Stretch film is a crucial component in packaging, serving to secure and protect products during storage and transportation. Its elastic properties allow it to cling tightly to items, minimizing movement and potential damage. Understanding stretch film sizes is essential for optimizing packaging efficiency. Different applications require specific sizes to ensure proper coverage and load stability. For example, larger rolls are better suited for industrial uses, while smaller sizes may be ideal for retail environments. Choosing the right stretch film sizes can significantly affect the overall effectiveness of the packaging process, influencing everything from material costs to operational productivity. Such as the film of economy stretch wrap, with its cost-effective characteristics, is an option for many applications. Therefore, selecting appropriate sizes is vital for achieving reliable and cost-effective packaging solutions. Stretch film sizes range from 2 to 30 inches, with standard sizes of 3–5 inches and a common 500 mm roll for hand or machine use.

Understanding stretch film sizes is essential for optimizing packaging operations. A Stretch Film Sizes Chart is essential for selecting the appropriate film dimensions and specifications to ensure optimal performance, cost-efficiency, and protection in various packaging and wrapping applications. In this section, we present a detailed chart listing various stretch film sizes commonly used in the industry.

| Size | Width | Gauge | Roll Length | Recommended Use |

|---|---|---|---|---|

| Small Roll | 12 inches | 80 gauge | 1000 feet | Ideal for small packages and retail applications |

| Medium Roll | 18 inches | 60 gauge | 1500 feet | Suitable for light to medium loads |

| Large Roll | 30 inches | 80 gauge | 1500 feet | Commonly used in warehouse environments |

| Extra Large Roll | 40 inches | 90 gauge | 2500 feet | Best for heavy-duty applications |

When discussing stretch film sizes, it’s important to understand the following common measurements:

Choosing the right stretch film wrap sizes can provide several advantages:

At PWP Stretch Film, we ensure that our offerings include a range of stretch film sizes tailored to meet diverse packaging needs. Selecting the appropriate sizes not only streamlines the wrapping process but also maximizes the performance of the film in various applications.

Selecting the right stretch film sizes is crucial for ensuring effective wrapping of products. Different types of stretch film wraps are available, each tailored to specific applications, which can greatly impact efficiency and safety during transportation. For those who handle smaller packaging tasks or require a customized approach, a home made stretch film wrapper can be a practical solution, allowing for better control over wrapping tightness and coverage. Understanding the right combination of film type and application method ensures optimal protection during transit.

Cast Stretch Film:

Blown Stretch Film:

| Application | Recommended Stretch Film Sizes | Type of Use |

|---|---|---|

| Pallet Wrapping | 20-40 inches wide | Machine or hand wrapping |

| Hand-Wrapping | 12-18 inches wide | Manual application |

| Heavy-Duty Loads | 30-40 inches wide | Machine use with high gauge film |

| Light-Duty Loads | 12-20 inches wide | Manual or machine application |

Choosing the right stretch film sizes involves considering several factors:

At PWP Stretch Film, we recognize that selecting the appropriate stretch film sizes enhances the overall wrapping process. By understanding the different types of wraps and their applications, we can provide tailored solutions that meet our customers’ needs effectively.

Stretch films come in various types, each designed for specific applications, and their sizes vary to meet diverse requirements. Below, we introduce the nine types of stretch films, their characteristics, and the commonly available sizes for each type.

Hand stretch films are designed for manual application, making them ideal for small-scale operations or irregularly shaped items. These films provide excellent stretchability and puncture resistance.

Common Sizes:

Machine stretch films are engineered for automated wrapping machines, ensuring uniform application and higher efficiency for large-scale operations.

Common Sizes:

Color stretch films are used for coding, branding, or concealing wrapped items. They come in various colors like black, blue, red, and green.

Common Sizes:

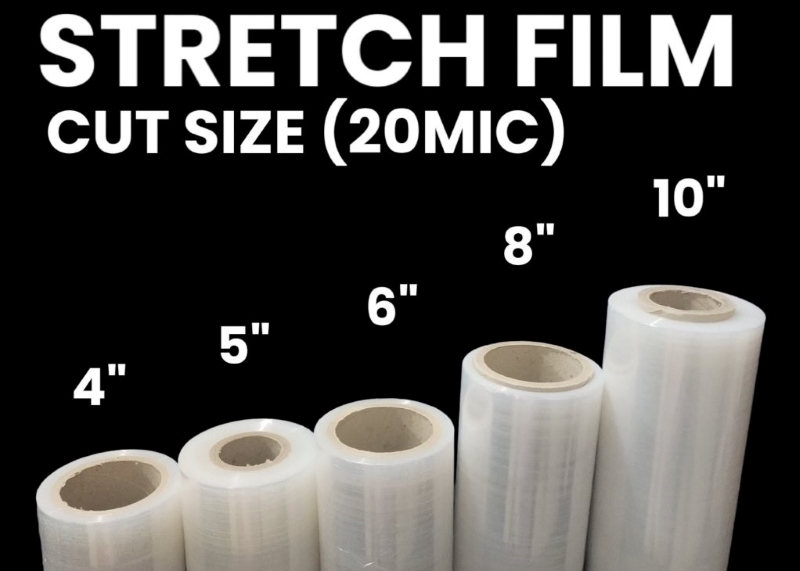

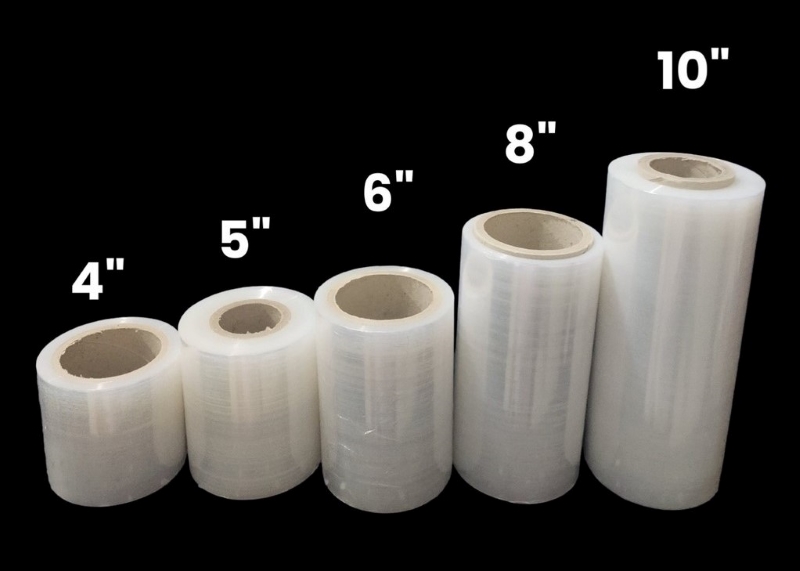

Bundling stretch films are narrow-width films used for securing small items or creating multipacks. They are often applied with handheld dispensers.

Common Sizes:

Mini stretch films are compact rolls designed for lightweight and small packaging tasks. They are user-friendly and reduce waste.

Common Sizes:

Pre-stretch films are pre-stretched during manufacturing, requiring less effort during application while maintaining high strength and cling.

Common Sizes:

VCI (Vapor Corrosion Inhibitor) stretch films protect metal products from rust and corrosion during storage or transport.

Common Sizes:

UVI (Ultraviolet Inhibitor) stretch films are designed for outdoor applications, protecting wrapped items from UV degradation.

Common Sizes:

Breathable stretch films feature perforations that allow air circulation, making them ideal for wrapping fresh produce or pallets requiring ventilation. Anti-corrosive stretch film versions of breathable wraps are also available to protect metal goods during storage or transit while still allowing airflow.

Common Sizes:

The stretch film sizes for each type allows businesses to choose the most appropriate film for their specific packaging needs, ensuring efficiency and cost-effectiveness.

When it comes to automated packaging systems, selecting the appropriate machine stretch wrap film sizes is vital for ensuring efficient and reliable operation. Machine stretch film is designed specifically for use with wrapping machines, providing a consistent performance that enhances productivity.

| Size | Width | Gauge | Common Applications |

|---|---|---|---|

| Standard Roll | 20 inches | 80 gauge | General-purpose wrapping |

| Large Roll | 30 inches | 90 gauge | Heavy-duty pallet loads |

| Extra Large Roll | 40 inches | 100 gauge | Industrial applications |

Selecting the correct machine stretch film sizes offers numerous advantages:

At PWP Stretch Film, we emphasize the importance of selecting the right stretch film sizes for machine applications. By understanding the machine stretch film of caracteristicas and benefits, our customers can achieve optimal performance and reliability in their packaging processes.

Hand stretch film is a versatile packaging solution that is commonly used for securing items during storage and transportation. This type of film is designed for manual application, making it ideal for a range of environments from warehouses to retail settings. Understanding hand stretch film sizes is essential for optimizing efficiency and ensuring effective protection of products.

Hand stretch film typically comes in various sizes to accommodate different wrapping needs. Common sizes include:

The size of hand stretch film significantly influences its ease of use and operational efficiency:

Different hand stretch film sizes are suitable for specific applications:

At PWP Stretch Film, we recognize the importance of choosing the right hand stretch film sizes to meet diverse packaging needs. By selecting the appropriate size, our customers can enhance their wrapping efficiency while ensuring optimal protection of their products during transit.

Stretch film standard size refers to the commonly accepted dimensions of stretch film rolls that are widely used across various industries. Adhering to these standard sizes ensures compatibility with machinery, facilitates easier handling, and promotes efficient wrapping processes.

In the packaging industry, stretch film sizes for stretch film are typically categorized by width, gauge, and roll length. The most recognized dimensions include:

Width:

Gauge:

Roll Length:

Utilizing standard sizes for stretch film provides several key advantages:

At PWP Stretch Film, we understand the critical role that stretch film standard sizes play in optimizing packaging efficiency. By choosing the correct dimensions, our customers can enhance their wrapping processes, ensuring both effectiveness and cost savings.

Effective stretch wrap packaging is essential for securing products during storage and transportation, and the choice of stretch film sizes plays a crucial role in achieving optimal results. Different sizes of stretch film can significantly influence the effectiveness of the wrapping process, ensuring products are protected and stable throughout their journey.

Selecting the appropriate stretch film sizes enhances packaging effectiveness in several ways:

When choosing stretch film sizes for specific applications, consider the following factors:

Load Type:

Weight Considerations:

Wrapping Method:

Environmental Factors:

At PWP Stretch Film, we recognize that understanding how stretch film sizes affect packaging efficiency is vital for our customers. By selecting the right sizes based on load type and weight, we can help ensure that products remain secure and undamaged throughout their shipping and storage processes.

The standard size of stretch film typically refers to the commonly used widths, gauges, and roll lengths in the packaging industry. Widths generally range from 12 inches to 40 inches, with 18 inches and 20 inches being the most frequently utilized for general applications. Gauges, which indicate the thickness of the film, usually vary from 50 to 120 mils, with 80 gauge being a popular choice for general-purpose use. Roll lengths can range from 1,000 to 2,500 feet, depending on the specific application. Using standard sizes helps ensure compatibility with wrapping machinery and enhances efficiency in packaging operations. Businesses often choose standard sizes to simplify their procurement process and ensure their packaging solutions are widely available and effective.

Stretch film is measured in several key dimensions: width, gauge, and roll length. Width refers to the measurement across the film, typically ranging from 12 to 40 inches. Gauge indicates the thickness of the film, measured in mils (1 mil = 1/1000 of an inch) or microns, with a higher gauge signifying a thicker film that offers greater strength and durability. Common gauges include 50, 60, 70, 80, and up to 120 mils, depending on the intended use. Roll length is the total length of film on a roll, usually measured in feet, ranging from 1,000 to 2,500 feet. Understanding these measurements is essential for selecting the right stretch film for specific packaging needs and ensuring optimal performance.

Calculating stretch film requires determining the film’s total area and weight based on your needs. Start by identifying the dimensions of the roll: width (in inches), length (in feet), and the film’s thickness or gauge. Multiply the width by the length to get the area in square inches, then convert it to square feet (divide by 144).

To determine the weight of the roll, use the film’s density (measured in pounds per cubic inch) and calculate the volume. Volume is derived by multiplying the area by the film thickness, converted to inches. Manufacturers may also provide roll weight calculators or specs for simplicity.

When purchasing, consider the load type (light, medium, or heavy-duty) and how much film you typically use per pallet. This ensures you choose the correct dimensions and quantity to minimize waste and optimize cost.

The appropriate gauge of stretch wrap depends on the weight and stability of your load. The gauge refers to the film’s thickness, with common options ranging from 47 to 120 gauge. For lighter loads under 1,500 pounds, a thinner film (47–63 gauge) suffices. Medium-duty loads (1,500–2,000 pounds) require 70–80 gauge film for adequate support. Heavier loads exceeding 2,000 pounds need a 90–120 gauge wrap for added strength.

Consider other factors like transit conditions, handling methods, and storage environments. A higher gauge ensures greater puncture resistance and load containment but may be less flexible, while lower-gauge wraps save costs and are better for uniform or lighter loads. Testing different gauges with your specific products can help find the optimal balance between performance and cost-efficiency.

Stretch in stretch film is measured as the percentage of elongation the film achieves before application or breakage. It represents the film’s ability to expand while maintaining structural integrity. Manufacturers often rate films by their stretch capacity, such as 150%, 200%, or higher.

To measure stretch, cut a 10-inch section of the film and pull it until resistance or breakage occurs. Measure the extended length and calculate the percentage increase:

Stretch Percentage=[ (Original Length – Extended Length) / Original Length]×100

For instance, if the 10-inch piece stretches to 25 inches, the stretch percentage is 150%. High-stretch films reduce usage while maintaining containment, ideal for cost and efficiency. Always align the film’s stretch percentage with the load type and desired load security.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed