Shrink wrap commercial solutions play a crucial role in various industries, offering a versatile and protective packaging method for different types of products. Shrink wrap packaging involves covering items with a thin plastic film that, when heated, shrinks tightly around the object, securing it in place. This method is commonly used across industries such as retail, manufacturing, and shipping, providing a reliable way to protect goods from dust, moisture, and damage during transportation. With the rise of advanced commercial shrink wrap machines and industrial heat shrink wrap products, businesses can streamline packaging processes, enhance product safety, and ensure consistent, high-quality wrapping. PWP Stretch Film offers solutions ideal for small to large-scale commercial applications. Shrink wrap commercial products protect against weather, with versatile options to meet industrial shrink wrap needs in construction and more.

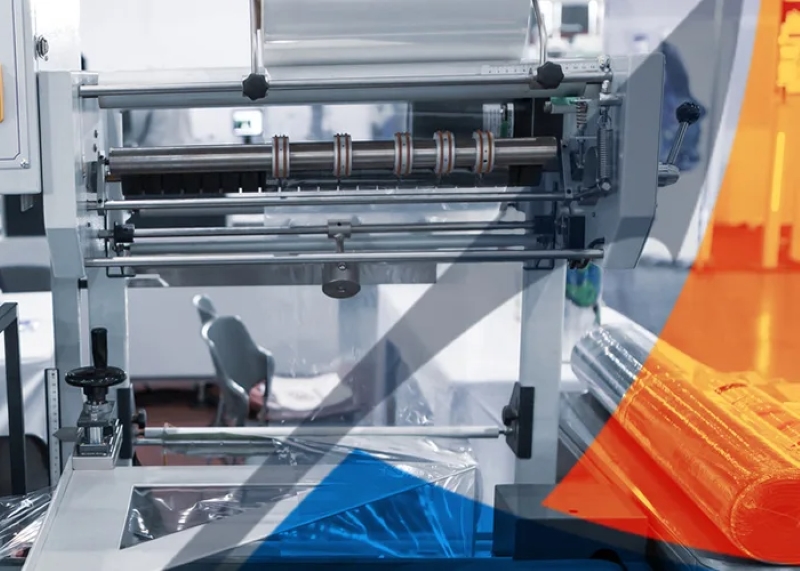

Shrink wrap commercial applications are widely used in industries for their efficiency and effectiveness in protecting products. Shrink wrap packaging is a process where a product is wrapped in a clear plastic film, usually made of polyolefin or PVC. Once the product is covered, heat is applied, typically through a heat gun or shrink tunnel. The heat causes the film to contract tightly around the item, forming a secure and protective seal.

Shrink wrap packaging works by utilizing a combination of heat and special plastic materials. The shrink film, which comes in various thicknesses, is placed over or around the product. When heat is applied, the film shrinks evenly, conforming to the shape of the product. This process not only holds the product in place but also provides a layer of protection against dust, moisture, and tampering. The tight seal that shrink wrap provides is crucial for preserving product quality during transportation and storage.

Shrink wrap commercial applications are essential in numerous industries, ranging from retail to heavy-duty industrial operations. In retail, clear plastic on a roll is commonly used for packaging consumer goods like electronics, books, food products, and toys. The clear plastic not only protects these items but also enhances their presentation by offering a professional, glossy finish. In industrial settings, shrink wrap is used to protect larger items such as machinery, construction materials, and even vehicles during transit.

One of the key benefits of shrink wrap commercial packaging is its ability to create a tamper-evident seal, which is especially important in industries that handle sensitive products such as pharmaceuticals or food. Additionally, the film can bundle multiple items together, making shipping and handling easier.

The most common materials used in shrink wrap commercial applications include polyolefin (POF) and polyvinyl chloride (PVC). Polyolefin is known for its durability, flexibility, and clarity, making it suitable for wrapping a wide range of products. It’s also food-safe, making it ideal for packaging edible items. PVC, on the other hand, is a cost-effective option often used in industrial applications. It offers excellent protection and has a stronger seal, though it is not typically used for food products due to chemical concerns.

Shrink wrap commercial applications often require specialized materials like industrial heat shrink wrap, which is a crucial tool for industries that demand durability and protection. Unlike regular shrink wrap used in retail settings, industrial heat shrink wrap is designed to handle more intensive tasks, providing robust protection for larger or more sensitive items. This form of shrink wrap is thicker, stronger, and often more versatile than its consumer-grade counterpart, making it an indispensable solution for heavy-duty commercial uses.

Industrial heat shrink wrap works similarly to regular shrink wrap, but with more advanced materials and thicker films, typically ranging from 6 to 12 mils in thickness. The process involves wrapping large or heavy-duty items, such as construction materials or industrial equipment, with a durable plastic film. Once applied, the film is heated using industrial-grade heat guns or shrink tunnels, causing it to shrink tightly around the object.

The primary difference between industrial heat shrink wrap and regular shrink wrap lies in its thickness and strength. Industrial shrink wrap can withstand harsh environmental conditions, offering protection from moisture, UV rays, and even physical damage during transport. Brands like PWP Stretch Film provide specialized industrial shrink wrap designed to handle these challenging conditions, ensuring that even the most delicate equipment is well protected during storage or transit.

Shrink wrap commercial applications are widespread across multiple industries, but industrial heat shrink wrap is particularly essential in the following sectors:

Industrial heat shrink wrap offers numerous benefits that make it indispensable for shrink wrap commercial applications:

Shrink wrap commercial applications require efficient and reliable packaging solutions, especially for high-volume production environments. Commercial shrink wrap machines are designed to streamline the wrapping process, ensuring that products are packaged quickly and consistently. These machines are ideal for businesses that need to shrink wrap products in large quantities, offering automation and control that can significantly reduce labor costs while improving the overall packaging quality. In this section, we will explore the different types of commercial shrink wrap machines, their advantages, and key features to consider when selecting the right machine for your needs.

There are two main types of commercial shrink wrap machines used in industrial and commercial settings: automatic and semi-automatic machines.

Both automatic and semi-automatic machines play a vital role in shrink wrap commercial applications, with the choice depending on the volume of packaging, budget, and specific operational needs.

Investing in a commercial shrink wrap machine offers numerous benefits for businesses, especially those dealing with high-volume packaging tasks. Here are six key advantages of using these machines:

When selecting a commercial shrink wrap machine, it’s essential to consider specific features that will meet the operational needs of your business. Here are six important features to look for:

In many industries, shrink wrap commercial solutions require durable and robust materials to protect large-scale projects. Utilizing 100 gauge shrink wrap, heavy-duty heat shrink wrap offers the ideal combination of strength, flexibility, and protection for industrial applications. This type of shrink wrap is designed to withstand harsh environments, ensuring that even the most sensitive or bulky items are securely protected during shipping, storage, or on-site covering.

Heavy-duty heat shrink wrap is distinguished by its superior durability and strength, which make it suitable for demanding industrial uses. Unlike lighter shrink wraps used in retail or small packaging, heavy-duty shrink wrap is typically made of thick plastic materials, such as polyolefin or polyethylene, and comes in high-gauge ratings for added protection. This thickness allows the wrap to resist tearing, puncturing, and damage from extreme weather conditions. For large-scale projects, the wrap creates a secure, weather-resistant barrier, safeguarding items from exposure to moisture, UV rays, and even physical impacts. PWP Stretch Film’s heavy-duty options are known for their resilience, making them perfect for long-term or high-stakes applications.

There are various types of heavy-duty heat shrink wrap designed to meet the needs of different industries. The most common types include:

Heavy-duty heat shrink wrap is essential for various large-scale projects in industries such as construction, transportation, and manufacturing. Some of the most common applications include:

Shrink wrap commercial solutions play a crucial role in the marine industry, especially when it comes to protecting boats and other marine equipment. Given the significant investment required for boats, shrink wrap is essential for maintaining their condition and safeguarding them from the elements. Whether it’s for off-season storage, long-distance transportation, or general protection against harsh weather, shrink wrap offers a secure and effective method to ensure that marine vessels and equipment remain in pristine condition.

In the marine industry, boats and marine equipment are constantly exposed to environmental factors like moisture, UV rays, saltwater, and debris, all of which can cause significant damage over time. This is where shrink wrap commercial applications prove their value. Shrink wrap provides a tight, weatherproof seal that acts as a protective barrier, preventing damage from rain, snow, and the sun’s harmful UV rays. Without adequate protection, boats can suffer from water damage, corrosion, fading, and even structural wear, especially during extended periods of storage or transport.

Shrink wrapping is particularly useful for owners who need to store their boats outdoors during the off-season or transport them across long distances. The material is strong enough to withstand high winds and heavy snow loads, keeping the boat secure and undamaged. This not only preserves the boat’s condition but also reduces the need for costly repairs or maintenance, making shrink wrap a vital tool in the marine industry.

One of the primary uses of shrink wrap in the marine sector is for winter storage. As boats are generally not used during the colder months, they are often left vulnerable to environmental exposure. Heavy snow, ice, and freezing temperatures can damage boats if not adequately protected. Shrink wrap offers a comprehensive solution by providing a sealed, insulated barrier that keeps moisture, dirt, and other contaminants out.

During winter storage, a boat is typically wrapped in shrink wrap after being properly cleaned and winterized. The heat-shrink process ensures the wrap conforms tightly to the boat’s shape, providing a customized fit that keeps the elements out. Unlike tarps or other loose coverings, shrink wrap remains secure in even the harshest weather conditions, eliminating the risk of snow or rainwater pooling on the boat’s surface.

In addition to winter storage, shrink wrap is also widely used for transportation. Whether a boat is being moved across the country or simply being towed a few miles to a different dock, shrink wrap ensures that the vessel remains protected from road debris, dust, and flying particles. The tight seal reduces the risk of scratching, denting, or exposure to elements that could damage the boat during transit. For marine equipment and smaller vessels, shrink wrap commercial solutions ensure that these valuable items arrive at their destination in top condition, without the need for additional protective covers.

To maximize the effectiveness of commercial shrink wrapping solutions in the marine industry, several accessories are available that enhance protection and ease of use. These accessories ensure that the wrap is applied properly and provides additional benefits during storage and transportation.

As with any shrink wrap commercial application, it’s important to consider the environmental impact of using shrink wrap for boats. Many marine-grade shrink wraps are made from recyclable materials, meaning they can be recycled after use. Companies like PWP Stretch Film offer eco-friendly shrink wrap options that reduce waste and promote sustainability in the marine industry. Proper disposal and recycling of shrink wrap materials after storage or transportation is essential to minimize environmental impact.

Shrink wrap is an essential tool in the marine industry for protecting boats and marine equipment. Whether it’s for seasonal storage, long-distance transportation, or general protection against weather and environmental factors, commercial shrink wrap supplies solutions offer an effective way to maintain the condition of valuable marine assets. With the right accessories and careful application, boat owners can ensure their vessels are protected from the elements year-round.

Shrink wrap commercial products are essential for various industrial applications, offering tailored solutions to meet diverse needs. This section introduces three key types—heavy-duty building shrink wrap, flame retardant shrink wrap, and general-purpose shrink wrap—detailing their features and uses. It also explores additional specialized types, such as UV-resistant, VCI (vapor corrosion inhibitor), anti-static, and custom-printed shrink wraps, each designed for specific industrial requirements. Whether for construction, transportation, storage, or branding, shrink wrap commercial options provide reliable protection and functionality for a wide range of industries.

1. Heavy-Duty Building Shrink Wrap

This type is engineered for large-scale construction projects, offering exceptional durability to shield buildings, scaffolding, or materials from harsh weather conditions. It is thick, tear-resistant, and ideal for long-term outdoor use, ensuring project timelines are unaffected by environmental factors.

2. Flame Retardant Shrink Wrap

Specially designed for safety-critical environments, this shrink wrap includes flame-retardant additives to prevent the spread of fire. It is commonly used in construction sites, industrial storage areas, and events where fire hazards are a concern. This type meets stringent safety standards, making it a reliable choice for industrial applications.

3. General-Purpose Shrink Wrap

A versatile and cost-effective option, general-purpose shrink wrap is used for packaging, storage, and transportation needs. It provides moderate protection against dirt, dust, and moisture and is ideal for items that do not require heavy-duty or flame-retardant properties.

4. UV-Resistant Shrink Wrap

This type is designed to withstand prolonged exposure to sunlight without degrading. UV-resistant shrink wrap is widely used in outdoor storage and transportation, particularly for vehicles, boats, and machinery.

5. VCI (Vapor Corrosion Inhibitor) Shrink Wrap

VCI shrink wrap is infused with corrosion inhibitors to protect metal parts and machinery from rust during storage or transport. It is especially useful in industries dealing with sensitive equipment or international shipping.

6. Anti-Static Shrink Wrap

Perfect for the electronics industry, anti-static shrink wrap minimizes static electricity buildup, reducing the risk of damage to electronic components during handling and transportation.

7. Custom Printed Shrink Wrap

For branding or labeling needs, custom printed shrink wrap allows businesses to include logos, product details, or handling instructions directly on the wrap, enhancing professional presentation while providing protection.

These diverse options make shrink wrap commercial products indispensable across industrial sectors, meeting unique demands with tailored solutions.

To ensure shrink wrap commercial applications are safe, efficient, and long-lasting, the right supplies and accessories play a critical role. These tools enhance the durability, functionality, and quality of shrink wrap projects, making them indispensable for industrial use. Below is an in-depth look at the most commonly used accessories and their functions:

1. Shrink Wrap Tapes

Shrink wrap tapes are essential for sealing seams and creating a secure enclosure.

2. Shrink Wrap Vents

Ventilation is crucial for preventing moisture accumulation, which can lead to mold, mildew, or damage to the covered items. Shrink wrap vents are strategically installed to:

3. Polyethylene Woven Strapping and Buckles

For securing larger shrink wrap installations, polyethylene woven strapping and buckles offer:

4. Zipper Doors

Zipper doors provide access to enclosed areas without compromising the protective shell of the shrink wrap. They are particularly useful in industrial settings for:

5. Heat Guns and Torches

While not mentioned in the original list, heat guns and propane torches are indispensable for applying shrink wrap. They provide the controlled heat required to shrink the material evenly, ensuring a tight and durable fit.

6. Corner Guards

Corner guards protect sharp edges or corners of packaged items, preventing the shrink wrap from tearing. This accessory is essential for fragile or irregularly shaped goods.

7. Label Holders and Markers

Label holders allow for secure placement of shipping or identification labels on the shrink-wrapped package, while industrial-grade markers are used for direct labeling on the wrap, enhancing organization during transport and storage.

By combining these essential accessories with shrink wrap commercial applications, businesses can ensure a higher level of quality, safety, and efficiency across a wide range of industrial projects.

When it comes to industrial shrink wrap solutions, PWP Stretch Film stands out as a trusted industry leader, offering high-quality, durable, and customizable shrink wrap commercial products tailored to your specific needs. With a commitment to exceptional product performance, sustainability, and customer service, PWP Stretch Film is the go-to choice for industrial shrink wrap material. Here’s why:

1. Proven Durability and Versatility

PWP Stretch Film’s shrink wrap commercial products are designed to handle the toughest industrial challenges. With tear-resistant, UV-resistant, and flame-retardant features, these materials ensure maximum protection for construction, transportation, and storage needs. Whether shielding large equipment or securing pallets, their shrink wrap performs reliably in diverse conditions.

2. Custom Solutions for Every Project

No two projects are the same, and PWP Stretch Film understands this. They offer custom-sized rolls, allowing you to optimize materials for efficiency and cost-effectiveness. Their expert team works closely with you to understand your unique requirements, providing guidance and tailored solutions to ensure your packaging needs are met seamlessly.

3. Commitment to Sustainability

PWP Stretch Film prioritizes eco-friendly practices, offering fully recyclable shrink wrap commercial products. This commitment to sustainability helps reduce environmental impact without compromising on quality or performance, making it an ideal choice for businesses aiming to meet green initiatives.

4. A Legacy of Excellence and Innovation

With over eighteen years of experience, PWP Stretch Film has solidified its reputation as a leading manufacturer and supplier of high-performance stretch films, shrink wraps, and pallet wraps. Their cutting-edge manufacturing processes and partnerships with premium suppliers ensure access to the latest innovations in packaging materials.

5. Comprehensive Support and Expertise

PWP Stretch Film isn’t just about products; it’s about partnership. Their team of professional sales representatives, account specialists, and engineers provide unmatched support from consultation to project completion. Whether it’s contract packaging, custom design, or technical guidance, PWP Stretch Film ensures a seamless and confident experience for every customer.

6. Advanced Manufacturing Capabilities

Equipped with state-of-the-art automated systems and dedicated production lines, PWP Stretch Film delivers high-quality, consistent shrink wrap commercial products. Their rigorous quality control and advanced technology ensure every roll meets strict industrial standards, offering peace of mind for your packaging projects.

7. Customer-Centric Philosophy

At the heart of PWP Stretch Film’s approach is a dedication to customer satisfaction. They prioritize understanding the unique needs of their clients and delivering results that exceed expectations, ensuring your goods are protected, transported, and presented with excellence.

Choosing PWP Stretch Film’s shrink wrap commercial products means partnering with a company that values quality, innovation, and customer success. For durable, sustainable, and expertly tailored industrial shrink wrap solutions, PWP Stretch Film is the name you can trust.

For inquiries, reach out to pwpstretchfilm@gmail.com and experience the difference that top-tier shrink wrap solutions can make.

When wrapping large building scaffolding with shrink wrap commercial, selecting the appropriate size is critical for achieving optimal coverage, durability, and efficiency. The size of the shrink wrap required depends on the dimensions of the scaffolding, including its height, width, and complexity.

1. Common Sizes for Scaffolding Projects

Shrink wrap commercial for scaffolding typically comes in wide rolls ranging from 12 feet to 60 feet in width and lengths up to 500 feet. For large scaffolding structures, rolls that are 32 to 60 feet wide are commonly used, allowing for fewer seams and a smoother, more secure finish.

2. Factors to Consider When Choosing Size

3. Custom Sizing Options

If standard sizes do not fit your specific scaffolding setup, many suppliers, including PWP Stretch Film, offer custom-sized shrink wrap commercial rolls tailored to your project’s requirements. Custom sizes minimize waste and improve installation efficiency.

For large building scaffolding, shrink wrap commercial rolls typically range from 32 to 60 feet wide, but precise measurements and project-specific factors will determine the ideal size for your application.

Shrink wrap commercial is a versatile solution suitable for both short-term and long-term storage protection. It provides a durable, weather-resistant barrier that shields items from dust, dirt, moisture, and UV rays. However, the effectiveness of shrink wrap for storage depends on proper application and specific precautions to ensure optimal performance over time.

1. Short-Term Storage

For short-term storage, shrink wrap commercial can be applied to protect items like machinery, furniture, or pallets during transportation or temporary storage. It offers:

Precautions for Short-Term Use:

2. Long-Term Storage

For long-term storage, shrink wrap commercial is ideal for covering large equipment, boats, or scaffolding over extended periods. It offers:

Precautions for Long-Term Use:

Shrink wrap commercial is highly effective for both short-term and long-term storage protection when applied correctly and with the necessary precautions.

The salary of shrink wrappers can vary depending on factors such as location, experience, industry, and specific job responsibilities. On average, shrink wrappers working in entry-level positions in packaging or manufacturing environments may earn between $10 and $15 per hour. In industries requiring specialized skills, such as marine or industrial shrink wrapping, wages can be higher, often reaching $20 or more per hour. Additionally, some shrink wrap professionals who work with large-scale or heavy-duty projects may earn a higher salary due to the complexity of the work. Full-time shrink wrapping technicians employed by packaging companies or construction services may have annual earnings ranging from $25,000 to $50,000, depending on their role and the region they work in. Skilled professionals using advanced shrink wrap commercial equipment and offering services for larger industries may command even higher rates.

Shrinkwrap licenses, typically referring to end-user license agreements (EULAs) or terms of use that are included with products and services, can be enforceable, but their validity often depends on the jurisdiction and the specific terms of the agreement. In general, a shrinkwrap license is considered enforceable if it is presented in a way that users can reasonably be expected to notice and understand, such as through product packaging or software installation prompts. Courts in many countries may enforce these licenses as long as they meet the legal requirements for contract formation, including notice, consent, and an offer and acceptance process. However, some courts have ruled that if the terms are hidden or not easily accessible, the enforceability may be questioned. For example, the user must be given a clear opportunity to view and agree to the terms before using the product. Ultimately, the enforceability of shrinkwrap licenses can vary depending on local laws and how the terms are presented to the user.

In commercial settings, a shrink wrap machine is often called a heat shrink machine, shrink tunnel, or shrink wrap sealer, depending on the specific function. For packaging operations, there are manual, semi-automatic, and fully automatic shrink wrap machines. Key types include L-bar sealers, shrink tunnels, and chamber shrink machines. L-bar sealers cut and seal the shrink film around the product, while a heat shrink tunnel or chamber applies heat, causing the film to conform tightly to the item. These machines are essential in industries like food, electronics, and retail for creating tamper-proof, visually appealing, and protective packaging. Advanced models are equipped with features like adjustable temperature controls, conveyor systems, and film alignment tools, making them versatile for high-volume commercial operations. For businesses looking to invest, choosing the right machine depends on production scale, product size, and packaging requirements.

The cost of shrink wrap varies based on the type, quantity, and quality of the material used, but it is generally considered an affordable packaging solution for commercial applications. Standard shrink wrap films, such as polyolefin or PVC, cost between $5 to $20 per roll for small-scale operations, while larger industrial rolls can range from $50 to $500 or more. Polyolefin, known for its durability and food safety compliance, is slightly pricier than PVC but more versatile. Costs also depend on the thickness, measured in microns or gauge, and the size of the rolls purchased. When evaluating expense, businesses should consider equipment costs, energy usage, and labor in addition to the film itself. Despite these variables, shrink wrap is economical for high-volume packaging due to its efficiency, lightweight nature, and ability to reduce shipping damage, making it a popular choice across industries.

Shrink wrap is highly durable, but its longevity depends on factors like material type, exposure conditions, and intended use. For commercial-grade polyolefin and PVC shrink films, the wrap can last anywhere from 6 months to 2 years when stored or used in optimal conditions. Prolonged exposure to sunlight, extreme temperatures, or high humidity may degrade the material, causing brittleness or loss of its sealing properties over time. UV-resistant shrink films are available for outdoor applications, extending their durability under harsh conditions. Proper storage, such as keeping the rolls in a cool, dry, and shaded environment, can prolong the shelf life of unused shrink wrap. For businesses, the longevity of shrink wrap ensures products remain secure during transport and display, reducing the risk of damage or tampering while maintaining a professional presentation for consumers.

The earnings of gift wrappers depend on their employment setting, skill level, and location. In commercial environments, such as department stores, gift wrappers typically earn $12 to $18 per hour, equating to an annual salary of $24,000 to $36,000 for full-time workers. Freelance or specialized gift wrappers, especially those working during the holiday season or offering custom designs, can charge per project or item, earning anywhere from $5 to $20 per package, depending on the complexity and materials used. In upscale markets or events, such as weddings or luxury brand packaging, earnings can be significantly higher, with some professionals making $50 or more per hour. For businesses offering gift-wrapping services, integrating shrink wrap into the process can enhance efficiency and aesthetics, appealing to customers and potentially increasing revenue through premium packaging options.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed