and integrity of goods stored for the long term. Whether it’s for raw materials, finished products, or sensitive items, using pallet shrink wrap effectively can protect goods from environmental factors, potential damage, and contamination during storage. Here’s a detailed look at the best practices for ensuring that security pallet wrap provides maximum protection during long-term storage:

Security pallet wrap plays a critical role in reducing the risk of unauthorized access or tampering during the storage, handling, and transportation of goods. Its tamper-evident and protective features ensure that products remain secure and intact throughout their journey. Here’s how security pallet wrap minimizes tampering risks:

One of the key features of security pallet wrap is its tamper-evident design. This means that any attempt to cut, tear, or remove the wrap from a pallet will leave visible signs of damage or disruption. For example, if someone tries to remove or breach the wrap, the integrity of the film will be compromised, creating obvious indicators of tampering. This provides a clear visual signal that the goods may have been accessed, deterring potential theft or unauthorized handling.

The high-cling properties of security pallet wrap ensure that the film sticks tightly to itself, binding the contents of the pallet securely. This creates a strong, unified barrier around the goods, preventing them from being easily accessed or moved. The wrap forms a secure seal that minimizes the risk of someone tampering with the load or accessing individual items without detection. The wrap ensures the load stays intact, reducing the chance of goods being stolen or mishandled during transit.

Unlike other packaging materials, security pallet wrap is difficult to remove without causing damage to the film itself. The strong cling and stretch properties create a tight hold around the pallet, making it challenging for unauthorized individuals to open or tamper with the load without leaving visible signs of tampering. Additionally, the wrap is designed to withstand rough handling and pressure, making it harder to puncture or cut without notice.

Black security pallet wrap adds an extra layer of protection by concealing the contents of the pallet. This is particularly useful when shipping high-value or sensitive items. The wrap obscures the load from plain sight, making it less likely to be targeted for tampering. For high-security shipments, the lack of visibility discourages potential theft or unauthorized access, as the contents remain hidden until they reach their final destination.

Security pallet wrap provides a protective barrier against environmental factors such as dust, moisture, and dirt. In addition to minimizing the risk of tampering, the wrap ensures that the contents of the pallet remain protected from contaminants that could compromise the quality of the goods. For instance, in the food industry or pharmaceuticals, maintaining the integrity of the packaging is crucial, and the wrap helps ensure that no external factors interfere with the goods.

Since security pallet wrap is designed to provide both tamper-evident and physical protection, it reduces the need for additional security measures, such as extra locking systems or excessive layers of packaging. The wrap itself provides an effective deterrent against unauthorized access, making it a more efficient and cost-effective solution for securing goods. For example, in high-risk industries or high-value shipments, the wrap alone can provide a significant level of security without requiring additional labor or materials.

Security pallet wrap helps businesses maintain better control over their products by ensuring that only authorized individuals can access the palletized load. The wrap acts as a barrier, and any attempt to breach it will be immediately noticeable, allowing for better accountability in the supply chain. It also helps in tracking goods more effectively, as the integrity of the wrap ensures that products have not been tampered with during transportation.

During the shipping process, security pallet wrap ensures that pallets remain tightly bound and secure, even in the most turbulent conditions. The wrap prevents goods from shifting, and it ensures that the contents of the pallet are not exposed to unauthorized personnel during handling or loading/unloading. The tightness of the wrap also prevents the possibility of accidental tampering, as it requires deliberate action to break the seal.

In addition to its tamper-evident properties, security pallet wrap often includes unique markings, such as logos or specific patterns, that can further indicate if the load has been tampered with. If someone tries to manipulate or remove the wrap, these markings will be disturbed or damaged, making it easy to identify if tampering has occurred. This added level of security helps deter unauthorized access and encourages compliance with shipping protocols.

Security pallet wrap plays a pivotal role in minimizing the risk of unauthorized access or tampering. Its tamper-evident features, secure cling, load concealment, and protective qualities all combine to create a highly effective barrier against theft, tampering, and environmental exposure. This makes security pallet wrap an essential tool for businesses that need to ensure their goods remain secure during storage, transit, and handling.

When looking for black security pallet wrap, sourcing the right product locally can provide several advantages, including faster delivery times, personalized customer service, and the ability to inspect the quality of the product in person. Here are some tips and considerations for finding reliable suppliers of pallet shrink wrap in your area and the benefits of local purchases:

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed