Stretch film is a highly versatile packaging material commonly used across various industries, including manufacturing and food. It provides a reliable solution for securing, bundling, and protecting products during transport and storage. The importance of stretch film applications lies in its ability to enhance operational efficiency and reduce product damage, making it essential for businesses that handle high volumes of shipments. PWP Stretch Film offers different types of stretch films, including hand stretch film, machine stretch film, and pre-stretch film, each tailored to meet specific packaging needs. These stretch film applications ensure that goods remain safe and secure throughout the logistics process, protecting them from external factors such as dirt, moisture, and physical impact. Stretch film applications include securing pallets, color coding, shipping, supply chains, construction, and various household uses.

Stretch film is a stretchable plastic material primarily made from low-density polyethylene (LDPE). It is widely recognized for its ability to stretch and cling, making it an ideal solution for securing items during transport or storage. Stretch film applications are commonly found in industries such as manufacturing and food, where the need to bundle, wrap, and protect products is essential. This versatile film can tightly wrap around items, offering protection against dust, moisture, and physical damage while ensuring that products remain securely in place.

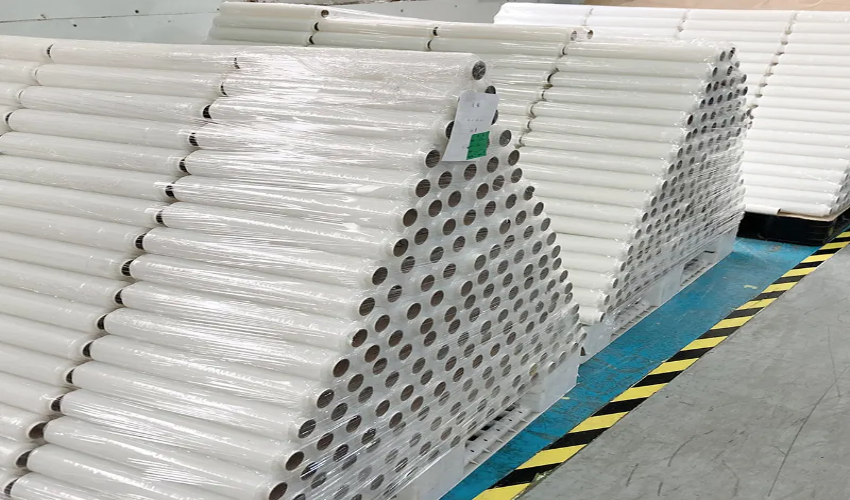

Stretch film is most commonly used for palletizing goods, where it wraps tightly around pallets of products to prevent movement and damage during shipping. In this application, stretch film is wrapped around the stacked goods to provide stability and create a barrier against environmental factors. It is especially effective when used to wrap around pallets, ensuring the load remains intact and secure throughout transit. Stretch film applications are not limited to palletizing; it is also used for bundling items, such as pipes, cables, and other loose products, which would otherwise be difficult to secure.

One of the key advantages of stretch film over other packaging materials, such as shrink wrap, is its ability to stretch without the need for heat. While shrink wrap requires heat to shrink and conform to the product, stretch film only requires tension during the application process. This makes it a more energy-efficient option, reducing the need for specialized equipment. Additionally, stretch film offers flexibility in its application—whether manually applied using hand stretch film or automatically through machine stretch film.

PWP Stretch Film provides a variety of options to meet specific packaging needs, including hand stretch film, machine stretch film, and pre-stretch film. Each type has unique benefits. For example, machine stretch film is applied with a mechanical stretch wrapper, making it highly efficient for high-volume operations. Hand stretch film is used in smaller-scale operations where products are wrapped manually. Pre-stretch film, on the other hand, is pre-stretched before application, which reduces the amount of force required during wrapping, making it an environmentally friendly option. For enhanced visibility or easy identification of bundled items, red stretch wrap offers a practical solution, particularly in industries requiring clear differentiation during shipping or storage.

Stretch wrap application offer a versatile and efficient packaging solution that is essential for bundling, protecting, and securing goods in various industries, particularly manufacturing and food. Its ability to stretch without heat, combined with the flexibility of different film types, makes it a preferred choice for businesses looking to optimize their packaging processes.

Stretch film applications play a vital role in the manufacturing sector, providing an efficient and versatile packaging solution for securing, bundling, and protecting various products. Whether used to stabilize pallets, bundle loose items, or safeguard machinery, stretch film is a key element in ensuring that goods are transported and stored safely. In manufacturing, the use of stretch film helps reduce product damage, improve operational efficiency, and minimize waste, making it an essential packaging material for a wide range of industries.

One of the most common stretch film applications in manufacturing is securing pallets for transport. Palletized goods are frequently moved between locations, whether it’s from a warehouse to a distribution center or directly to retailers. The role of stretch film in this process is crucial, as it ensures that the stacked items on the pallet remain stable and do not shift during shipping. Stretch film is wrapped tightly around the pallet, providing a firm hold that prevents movement, which could otherwise lead to product damage.

Using PWP Stretch Film, businesses can wrap pallets with machine-applied or hand-applied stretch film, depending on the volume of goods. Machine stretch film is typically used in high-volume operations and offers a faster, more consistent application, while hand stretch film is ideal for smaller-scale or specialized applications. Regardless of the method, securing pallets with stretch film improves the overall stability of the load, reduces the risk of damage during transportation, and enhances warehouse safety by preventing accidents caused by shifting loads.

In addition to palletizing, stretch film applications are also essential for bundling loose items. Manufacturing industries often deal with products that are difficult to package due to their shape or size, such as pipes, metal rods, cables, and other elongated items. Stretch film is an ideal solution for bundling these products together, ensuring they stay organized and protected during transport or storage.

Both machine and hand-applied stretch film can be used for bundling. Hand stretch film is often preferred for smaller or irregularly shaped items, while machine stretch film provides a more efficient option for bundling larger quantities or heavier products. The elasticity of stretch film allows it to conform tightly to the shape of the bundled items, providing a secure hold that prevents them from moving or separating during transit. This not only reduces the likelihood of product loss or damage but also streamlines the handling process, making it easier to transport bundled items in bulk.

Another important application of stretch film in manufacturing is the protection of delicate machinery and components. Manufacturing equipment often requires maintenance or transportation, and it is essential to protect these valuable assets from dust, dirt, and moisture. Stretch film serves as a protective layer that shields sensitive machine parts and components from environmental hazards during storage or shipping.

PWP Stretch Film offers different types of stretch film that can be used to wrap machinery, including heavy-duty film for larger equipment and pre-stretched film for more delicate items. By wrapping components with stretch film, manufacturers can prevent corrosion, contamination, and mechanical damage that could occur during handling or transportation. This protective barrier is particularly useful for machines that are stored outdoors or in environments where exposure to dirt and moisture is a concern.

Additionally, stretch film is a cost-effective solution compared to other protective packaging materials, such as foam or bubble wrap. It requires minimal effort to apply and remove, making it a convenient option for manufacturers who need to protect machinery and components on a temporary or long-term basis.

Stretch film applications in manufacturing are diverse and essential for ensuring the safe and efficient handling of products. From securing pallets to bundling loose items and protecting machinery, stretch film offers a versatile and cost-effective packaging solution that enhances operational efficiency while reducing the risk of damage during transportation and storage. PWP Stretch Film provides a range of stretch film options to meet the specific needs of the manufacturing industry, making it easier for businesses to implement reliable and sustainable packaging practices.

Stretch film applications are essential in the food industry, where they play a crucial role in preserving the freshness of food products, securing food trays and containers, and protecting display items in supermarkets and grocery stores. This versatile packaging material offers a hygienic and efficient way to safeguard food during storage, transportation, and display, ensuring that products remain uncontaminated and visually appealing to consumers. PWP Stretch Film provides high-quality food-grade stretch films that meet the unique requirements of the food industry, offering a range of solutions for different applications.

One of the primary stretch film applications in the food sector is the preservation of freshness. Food-grade stretch film is commonly used to wrap perishable items such as fruits, vegetables, meats, and other produce to extend their shelf life. The stretch film acts as a protective barrier that seals in moisture while preventing air exposure, which is a significant factor in food spoilage. By minimizing contact with oxygen, stretch film effectively slows down the process of oxidation, preserving the color, texture, and nutritional value of the food for a longer period.

In addition to its ability to keep food fresh, stretch film also offers a high level of hygiene. Food-grade stretch films are designed to meet strict safety and regulatory standards, ensuring that they do not introduce harmful chemicals or substances into the food. This makes stretch film a preferred packaging option for businesses in the food processing, packaging, and retail sectors. For example, stretch film is commonly used to wrap cuts of meat or bunches of vegetables in supermarkets, ensuring that they remain fresh and visually appealing to consumers.

Another critical stretch film application in the food industry is securing food trays and containers. Stretch film is frequently used in restaurants, catering services, and food production facilities to tightly wrap food trays and containers before transport or storage. By wrapping trays with stretch film, businesses can prevent food from spilling or becoming exposed to contaminants during transit, thus maintaining the integrity and cleanliness of the products.

PWP Stretch Film offers a variety of food-safe stretch films that are ideal for wrapping food trays. This type of packaging is especially important when transporting prepared meals, baked goods, or raw ingredients that need to stay fresh and protected until they reach their destination. The tight seal provided by the stretch film reduces the risk of contamination, ensuring that the food remains safe for consumption.

Stretch film also plays a role in portion control and organization within the food industry. For example, individual trays of pre-portioned meals or ingredients can be securely wrapped with stretch film to keep them organized and prevent cross-contamination. This is particularly useful in large-scale food production or catering services where different food items need to be separated and stored in a controlled environment.

Stretch film applications are also highly effective for protecting food display items in grocery stores and supermarkets. In these settings, it is important for food products to remain visually appealing while also being protected from dust, dirt, and potential contamination. Stretch film offers a transparent and secure covering that keeps food products safe without obstructing the customer’s view of the product.

Grocery stores frequently use stretch film to wrap baked goods, prepared meals, or trays of fruits and vegetables that are displayed for sale. The film provides a clear protective layer that prevents external elements from affecting the quality of the product, while still allowing customers to see the items before purchasing. This enhances the presentation of food products, ensuring that they look fresh and appetizing to consumers.

Furthermore, the use of stretch film in food displays helps reduce food waste. By protecting food items from spoilage and contamination, stores can extend the shelf life of perishable products, reducing the need to discard unsold items. This not only benefits the business but also supports sustainability efforts by minimizing food waste.

Stretch wrap film applications in the food industry are indispensable for preserving the freshness of food, securing trays and containers, and protecting display items. With its ability to create a secure, hygienic, and visually appealing packaging solution, stretch film helps businesses maintain the quality of their food products while improving operational efficiency. PWP Stretch Film offers a wide range of food-grade stretch films designed to meet the specific needs of the food industry, ensuring that products remain fresh, safe, and attractive from production to the point of sale.

Stretch film applications are diverse and integral in both the manufacturing and food industries, providing efficient packaging solutions for various operations. Different types of stretch films are utilized based on the specific needs of the industry, whether it’s securing large pallets in a manufacturing plant or safely packaging food items for retail. Innovative stretch film, with its advanced properties, enhances the performance of traditional stretch films, offering additional benefits such as improved load stability and better stretch capacity. Each type of stretch film serves a particular function, offering advantages that contribute to overall operational efficiency, waste reduction, and product protection.

Machine stretch film is designed for high-speed application using automated stretch wrap machines. This type of stretch film is commonly used in large-scale manufacturing operations where high volumes of products need to be palletized quickly and efficiently. Machine stretch film can be applied at a consistent tension, ensuring even coverage and providing maximum load stability during transportation.

In manufacturing, machine stretch film applications are vital for securing heavy and bulky loads on pallets. The use of automated machinery ensures that the film is applied tightly and uniformly, reducing the risk of product shifting or damage during transit. PWP Stretch Film offers a variety of machine stretch films that cater to different load sizes and requirements, providing businesses with the flexibility to choose the most suitable solution for their packaging needs.

Machine stretch film comes in different formulations, including cast and blown films. Cast machine stretch film offers excellent clarity and quiet unwind, making it ideal for applications where visibility of the packaged product is important. On the other hand, blown machine stretch film provides superior puncture resistance and strength, making it the best choice for wrapping irregularly shaped or sharp-edged products.

Hand stretch film is ideal for smaller-scale applications, particularly in environments where the volume of goods to be wrapped is lower, or where products are of irregular shapes that require manual wrapping. This type of stretch film is applied manually using handheld dispensers, making it a cost-effective and flexible solution for small businesses or operations where machine use is not feasible.

In the food industry, hand stretch film is often used to wrap smaller items, such as trays of food, produce, or containers. The manual application allows workers to ensure that each item is wrapped tightly and securely, preventing spills, contamination, and damage during storage or transport. Additionally, hand stretch wrap film applications offer flexibility in areas where space is limited or where specialized packaging requirements arise.

PWP Stretch Film offers a range of hand stretch films, each designed to meet the needs of different applications, whether it’s wrapping pallets, bundling products, or securing food trays. Hand stretch film is also available in a variety of thicknesses and strengths, ensuring that businesses can choose the most appropriate film for their specific tasks.

Pre-stretch film is a type of stretch film that has been pre-stretched before application, offering higher efficiency, reduced waste, and easier handling compared to traditional stretch films. Pre-stretched film requires less force to apply, making it an excellent choice for both machine and hand applications in manufacturing and food packaging.

One of the primary benefits of pre-stretch film is its ability to reduce material usage without compromising on strength or load stability. This makes pre-stretch film a cost-effective solution for businesses looking to optimize their packaging processes while minimizing waste. Additionally, pre-stretch film is lighter and easier to handle, which can reduce the risk of worker fatigue in manual applications.

In manufacturing, pre-stretch film applications are ideal for securing pallets and bundling products, while in the food industry, it is often used to wrap food containers, trays, and other products that require secure packaging. PWP Stretch Film provides high-quality pre-stretch films that offer excellent cling, puncture resistance, and load retention, ensuring that goods are well-protected during transport and storage.

Food-grade stretch film is specifically designed for use in food packaging, ensuring that it meets all safety and regulatory requirements. This type of stretch film is made from materials that are safe for direct contact with food, making it an essential component of packaging processes in the food industry. Food-grade stretch films are used to wrap fresh produce, meats, baked goods, and other perishable items, providing protection against contamination, moisture loss, and spoilage.

One of the key features of food-grade stretch film is its ability to maintain the freshness of food items while keeping them visible to consumers. In grocery stores and food service industries, this type of stretch film is often used to cover trays, containers, and display items, offering a clear and secure barrier that keeps food safe without obstructing its appearance.

In stretch film applications for the food industry, businesses benefit from using PWP Stretch Film’s food-grade options, which are available in various sizes and thicknesses. These films provide a reliable solution for packaging, transporting, and displaying food products in compliance with health and safety regulations, while also helping to reduce food waste by extending shelf life.

Stretch film applications in manufacturing and food industries rely on different types of stretch films to meet the specific demands of each sector. Machine stretch film is perfect for high-volume palletizing, hand stretch film provides flexibility for smaller-scale applications, pre-stretch film optimizes material usage and efficiency, and food-grade stretch film ensures that food products remain safe and fresh. PWP Stretch Film offers a comprehensive range of stretch films to suit these needs, ensuring that businesses can find the right packaging solutions to protect their goods and streamline their operations.

Stretch film applications provide a range of advantages for businesses in both the manufacturing and food industries. These benefits make stretch film an essential packaging material, improving efficiency, reducing costs, and protecting products during transport and storage. Whether it’s securing heavy pallets or keeping food fresh and safe from contamination, stretch film offers versatility and effectiveness. Below are six key benefits of stretch film in manufacturing and food-related applications.

One of the most significant advantages of stretch film applications is their cost-effectiveness. Stretch film provides a reliable and affordable packaging solution that helps businesses reduce packaging costs. Its ability to tightly wrap products with minimal material usage means less waste and lower costs in the long run.

For manufacturing, stretch film can replace more expensive packaging materials like boxes or rigid containers, while still offering the same level of protection. In the food industry, the lightweight nature of stretch film means businesses can save on shipping costs, as it adds minimal weight to the overall package. PWP Stretch Film offers various types of stretch film that help businesses optimize their packaging processes, reducing both material and labor costs.

Another critical benefit of stretch film applications is the enhanced load stability it provides. Stretch film is used extensively to secure products on pallets, preventing them from shifting during transport. This ensures that products remain intact and undamaged throughout the shipping process.

In manufacturing, where heavy or irregularly shaped products are often transported, stretch film plays a crucial role in ensuring load stability. By tightly wrapping the pallet, it holds items securely in place, reducing the risk of tipping or falling during movement. In food-related applications, stretch film is used to wrap food trays and containers, ensuring that they are tightly secured and protected from spills or movement.

PWP Stretch Film provides high-quality stretch films designed to maintain load stability, reducing the chance of product damage during handling and shipping. This not only improves efficiency but also reduces losses due to damaged goods.

As environmental concerns grow, many businesses are looking for sustainable packaging options. Stretch film applications offer environmentally friendly alternatives, with recyclable and eco-friendly options available. Using recyclable stretch films helps businesses reduce their environmental impact by minimizing plastic waste.

Many stretch films, such as pre-stretched and thinner gauge films, are designed to use less material while still providing the necessary strength and durability. These options allow businesses to maintain the same level of product protection while reducing their plastic usage. In both manufacturing and food industries, environmentally friendly stretch films contribute to sustainability efforts without sacrificing performance.

PWP Stretch Film offers a range of recyclable and eco-friendly stretch films that align with businesses’ sustainability goals, helping to reduce carbon footprints and meet environmental regulations.

Stretch film applications are vital for protecting products, particularly in food-related industries. One of the major benefits of stretch film is its ability to create a hygienic barrier that shields food items from contamination. Food-grade stretch films are designed to meet regulatory standards for food safety, ensuring that wrapped products remain uncontaminated and fresh.

By using stretch film to wrap food items, businesses can prevent exposure to dust, dirt, bacteria, and moisture, which could otherwise compromise the safety and quality of the products. This is particularly important for perishable items like fruits, vegetables, and meats, where hygiene is paramount. PWP Stretch Film offers food-safe stretch films that help businesses maintain strict hygiene standards, ensuring that their products reach consumers in perfect condition.

One of the standout benefits of stretch film is its versatility. Stretch film applications cover a wide range of packaging needs across both the manufacturing and food sectors. Whether it’s palletizing heavy goods in a manufacturing facility or wrapping food items in a supermarket, stretch film can be tailored to meet specific requirements.

For example, hand stretch film is ideal for small-scale operations or irregularly shaped products, while machine stretch film is designed for high-volume applications where speed and efficiency are critical. Pre-stretched film offers further versatility by reducing material usage and requiring less force during application. PWP Stretch Film offers a wide variety of stretch films that can be customized for different operational needs, ensuring optimal performance in any situation.

Lastly, stretch film applications offer superior product protection. The tight wrapping ability of stretch film shields products from external factors like dust, moisture, and physical damage. In the manufacturing industry, stretch film is used to wrap fragile or delicate items to prevent scratches or breakage during transport. Similarly, in the food industry, stretch film helps preserve freshness by creating a protective barrier that prevents spoilage.

This level of protection extends the shelf life of products, especially in food-related applications, where maintaining freshness is critical. PWP Stretch Film provides high-quality films that offer excellent puncture resistance and durability, ensuring that products remain safe from damage throughout the supply chain.

Stretch film applications offer numerous benefits for businesses in both the manufacturing and food industries. From cost-effectiveness and improved load stability to protection against contamination and environmental sustainability, stretch film plays an essential role in modern packaging. PWP Stretch Film provides a range of stretch films that cater to different packaging needs, ensuring businesses can maximize efficiency, reduce waste, and protect their products effectively.

Stretch film applications are influenced by various factors that determine its suitability for different tasks and industries. These factors range from the type of load being wrapped to environmental considerations and the characteristics of the stretch film itself. Understanding these factors is essential for selecting the right film to ensure effective performance, cost efficiency, and durability. Below, we explore key aspects that affect stretch film applications, including load type, film properties, application methods, and environmental conditions.

The characteristics of the load being wrapped play a significant role in determining the appropriate stretch film application.

Heavier, irregularly shaped, or unstable loads require stronger films with higher gauge thickness or enhanced elasticity.

Details:

The properties of the stretch film itself significantly impact its application and effectiveness.

Gauge thickness, stretchability, and specialized additives determine how well the film performs in specific applications.

Details:

The method used to apply the stretch film influences the type and thickness of the film required.

Manual and machine applications have different requirements for film strength and tension.

Details:

The environment in which the wrapped goods will be stored or transported also impacts stretch film applications.

Factors such as temperature, humidity, and UV exposure dictate the need for specific film properties.

Details:

These factors—load type, film properties, application methods, and environmental conditions—you can optimize stretch film applications to meet specific needs efficiently and effectively.

Stretch film is an essential tool for securing pallets, providing stability, protection, and convenience in various industries. This versatile material enhances the efficiency and safety of shipping and storage processes, ensuring that goods remain intact during transit or in warehouses. By tightly wrapping the palletized loads, stretch film minimizes the risk of shifting, protects against external factors, and offers cost-effective solutions for logistics. This article explores the applications of stretch film in fixing pallets from multiple perspectives, such as load stabilization, protection, sustainability, and operational efficiency.

Securing a pallet’s load is a critical aspect of transportation and storage, and stretch film excels in this role by providing consistent tension and tight wrapping.

In addition to securing goods, stretch film provides an effective barrier against external elements like dust, moisture, and debris.

Stretch film offers an economical alternative to other pallet-stabilizing methods, such as strapping or shrink wrapping, while maintaining excellent performance.

Sustainability is increasingly a priority in logistics, and stretch film applications in pallet fixing now include eco-friendly options.

The versatility of stretch film makes it an indispensable tool for securing pallets in diverse industrial settings.

The applications of stretch film in fixing pallets are vast, addressing key needs such as stability, protection, cost-effectiveness, sustainability, and adaptability. By leveraging its properties and specialized variants, businesses can enhance operational efficiency while ensuring the safe and secure handling of palletized goods. Stretch film continues to be a cornerstone of modern packaging and logistics solutions.

Stretch film plays a vital role in transportation protection by ensuring that goods remain secure and undamaged throughout transit. Its versatility allows it to be used across various industries, from shipping consumer products to transporting heavy machinery. The application of stretch film provides benefits such as load stability, weather resistance, and tamper prevention, making it an essential component of modern logistics. Below, we examine key aspects of stretch film applications in transportation protection, including load stability, environmental protection, tamper prevention, and cost efficiency.

Maintaining load stability during transportation is one of the primary purposes of stretch film.

Stretch film prevents goods from shifting, toppling, or becoming misaligned during transport, reducing the risk of damage.

Details:

Stretch film acts as a barrier to protect goods from environmental factors during transportation.

Whether dealing with rain, dust, or UV exposure, stretch film offers effective protection for various climates and conditions.

Details:

Stretch film also serves as a deterrent against tampering and theft during transport.

By providing a sealed, tight wrap, stretch film makes tampering evident and adds a layer of security for transported goods.

Details:

Effective use of stretch film can reduce transportation costs by minimizing damage and waste.

Stretch film provides a cost-effective solution to secure goods without the need for more expensive packaging materials.

Details:

By addressing load stability, environmental protection, tamper prevention, and cost efficiency, stretch film applications in transportation protection help ensure the safe, secure, and economical delivery of goods across industries.

The use of hand-made stretch film and machine-made stretch film varies significantly based on the scale of operation, efficiency requirements, and cost considerations. Both types are designed to secure palletized loads, but their application methods and suitability for specific tasks differ. Understanding these differences is crucial for businesses to choose the right stretch film solution for their needs. This article explores the distinctions between hand-made and machine-made stretch film applications across several aspects, including efficiency, cost, load consistency, and environmental considerations.

One of the most notable differences between hand-made and machine-made stretch film lies in their efficiency, particularly in high-volume settings.

The choice between hand-made and machine-made stretch film also impacts overall packaging costs, both in terms of material usage and labor.

The method of application affects the consistency and stability of palletized loads, with differences evident between the two types of stretch film.

Sustainability is another factor influencing the choice of stretch film application, as it impacts material usage and waste generation.

Different industries have varying requirements, and the choice between hand-made and machine-made stretch film depends on these specific needs.

The applications of hand-made and machine-made stretch film differ significantly, with each offering unique advantages. Hand-made stretch film provides flexibility and cost savings for smaller operations, while machine-made stretch film delivers efficiency, consistency, and sustainability for larger-scale applications. By understanding these distinctions, businesses can make informed decisions to optimize their packaging processes and meet operational demands effectively.

Stretch film applications vary widely depending on the type of stretch film used. Each type is engineered for specific uses, ensuring optimal performance in different industries and scenarios. From manual wrapping to specialized industrial needs, understanding the distinct applications of various stretch films helps businesses choose the most suitable option for their packaging requirements. Below, we explore the unique applications of hand stretch film, machine stretch film, color stretch film, and more.

Hand stretch film is designed for manual wrapping, making it ideal for small-scale operations or irregularly shaped loads.

Applications:

Machine stretch film is tailored for use with semi-automatic or fully automatic wrapping machines, ensuring consistent results in high-volume operations.

Applications:

Color stretch film is used for load differentiation and securing shipments.

Applications:

Bundling stretch film is used for wrapping smaller items together or securing individual product bundles.

Applications:

Mini stretch film is a smaller version of bundling film, used for quick, lightweight applications.

Applications:

Pre-stretch film is pre-stretched during production, making it lighter and more cost-effective.

Applications:

VCI (Vapor Corrosion Inhibitor) stretch film is used to protect metal goods from rust during storage or shipping.

Applications:

UVI (Ultraviolet Inhibitor) stretch film is designed to protect loads stored or transported under sunlight exposure.

Applications:

Breathable stretch film features perforations to allow airflow, making it ideal for temperature-sensitive or perishable goods.

Applications:

These tailored stretch film applications, businesses can maximize packaging efficiency, product protection, and operational cost-effectiveness across various industries.

Stretch film has a wide range of applications across various industries. Primarily, it is used for palletizing goods, where it secures products on pallets to prevent shifting during transportation. This is particularly important in industries like manufacturing and logistics, where products need to be kept stable to avoid damage. Stretch film is also commonly used for bundling loose items, such as metal rods, pipes, or boxes, to ensure they remain organized and intact during storage or transport. Additionally, in the food industry, stretch film is used to wrap trays, containers, and produce, keeping items fresh and protecting them from contamination. The versatility of stretch film applications makes it an essential tool for protecting and securing products in a variety of contexts.

Stretch film can be used in a variety of environments, depending on the type of product and the specific packaging needs. In manufacturing and warehousing, it is most commonly used to wrap pallets of goods before they are shipped. This ensures that items remain securely in place and reduces the risk of damage during transportation. Stretch film is also used in retail and grocery stores to wrap and protect food products, especially fresh produce, meats, and baked goods. It is ideal for securing food trays and containers to prevent spills and maintain cleanliness. Additionally, stretch film is used in smaller-scale settings, such as in offices or homes, where it can be applied for bundling items like documents, tools, or other loose objects for storage or transport.

Stretch film is used by a wide range of businesses and industries, making it one of the most versatile packaging materials available. In the manufacturing industry, it is extensively used to secure large shipments of products on pallets, ensuring that goods are safely transported from the factory to the warehouse or retail outlet. Logistics companies and warehouses rely on stretch film to stabilize loads during shipping, preventing movement that could cause damage. The food industry is another major user of stretch film, where it is used to wrap fresh produce, meat, and other food items to maintain freshness and hygiene. Additionally, stretch film is commonly used by retailers, moving companies, and even in household applications for bundling items and protecting goods during moves.

Stretch wrap is widely used across multiple industries, including logistics, manufacturing, retail, agriculture, and food and beverage. Logistics companies rely on stretch wrap for securing palletized goods during transportation. Manufacturing industries use it to bundle products and protect them from dirt, moisture, and damage. In retail, stretch wrap ensures the safe delivery of merchandise, particularly bulk items. The agricultural sector wraps hay bales and other products to preserve freshness. Food and beverage companies use it to stabilize and shield products like bottled drinks and packaged foods. Pharmaceutical industries utilize stretch wrap for safeguarding sensitive items during shipping. This versatile material serves as a cost-effective solution for stabilizing and protecting loads across these diverse sectors.

Yes, stretch film can be used for food, but only specific types that meet food safety standards. Stretch films made from FDA-approved materials, such as low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), are safe for direct contact with food. These films are commonly used to wrap perishable items, like fruits, vegetables, meats, and baked goods, ensuring freshness and hygiene. Stretch wrap designed for industrial or pallet use, however, is not food-grade and should not come into direct contact with food. Ensure the stretch film’s labeling specifies its suitability for food use before application. Using the correct type of stretch wrap protects food from contamination and spoilage.

The global stretch film market is substantial and continues to grow, valued at over $14 billion in 2023 and projected to exceed $18 billion by 2030. This growth is driven by increasing demand in packaging, logistics, and e-commerce industries. The market spans various product types, including hand-applied, machine-applied, and specialty stretch films tailored for specific uses, such as food-grade or UV-resistant films. Geographically, North America, Europe, and Asia-Pacific dominate the market, with Asia experiencing rapid expansion due to industrialization and manufacturing growth. Advances in sustainable stretch films, including biodegradable and recyclable options, also contribute to market development.

A stretch wrapper secures loads by wrapping stretch film tightly around palletized goods. The process can be manual, semi-automatic, or fully automatic. In manual wrapping, an operator applies the film by hand. Semi-automatic wrappers involve a turntable or arm that rotates the load while the film is dispensed. Fully automatic machines handle the entire process, from film application to cutting. These machines maintain consistent tension, ensuring uniform coverage and load stability. Stretch wrappers reduce labor, improve efficiency, and minimize material waste compared to manual methods. They’re ideal for high-volume operations, enhancing productivity while protecting goods during storage and transit.

Stretch wrap’s lifespan depends on storage conditions and usage. When stored in a cool, dry environment away from direct sunlight, stretch wrap can last up to two years without significant degradation. Prolonged exposure to UV light or extreme temperatures can weaken the film, reducing its stretchability and strength. Specialty UV-resistant stretch wraps are available for outdoor use, offering greater longevity. Once applied, the wrap’s effectiveness depends on the conditions it encounters; for stable indoor environments, it remains protective for extended periods, while exposure to harsh elements can shorten its functional life. Proper handling and storage ensure maximum durability.

Stretch wrap is remarkably strong for its thickness and can withstand significant tension and pressure. Its tensile strength varies depending on the material, thickness, and manufacturing process. Standard stretch wraps have a tensile strength of 5,000 to 6,000 psi, with heavy-duty options exceeding this range. High-quality stretch wraps are engineered to resist tearing, puncturing, and breaking, making them suitable for securing heavy or irregular loads. Stretch wrap’s elasticity allows it to tightly conform to items, providing excellent stability. For added durability, multi-layered or reinforced stretch films offer superior load containment and protection under demanding conditions.

To use stretch wrap film effectively, first secure the film to the base of the pallet or load by tying or tucking the end. Begin wrapping at the bottom, moving around the load while applying consistent tension. Overlap each layer by 50% to ensure stability and prevent gaps. Gradually work your way up, covering the entire load, and finish with a few extra wraps at the top for added security. For manual applications, ensure an even pull to prevent tearing. Machine wrapping involves setting the appropriate tension and speed for the load’s size and weight. Proper technique ensures load stability and reduces material waste.

Stretch wrap is water-resistant but not entirely waterproof. It protects loads from moisture, dust, and light rain during storage or transit. However, it is not designed to provide a completely watertight seal, as small gaps may occur between layers. For enhanced water resistance, additional wrapping layers or waterproof covers can be used. Some specialty stretch wraps are designed with water-repellent coatings or properties, making them more suitable for outdoor applications. While stretch wrap offers basic protection, it’s essential to assess environmental conditions and consider supplementary measures for safeguarding against heavy rain or prolonged water exposure.

Stretch film specifications include thickness, width, length, and material type. Thickness is measured in microns or gauge, with common options ranging from 12 microns (47 gauge) to 35 microns (140 gauge). Widths typically vary between 12 and 30 inches, while lengths range from 1,000 to 5,000 feet per roll for hand or machine applications. Stretch films are made from low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), offering durability and flexibility. Specifications also cover tensile strength, stretchability (up to 300% for high-performance films), and resistance to punctures or tears. Specialty options include UV-resistant, anti-static, or colored films tailored to specific applications.

Alternatives to stretch film include shrink wrap, strapping, pallet nets, reusable pallet bands, and stretch hooding. Shrink wrap is heat-activated, forming a tight seal around products, while strapping uses metal or plastic bands for load stability. Pallet nets provide breathability for fresh produce or items requiring airflow. Reusable pallet bands offer an eco-friendly option for stabilizing goods without disposable materials. Stretch hooding, often used for industrial applications, provides a snug cover for pallets using a pre-stretched polyethylene sleeve. These alternatives cater to specific needs, balancing environmental concerns, load stability, and cost.

The main difference between 60 gauge and 80 gauge stretch wrap lies in thickness and strength. A 60-gauge wrap is thinner, suitable for lightweight or less demanding applications such as bundling small items. It provides basic protection against dust and minor impacts but is more prone to tearing. An 80-gauge wrap, being thicker and more robust, is ideal for medium-weight pallet loads. It offers greater resistance to punctures, better load containment, and enhanced durability during transit. While 60-gauge wrap is cost-effective for light-duty tasks, 80-gauge wrap is a versatile choice for securing various load types.

Cast stretch wrap is made through a flat-die extrusion process, producing a smooth, transparent film with excellent cling and quiet unwinding. It’s ideal for applications requiring clarity for barcodes or labels. Blown stretch wrap, produced by blowing molten plastic into a bubble, has a hazy appearance but superior strength and puncture resistance. It’s noisier to unwind and has higher manufacturing costs but performs well in rugged conditions or irregular loads. The choice depends on priorities: cast wrap offers ease of application and clarity, while blown wrap excels in durability and heavy-duty applications.

Cling film and stretch film differ in use, thickness, and properties. Cling film, also known as food wrap, is thin, typically 8-12 microns, and designed for wrapping food items to preserve freshness. Stretch film, on the other hand, is thicker (12-35 microns) and used for industrial purposes, such as stabilizing palletized goods. While both materials offer elasticity, cling film focuses on adherence for sealing food containers, whereas stretch film provides tensile strength for securing heavy loads. Cling film is primarily food-safe, while stretch film is tailored for transportation and storage.

Shrink film and stretch film differ in application and behavior. Shrink film requires heat to shrink tightly around an item, providing a secure seal ideal for protecting products against dust and tampering. Stretch film, conversely, is applied by stretching and wrapping around loads, relying on tension for stability. Shrink film is non-elastic and commonly used for individual or small bundles, while stretch film is elastic and designed for palletized goods. The two materials serve distinct purposes: shrink film excels in product protection, while stretch film focuses on load containment.

Stretch film is a plastic film made from linear low-density polyethylene (LLDPE), known for its elasticity, durability, and puncture resistance. Its key characteristic is the ability to stretch and conform tightly to products or palletized loads, securing them for transportation or storage. Available in both cast and blown variants, stretch film offers specific advantages depending on the application. Cast films provide clarity and quiet unwinding, while blown films deliver superior strength for heavy-duty loads. Specialty stretch films, such as UV-resistant, anti-static, or pre-stretched options, cater to unique requirements across industries like logistics, retail, and agriculture.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed