Moisture Barriers: Using pallet covers or shrink wrap beneath the UVI film adds a layer of protection against moisture and dust.

Edge Protectors: Placing corner boards or edge protectors safeguards against strapping damage and reinforces pallet edges.

Improved Load Stability

Strapping and Banding: Adding polyester or steel strapping can further secure heavy or irregular loads.

Stretch Hooding: Employing a stretch hood over the pallet before wrapping can encapsulate the load, providing additional stability.

Product Cushioning

Bubble Wrap or Foam Sheets: Wrapping individual items with bubble wrap or foam before palletizing offers shock absorption.

Corrugated Sheets: Placing corrugated cardboard layers between products prevents friction and adds rigidity.

Identification and Branding

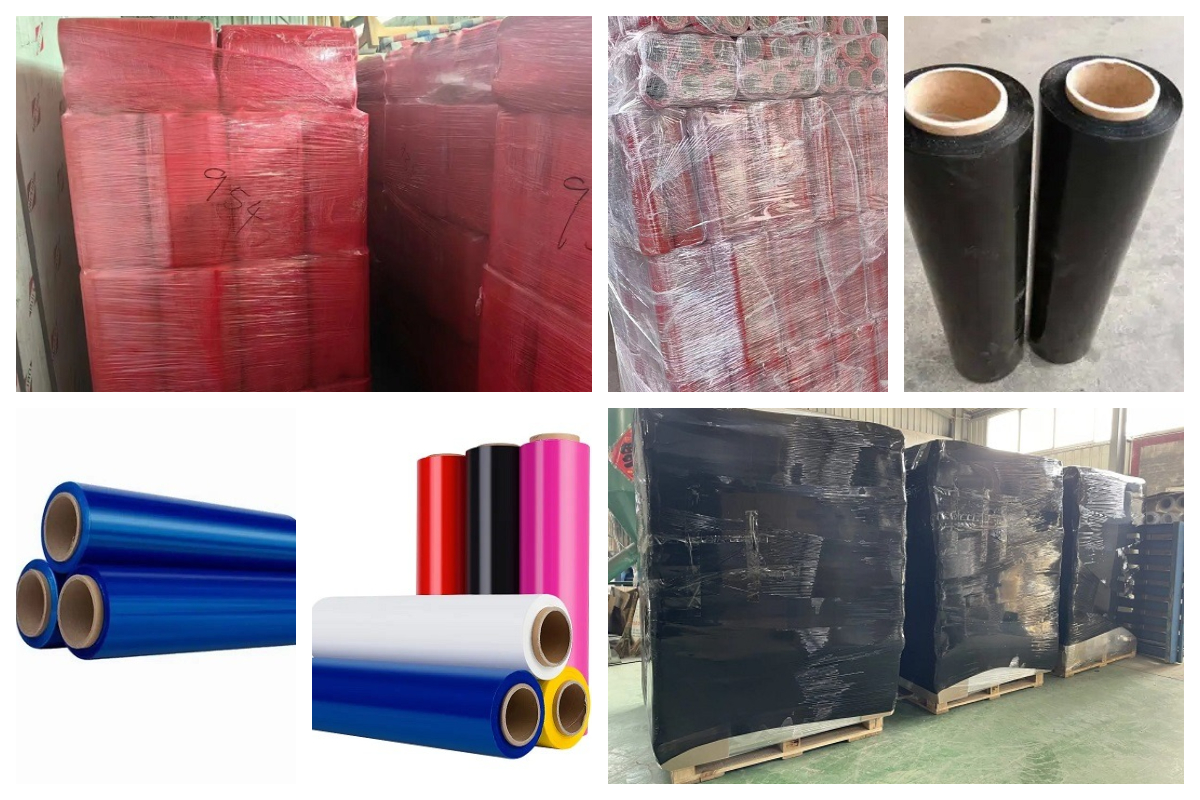

Colored Films or Labels: Using colored stretch films or applying labels beneath the UVI film aids in product identification and branding.

Printed Wraps: Incorporating printed shrink wraps with company logos or handling instructions beneath the UVI layer enhances visibility and communication.

Temperature Control

Insulated Blankets: Combining thermal blankets or insulated liners with UVI film helps maintain temperature-sensitive products.

Reflective Films: Using reflective materials beneath the UVI film can deflect heat, keeping products cooler.

Security Enhancement

Tamper-Evident Seals: Applying security tapes or seals under the UVI film indicates any unauthorized access.

Opaque Films: Using an opaque layer beneath the clear UVI film conceals high-value items from view.

Common Packaging Materials to Pair with UVI Stretch Film

Pallets

Wooden Pallets: Standard choice for most industries, providing a sturdy base.

Plastic Pallets: Resistant to moisture and ideal for hygienic applications.

Pallet Covers and Bags

Top Sheets: Placed over the top of the pallet to protect against dust and moisture.

Gusseted Bags: Fit over the entire pallet load for comprehensive coverage.

Edge Protectors

Corner Boards: Made from plastic or cardboard to reinforce pallet edges.

V-Boards: Provide added strength and prevent crushing.

Strapping

Polypropylene Straps: Lightweight and suitable for lighter loads.

Steel Straps: Ideal for heavy-duty applications requiring maximum strength.

Cushioning Materials

Bubble Wrap: Protects individual items from impact.

Foam Padding: Offers additional cushioning and vibration dampening.

Labels and Markings

Handling Labels: Indicate special instructions like “Fragile” or “This Side Up.”

Barcodes and RFID Tags: For inventory tracking and management.

Best Practices for Combining UVI Stretch Film with Other Materials

Assess Product Requirements

Environmental Exposure: Determine the extent of UV exposure and need for moisture protection.

Load Characteristics: Consider weight, shape, and fragility of the products.

Select Complementary Materials

Compatibility: Ensure that additional materials do not interfere with the effectiveness of the UVI film.

Efficiency: Choose materials that streamline the packaging process without compromising protection.

Optimize Wrapping Techniques

Layering: Apply inner protective layers before wrapping with UVI film.

Tension Adjustment: Adjust stretch film tension to accommodate added materials and maintain load stability.

Safety and Compliance

Regulatory Standards: Comply with industry-specific packaging regulations.

Material Handling: Train staff on proper handling to prevent damage to both products and packaging materials.

Advantages of Pairing UVI Stretch Film with Other Materials

Comprehensive Protection: Combines UV shielding with other protective features like moisture resistance and cushioning.

Extended Product Life: Protects both packaging and products from environmental degradation.

Customization: Tailors packaging solutions to specific product needs and logistical challenges.

Cost Efficiency: Reduces potential losses from product damage, enhancing overall cost-effectiveness.

Brand Integrity: Maintains product quality and appearance, reinforcing brand reputation.

Applications Across Industries

Agriculture

Protecting farm produce and equipment stored outdoors.

Combining with moisture barriers for sensitive crops.

Construction

Securing building materials like lumber and metal components.

Using edge protectors to prevent damage to materials.

Chemical and Industrial Goods

Shielding chemicals and industrial products from UV degradation.

Incorporating hazard labels beneath the UVI film.

Food and Beverage

Protecting perishable goods during outdoor events or storage.

Pairing with insulated materials for temperature control.

Pharmaceuticals

Safeguarding medicines and medical equipment sensitive to light.

Ensuring compliance with strict packaging regulations.