Stretch film is a versatile and essential packaging material widely used across various industries. Stretch film, made from LLDPE, offers high puncture resistance, excellent load containment, and superior elongation. Its primary purpose is to securely wrap products, providing protection during storage and transport while maintaining product integrity. The significance of stretch film lies in its ability to adapt to different shapes and sizes, ensuring that goods remain stable and undamaged throughout the supply chain. In this article, we will explore the key stretch film características, including its various types and applications. Additionally, we will discuss pricing factors that influence the cost of stretch film, helping you make informed decisions for your packaging needs. Understanding these aspects is crucial for selecting the right film to optimize your packaging processes.

Stretch film is widely used for packaging, securing, and protecting products during storage and transportation. Its versatility, strength, and cost-efficiency make it an ideal choice in various industries. In this article, we will delve into the key characteristics of stretch film, focusing on the materials used in its production, their properties, and how they influence the performance of stretch films.

Stretch films are primarily made from different types of plastics, each contributing to specific features such as stretchability, strength, and durability. The most common materials used in stretch film production include:

The choice of material for stretch film production affects various physical and functional characteristics of the film. Below are some of the most important material properties that influence the performance of stretch films:

Each material used in the production of stretch films has specific advantages. Here are the benefits associated with the main materials:

As with many plastic products, stretch films can have an environmental impact. The materials used in stretch film production play a key role in the sustainability of the product. Some key factors to consider include:

Stretch film materials, including LDPE, LLDPE, PVC, and others, play a critical role in determining the film’s performance, strength, and suitability for various applications. Understanding the characteristics and benefits of these materials helps manufacturers choose the right stretch film for their specific packaging needs. Whether used for securing products during transit, protecting against environmental factors, or ensuring product visibility, stretch films provide a cost-effective and reliable solution. With ongoing innovations in material science, the future of stretch film looks promising, particularly in terms of sustainability and performance.

Stretch film, produced by a stretch film factory, is a highly elastic, transparent plastic material primarily made from linear low-density polyethylene (LLDPE). It is designed to be wrapped around products to secure them tightly, providing a protective barrier against dust, dirt, moisture, and physical damage. Manufactured in various thicknesses and widths, stretch film caters to a wide range of packaging needs. Its remarkable stretchability enables it to cling tightly to items, maintaining a snug fit that minimizes the risk of shifting during transport.

One of the most significant uses of stretch film is in the packaging of products, particularly in warehouses and distribution centers. It is commonly used to secure loads on pallets, ensuring that goods remain stable during storage and transport. By wrapping multiple items together, stretch film helps to consolidate products, making handling more efficient. This consolidation not only facilitates easier transport but also optimizes warehouse space by stacking and wrapped pallets securely.

In addition to securing loads, stretch film serves as a protective layer for goods in transit. Its properties allow it to shield products from environmental factors such as moisture and dust, which can lead to deterioration. For instance, stretch film can prevent water damage during rain or spills, safeguarding sensitive items like electronics or food products. Moreover, its tear-resistant nature helps to protect against scratches and other physical damages that may occur during handling and transport.

Stretch film offers numerous advantages over other packaging materials. Its lightweight design reduces shipping costs, as it adds minimal weight to the overall load. Additionally, its transparency allows for easy identification of the wrapped items without the need to remove the film. This is particularly beneficial in warehouse settings where quick inventory checks are necessary.

Furthermore, stretch film is economical and cost-effective. It provides significant savings in terms of material costs compared to alternatives such as shrink wrap or strapping. The application of stretch film can also be automated, which enhances efficiency and reduces labor costs in packaging operations.

Stretch film is a versatile packaging solution with a range of uses, particularly in securing and protecting goods during transport. Its unique properties, including elasticity and durability, make it an indispensable tool in modern logistics. By understanding the key stretch film características, businesses can make informed decisions about their packaging strategies, ensuring that products are delivered safely and efficiently to their destinations. As demand for effective packaging solutions continues to grow, stretch film remains a vital component in the packaging industry.

Stretch film, also known as stretch wrap or cling film, is a versatile plastic film used for packaging and securing goods. It is most commonly used to wrap pallets, boxes, and other items to ensure they remain tightly bound and stable during transportation and storage. This plastic material is stretched over the product or package to hold it in place, offering benefits like protection from dust, moisture, and damage. In this article, we will explore the key characteristics of stretch film and the technology behind its production and usage.

The production of stretch film involves advanced manufacturing technologies that allow for the creation of films with specific characteristics suited to different applications. The main technologies used in the production of stretch films include:

While stretch film offers many benefits, it is important to consider the environmental impact of plastic packaging. In response to these concerns, manufacturers have developed stretch films made from recyclable or biodegradable materials. Additionally, the lightweight nature of stretch films means less material is used, which can help reduce the overall environmental footprint of packaging.

Stretch film is an essential component of modern packaging, offering a combination of strength, flexibility, and cost-effectiveness. Thanks to advanced manufacturing techniques, it has become a versatile solution for a wide range of industries. Whether used for pallet wrapping, retail packaging, or securing products during transit, stretch film provides numerous benefits, including protection, efficiency, and sustainability. With ongoing innovations in stretch film technology, the future looks promising for even more advanced and eco-friendly packaging solutions.

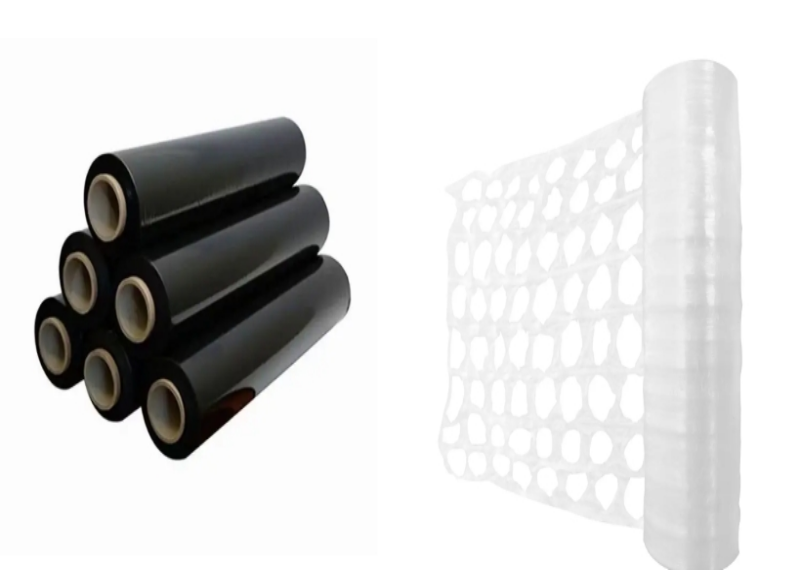

Stretch film is available in several types, each designed to meet specific packaging needs. Understanding the different stretch film características is crucial for selecting the right type for your application. Below is an overview of the most commonly used types of stretch film:

Choosing the right type of stretch film is essential for optimizing packaging processes and ensuring product safety. Each type of wrapping film has unique stretch wrap properties that cater to various applications, making it important to assess your specific needs before making a selection. By understanding these differences, businesses can enhance their packaging strategies and improve overall efficiency in their operations.

Understanding the pricing of stretch film is essential for businesses looking to manage costs effectively while ensuring high-quality packaging solutions. The stretch film características significantly influence the price, which can vary based on several factors. Here are the key elements that impact the pricing of stretch film:

When evaluating stretch film precio, it’s essential to consider these factors to ensure you select the most cost-effective option that meets your packaging needs. By understanding the interplay between film characteristics, size specifications, and purchasing options, businesses can make informed decisions that balance quality with budget constraints, ultimately leading to efficient and effective packaging solutions.

Stretch film is an indispensable tool in the packaging industry, thanks to its versatility and effectiveness in securing and protecting a wide range of products. Understanding the stretch film características allows businesses to leverage its benefits across various sectors. Here are six key applications of stretch film in different industries:

In the retail and e-commerce sectors, stretch film enhances packaging efficiency and presentation:

The manufacturing and logistics industries benefit significantly from stretch film’s protective qualities:

In the pharmaceutical industry, stretch film is crucial for maintaining product integrity:

In the medical field, the use of stretch film is critical for ensuring the safety and integrity of sensitive products. Polyurethane stretch film, with its superior clarity, elasticity, and resistance to contaminants.

In industrial settings, stretch film offers robust protection for heavy and bulky items:

The building and construction industry uses stretch film to protect materials:

The diverse applications of stretch film in packaging underscore its importance across various industries. By leveraging the unique stretch film características, businesses can enhance product protection, improve efficiency, and ultimately deliver higher quality goods to their customers.

When considering packaging solutions, it’s essential to understand the differences between stretch film and shrink film. Both serve critical roles in the packaging industry, but they have distinct characteristics and applications. Below is a comprehensive comparison that highlights their unique features.

Understanding the stretch film características compared to shrink film is crucial for selecting the appropriate packaging solution. While stretch film is highly adaptable and cost-effective, shrink film offers superior protection for specific applications. Businesses should assess their packaging needs and the nature of the products being wrapped to determine the most suitable option.

Stretch film is a versatile packaging material that possesses several key characteristics making it ideal for securing and protecting goods. Below are five primary features that define its effectiveness and utility in various applications.

The characteristics of stretch film—such as clarity and transparency, tear resistance, stretchability, adhesiveness, and customization—make it an indispensable tool in the packaging industry. Understanding these stretch film características helps businesses optimize their packaging strategies, ensuring products are secure and well-presented throughout their journey.

When selecting the right stretch film for packaging, it’s essential to consider a variety of factors that influence its performance and suitability for specific applications. Stretch films are made from different materials, and their characteristics can vary significantly depending on the type, thickness, and design. In this article, we will provide a detailed guide to help you understand the key characteristics of stretch films and how to choose the right one for your needs.

When choosing the right stretch film, several key characteristics will determine its performance and suitability for your application. These characteristics include:

Stretch films are designed to provide protection from environmental elements like moisture, dirt, and UV radiation. Depending on the specific needs of your application, you may want to consider the following:

Choosing the right stretch film depends on understanding the key characteristics that influence its performance. By considering factors such as stretchability, tensile strength, puncture resistance, and environmental resistance, you can ensure that the stretch film you select is well-suited to your packaging needs. Whether you’re securing light retail products or wrapping heavy industrial loads, understanding these characteristics will help you make an informed decision that maximizes protection, efficiency, and cost-effectiveness in your packaging operations.

Stretch film, also known as stretch wrap, is predominantly made from linear low-density polyethylene (LLDPE). This material is chosen for its robust elastic properties, allowing the film to be stretched and retain its shape without compromising strength. LLDPE is lightweight yet durable, making it ideal for securely wrapping and protecting items during transit or storage.

The thickness of stretch film is typically measured in microns. Standard stretch film thickness ranges from about 10 microns to 30 microns. This variation allows for different applications—thinner films are generally used for lighter loads, while thicker films provide greater security and strength for heavier or more irregularly shaped items.

Stretch film can generally be stretched up to 500% of its original size under optimal conditions, although the usual stretching falls between 100% and 300%. This high stretchability is critical for tightly securing products, as it allows the film to conform to the shape of the item, providing improved stability during transportation. The actual stretchability can depend on the quality and thickness of the film used.

Stretch wrap is primarily made of a type of plastic called polyethylene, specifically linear low-density polyethylene (LLDPE). LLDPE is preferred for its superior stretch qualities coupled with resistance to punctures and tearing. It is a versatile plastic that balances strength and flexibility, making it highly effective for securing a wide variety of goods in different industrial and commercial contexts.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed