Stretch film plays a crucial role in the packaging industry, offering a reliable solution for securing products during transport and storage. Known for its versatility and durability, stretch film is widely used across industries such as logistics, manufacturing, and retail. The material’s stretchability and strength make it essential for ensuring that loads remain stable, reducing the risk of product damage. Patented stretch film technologies have further enhanced the film’s performance, offering unique features such as improved cling properties, greater elasticity, and stronger load containment capabilities. As businesses become more focused on sustainability, the practice of stretch film upcycling is gaining traction, with companies repurposing used film into new products, reducing waste and contributing to circular economy efforts. When considering stretch film specifications, businesses focus on factors such as thickness, elasticity, and cling properties. These specifications directly impact packaging efficiency and costs, allowing companies to choose the best type for their unique needs, whether for high-stretch hand applications or machine wrapping that maximizes load stability. Stretch film specifications include thickness, strength, elongation, and widths from 12-20 inches, made from LLDPE for versatile packaging needs.s or machine wrapping that maximizes load stability. Stretch film specifications include thickness, strength, elongation, and widths from 12-20 inches, made from LLDPE for versatile packaging needs.

Stretch film specifications refer to the technical characteristics of the film, such as thickness, strength, elongation, and puncture resistance, that determine how well the film performs in various packaging applications. These specifications are crucial for businesses aiming to secure loads effectively and minimize product damage during transportation.

Each specification influences packaging outcomes differently. Thickness, for instance, affects the durability of the wrap, while elongation defines how much the film can stretch without breaking. Selecting the right combination of specifications ensures both cost-efficiency and packaging reliability.

Gauge and Micron: Gauge and micron indicate the thickness of the stretch film. Thicker films (higher gauge or micron) generally offer greater strength, while thinner films are often more cost-effective.

Pre-stretch: This term refers to how much the film can be stretched before application. Pre-stretched films use less material and require less energy to apply, making them ideal for efficient wrapping.

Dart Drop: Dart drop measures the puncture resistance of the film, an essential specification for loads with sharp edges or items that may shift during transport.

Technical data sheets provide essential information on each stretch wrap film specification, allowing companies to choose films tailored to their specific packaging requirements.

Typical Specifications: Hand stretch film is designed for manual application, with specifications that include lighter weight and a stretch film micron thickness ranging typically between 15 and 23 microns. These specifications ensure ease of handling while providing sufficient strength for small-to-medium loads.

Applications: Hand stretch film is ideal for smaller operations or warehouses where automated systems aren’t available. With these stretch wrap specifications, hand films work well in securing packages that require flexibility in wrapping.

Higher Stretch Ratios and Strength: Machine stretch films come with enhanced stretch film specifications, such as a thicker gauge and higher elongation percentages, often ranging between 100% to 300% or more. These films are designed to handle heavy-duty applications and work seamlessly with automated wrapping systems.

Machine Wrap Requirements: These stretch wrap specifications make machine film suitable for high-volume operations, delivering consistent tension and load stability across large shipments.

Specifications for Efficiency: Pre-stretch film is pre-stretched during production, reducing the amount of film required while maintaining durability. These stretch film specifications promote increased efficiency and reduced film consumption, making them ideal for operations aiming to lower material costs.

Load Stability: The lightweight properties provided by pre-stretch wrap specifications make it easier to apply, yet it holds loads tightly, making it suitable for both manual and machine applications.

Unique Specifications for Specialized Applications: Specialty stretch films cater to specific needs and come with distinct stretch wrap specifications. For example:

Colored Stretch Film: Often used for product identification, colored film’s specifications are geared towards opacity and visibility.

Nano Stretch Film: This multi-layer stretch film is designed with several layers to provide advanced strength and puncture resistance, all while maintaining a minimal thickness. The multiple layers enhance its durability, ensuring reliable protection for your items without adding extra bulk.

UV Resistant Film: UV stretch film specifications include protective properties that shield wrapped loads from sun damage, making it ideal for outdoor storage and transport.

Specifications charts for stretch wrap standards provide a clear, comparative view of different stretch film specifications, such as thickness, stretch capacity, and puncture resistance. By analyzing these charts, users can easily compare types and brands of films to determine the best fit for specific packaging needs.

Each stretch film specification on the chart, including gauge, elasticity, and load capacity, helps in identifying films that match desired performance outcomes, such as durability or stretch efficiency.

The following chart shows a sample comparison of specifications like thickness and stretch capacity. By examining this table, users can observe how films vary in performance based on their specifications:

| Film Type | Thickness (Microns) | Stretch Capacity (%) | Puncture Resistance | Ideal Application |

|---|---|---|---|---|

| Hand Stretch Film | 15 - 23 | 100 - 150 | Medium | Small to medium loads |

| Machine Stretch Film | 20 - 35 | 200 - 300 | High | Automated high-volume loads |

| Pre-Stretch Film | 8 - 15 | Pre-stretched | Medium | Cost-efficient applications |

| Nano Film | 12 - 20 | 300+ | Very High | Heavy-duty, puncture-prone loads |

| UV Resistant Film | 20 - 30 | 100 - 200 | Medium to High | Outdoor storage applications |

Reviewing the stretch wrap film specifications in a chart allows businesses to select films tailored to their specific needs. For instance:

By leveraging these charts, users can make informed choices based on each stretch film specification, ensuring cost efficiency and optimal performance in packaging.

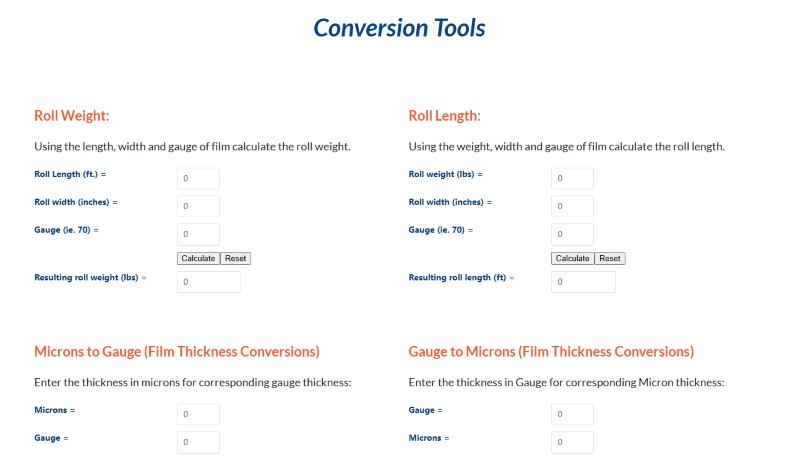

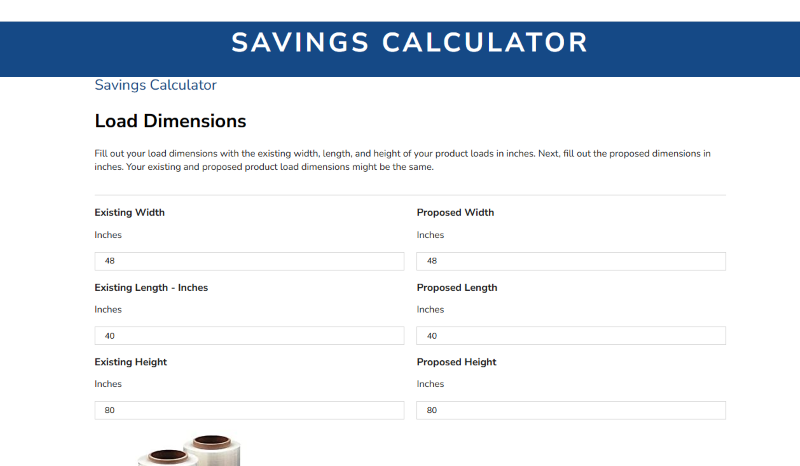

A stretch film specifications calculator can be a helpful tool for estimating the amount and type of stretch film required based on specific load dimensions, film type, and wrapping method. By inputting factors like pallet height, width, and the number of wraps, the calculator provides an estimate of film consumption, enabling cost-effective decisions.

Many online tools allow users to customize inputs based on their needs. For instance, by selecting different stretch film specifications, such as thickness or elasticity, users can see how much film will be consumed in different wrapping scenarios. This customization ensures that businesses only purchase the exact film they need, reducing waste and optimizing inventory.

Load Stability: The stability of the load plays a significant role in determining the stretch film specifications needed. Heavier or irregularly shaped loads require stronger film with a higher gauge or thicker profile.

Environmental Conditions: Temperature, humidity, and UV exposure can impact the performance of stretch films. For outdoor storage or transport, choosing UV-resistant or thicker gauge films can ensure durability.

Equipment Compatibility: The type of wrapping equipment used also affects film choice. Machine stretch films, for example, are designed to work with automated wrapping machines that require specific stretch film specifications like high stretch capacity and puncture resistance.

Suppose a business needs to wrap a standard 48″x48″x60″ pallet for transport. By inputting these dimensions into a stretch film specifications calculator and selecting a machine-grade film with a medium gauge, the calculator can suggest:

This precise approach helps businesses accurately estimate stretch wrap requirements, streamlining budget and inventory planning.

Purpose of a TDS

A Technical Data Sheet (TDS) is a critical document providing detailed information on stretch film specifications, including physical properties, performance data, and recommended applications. It helps users understand the capabilities and limitations of each film type, allowing them to make informed purchasing decisions.

Importance for Users

TDS sheets are essential for assessing whether a specific stretch film will meet the demands of their packaging tasks. They include performance metrics that guide in selecting films suited for different load types, environments, and methods of application.

Aligning Specifications with Applications

By understanding the specifications listed in a TDS, users can select stretch film suited to their specific needs:

Stretch Wrap Gauge Recommendation Based on Load Requirements

Choosing the appropriate gauge is essential in ensuring load stability and optimizing material usage. Here are typical recommendations:

Selecting by Gauge

Reviewing gauge options within stretch film specifications ensures each load is wrapped securely, without excessive film usage, for the best material cost-efficiency.

Different gages offer varying levels of strength and flexibility, making them suitable for distinct applications:

Lightweight and commonly used for small items or stable loads that don’t require high containment force. This gauge offers cost savings while still providing sufficient wrap for lighter applications.

The industry standard for most medium-weight loads, balancing strength and flexibility, and widely used across industries for general-purpose wrapping.

For heavy loads or items with sharp edges, 120-gauge stretch film specifications deliver increased tear and puncture resistance, ensuring product integrity even under challenging conditions.

Understanding the difference between gauges for stretching film helps in selecting the appropriate film strength, ensuring load stability without excessive material use. For example, bale silage stretch film is designed to provide a tight seal around silage bales, minimizing oxygen exposure while maintaining strength for agricultural use. By aligning gauge options with specific stretch film specifications, businesses can ensure optimal protection for each application, whether it’s for pallet loads or specialized needs like silage wrapping.

Choosing the right stretch film involves understanding specific stretch film specifications that match your packaging needs. Key points include evaluating load weight, size, and the storage or transportation conditions. Heavier or irregular loads often require higher gauge and stronger puncture-resistant film, while lighter, more stable loads can use thinner films.

Different industries have unique demands, so reviewing the stretch film specifications in a technical data sheet helps ensure optimal load security and cost-efficiency. For instance, manufacturing might prioritize high tear resistance, while retail may favor transparency and cling.

Choosing the Right Gauge for Freight Wrapping

The stretch wrap gauge needed to wrap freight depends on factors like load weight, product stability, and whether the freight will undergo multiple handling stages.

Making Gauge Selection Based on Freight Type

By choosing the correct gauge, companies can prevent overuse of film and ensure products arrive intact, making freight wrapping both cost-effective and reliable.

When selecting stretch film, discussing your needs with suppliers can provide insights into the best stretch film specifications for your application. Suppliers can recommend films based on your load characteristics, wrapping methods, and environmental conditions.

Review specification sheets carefully to confirm compatibility with intended uses, especially for unique applications like outdoor storage or high-frequency transport. Matching film performance metrics, such as tensile strength and elongation, ensures compatibility and optimizes performance.

Choosing eco-fOpting for eco-friendly stretch films, particularly those incorporating Post Consumer Recycled (PCR) materials, plays a pivotal role in reducing waste and advancing sustainability efforts. PCR stretch films, crafted from recycled consumer products, maintain the same high performance as traditional options while significantly lowering environmental impact. By selecting these films, businesses not only enhance their operational efficiency but also contribute to the circular economy, ensuring that packaging choices support long-term environmental goals.

Implementing recycling programs for used stretch film is essential, especially for companies with high packaging volumes. Recycling reduces environmental impact and minimizes waste, allowing businesses to align with sustainability goals while maintaining efficient operations.

Stretch film is typically made from linear low-density polyethylene (LLDPE) with characteristics including high transparency, strong tear strength, and self-adhesive properties. It comes in various dimensions and mechanical properties, tailored for different applications. Common specs include:

Material Type: Polyethylene, multi-layer.

Thickness: Various thicknesses available, often measured in microns or mils.

Width: Widths can vary significantly depending on application needs.

Performance Specs: Includes tensile strength, puncture resistance, and elongation at break.

Film Types: Cast and blown stretch films, each with different technical attributes and suitability for specific uses

Stretch film must meet specific mechanical, optical, and barrier property requirements to ensure its performance and durability. These requirements often include:

Tensile Strength: The film should maintain integrity under high tension.

Puncture Resistance: Ability to withstand sharp objects without tearing.

Elongation: Stretch ability before breaking.

Coefficient of Friction: Ensuring optimal wrapping and unwrapping processes.

Oxygen and Moisture Transmission Rates: Protecting goods from environmental factors.

The primary material used for stretch film is linear low-density polyethylene (LLDPE). This material provides a balance of strength, flexibility, and clarity, which are essential for the effective performance of stretch film.

While stretch film and cling wrap share some similarities, they are not the same. Both are plastics used to wrap items, but they differ in applications and properties:

Stretch Film: Primarily used for shipping and packaging, known for its tensile strength and ability to secure loads on pallets.

Cling Wrap: Primarily used for food storage, designed to adhere lightly to surfaces and itself, without the robust mechanical properties of stretch film.

Stretch film is primarily made from LLDPE (Linear Low-Density Polyethylene), a material known for its superior stretchability and puncture resistance compared to LDPE (Low-Density Polyethylene). LLDPE is produced using copolymerization of ethylene with short-chain alpha-olefins, which gives it a linear structure and improved mechanical properties. While LDPE is more flexible and often used in applications like shrink films or bags, it lacks the tensile strength and elongation properties required for stretch film. LLDPE’s higher stretch ratio and tear resistance make it ideal for securely wrapping and stabilizing loads, even in demanding conditions. Additionally, LLDPE films can be manufactured thinner without compromising strength, leading to cost and material savings. Innovations in multi-layer co-extruded LLDPE films further enhance performance, allowing them to cater to specific requirements such as UV resistance, anti-static properties, or food-grade applications.

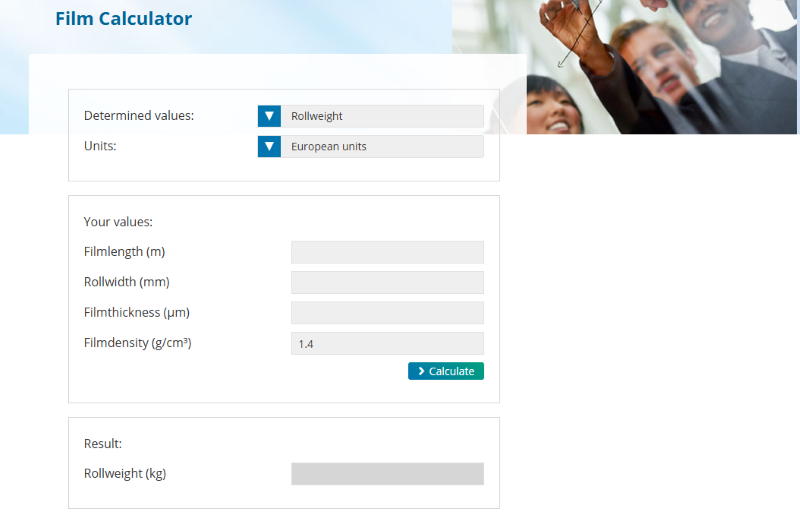

Calculating stretch film involves determining the quantity, weight, or cost required for specific applications, as well as assessing film usage efficiency. One standard method is to calculate the film weight using its thickness, width, length, and density. The formula is:

Film Weight (kg)=Width (m)×Length (m)×Thickness (microns)×Density (g/cm³)/1,000,Density of LLDPE is typically around 0.92 g/cm³. For example, a roll 500mm wide, 1,500 meters long, and 17 microns thick weighs approximately 11.7 kg. Stretch efficiency can also be measured as the stretched length divided by the original length, expressed as a percentage. Understanding these calculations ensures optimal film usage, minimizing waste and cost while achieving secure wrapping. Advanced tools like stretch film calculators or testing equipment can further refine usage estimates based on specific load requirements.

LLDPE stands for Linear Low-Density Polyethylene, a type of polyethylene that is widely used for stretch film production. Its “linear” molecular structure results from copolymerization, giving it unique mechanical and chemical properties compared to other polyethylene variants. LLDPE is characterized by its high tensile strength, puncture resistance, and elongation capacity, making it ideal for stretch film applications. It can stretch extensively without breaking, ensuring loads are tightly secured during transit. LLDPE also offers excellent impact resistance and durability in various temperatures, making it versatile for industrial and consumer use. Additionally, LLDPE has environmental benefits—it allows for thinner film production, reducing material usage and waste. Its properties can be further enhanced through co-extrusion processes to meet specific needs, such as UV resistance or anti-static functionality, making LLDPE the preferred material for high-performance stretch films.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed