Stretch film plays a crucial role in securing loads during transportation, offering protection against shifting, damage, and contamination. It works by wrapping tightly around the goods, creating tension that holds everything in place. However, simply applying stretch film is not enough; proper stretch film tension measurement is essential to ensure the load is securely contained. Inaccurate tension can lead to weak containment, causing damage during transit, or excessive tension, potentially damaging the goods. By accurately measuring the tension, companies can achieve optimal containment, reduce product loss, and minimize costs associated with damaged shipments. The use of tools and techniques for stretch film tension measurement ensures safety and efficiency throughout the shipping process. Stretch film tension measurement ensures proper force on the load, maximizing the film’s holding capacity and preventing displacement or damage during transport.

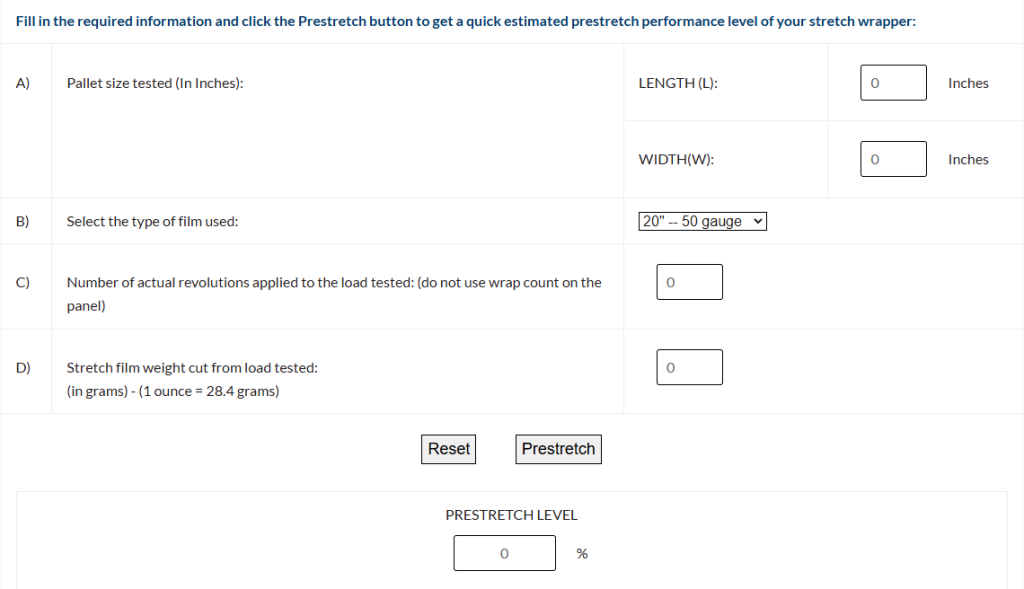

Accurate tension is key to ensuring that loads wrapped in stretch film are secure and stable during transit. A stretch film tension measurement calculator helps users calculate the correct amount of tension to apply when wrapping loads, ensuring optimal containment without damaging the products. This tool is designed to make the process easier by providing precise measurements that factor in the film type, load weight, and other variables. Using a calculator not only reduces the risk of over- or under-wrapping but also enhances load safety and decreases material waste.

The stretch film tension measurement calculator is a specialized tool that allows users to input key variables, such as film width, thickness, and load dimensions, to determine the correct tension needed for secure wrapping. It eliminates the guesswork often associated with manual tension adjustments, providing accurate data that can be applied to ensure proper containment force.

The calculator is especially useful for businesses that deal with a variety of load sizes and shapes, as it allows them to customize their wrapping process for each unique application. By calculating the appropriate tension, users can avoid the potential issues caused by improper wrapping, such as product damage or load shifting during transit. This tool also helps in optimizing the use of stretch film, reducing material costs over time.

Gather Your Data:

Before using the calculator, collect all necessary data about your load and stretch film. You’ll need information such as the weight of the load, the dimensions (height, width, and depth), and the type of stretch film being used (e.g., thickness and pre-stretch percentage).

Input Load Details:

Start by entering the load details into the calculator. This typically includes the weight of the load and its dimensions. These factors influence the amount of tension required to properly secure the load without causing damage.

Input Stretch Film Specifications:

Next, input the specifications of the stretch film being used. This includes the width of the film, its wrap gauge (thickness), and the pre-stretch percentage. Some calculators may also ask for the number of wraps or revolutions of the film around the load.

Adjust Film Force Settings:

Some calculators allow you to adjust the film force settings, which can impact how tightly the film is applied to the load. You can experiment with different tension settings to find the right balance between load security and avoiding damage.

Run the Calculation:

After all the data has been entered, click the calculate button to determine the appropriate stretch film tension. The calculator will provide a recommended tension setting, typically displayed in pounds per square inch (PSI) or Newtons, depending on the region and calculator used.

Apply the Tension:

With the tension measurement in hand, adjust your stretch wrapper to match the calculated settings. If you’re using a hand stretch film dispenser, apply the calculated tension by adjusting how tightly you pull the film around the load. For automated systems, you can directly input the tension value to ensure the machine applies the correct force.

Test the Load:

Once the load has been wrapped with the calculated tension, it’s a good idea to test the containment force. This can be done using a containment force tool, which measures the holding force of the film on the load. Compare the results with the calculator’s recommended settings to ensure everything is accurate.

Re-evaluate Periodically:

Over time, the stretch film tension may need to be adjusted as loads, films, and environmental factors change. Regularly re-evaluate your settings with the calculator to maintain consistent tension and optimal load security.

Let’s walk through an example to demonstrate how the stretch film tension measurement calculator can be applied to different load types.

Example 1: Standard Pallet Load

Load weight: 1,200 pounds

Load dimensions: 48 inches by 40 inches by 60 inches

Stretch film width: 20 inches

Film gauge: 80 gauge

Pre-stretch percentage: 250%

By entering this information into the calculator, the recommended tension might be around 30 PSI. You would then set your stretch wrapper or manual dispenser to this tension setting to ensure the load is securely wrapped.

Example 2: Irregular Load

Load weight: 500 pounds

Load dimensions: 36 inches by 36 inches by 48 inches

Stretch film width: 15 inches (narrow stretch wrap)

Film gauge: 60 gauge

Pre-stretch percentage: 200%

For this irregular load using narrow stretch wrap, the calculator might suggest a lower tension setting, around 20 PSI, to avoid crushing the load while still maintaining sufficient containment force.

The stretch film tension measurement calculator is an invaluable tool for ensuring that loads are securely wrapped without risking damage or instability. By following the steps outlined above, you can easily calculate the appropriate tension for any load type, ensuring consistent results and minimizing material waste. Regular use of the calculator also helps optimize stretch film usage, improving overall efficiency in the wrapping process.

Accurately measuring tension in stretch film is vital for ensuring the stability and safety of loads during transit. Over-tensioned stretch film can damage goods, while under-tensioned film can lead to load shifting, risking damage during transportation. This is where specialized tools for stretch film tension measurement come into play. These tools help users apply the correct amount of tension to optimize containment force, reduce product damage, and enhance overall load security. Below is an overview of the key tools used in measuring and maintaining proper stretch film tension, along with a detailed explanation of their features and benefits.

When it comes to measuring stretch film tension, both manual and digital devices are available to suit different needs and preferences.

Manual Devices: These tools usually rely on mechanical components to gauge the tension applied during film wrapping. Operators use these devices to manually measure the force applied to the film. While more affordable and straightforward, they require skilled handling to ensure accuracy.

Digital Devices: Digital tension measurement tools are more advanced, providing precise data on the tension applied. With easy-to-read displays and automatic calculations, digital tools help reduce human error and offer a more consistent reading. Although digital tools tend to be more expensive, they offer better accuracy and ease of use, making them suitable for high-volume operations or environments where precision is critical.

One of the most commonly used tools for measuring and maintaining containment force in stretch wrapping is the Stretch Wrap Containment Force Tool. This tool is essential in ensuring that the film is applied with the correct tension, securing the load without crushing or damaging it.

How It Works: The tool measures the containment force by gauging the pressure the stretch film applies to the load. By placing the tool at different points on the load—usually the top, middle, and bottom—it provides accurate data on the containment force. This allows operators to adjust their wrapping techniques or machine settings to ensure consistent tension across the entire load.

Benefits:

Accurate Containment: Ensures that loads are securely wrapped without being over-tightened, reducing the chances of damage.

Easy to Use: Operators can quickly measure tension in real-time, adjusting wrapping methods as needed.

Cost-Effective: Helps reduce the amount of film used by ensuring that the correct amount of tension is applied, minimizing waste.

The Stretch Wrap Containment Force Tool is a must-have for businesses seeking to optimize their stretch film applications. By providing instant feedback on containment force, it ensures that every load is wrapped securely without excess film usage.

Achieving optimal containment with stretch film requires precise tension and force application. This is where a stretch film test kit comes into play, providing all the tools necessary to verify that the correct tension is applied to loads during wrapping. Ensuring accurate measurements helps prevent product damage, optimize film usage, and enhance overall load stability. In this section, we will explore the components of a typical stretch film test kit, discuss its importance in achieving accurate stretch film tension measurement, and compare different test kits available in the market.

A standard stretch film test kit is designed to provide operators with the tools they need to measure and maintain optimal tension and containment force during the wrapping process. The contents of a typical test kit include:

Containment Force Tool: The primary device used to measure the containment force of stretch film on a load. It provides readings that indicate whether the applied force is sufficient to secure the load without causing damage.

Film Scale: A digital or manual scale used to weigh the amount of stretch film applied to the load, ensuring that the right amount of film is being used efficiently.

Tape Measure: Used to measure the dimensions of the load and the amount of film being applied. This helps calculate the number of film wraps and ensures even application across the entire load.

Pre-Stretch Marking Device: This tool helps mark the stretch film to measure its elongation and ensure the correct pre-stretch percentage is applied during wrapping. Pre-stretch is essential in ensuring proper tension without using too much film.

Markers: Included for labeling the test points on the load (top, middle, and bottom) to provide consistent measurements throughout the wrapping process.

Box Knife: Used to cut the film cleanly during the testing process to avoid any tears or damage that could skew the measurements.

Carrying Case: A portable case that makes it easy to transport the kit and ensure that all tools are kept in good condition.

Accurate stretch film tension measurement is crucial for load safety and efficiency. A stretch film test kit allows operators to verify the tension and containment force applied to loads, providing several key benefits:

Enhanced Load Security: By using a test kit to measure containment force, operators can ensure that the correct amount of tension is applied to keep loads stable during transport. This reduces the risk of load shifting or damage, especially during long-distance shipping.

Reduced Film Waste: Verifying tension with a test kit helps operators apply just the right amount of stretch film. Over-wrapping wastes material and increases costs, while under-wrapping can lead to load instability. Using a test kit ensures optimal film usage, saving costs over time.

Improved Consistency: Stretch film test kits enable operators to achieve consistent tension across all loads. This uniformity is essential for businesses that handle a high volume of shipments, as it ensures that every load is wrapped with the same level of security.

Compliance with Industry Standards: Many industries have specific guidelines for load containment and safety during transport. A stretch film test kit helps businesses comply with these standards by ensuring the right tension and containment force are applied.

Various stretch film test kits are available, each designed to meet the specific needs of different businesses and industries. Below is a comparison of key features to help you choose the right test kit for your operations:

| Feature | Basic Test Kit | Advanced Test Kit | Premium Test Kit |

|---|---|---|---|

| Containment Force Tool | Manual | Digital with LCD display | Digital with real-time data logging |

| Film Scale | Manual | Digital | Digital with memory storage |

| Pre-Stretch Marking Device | Included | Included with higher precision | High-precision device with percentage display |

| Tape Measure | Standard | Standard | Laser-guided measurement tool |

| Markers | Basic | Standard | High-visibility markers |

| Carrying Case | Included | Included | Durable, weather-resistant case |

| Suitability | Small businesses with limited loads | Medium-sized operations with moderate load variation | Large-scale operations with high volume and complex loads |

| Cost | Low | Moderate | High |

Using a stretch film test kit is essential for businesses that want to ensure the safety and stability of their loads during transport. The kit provides all the necessary tools to measure and verify stretch film tension measurement, ensuring that the right amount of tension and containment force is applied. This reduces product damage, improves load stability, and enhances overall efficiency by minimizing film waste. Whether you are a small business or a large operation, investing in the right stretch film test kit can greatly improve the quality of your packaging processes. By selecting the kit that best meets your needs, you can ensure consistent, secure loads and optimize your wrapping procedures.

Narrow stretch wrap, as the name suggests, refers to a type of stretch film that is much narrower in width compared to standard rolls. Typically ranging from 2 to 5 inches wide, it is widely used in industries where smaller, irregular loads need to be securely wrapped, or where specific sections of a larger load require extra reinforcement. Although it may not be as commonly used as traditional wider rolls, narrow stretch wrap serves a critical role in improving the stability and containment of certain types of shipments. In this section, we’ll explore the specific uses of narrow stretch wrap, its effect on stretch film tension measurement, and the best practices for ensuring accurate tension when wrapping smaller or irregularly shaped loads.

Narrow stretch wrap is used across various industries, especially in situations where precision wrapping is required. Below are some of its common applications:

Bundling Small Items: In industries such as automotive, electronics, and hardware, narrow stretch wrap is ideal for bundling small parts, tools, or other compact items. Its smaller width allows for easier handling and more precise wrapping compared to standard stretch film.

Securing Long, Thin Loads: Long, narrow items such as pipes, tubes, rods, and lumber are often wrapped using narrow stretch wrap. The wrap’s ability to target specific sections of the load helps secure the materials without unnecessary bulk.

Reinforcing Pallets: In some cases, narrow stretch wrap is used to reinforce specific areas of a pallet load. For example, the bottom or middle of a pallet may require additional containment force, and narrow stretch wrap can be applied in these areas to ensure extra security without stretch film wasted.

Packaging Irregularly Shaped Items: Items with unusual shapes or protruding parts can be challenging to wrap with standard film. Narrow stretch wrap provides the flexibility needed to wrap around corners or odd angles, offering enhanced containment for irregular goods.

When using narrow stretch wrap, the application of tension becomes even more critical than with wider stretch films. The smaller width of the film means that it applies tension over a more concentrated area, which can significantly affect the overall containment force of the wrapped load. Here’s how narrow stretch wrap impacts stretch film tension measurement and containment force:

Higher Tension Concentration: Since narrow stretch wrap covers less surface area than wider rolls, the tension applied is concentrated on a smaller part of the load. This concentrated tension can create stronger containment in specific areas, but it also raises the risk of over-tightening and damaging the load if the tension is not carefully controlled.

Need for Precise Tension Measurement: Measuring and maintaining the correct tension is especially important when using narrow stretch wrap. Because the wrap covers smaller sections of the load, even minor adjustments in tension can result in significant changes to the containment force. This is why tools designed for stretch film tension measurement are essential when working with narrow stretch wrap, as they ensure the tension remains consistent and appropriate for the load.

Variable Containment Force: Depending on the load type, narrow stretch wrap may create variable containment force throughout the load. For instance, using narrow wrap on the middle of a pallet may provide excellent containment in that area but leave the top and bottom of the load with inadequate force. It’s essential to combine narrow wrap with other containment techniques, or to apply multiple layers, to achieve balanced containment.

Ensuring accurate tension when using narrow stretch wrap can be challenging, but following certain best practices can help maintain load security and prevent damage. Here are a few tips for measuring and applying tension effectively with narrow stretch wrap:

Use the Right Tools for Tension Measurement:

Tools such as the Stretch Wrap Containment Force Tool and digital tension gauges are invaluable when applying narrow stretch wrap. These tools help measure the containment force applied at different points on the load, ensuring that the tension is consistent and appropriate. Regularly checking the tension throughout the wrapping process will help prevent over-tightening, which can damage the goods, or under-tightening, which can compromise the load’s security.

Apply Multiple Layers if Necessary:

Since narrow stretch wrap provides tension over a smaller surface area, it’s often necessary to apply multiple layers to achieve the desired containment force. When using narrow wrap to secure a pallet or an irregular load, adding extra layers can help evenly distribute the tension and ensure the load is fully secured. However, it’s essential to use your stretch film tension measurement tool to ensure that the additional layers do not over-tighten or crush the load.

Wrap Key Areas of the Load First:

When using narrow stretch wrap on irregular loads, focus on wrapping the key areas that require the most containment force first. For example, wrap around corners, protruding parts, or the middle section of a pallet where load shifting is most likely to occur. After securing these areas, use your tension measurement tools to adjust the force as needed.

Combine Narrow Wrap with Standard Film:

For larger loads, narrow stretch wrap can be used in combination with standard-width film to reinforce specific areas. This hybrid approach ensures that the entire load is secured while still allowing for targeted tension in high-risk areas. As always, check the tension with a measurement tool to ensure consistency throughout the wrapping process.

Narrow stretch wrap plays a vital role in industries where smaller or irregularly shaped loads need to be secured. However, its narrower width means that careful attention must be paid to stretch film tension measurement to avoid over-tightening or under-securing the load. By using the right tools, applying multiple layers when necessary, and following best practices for tension control, businesses can ensure that narrow stretch wrap provides the optimal containment force for any load. This not only improves load security but also reduces the risk of product damage and stretch wrap material waste.

Changing stretch film tension is a key step in ensuring that the film is applied correctly to secure the load without over-stretching or under-stretching the film. Proper tensioning helps optimize the load-holding capacity of the film, preventing damage or slippage during transport. Below are the various aspects to consider when adjusting stretch film tension.

Most modern packaging machines allow operators to adjust the stretch film tension directly through the machine’s control panel. This is the most common way to modify the tension for optimal performance. The machine typically has tension settings for both the pre-stretch and film application stages.

The carriage mechanism on a stretch wrapper is responsible for applying the film to the load. You can adjust the tension by changing the speed at which the film is pulled from the roll. Slower carriage speeds can reduce tension, while faster speeds increase the tension.

Some machines have a film roll holder where tension can be adjusted by modifying the brake or drag setting. The brake mechanism controls the speed at which the film is dispensed, influencing how tightly the film adheres to the load.

Environmental factors, such as temperature and humidity, can affect the behavior of stretch film and, consequently, its tension. Stretch film tends to behave differently in colder temperatures and may require adjustments to the tension settings to ensure proper film application.

Different types of stretch films (e.g., cast stretch film, blown stretch film) have different stretchability and tension requirements. It’s important to adjust the tension based on the specific type of film being used, as some films require higher tension to perform optimally.

Stretch film tension measurement and adjustment are essential to ensuring that the film is applied correctly, maximizing the load-holding capacity while minimizing waste or film breakage. By adjusting machine settings, the carriage mechanism, roll holder, and considering environmental factors, operators can fine-tune the tension to suit specific load requirements. Proper tensioning ensures that stretch film performs at its best, providing effective load security during transport.

Stretch film tension measurement is crucial to ensuring that the film is applied correctly and provides optimal load security. Regular measurement of tension helps prevent over-stretching or under-stretching, which can affect the performance and integrity of the stretch film. Below is a detailed breakdown of how often stretch film tension should be measured and the key factors influencing this frequency.

For most production environments, measuring stretch film tension should be part of the daily or even hourly quality control process. This ensures that tension levels remain consistent throughout the production run, preventing variations that could affect product integrity.

Whenever a new roll of stretch film is introduced, or after any changes to the film type, the tension should be re-measured. Different films may require different tension settings depending on their thickness, stretchability, and material type.

Any adjustments to the stretch wrapping machine—such as speed changes, carriage modifications, or changes to the brake settings—can affect the tension applied to the film. Regular measurement should be conducted to ensure that these adjustments don’t negatively impact film performance.

In high-output or multi-shift operations, it’s important to measure the stretch film tension at shift changes to ensure consistency in film application across different operators or shifts.

Changes in the environment—such as temperature, humidity, or pressure—can impact the stretch film’s behavior. For example, colder temperatures may cause the film to become more brittle, while high humidity can cause the film to stretch more easily. These changes can affect film tension and should be monitored.

Even if the machine is running smoothly, periodic audits are essential for long-term quality control. Routine audits allow operators to verify that the tension is consistent over time and that no hidden issues (such as wear on machinery or deterioration of film quality) are affecting the packaging process.

Stretch film tension measurement should be conducted regularly—at least daily or after any major change—to ensure the film is applied correctly and performs at its best. Measuring tension after film changes, equipment adjustments, shift changes, and environmental variations ensures optimal film performance. Routine tension checks help maintain consistent load security, reduce film wastage, and prevent packaging failures. Regular measurement is a key factor in maximizing the efficiency of stretch wrapping systems and ensuring product safety during transport.

Stretch film is typically measured by its thickness, width, and length. The most common unit of measurement for the thickness of stretch film is the gauge, with higher numbers indicating thicker film. For example, an 80-gauge film is thicker than a 60-gauge film. Stretch film can also be measured in microns, especially in countries that use the metric system.

The width of the film roll, which usually ranges from 12 to 30 inches, is another important factor. The wider the film, the more surface area it can cover with each pass around a load. Lastly, the length of the roll, typically expressed in feet or meters, indicates how much film is available per roll. These measurements combined help determine how effective the film will be for different types of loads and how much will be required for a specific application.

Calculating stretch film usage involves several factors, including the size of the load, the number of wraps required, and the width of the film. To calculate usage, first determine the total surface area of the load you are wrapping by multiplying its length, width, and height. Next, estimate how many layers or revolutions of film are needed to secure the load.

For example, if you are wrapping a standard pallet and require five revolutions to secure it, you multiply the perimeter of the pallet by the number of revolutions. Then, you divide this figure by the width of the stretch film roll to calculate how many feet or meters of film will be used per load. To refine this estimate, you can also factor in the pre-stretch percentage if you are using a machine that pre-stretches the film before application.

The main difference between 60-gauge and 80-gauge stretch wrap is their thickness and strength. A 60-gauge stretch wrap is thinner and typically used for lighter loads, making it more economical when wrapping products that don’t require a lot of containment force. It’s suitable for items like smaller boxes, soft goods, or palletized products that won’t shift significantly during transit.

On the other hand, 80-gauge stretch wrap is thicker and provides more strength and durability. It is ideal for heavier or irregularly shaped loads that need more containment force to stay secure during transportation. The extra thickness of 80-gauge wrap offers better puncture resistance, making it less likely to tear if the load has sharp edges or protrusions. Choosing between these gauges depends largely on the weight and nature of the products being wrapped.

In the context of stretch film tension measurement, the term “mil” refers to a unit of thickness used for measuring plastic films like stretch wraps. One mil is equal to 1/1000th of an inch. Therefore, a 2 mil stretch wrap is 0.002 inches thick. Stretch wraps with this thickness are commonly used for light to medium-duty applications such as wrapping smaller packages or palletizing products in industries like retail and logistics.

The tension applied during the wrapping process is critical for maintaining the strength and durability of the stretch film. When wrapping with a 2 mil stretch wrap, it’s important to monitor the tension to ensure the film is stretched to its optimal performance level, preventing breakage or under-stretching that could lead to poor load stability. The gauge of the wrap directly influences its tensile strength, tear resistance, and stretchability.

Converting gauge to micron is a straightforward process but requires knowledge of the relationship between the two units. One gauge (mil) is equivalent to approximately 25.4 microns. To convert gauge to micron, simply multiply the gauge value by 25.4.

For example, to convert a 2 mil stretch film to microns:

2 mil × 25.4 = 50.8 microns.

In stretch film tension measurement, knowing the film’s thickness in microns is useful for determining the appropriate tension settings. Films with a higher micron thickness generally offer more durability and stretch resistance, which is crucial for applications requiring higher stretch forces. Micron thickness helps define the film’s stretchability, tear resistance, and load-holding capacity. Proper tensioning ensures that the stretch film is stretched to its optimal point, enhancing its load containment properties.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed