Understanding stretch wrap roll weight is essential for efficient logistics and packaging processes. Knowing the exact weight of each stretch wrap roll for packing helps businesses plan for transportation costs, storage requirements, and inventory management, especially when handling high volumes. Calculating stretch wrap roll weight accurately allows for precise usage, which minimizes waste and ensures pallets are securely wrapped for transit. Various tools, like charts and online calculators, simplify this process by providing quick weight estimates based on roll dimensions, film gauge, and length. Using these tools, businesses can streamline operations, reduce material costs, and improve productivity, making accurate weight calculations a key element in packaging logistics. The Stretch Wrap Roll Weight Calculator finds the stretch wrap roll weight by dividing roll length × width × thickness by 250,000.

A stretch wrap roll weight chart provides a quick and easy reference for determining the weight of stretch wrap rolls based on their dimensions, thickness (gauge), and length. By using a chart, businesses can avoid manual calculations and save time when estimating roll weights. Here’s a detailed breakdown of how to effectively use and benefit from these charts.

Simplifying Calculations with a Stretch Wrap Roll Weight Chart

How to Read a Stretch Wrap Roll Weight Chart Effectively

Benefits of Using a Chart in Routine Packaging and Inventory

Using a stretch wrap roll weight chart simplifies daily packaging operations, ensuring that businesses are prepared for all wrapping needs with minimal waste and maximum efficiency.

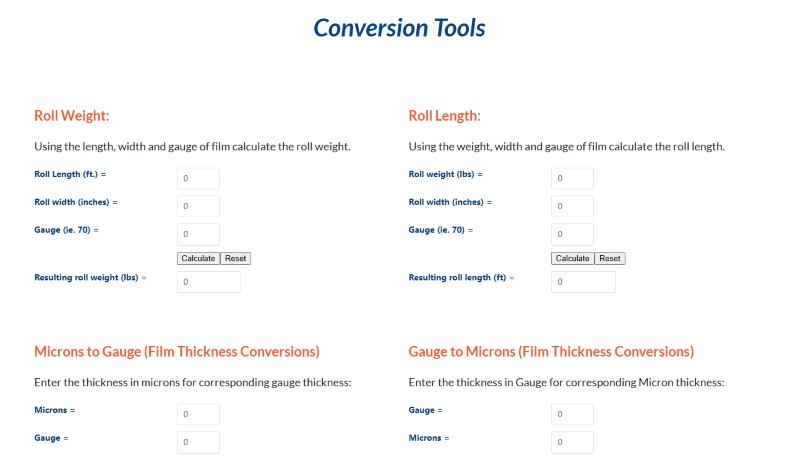

A stretch wrap roll weight calculator is a convenient online tool designed to help users quickly determine the exact weight of stretch wrap rolls based on specific measurements. It simplifies packaging planning by providing accurate weights, which are crucial for logistics, storage, and inventory management. Below, we explain how to use the calculator effectively and highlight its benefits.

Purpose of a Stretch Wrap Roll Weight Calculator

Step-by-Step Guide for Using a Stretch Wrap Roll Weight Calculator

Benefits of Using a Stretch Wrap Roll Weight Calculator

The gsm of stretch film (grams per square meter) is a critical measure of film density, which affects both weight and durability. Calculating the gsm provides insights into the film’s weight per unit area, helping users make informed choices based on roll density, especially when selecting machine stretch film for industrial applications.

Why GSM Matters:

For many businesses, measuring stretch wrap roll weight in kilograms (kg) is essential, especially for international operations. Using kilograms aligns with global standards, simplifies logistics, and enhances accuracy in cross-border transactions. Below, we discuss the importance of kg measurements, conversion steps, and international standards for stretch wrap roll weight.

Why Businesses Prefer Stretch Wrap Roll Weight in Kg

Converting Stretch Wrap Roll Weight from Pounds to Kg

International Weight Standards in the Stretch Wrap Industry

The cut and weigh stretch film method is a common technique used for accurately determining the weight of a particular stretch film sample.

How to Use the Cut and Weigh Stretch Film Method

Locating accurate stretch wrap roll weight information from nearby suppliers can streamline purchasing and logistics, providing convenient options and potential cost savings. Here’s how to effectively find local sources, along with the advantages of working with nearby suppliers.

Using these methods to find stretch wrap roll weight information near you supports a more efficient, cost-effective, and tailored packaging operation.

A pallet wrap calculator is a practical tool designed to estimate how much stretch film is required to wrap a pallet, streamlining packaging and reducing waste. The calculator uses dimensions, wrap type, and stretch percentage to provide a precise answer for each wrapping job. Understanding stretch wrap roll weight in this context can help businesses manage inventory and costs effectively.

The pallet wrap calculator and stretch wrap calculator and stretch wrap measurements are invaluable tools for achieving optimal packaging efficiency, improving cost management, and ensuring secure pallet loads for transport.

Choosing between a stretch wrap roll weight calculator and a stretch film weight calculator depends on specific packaging requirements and desired information. Each calculator serves a different function, helping users estimate weight for individual rolls or entire film applications. Below, we explain the differences, ideal use cases, and the benefits and drawbacks of each tool.

| Feature | Stretch Film Weight Calculator | Stretch Wrap Roll Weight Calculator |

|---|---|---|

| Primary Purpose | Calculates the weight of stretch film used in specific applications or per square footage | Calculates the total weight of an individual roll based on dimensions, gauge, and length |

| Input Requirements | Area of film needed, thickness (gauge), weight per unit area | Roll length, width, and gauge |

| Output | Total weight for the specified film area | Weight of a specific roll |

| Ideal for | Estimating material weight used on pallets or packaging projects | Inventory management, logistics planning, and shipping weight estimation |

| Precision | Provides accurate estimates per project | Offers precise roll weights for bulk orders |

Understanding how much does stretch wrap weigh is essential for efficient logistics and accurate cost calculations.

Both calculators, along with an understanding of how much does stretch wrap weigh, allow businesses to optimize their packaging operations and streamline logistics effectively.

To calculate the weight of stretch film, you need to know the dimensions and the density of the material. The formula involves multiplying the length, width, and thickness (measured in mils or microns) of the film. You may also need to know the density of the film material, which is typically measured in grams per cubic centimeter

The weight of a roll of pallet wrap can vary based on its dimensions and material. Typically, a standard roll of hand stretch film might weigh around 5 to 10 pounds (2.27 to 4.54 kg). Industrial rolls used with wrapping machines can be significantly heavier, sometimes weighing upwards of 50 pounds (22.68 kg).

The number of pallets one roll of stretch wrap can cover depends on several factors, including the size of the pallets, the extent of wrapping needed (e.g., one layer or multiple layers), and the dimensions of the stretch film roll. On average, a standard roll of hand stretch film can wrap around 15 to 25 pallets, but this number can vary significantly based on usage and requirements.

The gauge of stretch wrap refers to its thickness, with a higher gauge indicating a thicker film. 60 gauge stretch wrap is thinner and more lightweight compared to 80 gauge stretch wrap. This makes 60 gauge wrap more suitable for lighter, less demanding applications, while 80 gauge wrap is stronger and better suited for heavier loads or items that require more secure wrapping. Gauge thickness impacts the durability, stretchability, and puncture resistance of the film.

The weight of stretch film varies depending on its dimensions, material composition, and thickness. Typically, the weight of a roll is determined by the film’s length, width, and gauge (thickness). For example, a standard roll of 18-inch wide, 80-gauge stretch film that is 1,500 feet long weighs approximately 6-7 pounds. Larger industrial rolls or heavier gauges will weigh significantly more. Factors such as core weight and whether the film is blown or cast also contribute to the overall weight.

To calculate the weight of a stretch film roll, use the formula:

Weight = (Film thickness × Width × Length × Density) + Core weight

Film thickness: Convert gauge or microns to mils (1 mil = 0.001 inches).

Width and Length: Usually in inches and feet, respectively.

Density: Typically around 0.92 g/cm³ for polyethylene.

Add the core weight (commonly around 1-2 pounds for standard rolls).

For precision, refer to the manufacturer’s specifications.

A 2-mil stretch wrap equates to 200 gauge. To convert mils to gauge, multiply the mil thickness by 100 (1 mil = 100 gauge). A 2-mil stretch wrap is significantly thicker than the standard 80-gauge wrap, offering greater durability and puncture resistance. This thickness is typically used for heavy-duty applications such as securing large or irregularly shaped loads.

The weight of a net wrap roll depends on its length, width, and material. A standard roll of net wrap for baling, typically 64 or 67 inches wide and 7,000 feet long, weighs between 40 and 50 pounds. Lightweight versions may weigh less, while high-strength or extra-long rolls can exceed 60 pounds. Core material and density also impact the weight.

The weight of a single stretch wrap layer depends on its gauge and dimensions. For instance, a layer of 80-gauge film wrapped around a 48-inch by 40-inch pallet weighs about 0.2 to 0.3 pounds. For a full pallet wrap using multiple layers, the total weight may range from 1 to 3 pounds, depending on the number of layers and wrap tension.

Cast stretch wrap is produced by extruding molten resin through a flat die and cooling it on chilled rollers. It has high clarity, quiet unwind, and uniform thickness but offers less tear resistance. Blown stretch wrap is made by blowing molten resin into a bubble. It is tougher, with better puncture resistance and stretch memory, but has a noisier unwind and cloudy appearance.

An 80-gauge stretch wrap is 0.8 mils thick (0.0008 inches). This thickness is ideal for medium-duty applications, such as securing standard pallet loads weighing 1,500 to 2,000 pounds. It provides a balance of strength, stretchability, and cost-effectiveness, making it a popular choice for general-purpose wrapping.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed