Corrosion is one of the most common and costly issues faced by exporters, especially when shipping metal parts overseas. Factors such as moisture, salt, and varying temperatures can cause metals to rust, tarnish, or oxidize during transit. This not only damages the products but also leads to expensive replacements and delays. To combat this, many exporters rely on advanced packaging solutions, such as VCI (Vapor Corrosion Inhibitor) stretch films. A VCI antirust stretch film exporter provides specialized films that release corrosion-inhibiting vapors, forming an invisible protective layer around metal parts. These exporters typically source their films from VCI antirust stretch film manufacturers, who develop and produce the high-quality films using advanced technology and rigorous testing to ensure optimal corrosion protection. This innovative solution ensures that metal components remain rust-free and in perfect condition, reducing the risk of damage and enhancing the longevity of goods during export.

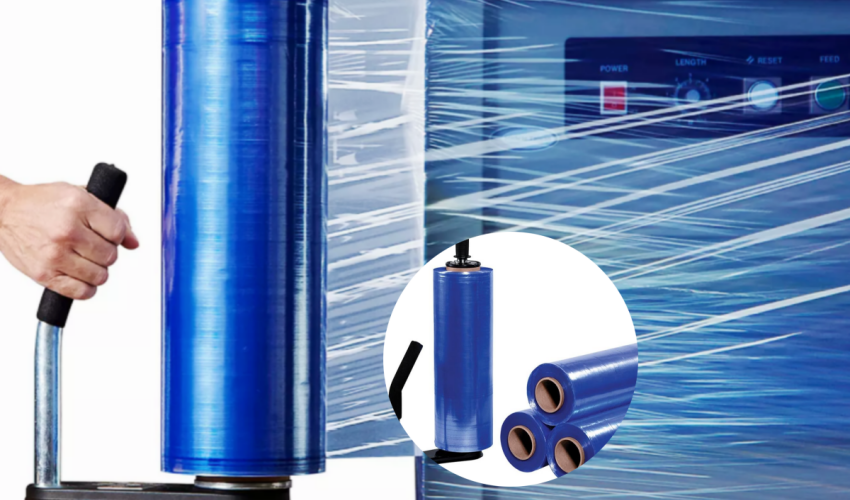

VCI (Vapor Corrosion Inhibitor) Antirust Stretch Film is an advanced packaging material designed to protect metal parts from corrosion during storage and transportation. The film is made from a high-quality plastic substrate, often polyethylene, which is embedded with VCI technology. This innovative film works by releasing corrosion inhibitors that form a protective layer around metal surfaces, preventing rust, tarnish, and oxidation. Manufactured in a VCI antirust stretch film factory, this film is produced with precision to ensure optimal performance in safeguarding metal goods. Classified under the HS code for plastic stretch films, this VCI Antirust Stretch Film is essential for exporters looking to safeguard metal goods during transit.

VCI stretch film is specifically formulated with corrosion inhibitors that are released in a vapor phase when the film is sealed around metal components. These vapors settle on the metal surfaces, forming a protective layer that prevents the metal from coming into contact with moisture, air, or other elements that can cause rust or corrosion. Unlike traditional packaging methods, which only provide physical barriers, VCI stretch films provide both physical protection and an active anti-corrosion environment.

VCI technology works by emitting corrosion-inhibiting molecules that form a thin, invisible layer on the surface of metals. These molecules actively bond with the metal surfaces, creating a protective film that prevents the formation of rust and oxidation. The vapor phase allows for complete coverage, even in hard-to-reach areas, ensuring comprehensive protection for complex or irregularly shaped metal parts. This makes VCI stretch film, classified under plastic stretch film HS code, ideal for a wide range of industries, including automotive, aerospace, and engineering, where metal parts are vulnerable to corrosion during shipping and storage.

By working with a VCI rust preventive stretch film exporter, businesses can ensure that their metal goods are effectively shielded from environmental factors that could lead to corrosion, reducing damage and maintaining the quality of their products throughout the supply chain.

VCI (Vapor Corrosion Inhibitor) stretch film is a cutting-edge packaging solution designed to offer robust corrosion protection for metal parts, making it a preferred choice for industries requiring safe and reliable shipment of metal goods. A VCI antirust stretch wrap film exporter provides this advanced film, ensuring that exporters can protect their metal products during storage and transit. Below are some of the key features that make VCI stretch film essential for corrosion prevention:

One of the primary benefits of VCI stretch film is its ability to prevent rust, tarnish, oxidation, and other forms of corrosion. By emitting corrosion inhibitors in a vapor phase, the film creates an invisible protective layer over the surface of the metal, shielding it from moisture, air, salts, and other contaminants that typically lead to corrosion. Whether dealing with iron, steel, aluminum, or copper, VCI stretch film ensures that metal parts are free from corrosion damage, providing long-term protection throughout their journey. This makes it especially valuable for industries like automotive, machinery, and electronics, where even minor oxidation can lead to significant damage.

VCI stretch films are not only corrosion-resistant but also highly durable and stretchable. The film is designed to stretch up to 300% of its original length, allowing it to tightly wrap around irregularly shaped parts or large metal components. This high level of flexibility ensures that all surfaces are securely covered, providing comprehensive protection even for complex parts. The film also maintains its strength during handling, preventing tears or punctures while still clinging firmly to the wrapped items, making it ideal for industrial use.

Many VCI antirust stretch film exporter offerings include eco-friendly and recyclable options. With increasing global emphasis on sustainability, the demand for environmentally responsible packaging materials has grown significantly. VCI stretch film is often made from recyclable polyethylene, which helps businesses reduce their carbon footprint. These films can be reused or recycled after their protective use, making them a suitable choice for exporters who are looking to meet environmental regulations and reduce waste, while still providing excellent corrosion protection.

Another outstanding feature of VCI stretch film is its ability to provide extended protection for up to 5 years when stored properly. This long-lasting defense is crucial for businesses that need to store or transport goods over long periods of time. The film continues to release corrosion inhibitors for years, offering ongoing protection to metal parts without the need for additional treatment or maintenance. This extended protection capability ensures that metal components arrive at their destination in the same condition as when they were packaged, reducing the risk of returns or costly repairs due to rust or oxidation.

By choosing a anti-rust VCI stretch film exporter, companies can ensure that their products are protected for extended periods, maintaining their quality and reducing costs associated with corrosion damage.

VCI (Vapor Corrosion Inhibitor) stretch film has proven to be a highly effective and versatile solution for corrosion protection across various industries, especially in the context of international exports. A VCI antirust stretch film exporter plays a critical role in providing this specialized film, ensuring that metal products remain safe from corrosion throughout the shipping and storage process. Below are some of the key applications of VCI stretch film for exporters:

The automotive and engineering industries rely heavily on precision metal components, which are often highly susceptible to rust, tarnish, and oxidation when exposed to moisture or environmental pollutants during shipping. VCI stretch film is ideal for wrapping engine parts, gears, transmission components, and other precision machinery. When used by a VCI antirust stretch film exporter, this stretch film provides an invisible barrier that protects against moisture and oxygen, both of which are major contributors to corrosion. This is especially important for high-value parts that need to maintain their functionality and appearance upon arrival at their destination. Whether exporting small parts or large engine blocks, VCI stretch film ensures that products remain in pristine condition, reducing the risk of returns or costly repairs due to rust damage.

For exporters in industries that deal with large or irregularly shaped metal items, such as metal coils, sheets, and tubes, VCI stretch film is an essential packaging solution. These items are typically exposed to environmental elements that promote corrosion, especially during long journeys across oceans or through fluctuating climates. The stretch film’s ability to conform tightly to irregular shapes ensures comprehensive protection, even for bulky or unevenly shaped items like metal tubes or coils. VCI stretch film wraps these items securely, forming a protective shield that prevents moisture and contaminants from affecting the surface of the metal. A VCI antirust stretch film exporter provides this critical protection to ensure the integrity of these large metal products during transport, making sure they arrive at their destination rust-free.

Many electronics and machinery components, such as circuit boards, metal casings, and delicate machinery parts, are susceptible to oxidation. Unlike traditional anti-corrosion methods, VCI stretch film offers the advantage of preventing oxidation without impacting the electrical or surface properties of the parts. The vapor-phase corrosion inhibitors in the VCI film form a thin protective layer on the metal without interfering with its functionality. This makes VCI stretch film an ideal choice for high-tech industries where precision and performance are essential. Exporters of electronics and machinery benefit from working with a VCI antirust stretch film exporter, ensuring that these sensitive components arrive at their destination in perfect condition, free from corrosion damage or performance issues.

When shipping metal goods across long distances, especially overseas, exporters face a unique set of challenges due to the exposure to moisture, salt, and harsh environmental conditions—especially in maritime shipping. The combination of saltwater, humidity, and temperature changes can accelerate the corrosion process and compromise the quality of metal products. VCI stretch film is especially effective for industrial and maritime exports, as it provides a strong, durable layer of protection that shields metal parts from the corrosive effects of salt and moisture. Whether it’s heavy machinery, automotive parts, or engineering components, VCI stretch film ensures that metal products are safeguarded during long transit periods over sea or land. A VCI antirust stretch film exporter provides this advanced solution, enabling companies to ship metal products globally with confidence, knowing they will arrive in excellent condition.

When it comes to protecting metal parts during shipping and storage, the quality of the packaging material is crucial. Antirust LLDPE stretch film offers a highly effective solution for corrosion prevention, ensuring that your metal goods are shielded from rust and oxidation during their journey. A VCI antirust stretch film exporter provides this specialized type of film, ensuring that your metal parts remain safe and rust-free throughout the entire supply chain. Below are the key reasons why choosing an antirust LLDPE stretch film exporter is essential for your business.

Antirust LLDPE (Low-Density Linear Polyethylene) stretch film is a high-quality packaging material specifically designed to prevent rust and corrosion on metal components. Unlike traditional stretch films, this type is embedded with corrosion inhibitors that are activated upon contact with metal surfaces. The film releases these inhibitors in a vapor form, creating a protective barrier around the metal, effectively preventing oxidation, tarnish, and rust. It’s particularly well-suited for industries that deal with metal parts, such as automotive, aerospace, and heavy machinery. The VCI antirust stretch film exporter ensures that this innovative material is available to meet the specific needs of different industries, offering superior protection for metal goods during storage and transport.

Choosing a reputable VCI antirust stretch film exporter comes with several advantages, particularly in ensuring the quality, flexibility, and reliability of your packaging solutions. Here are the key benefits of working with these specialized exporters:

When selecting a VCI antirust stretch film exporter, there are several important factors to consider to ensure that you’re working with a reliable partner.

When selecting the right corrosion protection for metal parts during shipping, it’s crucial for exporters to choose a VCI stretch film that matches their specific needs. A VCI antirust stretch film exporter offers various types of stretch films, each designed to provide reliable protection from corrosion while meeting the requirements of different industries and shipping conditions. Below are some of the most common types of VCI stretch films available for exporters:

Standard VCI (Vapor Corrosion Inhibitor) film provides essential corrosion protection for metal parts during storage and transit. This type of film is ideal for applications where basic rust and oxidation prevention are required. It effectively protects metals such as steel, iron, and non-ferrous metals from environmental factors like moisture, salt, and other contaminants that can lead to corrosion. Standard VCI film is typically used for smaller, less sensitive parts that do not require high-strength or long-term protection. It’s a cost-effective solution for many exporters who need reliable protection for metal items such as fasteners, machine parts, and small components. By working with a VCI antirust stretch film exporter, you can ensure that these standard films meet the necessary quality standards and provide adequate protection for your products.

For larger, heavier, or more exposed metal parts, high-strength and UV-stabilized VCI stretch films offer an extra layer of durability and protection. These films are designed for tough environments, such as outdoor storage or long-term shipments that require extended exposure to sunlight. The UV stabilization prevents the film from degrading under sunlight, ensuring it retains its protective properties even in harsh outdoor conditions. These high-strength films are ideal for larger items like automotive parts, engines, or industrial machinery that need to be protected from both physical damage and corrosion. A VCI antirust stretch film exporter can provide these high-performance films in various sizes and thicknesses, ensuring that your larger metal products are safely wrapped and protected from both the elements and rust-causing contaminants during shipment.

One of the key advantages of working with a VCI antirust stretch film exporter is the ability to choose from a wide range of custom sizes and thicknesses tailored to your specific needs. Whether you require small, precision wraps for intricate components or large, heavy-duty films for oversized machinery, the trusted VCI antirust stretch film suppliers of export can supply stretch films in the dimensions and strength that best suit your products. Customization is particularly beneficial for automated packaging lines, where specific film sizes are needed to fit the equipment or product sizes. Additionally, various thicknesses are available depending on the level of protection required. For example, thinner films may suffice for lighter parts, while thicker films provide extra strength for larger or more vulnerable items. Custom options from VCI antirust stretch film suppliers ensure that the film conforms properly to the shape of the product, providing maximum surface protection and preventing exposure to harmful environmental factors.

When it comes to safeguarding valuable metal parts during shipment and storage, using VCI stretch film offers numerous benefits. By working with a VCI antirust stretch film exporter, businesses can take advantage of corrosion prevention technologies that provide long-lasting protection while supporting efficiency and cost-effectiveness in their operations. Below are some of the key benefits of using VCI stretch film for exporters:

One of the most significant advantages of using VCI stretch film is the extension of the product’s lifespan. By preventing corrosion, rust, and oxidation during transit and storage, VCI films ensure that metal parts maintain their structural integrity and appearance, reducing the need for costly repairs or replacements. Exporters who utilize VCI antirust stretch film not only protect their goods but also avoid the expense of returning damaged items, which can be costly both in terms of time and resources. While considering the anti-rust VCI stretch film price, it’s important to factor in the long-term savings from preventing damage and extending product life. Whether it’s automotive components, machinery parts, or precision metal goods, the use of VCI stretch film ensures that products remain rust-free and ready for use upon arrival. This increased lifespan can translate into lower overall costs, fewer warranty claims, and reduced customer dissatisfaction, making it a sound investment for businesses that rely on shipping metal items.

VCI stretch film is designed for simple and secure application, making it an ideal solution for exporters looking for both effectiveness and efficiency in their packaging processes. The VCI antirust stretch film exporter provides films that are easy to handle and apply, whether manually or using automated wrapping equipment. The stretchable nature of the film allows it to conform tightly around metal products, providing a secure, protective layer that prevents exposure to moisture and air. This ease of use also extends to the fact that the film is quick to apply, ensuring that businesses can wrap items quickly without compromising on the quality of protection. Furthermore, VCI films are lightweight, which helps reduce shipping costs while still providing superior protection from corrosion. This efficiency and simplicity make VCI stretch film an ideal choice for businesses that need reliable packaging without added complexity.

In today’s environmentally conscious market, sustainability is an essential factor for many exporters. Fortunately, VCI antirust stretch film aligns with sustainability goals by offering eco-friendly options. Many VCI films are made from recyclable materials, reducing their environmental impact and helping companies meet their green initiatives. By choosing an environmentally friendly VCI stretch film from a trusted exporter, businesses not only protect their metal goods from corrosion but also contribute to reducing plastic waste in the supply chain. Additionally, the long-lasting protection provided by these films reduces the need for additional packaging materials, further minimizing environmental footprints. By partnering with a VCI antirust stretch film exporter that prioritizes eco-friendly practices, businesses can ensure their packaging solutions align with both operational efficiency and environmental responsibility.

VCI (Vapor Corrosion Inhibitor) film is a type of packaging material that helps protect metal products from corrosion during storage and shipment. It contains chemicals that release corrosion-inhibiting vapors, which form a protective layer on the surface of metal items, preventing rust, oxidation, and other forms of deterioration. The film is commonly used to wrap metal components like automotive parts, machinery, and electronics, especially when they are exposed to environmental factors such as moisture, salt, or air, which can trigger corrosion. The vapor-phase inhibitors in VCI film target both ferrous and non-ferrous metals, offering broad protection for various industries. It is a highly effective and cost-efficient solution for businesses that need to protect valuable metal goods during transportation or long-term storage. Available in various thicknesses, sizes, and formats, VCI films are easy to apply and ideal for both manual and automated packaging systems. Its transparency allows for easy identification of the wrapped products without unwrapping them, adding convenience in handling and inspection.

VCI paper is produced by impregnating a base paper with specialized corrosion-inhibiting chemicals. The process begins with selecting high-quality paper that is porous enough to allow for the diffusion of the vapor-phase inhibitors. The paper is then treated with a liquid solution containing VCI compounds, which may include substances like amines or thiols. These chemicals are designed to evaporate slowly and provide a protective coating on metal surfaces. The paper may be treated through various methods, such as soaking, spraying, or dipping, depending on the desired application and the manufacturer’s capabilities. Once impregnated, the VCI paper is dried and rolled into sheets or converted into other forms like bags or wraps. This makes it easy to use for a wide range of packaging needs. The paper’s protective qualities are maintained over a period of time, offering an effective and eco-friendly corrosion solution. Many VCI papers are also recyclable, providing a sustainable option for companies looking to minimize their environmental impact while ensuring the safety of their metal goods during storage and shipping.

In packaging, VCI stands for Vapor Corrosion Inhibitor, a term that refers to materials designed to protect metal items from corrosion during storage or transit. VCI packaging materials—such as films, papers, bags, and wraps—are treated with corrosion-inhibiting chemicals that release vapors which create a protective barrier on the surface of metals. These materials are commonly used in industries that deal with sensitive metal products, such as automotive, electronics, manufacturing, and aerospace. The vapor released by VCI materials surrounds the metal objects, forming a thin, invisible layer that prevents rust, oxidation, tarnish, and other forms of corrosion. VCI packaging is particularly useful in scenarios where metals are exposed to environmental factors like humidity, salt, or pollution, which accelerate the corrosion process. VCI packaging is highly valued because it is easy to apply, does not require additional coatings or treatments, and is effective in protecting metals over long periods, even in challenging shipping or storage conditions. It’s a reliable solution for exporters and manufacturers seeking efficient ways to ensure the integrity of their metal goods.

VCI coating refers to a protective layer applied to metal surfaces to prevent corrosion. Unlike VCI packaging materials such as films or papers, VCI coatings are typically sprayed or brushed directly onto the metal parts before they are stored or shipped. These coatings contain corrosion inhibitors that work by releasing vapor-phase inhibitors into the surrounding environment, providing a protective layer that shields the metal from moisture, salt, and other corrosive agents. The VCI coating is ideal for metal components that will be exposed to harsh conditions or long-term storage, offering robust protection without the need for wrapping or additional packaging. Once applied, VCI coatings remain effective for varying periods depending on the type of inhibitor used and the storage conditions. These coatings can be used on both ferrous and non-ferrous metals, making them versatile for different applications, such as automotive parts, industrial machinery, and electronic components. VCI coatings are often used in combination with other packaging materials to enhance overall corrosion protection and provide a complete solution for preserving metal products during shipping and storage.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed