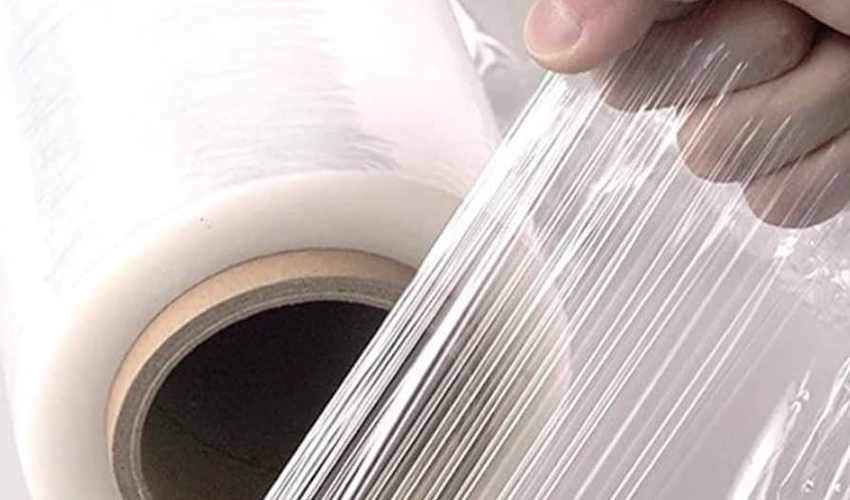

Tensile strength of stretch film refers to the maximum amount of tensile stress that the film can withstand while being stretched before breaking. This property is crucial in determining how well the film performs in securing loads during transportation and storage. A higher tensile strength of stretch film ensures that the material can maintain its integrity under various conditions, minimizing the risk of breakage or failure. For example, triwrap stretch film, along with Pre-stretch film, is engineered with enhanced tensile strength, offering superior performance compared to standard films. This allows triwrap and Pre-stretch film to better secure loads, especially in demanding conditions, ensuring greater stability and protection from damage. By understanding the tensile strength of stretch film, manufacturers and users can make informed choices, optimizing their packaging processes and enhancing overall supply chain performance. The tensile strength of stretch film is its max stress before breaking, enhanced by pre-stretching for heavier loads and greater durability.

The tensile strength of stretch film is a critical property that determines its ability to withstand stress during stretching and load containment. Several factors influence this characteristic, affecting the film’s performance in various applications.

The tensile strength of stretch film refers to the maximum force the film can withstand while being stretched before it breaks. This critical property measures the film’s ability to resist tearing or breaking under tension, making it essential for securing and protecting loads during transportation or storage. Tensile strength ensures the film maintains its integrity under stress, providing reliable containment for both light and heavy loads. This characteristic is influenced by factors such as material composition, film thickness, and manufacturing processes, making it a key parameter in determining the performance and suitability of stretch film for various applications.

The type of material used, such as linear low-density polyethylene (LLDPE), polypropylene (PP), or polyvinyl chloride (PVC), significantly impacts tensile strength.

The thickness of the film directly correlates with its tensile strength.

The production method affects molecular alignment and strength.

The degree to which the film is pre-stretched affects its strength.

Extreme temperatures can alter the film’s strength.

The type and weight of the load determine the required tensile strength.

Incorporating additives during manufacturing can improve performance.

By considering these factors, manufacturers and users can select the appropriate stretch film with optimal tensile strength for specific applications, ensuring secure load wrapping and long-term durability.

In the realm of packaging, understanding the tensile strength of stretch film is essential. Various resources available in PDF format offer in-depth insights into this critical property. These documents typically provide detailed information about how tensile strength is measured and its implications for packaging efficiency.

Numerous studies and reports delve into the tensile strength of stretch film, offering valuable data:

Accessing tensile strength data from PDFs is straightforward:

Calculating the tensile strength of stretch film is essential for ensuring that packaging materials can withstand the demands of transportation and storage. The formula used to determine tensile strength is a straightforward representation of how much force a film can handle before it breaks.

The tensile strength of stretch film can be expressed with the following formula:

Tensile Strength=Maximum Force (N or lbs)/Cross-sectional Area (mm² or in²)

This formula indicates that tensile strength is calculated by dividing the maximum force that the stretch film can endure before breaking by its original cross-sectional area.

If you want to calculate the tensile strength of the stretch film through the formula, you need to first know the stretch film specifications parameters mentioned in the formula;

Understanding how to apply the tensile strength of stretch film formula can benefit businesses in various ways:

By effectively applying the tensile strength of stretch film formula, companies can optimize their packaging strategies, enhancing both product protection and overall operational efficiency.

Charts play a critical role in visualizing the tensile strength of stretch film, providing essential insights that facilitate informed decision-making for packaging solutions. By representing data graphically, these charts help stakeholders quickly grasp key information regarding the performance characteristics of various stretch films.

Various types of charts are commonly used to display tensile strength data effectively:

Using charts effectively can streamline the selection process for stretch films:

Stretch film is primarily made from linear low-density polyethylene (LLDPE), but other materials like polypropylene (PP) and polyvinyl chloride (PVC) are also used for specific applications.

Each material offers distinct properties, including variations in tensile strength:

The tensile strength of stretch film varies significantly with the material. LLDPE strikes a balance between stretchability and strength, making it ideal for high-stretch applications. PP provides higher tensile strength but with reduced elasticity, suitable for static bundling. PVC offers moderate strength but excels in cling and optical properties for lighter tasks.

Selecting the right material depends on the application’s load requirements and desired film characteristics.

When purchasing or manufacturing stretch wrapping film, understanding its technical parameters is crucial. These parameters are categorized into size specifications, appearance standards, and physical and mechanical properties, each playing a vital role in ensuring quality and performance.

Size specifications are essential for meeting customer requirements and include:

The film’s appearance reflects its manufacturing quality, addressing:

Key performance metrics for stretch film include:

By focusing on these parameters, manufacturers can optimize stretch film for specific applications, ensuring reliable performance, durability, and consistent tensile strength for secure load containment.

Stretch film is renowned for its strength and durability, making it a preferred choice in various packaging applications. Typically, the tensile strength of stretch film can range from 20 to 30 megapascals (MPa), depending on the specific type and gauge of the film. The strength of stretch film is crucial for ensuring that it can securely hold loads without tearing or breaking during transportation and storage. Additionally, high-performance stretch films can exhibit even greater tensile strength, reaching up to 40 MPa or more. Factors such as the thickness of the film, the manufacturing process, and the type of polymer used contribute to its overall strength. Choosing the right stretch film with adequate tensile strength is essential for maintaining load stability and preventing product damage. When evaluating stretch film options, it’s important to consider both the load weight and the conditions under which the film will be used.

Tensile strength is a measure of a material’s resistance to breaking under tension. For stretch films, this property is particularly important as it determines how much force the film can withstand before failing. Typically, the tensile strength of stretch film can be tested and reported in terms of ultimate tensile strength (UTS), which reflects the maximum stress the film can endure. The tensile strength of standard stretch films generally falls between 1,500 to 3,000 pounds per square inch (psi) or approximately 10 to 20 MPa. Various factors influence the tensile strength, including the film’s thickness, material composition, and the manufacturing method. Higher tensile strength films offer advantages in load stabilization and protection, making them suitable for heavier or irregularly shaped loads. When selecting stretch film, it’s essential to consider its tensile strength in conjunction with other performance attributes to ensure optimal packaging effectiveness.

The tensile strength of stretch film refers to the maximum force the film can withstand while being stretched without breaking. Typically measured in pounds per square inch (PSI) or megapascals (MPa), this property indicates the material’s resistance to being pulled apart. Stretch film, made of materials like linear low-density polyethylene (LLDPE), generally has a tensile strength ranging between 4,000 and 7,000 PSI.

Tensile strength is crucial for applications where the film must securely wrap and protect loads during transportation or storage. A high tensile strength ensures the film can stretch effectively without tearing, maintaining its integrity under stress. Manufacturers test tensile strength using standardized procedures, such as ASTM D882, to ensure consistent performance. For specific applications, the required tensile strength can vary depending on the film’s gauge, stretch capacity, and intended use, such as pallet wrapping or bundling.

The tensile strength of film refers to the maximum stress a film material can endure while being stretched or pulled before breaking. It is a fundamental mechanical property used to evaluate the film’s performance under tension. This property is typically measured using standardized testing methods like ASTM D882, with results expressed in PSI or MPa.

Different types of films, such as polyethylene (PE), polypropylene (PP), or stretch films, exhibit varying tensile strengths depending on their composition and manufacturing processes. For example, films used for industrial packaging require higher tensile strength to withstand heavy loads, while films for food packaging may prioritize other properties like flexibility.

Tensile strength plays a vital role in determining the film’s suitability for specific applications, such as wrapping, sealing, or bundling. It ensures the material can resist tearing, maintain load security, and provide durability during use.

Thermoplastic polyurethane (TPU) film exhibits excellent tensile strength, typically ranging from 6,000 to 10,000 PSI, depending on the specific formulation and processing. TPU films are valued for their combination of strength, elasticity, and durability, making them ideal for applications requiring flexibility and resistance to mechanical stress.

TPU films’ tensile strength allows them to endure significant stretching without tearing, providing high performance in demanding environments. These films are used in industries like medical devices, outdoor gear, and automotive applications, where both mechanical strength and elasticity are essential.

Testing for TPU tensile strength is conducted according to standardized methods, such as ASTM D412 or ISO 37, ensuring reliable and consistent results. Beyond tensile strength, TPU films offer additional advantages, such as abrasion resistance and weatherproofing, which enhance their functionality across diverse applications.

Tensile strength is calculated by dividing the maximum force applied to a material during a tensile test by its original cross-sectional area. The formula is:

Tensile Strength=Maximum Force (N or lbs)/Cross-sectional Area (mm² or in²)

The test involves clamping a specimen of the material into a tensile testing machine, which applies a controlled, increasing force until the material breaks. The maximum force sustained before breaking is recorded.

For films like stretch film, the test follows standards such as ASTM D882 or ISO 527, which specify the preparation, testing procedure, and conditions. Accurate tensile strength measurements help manufacturers ensure the film meets application-specific requirements, such as load containment, tear resistance, or stretchability. Consistent tensile strength evaluation is critical for maintaining quality and optimizing material performance in packaging or industrial uses.

Tension in film refers to the force applied to the film as it is stretched, either during application or use. It is a critical factor in ensuring that the film provides adequate load containment, sealing, or bundling. Proper tension allows the film to stretch uniformly and maintain its properties without tearing or over-stressing the material.

In stretch films, tension is controlled during application using stretch wrapping machines or manual stretching techniques. Too much tension can cause the film to tear, while too little tension can result in inadequate load stability. The tension must balance the film’s tensile strength and elongation properties to optimize performance.

Measuring tension helps evaluate the film’s behavior under stress and its ability to maintain integrity during transport or storage. Ensuring optimal tension is essential for achieving the desired load security and minimizing material waste.

Tensile strength and elongation are interconnected properties that describe a material’s performance under stress. Tensile strength measures the maximum force a material can endure before breaking, while elongation measures how much the material can stretch, expressed as a percentage of its original length.

For stretch films, a balance between tensile strength and elongation is critical. High tensile strength ensures the film resists tearing, while adequate elongation allows it to stretch and conform to loads without breaking. Materials with high tensile strength and low elongation are rigid, whereas those with moderate tensile strength and high elongation offer flexibility.

In practical terms, stretch film designed for wrapping applications combines both properties to provide optimal load stability and resilience. Testing methods like ASTM D882 assess these parameters, helping manufacturers tailor films to meet specific application demands, such as heavy-duty wrapping or high-stretch bundling.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed