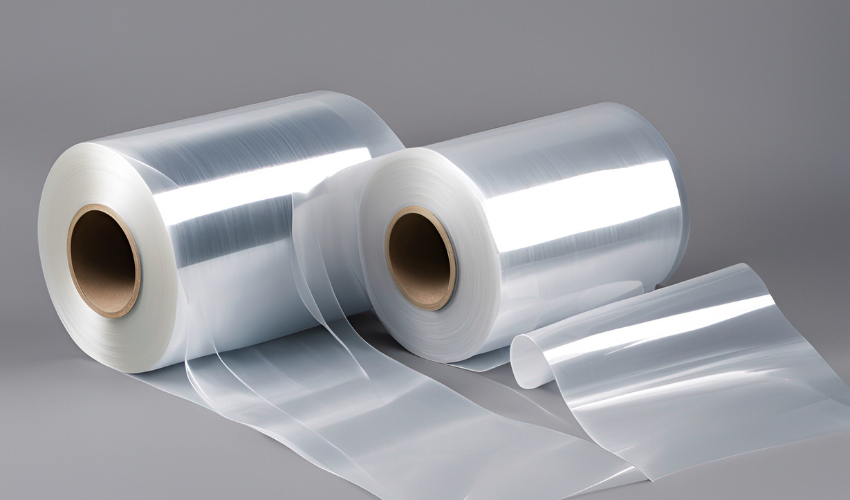

Thin plastic roll is a lightweight yet versatile material used across multiple industries, including construction, home improvement, and packaging. Its flexibility and ease of use make it a go-to solution for projects requiring surface protection or temporary barriers. Available from popular suppliers like PWP Stretch Film, thin plastic roll can range from transparent sheeting for visibility to heavy-duty options designed for demanding tasks, such as renovations or concrete work. It is widely used for covering floors, furniture, or windows to safeguard against dust, dirt, and moisture. For projects that demand additional protection, VCI stretch film can be used to safeguard metal surfaces from corrosion, offering an extra layer of security when protecting valuable equipment. Whether for professional contractors or DIY enthusiasts, thin plastic roll offers a practical and cost-effective way to protect materials and surfaces throughout various projects.

Thin plastic roll is available in multiple forms, each suited for specific tasks across home improvement, construction, and industrial projects. From clear plastic sheeting to heavy-duty construction rolls, selecting the appropriate thin plastic film roll ensures optimal coverage, protection, and durability for various applications.

Thin plastic roll is a popular choice for DIY enthusiasts tackling home improvement projects, offering protection for surfaces like walls, floors, and furniture.

Heavy-duty plastic sheeting roll offers enhanced durability, making it ideal for large-scale renovation and construction tasks. These rolls can withstand rough handling and provide long-lasting protection.

This version of thin plastic film roll provides transparent coverage, allowing visibility of the protected surfaces. It’s especially useful in environments where monitoring is essential.

Plastic roll for covering is essential for safeguarding items during storage, moving, or renovation.

Construction-grade thin plastic roll is designed for rugged outdoor use, providing reliable protection in various building scenarios.

Hard plastic sheeting roll offers added rigidity, ideal for tasks that require structural support. It’s suited for projects where long-term durability is essential.

Choosing the right thin plastic film roll ensures that your project receives the appropriate level of protection, durability, and flexibility. LDPE film roll, known for its flexibility and resistance to impact, can be an excellent alternative when a more lightweight solution is needed, especially for tasks that require a balance between durability and ease of handling. Whether it’s a lightweight roll for home improvement or a heavy-duty option for construction, each type offers specific advantages tailored to various tasks, ensuring smooth and efficient operations.

Selecting the appropriate thin plastic roll is crucial to ensure your project achieves the desired protection and durability. From thickness to material type, each factor plays an essential role in determining the right product for your specific needs. Below, we explore key considerations for choosing the perfect thin plastic roll for any application.

The thickness of the thin plastic roll directly impacts its strength, flexibility, and durability. Rolls typically range from 6 mil to 20 mil, with each thickness suited for different purposes.

Ideal for light-duty applications like protecting furniture, covering floors during painting, or shielding windows during renovations.

Thin and flexible, easy to apply and remove without tearing.

Suitable for medium-duty tasks, such as creating vapor barriers in basements or encapsulating crawl spaces.

Provides moderate resistance to punctures and wear.

Designed for heavy-duty use in construction projects, including concrete pours or equipment storage.

Highly resistant to tears and punctures, ensuring long-term durability in demanding environments.

Choosing the correct thickness ensures that the thin plastic roll meets the demands of your project, preventing damage and improving efficiency.

Different material types offer varying benefits, including visibility, privacy, and resistance to environmental factors. Choosing the right type of thin plastic roll depends on the specific needs of your project.

Allow visibility of the protected surface or item, making them ideal for greenhouses or temporary barriers on construction sites.

Provide light transmission while protecting against dust and dirt.

Provide complete privacy, concealing the contents from view.

Suitable for outdoor storage or situations requiring theft prevention, especially when wrapping pallets for outdoor storage.

Designed to withstand prolonged exposure to sunlight, preventing degradation.

Commonly used for outdoor applications, such as scaffolding covers or ground sheets, UV-resistant rolls offer protection in harsh conditions. For specific applications requiring sensitive handling, anti static plastic wrap is often used in conjunction with UV-resistant rolls. This wrap helps to prevent the buildup of static charges, safeguarding sensitive electronics and components.

When thin plastic film is stretched during application, it offers enhanced cling and durability, making it ideal for specific use cases.

Thin plastic film stretched refers to the process where the plastic material is pulled and applied tightly over a surface, creating a secure and protective barrier. This technique is commonly used in logistics, packaging, and agricultural applications.

Choosing a reliable supplier ensures that you receive high-quality thin plastic roll products tailored to your specific needs. Retailers like PWP Stretch Film offer a wide range of plastic rolls in various sizes, thicknesses, and materials to accommodate different applications.

Choosing the right thin plastic roll involves carefully assessing the thickness, material type, and intended use. Whether you need a clear roll for visibility, a black roll for privacy, or a UV-resistant roll for outdoor use, selecting the right product ensures optimal performance. For applications requiring enhanced security and stability, such as pallet protection, a durable plastic roll can offer excellent coverage. Suppliers like PWP Stretch Film make it easy to find high-quality rolls for every project, ensuring long-lasting protection and efficiency. Additionally, using thin plastic film stretched enhances durability and cling, offering superior coverage for specialized tasks. With the right thin plastic roll, you can confidently tackle any project, from home improvements to heavy-duty construction.

Thin clear plastic is commonly referred to as “polyethylene terephthalate” (PET) or “polyvinyl chloride” (PVC). These materials are frequently used in various applications due to their transparency and durability. PET is often utilized in the packaging industry for bottles and containers, while PVC is used for applications such as clear vinyl sheets and protective coverings. Both of these plastics are valued for their clarity, flexibility, and strength, making them ideal for a range of consumer and industrial uses.

A plastic roll is typically termed as “plastic sheeting” or “plastic film”. These rolls can be made from a variety of plastic materials like polyethylene, polyvinyl chloride, or polypropylene. Plastic sheeting is commonly used for protective covers, agricultural purposes, construction, and packaging. They can come in different thicknesses and sizes, and may be clear or colored depending on their intended use. The versatility and durability of plastic sheeting make it a popular choice for many industrial and household applications.

The name of the thin plastic can vary depending on its composition and usage. Common types include “polyethylene film,” “acetate film,” and “cellophane.” Polyethylene film is often used for packaging and protective wraps, while acetate film can be found in applications like overhead transparencies and craft projects. Cellophane is typically used for wrapping food items, as it offers a good barrier against moisture. These thin plastics are all designed to be flexible, clear, and relatively strong, making them suitable for numerous practical applications.

Thin flexible plastic is often known as “polyethylene film” or “polypropylene film.” These types of plastics are renowned for their flexibility, light weight, and durability. They are commonly used in packaging, as they can easily be molded and wrapped around various shapes. Another popular type of thin flexible plastic is “vinyl,” which is frequently used in applications like shower curtains, tablecloths, and flexible tubing. The term “film” is generally applied to these materials due to their thin and pliable nature, which allows them to be used in a wide range of settings and purposes.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed