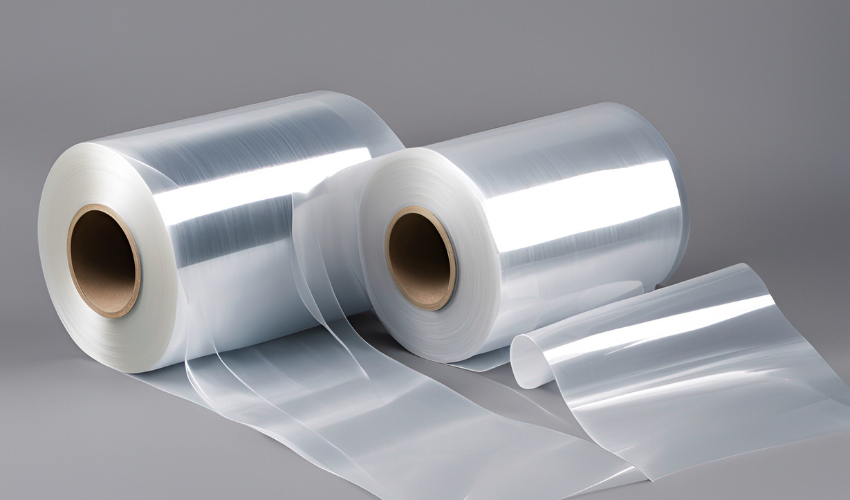

Thermal pallet wrap is a specially designed packaging material used to protect temperature-sensitive goods during transportation. Unlike regular wraps, thermal pallet wrap provides a crucial insulation layer that helps maintain stable temperatures, shielding products from extreme heat or cold. This makes it essential for industries like food transportation, pharmaceuticals, agriculture, and chemicals, where temperature fluctuations can lead to product spoilage or degradation. By using thermal pallet wrap, companies can prevent costly losses and ensure that goods arrive in optimal condition. PWP Stretch Film’s thermal pallet wrap options offer solutions for all sectors needing reliable temperature control, making it an ideal choice for both local and long-distance shipments.

PWP Stretch Film’s selection of thermal pallet wrap includes solutions that meet local needs for temperature-sensitive goods while supporting efficient, cost-effective, and environmentally responsible shipping practices.

Thermal pallet wrap plays a critical role in managing the safe transportation of temperature-sensitive goods across various industries. Selecting the best thermal pallet wrap can protect products from environmental changes, reducing risks of damage due to temperature fluctuations. PWP Stretch Film’s high-quality thermal wraps, with their innovative pallet wrap design, are engineered to provide optimal protection, reliability, and ease of use for both large and small-scale businesses. This design ensures secure coverage and consistent temperature control, making it an ideal solution for safeguarding sensitive goods during transit.

An effective thermal pallet wrap must incorporate specific qualities to offer the best insulation and protection for temperature-sensitive shipments. Here are the key features to consider:

Advantages of Effective Thermal Pallet Wrap:

Choosing the best insulation material for thermal pallet wrap depends on the specific temperature requirements of the products, the expected environmental conditions, and budget considerations. Below is a comparison of common insulation materials used in thermal pallet wraps:

| Insulation Material | Description | Advantages | Limitations |

|---|---|---|---|

| Radiant Barrier | Reflective material that deflects heat away from products | High reflectivity, excellent for hot environments, often lightweight | May not be as effective in cold conditions without additional insulation layers |

| Bubble Wrap Layer | Small air-filled bubbles provide an insulation buffer | Lightweight, effective at trapping heat, cost-efficient | Limited durability; bubbles can be punctured, reducing effectiveness |

| Foil Layers | Often used with other materials, acts as a thermal barrier | Strong thermal resistance, useful in both hot and cold settings, highly durable | Can be heavier and more rigid, higher cost |

| Polyethylene Foam | Thick layer providing both cushioning and insulation | High durability, resistant to punctures, excellent for fragile items | Bulkier and may increase shipping weight, higher cost than simple bubble wrap |

Each material serves unique purposes based on shipping needs, and often, PWP Stretch Film’s thermal pallet wraps may integrate multiple materials to combine benefits. For instance, a radiant barrier paired with polyethylene foam creates a highly durable and effective temperature shield suitable for perishable goods in long-distance shipments.

Factors to Consider When Choosing Insulation Materials:

Thermal pallet wrap is indispensable for businesses that rely on efficient and safe product transport. By carefully choosing the best thermal pallet wrap and understanding the benefits of each insulation material, companies can significantly improve their shipping efficiency and product quality while maintaining environmental sustainability.

When searching for thermal pallet wrap for sale, selecting the right option is essential for maintaining the quality and safety of temperature-sensitive goods during transportation. Here is a comprehensive guide to choosing a thermal pallet wrap that meets industry standards, ensures optimal performance, and matches the specific needs of your business.

Finding a reliable supplier for thermal pallet wrap can make a significant difference in product quality, delivery times, and overall cost-effectiveness. Choosing a supplier involves more than simply finding the lowest price; it requires careful consideration of product quality, supplier reputation, and the level of customer service provided. PWP Stretch Film offers a range of thermal pallet wraps suitable for various industries, ensuring effective temperature control and durability.

Factors to consider when choosing a supplier for thermal pallet wrap include:

Advantages of Choosing a Trusted Supplier:

Every industry has specific requirements for shipping and protecting products, and thermal pallet wrap suppliers like PWP Stretch Film often offer customization options to meet these diverse needs. Customizable thermal wraps allow businesses to tailor products according to size, thickness, insulation level, and other key features, ensuring they receive the most suitable wrap for their applications.

Here are some common customization options for thermal pallet wrap:

Examples of Industries Benefiting from Custom Thermal Wraps:

Choosing the right thermal pallet wrap and supplier is essential to effective temperature-sensitive shipping. By considering these factors and customization options, businesses can ensure their products arrive safely and efficiently. PWP Stretch Film not only offers high-quality thermal wraps but also provides other stretch films, such as hand stretch film and machine stretch film, to suit various packaging needs. Working with a trusted supplier like PWP Stretch Film and selecting the correct custom features can optimize temperature control, reduce waste, and support brand representation in the competitive logistics market.

Thermal blankets are essential for food transportation, offering the insulation required to preserve freshness and prevent spoilage of perishable goods. The primary purpose of using thermal pallet wrap and blankets in food logistics is to maintain stable temperatures throughout the journey, even when facing fluctuating external conditions. This protection is invaluable for ensuring that food products arrive in optimal condition, reducing waste and enhancing consumer satisfaction. PWP Stretch Film’s thermal blankets are specifically designed to meet the high demands of the food transportation industry, making them an ideal choice for companies prioritizing quality and freshness.

Thermal blankets serve a crucial role in the food industry due to their unique properties and ability to maintain a controlled environment for sensitive products. Here are the main reasons thermal blankets are so effective for food transport:

Benefits of Using Thermal Blankets in Food Transport:

Thermal pallet wrap and blankets are widely applicable across the food industry, from fresh fruits and vegetables to frozen products. Their use cases illustrate how these wraps cater to different food types with unique requirements:

PWP Stretch Film’s thermal pallet wrap options cater to the diverse needs of the food industry, ensuring reliable and affordable temperature control. Whether for fresh produce or frozen items, these wraps are an invaluable resource for protecting food quality and maintaining safety throughout the transportation process.

Pallet blankets play a significant role in enhancing cost efficiency in temperature-sensitive logistics by providing an affordable alternative to refrigerated shipping. Thermal pallet wrap and insulated pallet blankets not only maintain product quality but also allow companies to optimize their shipping costs, reducing waste and extending the shelf life of transported goods. PWP Stretch Film’s pallet blankets offer businesses a practical and flexible solution for cost-effective temperature management, suited for a variety of industries from pharmaceuticals to food transport.

Choosing between reusable and disposable pallet blankets involves considering the cost, environmental impact, and specific logistical needs of the business. While both types of pallet blankets serve the same purpose of protecting goods from temperature fluctuations, their benefits vary depending on the use case.

Cost-Effectiveness of Reusable Pallet Blankets:

Reusable pallet blankets are designed to be durable and withstand multiple uses, providing long-term savings for companies with ongoing shipping needs. Despite a higher upfront cost, reusable blankets are an economical option in the long run, particularly for businesses shipping large volumes of temperature-sensitive goods.

Advantages of Disposable Pallet Blankets:

For companies that ship temperature-sensitive goods infrequently or need single-use solutions, disposable pallet blankets are a practical choice. These blankets typically cost less initially and are designed for one-time use, making them ideal for shorter shipping cycles or for companies that require cost-effective, lightweight options for occasional shipments.

Thermal pallet wrap and insulated pallet blankets also contribute to energy savings by reducing the need for refrigerated transportation. By providing an effective thermal barrier, these covers help maintain a stable temperature for perishable items, lessening the dependency on energy-intensive refrigeration during transit. For businesses, this translates into lower operational costs, a smaller carbon footprint, and greater flexibility in shipping arrangements.

Energy and Cost Benefits of Using Insulated Pallet Covers:

PWP Stretch Film’s thermal pallet wrap and pallet blankets offer businesses a cost-effective solution for temperature control that does not rely solely on costly refrigeration. Whether using reusable or disposable options, insulated pallet blankets help businesses achieve significant savings and environmental benefits, making them a valuable component in modern temperature-sensitive logistics.

Yes, thermal pallet covers are highly effective for maintaining consistent temperatures, especially for temperature-sensitive goods. These covers work by providing an insulation barrier that reduces the impact of external temperatures, helping to keep products within a safe temperature range during transport. This insulation is often made from multiple layers, including radiant barriers, bubble layers, or foam, which work together to block heat transfer, ensuring protection against both heat and cold.

Thermal pallet covers are widely used across industries like food, pharmaceuticals, and chemicals, where even slight temperature variations can lead to product spoilage or degradation. By using thermal pallet covers, businesses can avoid relying solely on refrigerated transport, which is both costly and energy-intensive. Instead, these covers allow companies to maintain product integrity in a cost-effective way, making them a valuable investment for any business dealing with sensitive shipments. Overall, thermal pallet covers are a reliable solution to manage temperatures, reduce waste, and cut costs in logistics.

Shrink wrap and pallet wrap serve different purposes and have distinct characteristics. Shrink wrap is a polyethylene-based material that shrinks tightly around items when heat is applied, creating a secure and tamper-resistant seal. It is most commonly used for smaller items, bundling products together for retail displays, or packaging irregularly shaped items. The application of heat helps the shrink wrap conform to the shape of the items, providing moisture and dust protection.

Pallet wrap, often referred to as stretch wrap, is designed to stabilize large loads on pallets without the use of heat. It’s made from a stretchable plastic that wraps around the pallet load multiple times, binding items securely together through tension rather than shrinkage. Unlike shrink wrap, pallet wrap is typically applied manually or with a wrapping machine and is favored for heavy, large, or fragile items on pallets. In logistics, pallet wrap is essential for stabilizing shipments and preventing items from shifting during transit, offering a cost-effective and practical alternative for large-scale shipping needs.

The amount of pallet wrap needed to securely wrap a pallet depends on several factors, including pallet size, load type, and the wrap thickness or stretch level. Generally, a standard pallet wrap roll is between 15 to 20 inches wide and can vary in thickness, typically measured in microns or gauge. For a typical 48” x 40” pallet with a load height of around 5 feet, it may take around 200-300 feet of wrap, depending on how many layers are applied and the specific wrapping technique.

There are tools and calculators available to help determine exact requirements. For example:

Pallet Dimensions: Larger or taller pallets will naturally require more wrap to cover all sides and secure the load adequately.

Stretch Level: High-stretch wraps extend further with less material, covering more area per foot.

Type of Load: If the load is irregular or contains fragile items, additional layers are often applied to prevent movement.

For high-volume users, understanding these factors can optimize wrap usage, reducing costs and waste while ensuring a stable, well-secured load.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed