VCI technology plays a crucial role in preventing corrosion, particularly for metal parts exposed to harsh environments. A reliable vci antirust stretch film manufacturer provides essential solutions that safeguard these components from moisture and other corrosive elements. By producing high-quality stretch films infused with vapor corrosion inhibitors, manufacturers ensure long-lasting protection during storage and transportation. Additionally, these manufacturers conduct rigorous testing and quality control to meet industry standards, ensuring their products effectively deliver the desired results. This commitment not only enhances the performance of the VCI solutions but also builds trust with clients who rely on these materials to protect their valuable assets from rust and deterioration.

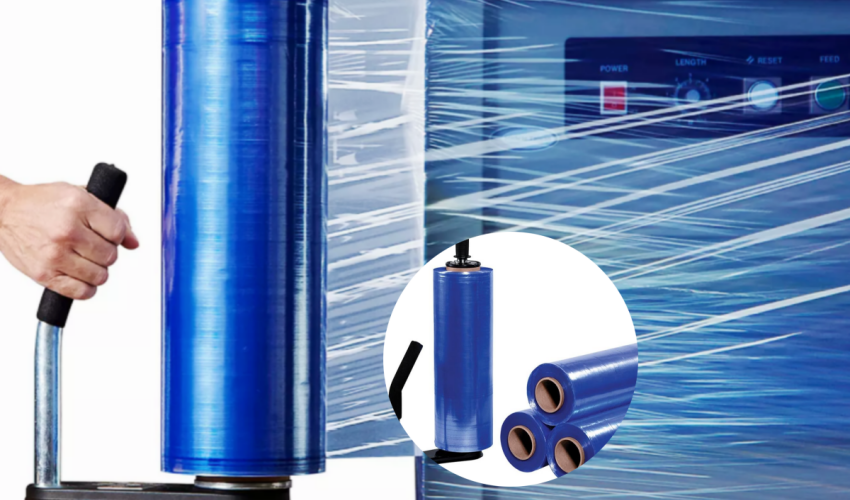

Choosing a vci antirust stretch film manufacturer can significantly enhance the protection of metal components against corrosion. The unique properties of VCI stretch film provide several advantages that make it an ideal choice for various industries.

VCI stretch film is specifically designed to prevent rust and corrosion on metal surfaces. Here are some key benefits:

Corrosion Inhibition: The VCI technology releases vapor that forms a protective layer around metal surfaces, effectively preventing rust formation.

Enhanced Durability: VCI stretch film is often made from high-quality polyethylene, offering excellent puncture and tear resistance during handling and transportation.

Visibility and Identification: The film is typically transparent or lightly tinted, allowing users to easily identify packaged items without unwrapping them.

Adaptability: VCI stretch film can conform to various shapes and sizes of metal parts, providing comprehensive coverage and protection.

Investing in products from a reliable vci antirust stretch film manufacturer also brings cost and efficiency benefits, making it a smart choice for businesses. Consider the following advantages:

Reduced Shipping Costs: Lightweight VCI stretch film helps decrease shipping weights, leading to lower transportation costs.

Longer Shelf Life: Properly packed metal components can be stored for extended periods without risk of corrosion, minimizing inventory losses.

Streamlined Packaging Processes: The stretch film can be easily applied by hand or with machinery, speeding up the packaging process and increasing productivity.

Environmental Benefits: Many manufacturers are adopting sustainable practices, offering recyclable or biodegradable options for VCI stretch film, which can enhance a company’s environmental profile.

Selecting a vci antirust stretch film manufacturer provides numerous benefits that are essential for effective metal protection. The advanced technology and materials used in VCI stretch film ensure that metal components remain rust-free during storage and transportation. By choosing the right manufacturer, businesses can enjoy cost savings, increased efficiency, and peace of mind knowing their assets are well-protected against corrosion.

When selecting a vci antirust stretch film manufacturer, it’s essential to understand the key features of their products. These characteristics are designed to maximize corrosion protection and ensure the safe storage and transportation of metal components.

VCI stretch film is engineered with specific attributes that set it apart from conventional packaging materials. Here are some critical features:

High Puncture and Tear Resistance: The film’s robust construction ensures it withstands the rigors of handling and transportation, protecting the underlying metal from physical damage.

Stretchability: This film can stretch significantly without losing its strength, allowing for tight wrapping that conforms to the shape of the object, ensuring complete coverage.

Cling Properties: The adhesive quality of the film allows it to stick to itself without the need for additional tapes or adhesives, making it easy to use and reducing packaging time.

Transparency: The clarity of the film allows for easy identification of the packaged items, facilitating inventory management and reducing the need for unwrapping.

UV Resistance: Many manufacturers incorporate UV stabilizers into the film, providing added protection for items stored outdoors or in direct sunlight, which can lead to degradation over time.

Custom Sizes and Thicknesses: VCI stretch film is available in various thicknesses and widths, allowing customers to select the ideal product for their specific needs.

The unique characteristics of VCI stretch film directly contribute to its effectiveness in preventing corrosion. Here’s how:

Corrosion Inhibition: The VCI technology embedded within the film releases vapor that permeates the packaging, forming a protective barrier around metal surfaces. This vapor actively neutralizes corrosive elements, ensuring that even hard-to-reach areas are protected.

Sealing Against Moisture: The tight wrapping capabilities of the film prevent moisture intrusion, a primary catalyst for corrosion. By minimizing exposure to humidity and environmental factors, the risk of rust formation is significantly reduced.

Extended Shelf Life: The protective qualities of VCI stretch film allow metal components to be stored for longer periods without degradation. This is particularly beneficial for manufacturers and suppliers who need to keep their products in optimal condition.

Versatility in Application: The film can be used in various industries, including automotive, aerospace, and manufacturing, due to its adaptability to different shapes and sizes of products, ensuring widespread corrosion protection.

Cost Efficiency: By reducing the risk of corrosion, businesses can avoid costly repairs and replacements, leading to substantial savings over time. The longevity of the protection offered by the film also minimizes the need for frequent repackaging.

The features of products from a anti-rust vci stretch film manufacturers play a pivotal role in providing effective corrosion protection. Understanding these characteristics helps businesses make informed decisions when selecting packaging solutions for their metal components. By investing in high-quality VCI stretch film, companies can safeguard their assets, enhance operational efficiency, and ultimately ensure the longevity of their products.

The use of VCI antirust stretch film has become increasingly popular across various industries, thanks to its effective corrosion protection properties. Understanding the applications of products from a vci antirust stretch film manufacturer can help businesses make informed choices about their packaging needs.

Several industries have embraced VCI stretch film as a crucial component of their packaging solutions. Here are some of the key sectors:

Automotive Industry: Protecting metal components during manufacturing and storage to prevent rust and ensure longevity.

Aerospace Sector: Safeguarding critical metal parts from corrosion during transit and while in storage.

Manufacturing: Used in the packaging of machined parts, tools, and assemblies to maintain quality and performance.

Electronics Industry: Protecting sensitive metal components from corrosion and electrostatic discharge during shipping and storage.

Marine Industry: Providing corrosion protection for components exposed to saltwater environments, reducing maintenance costs.

The versatility of VCI stretch film allows for its use in various specific applications across different sectors:

Automotive Components: In the automotive industry, manufacturers wrap engines, transmission parts, and other metallic components in VCI stretch film to prevent rust during storage or transportation to assembly lines. This is crucial for maintaining quality in a competitive market.

Aerospace Parts: Aerospace manufacturers utilize VCI stretch film to protect turbine blades, landing gear components, and other sensitive metal parts. These components are often exposed to harsh conditions, and VCI film ensures that they remain rust-free until installation.

Machinery Parts in Manufacturing: In manufacturing facilities, VCI stretch film is used to wrap tools, gears, and machined components. This protects them from moisture and oxidation, reducing the risk of product failure during production.

Electronics Packaging: The electronics sector often deals with delicate metal components that can be easily damaged by corrosion. VCI stretch film provides a protective barrier that prevents rust while also shielding against electrostatic discharge, ensuring the integrity of electronic parts.

Marine Equipment: Marine applications frequently involve exposure to corrosive elements like saltwater. VCI stretch film is ideal for wrapping metal boat parts, engines, and equipment, significantly extending their lifespan and reducing maintenance efforts.

Storage Facilities: Warehouses and storage facilities utilize VCI stretch film to wrap pallets of metal goods, ensuring long-term protection during storage. This is especially important for businesses that stock large inventories of metal parts.

The applications of VCI antirust stretch film from a vci antirust stretch film manufacturer are diverse and impactful across numerous industries. By effectively preventing corrosion, this specialized packaging solution helps businesses protect their valuable metal assets, ultimately leading to cost savings and enhanced product longevity. Companies that leverage VCI stretch film can confidently store and transport their products, knowing they are shielded from the damaging effects of rust and corrosion.

When selecting a vci antirust stretch film manufacturer, understanding the quality standards they adhere to is essential. High-quality products not only ensure effective corrosion protection but also reflect a manufacturer’s commitment to excellence.

Adhering to established industry standards and certifications is crucial for any reputable anti-rust vci stretch film manufacturer. Here are some key reasons why:

Product Safety: Compliance with safety standards ensures that the materials used in VCI stretch film do not pose any risks to users or the environment.

Consistent Quality: Following industry guidelines helps maintain uniformity in production, resulting in reliable products that meet customer expectations.

Market Trust: Certifications from recognized organizations enhance the credibility of the manufacturer, making it easier for clients to trust their products.

Regulatory Compliance: Meeting local and international regulations protects manufacturers from legal liabilities and helps them avoid costly fines.

Customer Satisfaction: By adhering to high-quality standards, manufacturers can provide products that consistently meet or exceed customer requirements, leading to long-term relationships.

Quality assurance processes are integral to the manufacturing of VCI stretch film. These processes directly influence the effectiveness and reliability of the product. Consider the following factors:

Rigorous Testing: Manufacturers often conduct extensive testing on their VCI stretch films to ensure they perform under various conditions. This includes assessing puncture resistance, moisture barrier properties, and corrosion inhibition effectiveness.

Raw Material Selection: High-quality materials are crucial for producing effective VCI stretch film. A reputable manufacturer carefully selects materials that provide superior strength, durability, and corrosion resistance.

Production Techniques: Advanced manufacturing techniques play a significant role in ensuring the final product meets quality standards. Continuous monitoring during production helps identify and rectify issues early, reducing defects and waste.

Feedback and Improvement: A commitment to quality assurance involves gathering feedback from customers and using it to improve product formulations and manufacturing processes. This iterative approach ensures that products remain competitive and effective in the market.

Documentation and Traceability: Quality standards often require comprehensive documentation of manufacturing processes and materials used. This traceability allows manufacturers to quickly address any issues that may arise and ensures accountability.

The quality standards upheld by a vci antirust stretch film manufacturer are vital for delivering effective and reliable corrosion protection solutions. Adherence to industry standards and rigorous quality assurance processes not only enhances product performance but also builds trust with clients. Companies that prioritize quality can ensure that their VCI stretch film effectively protects metal assets, thereby contributing to the overall success of their operations.

As the demand for effective corrosion protection solutions continues to grow, the role of a vci antirust stretch film manufacturer is evolving. Innovations in VCI technology are paving the way for new applications and enhanced product performance.

Several key trends are shaping the future of VCI technology, enhancing its effectiveness and usability:

Biodegradable Materials: There is a growing focus on sustainability, leading manufacturers to explore biodegradable options for VCI stretch films. This shift not only addresses environmental concerns but also meets consumer demand for eco-friendly products.

Smart Packaging Solutions: Integration of smart technology, such as sensors that monitor humidity and temperature, is becoming more prevalent. These innovations allow for real-time tracking of packaging conditions, providing valuable data for users.

Advanced VCI Formulations: Ongoing research into new VCI compounds is resulting in more effective corrosion inhibitors. These advancements aim to enhance the protective capabilities of the films, ensuring even greater longevity for the packaged items.

Customization Options: Manufacturers are increasingly offering customized solutions tailored to specific industries and applications. This flexibility allows clients to select products that best meet their unique requirements.

Enhanced User Experience: Innovations in film application and usability, such as easier unwinding and smoother application processes, are being prioritized to improve the overall user experience.

In response to these emerging trends, vci antirust stretch film manufacturers are adapting their strategies to stay competitive:

Investing in Research and Development: Manufacturers are allocating resources to R&D to explore new materials and technologies, ensuring they remain at the forefront of VCI innovations.

Collaborating with Industry Experts: Partnerships with experts in materials science and packaging technology enable manufacturers to develop cutting-edge solutions that address specific industry challenges.

Incorporating Customer Feedback: By actively seeking and incorporating feedback from end-users, manufacturers can refine their products and services, ensuring they meet the evolving needs of their customers.

Expanding Product Lines: Manufacturers are diversifying their product offerings to include a wider range of VCI solutions, catering to various sectors such as automotive, aerospace, and electronics.

Emphasizing Sustainability: Many manufacturers are making sustainability a core aspect of their business strategy, focusing on reducing waste and utilizing eco-friendly materials in their products.

The future of a vci antirust stretch film manufacturer is bright, driven by continuous innovation and adaptation to market demands. By embracing emerging trends and enhancing their product offerings, these manufacturers are poised to deliver even more effective solutions for corrosion protection. As the industry evolves, companies that prioritize research, sustainability, and customer-centric approaches will thrive in this competitive landscape.

VCI (Vapor Corrosion Inhibitor) antirust stretch film is a specialized packaging material designed to protect metal items from corrosion during storage and transportation. This film emits vapor molecules that create a protective layer around the metal surfaces, preventing rust and oxidation. When the film is applied, it adheres tightly to the wrapped items, ensuring that the VCI vapors can effectively surround and protect the surfaces from moisture and contaminants. The unique composition of the film allows it to be strong and stretchable, making it suitable for wrapping large or irregularly shaped metal parts. This protective measure can extend the lifespan of the items being stored or transported, ultimately reducing maintenance costs and improving overall product quality.

Choosing a reputable VCI antirust stretch film manufacturer is crucial for ensuring the quality and effectiveness of the packaging solutions you use. A reliable manufacturer adheres to strict industry standards and certifications, which guarantees that their products are safe and effective. Quality assurance processes, such as rigorous testing and raw material selection, are key indicators of a manufacturer’s commitment to excellence. Moreover, established manufacturers often offer a range of innovative products tailored to various applications, providing you with customized solutions that meet your specific needs. By partnering with a trusted manufacturer, you can enhance your packaging efficiency, protect your metal assets from corrosion, and ultimately save costs associated with rust-related damage.

VCI stretch film significantly enhances storage and transportation efficiency by providing reliable corrosion protection for metal components. When properly applied, the film not only shields items from moisture and environmental contaminants but also allows for space-saving stacking in warehouses or shipping containers. Its stretchable nature enables it to conform tightly to wrapped items, minimizing the risk of damage during transit. Additionally, the lightweight nature of VCI stretch film helps reduce shipping costs compared to heavier alternatives. By ensuring that metal components remain rust-free, businesses can reduce the frequency of inspections and maintenance during storage, leading to streamlined operations and improved inventory management.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed