How to Choose the Right VCI Stretch Film Exporter

VCI (Vapor Corrosion Inhibitor) stretch film is a specially designed packaging material that protects metal products from rust and corrosion during storage and transportation. The

Home >> VCI Stretch Film

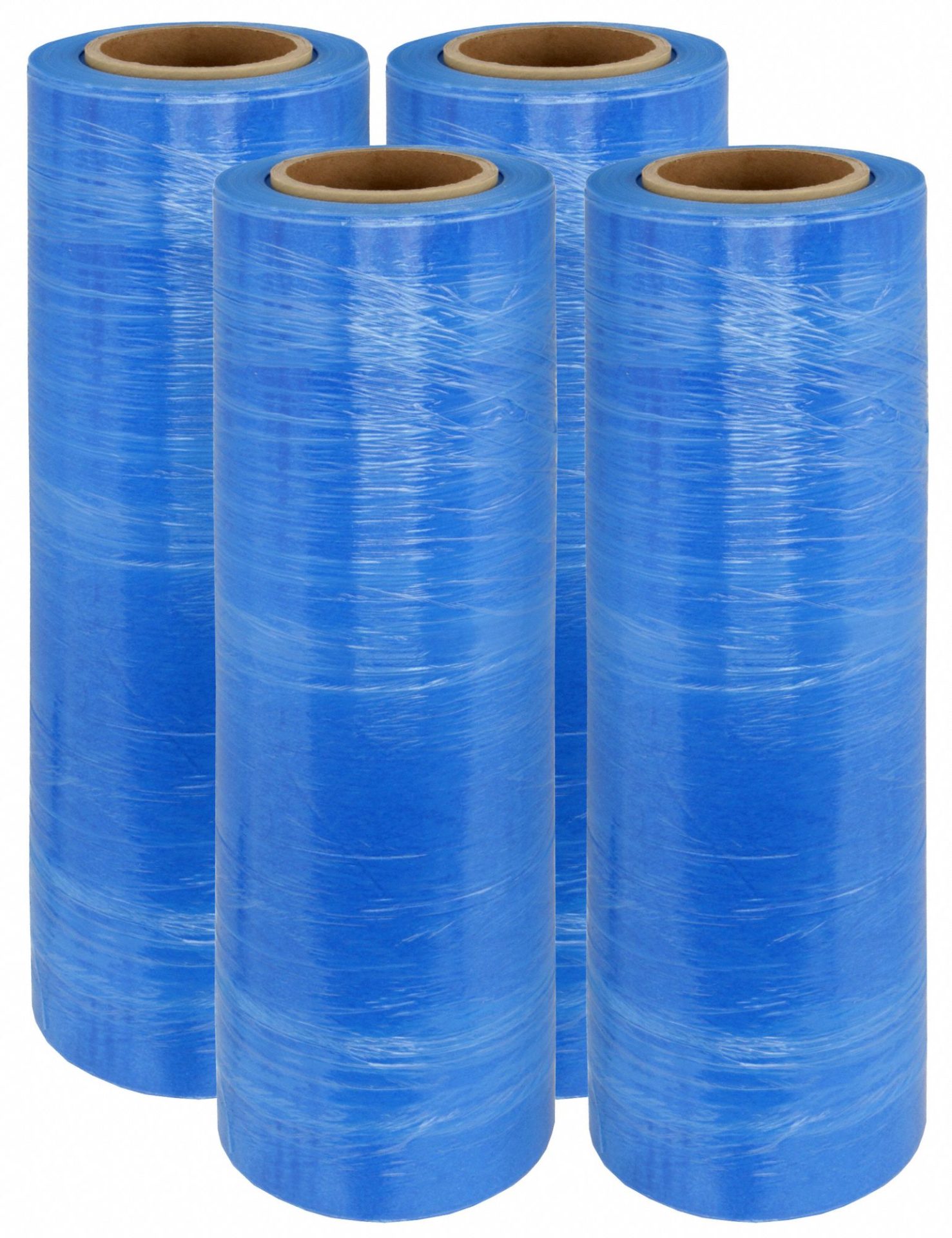

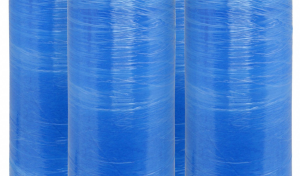

VCI Stretch Film, or Volatile Corrosion Inhibitor stretch film, is an advanced packaging solution designed to protect metal products from corrosion, rust, and oxidation during storage and transit. This specialized film releases vapor corrosion inhibitors (VCI) that create a protective layer, just 2-3 molecules thick, on metal surfaces, preventing damage caused by moisture, dust, and environmental factors. With its transparent blue film, VCI stretch film allows for easy product identification while offering the strength and handling ease of polyethylene combined with the corrosion protection of VCI technology.

In addition to stretch film, VCI sheeting and shrink wrap are also effective solutions for safeguarding metal components. Ideal for wrapping large mechanical parts or engines, VCI stretch film ensures reliable protection in various industries, including automotive and manufacturing. VCI sheeting provides additional coverage for larger products, while VCI shrink wrap offers a tight fit that further seals out moisture and contaminants, ensuring maximum corrosion protection.

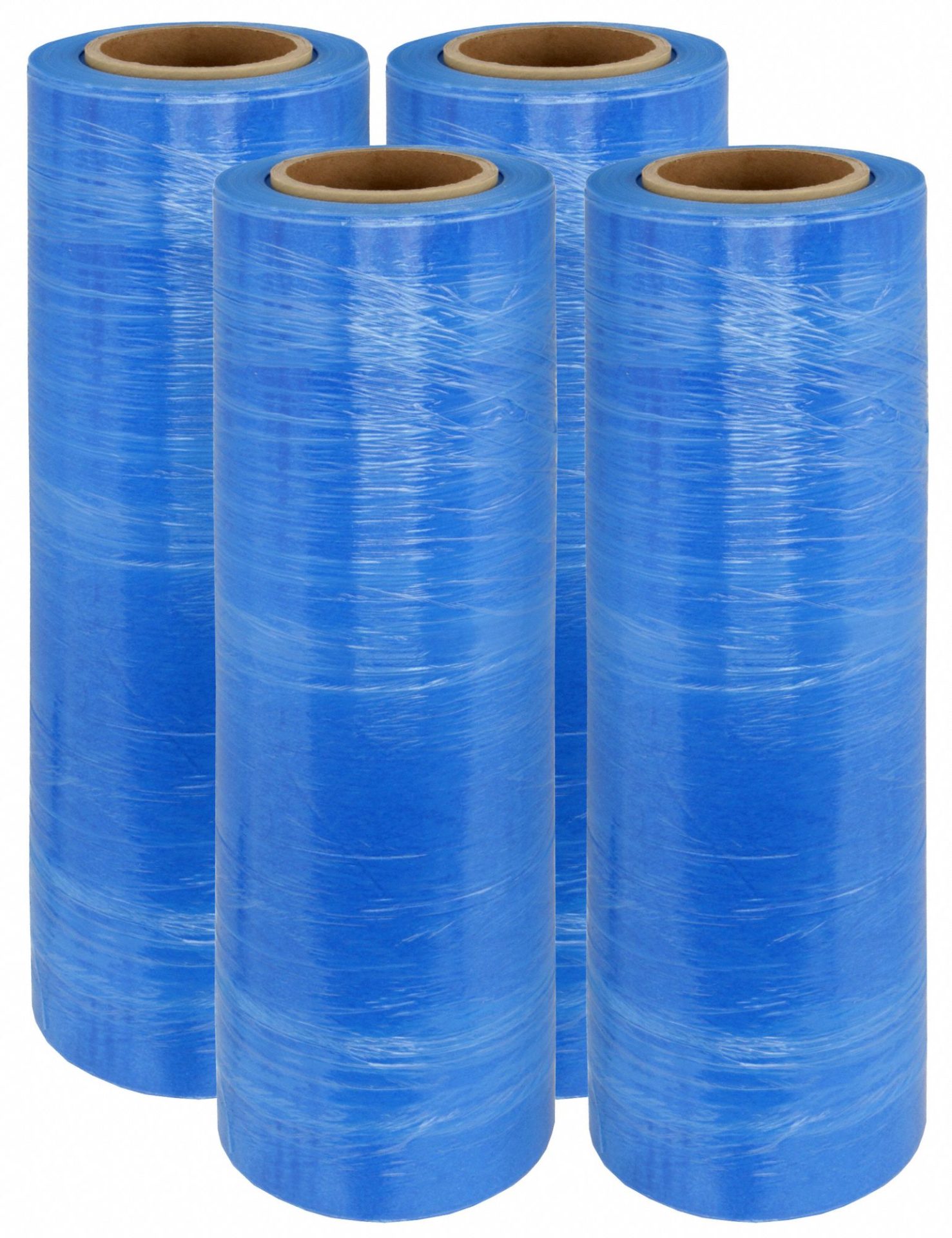

Our VCI stretch film is mil-prf-3420h compliant stretch wrap, ensuring that it meets stringent standards for durability and performance. It is also ASTM G85 salt spray test film certified, confirming its ability to withstand harsh environmental conditions and protect against corrosion even in challenging settings. This makes VCI stretch film the go-to choice for businesses looking to protect metal parts during long-term storage and overseas shipping.

For those seeking environmentally friendly options, we offer biodegradable VCI film options, which maintain the same level of protection while being eco-conscious. Furthermore, our VCI stretch film is RoHS compliant corrosion film, ensuring it meets the highest safety and environmental standards.

VCI stretch film is an essential packaging solution for maintaining the optimal condition of metal items and reducing the need for additional corrosion-resistant treatments. By utilizing VCI stretch film, sheeting, and shrink wrap, businesses can significantly improve the durability and longevity of their metal products during storage and transportation, all while benefiting from superior clarity, adhesion, flexibility, and corrosion protection.

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Material | Linear Low Density Polyethylene |

| Type | VCI Stretch Film |

| Features | Moisture-proof, High Stretchability |

| Hardness | Soft |

| Processing Type | Casting, Blow Molding |

| Transparency | Translucent, Opaque |

| Color | Customized |

| Thickness | Customized |

| Width | Customized |

| Size | Customized Size Accepted |

| Application | Packaging |

| Printing | Customized Printing |

| Surface | Smooth, High Gloss |

| Packaging Details | Available as per Customer's Requirements |

VCI Stretch Film is a specialized packaging material designed to safeguard metal products from corrosion. This type of stretch film is infused with Volatile Corrosion Inhibitor (VCI) technology, which offers superior protection compared to standard stretch films. VCI Stretch Film is typically made from polyethylene, a durable plastic that is combined with corrosion-inhibiting chemicals during VCI stretch film manufacturers manufacturing it. These chemicals, when released, form a protective barrier on metal surfaces, preventing rust and oxidation. The integration of VCI technology makes this film ideal for various stretch film applications in which metal parts need to be stored or transported without exposure to moisture and corrosive elements.

The protective mechanism of VCI Stretch Film is based on its ability to release corrosion-inhibiting vapors into the enclosed environment. When the film is applied around metal items, the VCI compounds evaporate and diffuse throughout the packaging. These vapors adhere to the metal surfaces, forming a molecular shield that inhibits the electrochemical reactions responsible for corrosion. This process not only protects the metal from environmental factors such as humidity and pollutants but also ensures that the metal remains in pristine condition upon unpacking. VCI Stretch Film provides a reliable, long-term solution for protecting metal components during storage and transit, reducing the need for additional rust prevention treatments.

Corrosion Protection:

Transparency:

Versatile Applications:

Long-lasting Protection:

Shelf Life:

Ease of Use:

VCI Stretch Film is highly effective for preventing rust on metal parts, especially those with irregular shapes or large dimensions. This specialized film, produced by an advanced VCI antirust stretch film factory, incorporates Volatile Corrosion Inhibitor (VCI) technology, which releases corrosion-inhibiting vapors that form a protective layer on metal surfaces. When wrapped with VCI Stretch Film, metal components are shielded from moisture and air, which are primary contributors to rust formation. This makes VCI Stretch Film an excellent choice for protecting machinery parts, automotive components, and industrial tools during storage and shipment. The film’s ability to conform to various shapes ensures comprehensive coverage and long-lasting protection against rust, even in challenging packaging scenarios.

VCI Stretch Film is versatile and can be used in a wide range of packaging scenarios. Its durability and protective properties make it ideal for packaging moving boxes, shipping boxes, and other items that require safeguarding from environmental factors. The film’s excellent stretchability allows it to securely wrap and bundle items, preventing shifting and damage during transit. Whether used for consolidating packages, wrapping bulky items, or protecting individual products, VCI Stretch Film provides a reliable barrier against corrosion and physical damage. Additionally, its clarity helps in easy identification of contents, which is particularly useful for inventory management and streamlining logistics. VCI Stretch Film enhances packaging efficiency and ensures that products remain in optimal condition throughout their journey.

For businesses requiring long-term storage solutions, eco-friendly vci stretch wrap suppliers – PWP Stretch Film offers excellent protection against corrosion. Our robust VCI Stretch Film prevents the intrusion of moisture and air, which can lead to rust and deterioration over time. Ideal for storing metal parts, tools, and equipment, our film ensures that items remain in optimal condition, even during prolonged periods of inactivity. The protective qualities of our film help reduce maintenance costs and extend the life of stored products, buy VCI stretch film is a valuable investment for clients looking to preserve their assets.

PWP Stretch Film excels in bundling and securing multiple items together, providing stability during transit. Our strong stretchability allows users to tightly wrap items, preventing them from shifting or getting damaged while in transit. This application is particularly useful for bundling tools, machine parts, and construction materials. The clarity of our film aids in easy identification of the bundled contents, enhancing efficiency in logistics and inventory management. By using our VCI Stretch Film for bundling, clients can streamline their operations and ensure that all items are delivered intact and in good condition.

At PWP Stretch Film, we pride ourselves on our ability to custom VCI stretch film to meet specific packaging needs, making it a flexible solution for various industries. Whether for wrapping irregularly shaped items or creating custom packaging configurations, our film’s adaptability ensures that products are well-protected. We encourage our clients to utilize PWP Stretch Film in conjunction with other packaging materials to create comprehensive protective solutions. This versatility is particularly valuable in sectors such as automotive, aerospace, and heavy machinery, where unique packaging requirements are common. By integrating our VCI Stretch Film into their packaging processes, businesses can enhance the overall protection of their products while maintaining a professional appearance.

When comparing VCI Stretch Film to traditional stretch film, the key difference lies in the added layer of protection offered by VCI technology. While traditional Bundling Stretch Film is primarily used for bundling and securing items, it does not provide any specific protection against corrosion. In contrast, VCI Stretch Film is engineered with Volatile Corrosion Inhibitor (VCI) technology, which releases corrosion-inhibiting vapors to form a protective barrier on metal surfaces. This makes VCI Stretch Film ideal for applications where rust prevention is critical. Additionally, VCI Stretch Film maintains all the benefits of traditional stretch film, such as high strength and stretchability, but with the added advantage of safeguarding metal items from environmental damage.

VCI Stretch Film and shrink wrap serve different purposes and offer distinct protective properties. VCI Stretch Film is designed to provide a flexible, protective layer that adheres to itself and conforms to various shapes, offering corrosion protection through its VCI technology. It is ideal for wrapping items where flexibility and protection against rust are required. On the other hand, shrink wrap is a plastic film that shrinks tightly over items when heat is applied, creating a snug, sealed package. While shrink wrap is effective for protecting items from moisture and dirt, it does not offer the same level of corrosion protection as VCI Stretch Film. VCI Stretch Film is particularly beneficial for metal parts and components that need protection from rust during storage and transit, whereas shrink wrap is more suited for general packaging needs where a tight seal is essential.

When comparing VCI Stretch Film to bubble wrap, the primary distinction lies in the type of protection each offers. Bubble wrap is designed to provide cushioning against impact, making it ideal for protecting fragile items during transit. However, it does not provide any corrosion protection. In contrast, VCI Stretch Film incorporates Volatile Corrosion Inhibitor (VCI) technology, which releases vapors that protect metal surfaces from rust and oxidation. While bubble wrap is excellent for shock absorption, VCI Stretch Film is essential for safeguarding metal parts and components against environmental damage during storage and shipping. This makes VCI Stretch Film a superior choice for businesses looking to prevent corrosion while still maintaining the protective qualities of traditional packaging.

VCI Stretch Film and plastic pallet covers serve different purposes, especially when it comes to protecting products from corrosion. Plastic pallet covers are typically used to shield entire pallets of goods from dust, moisture, and dirt. While they provide a barrier against environmental elements, they do not offer the specialized corrosion protection that VCI Stretch Film does. VCI Stretch Film, with its VCI technology, releases corrosion-inhibiting vapors that form a protective layer on metal surfaces. This makes it ideal for applications involving metal items, where rust prevention is critical. While both options provide a degree of protection, VCI Stretch Film is the clear choice for companies needing to safeguard metal components from oxidation during storage and transportation.

Heavy-duty packaging film is often used for wrapping large or bulky items, providing a strong and durable layer of protection. However, it typically does not incorporate any corrosion-inhibiting properties. In contrast, VCI Stretch Film is designed specifically to protect metal surfaces from rust and corrosion through its unique VCI technology. While heavy-duty film excels in providing physical protection against punctures and tears, it lacks the chemical protection that VCI Stretch Film offers. Therefore, for businesses looking to combine the strength of heavy-duty packaging with the anti-corrosion benefits of VCI technology, VCI Stretch Film presents a more comprehensive solution for protecting metal goods during storage and transit.

VCI shrink wrap and VCI stretch wrap from various VCI LDPE stretch film suppliers are both used to protect metal components from corrosion, but they differ in application, material, and protection. VCI shrink wrap, made from polyethylene or polyolefin, requires heat to form a tight seal and is ideal for long-term storage, providing superior protection against moisture and contaminants. It’s often used for individual items like machinery parts. VCI stretch wrap, made from LLDPE, is applied by stretching around pallets and is more cost-effective for large-scale operations. It provides corrosion protection during transportation and is typically used for palletized goods like automotive parts.

The environmental impact of using VCI Stretch Film is an important consideration, particularly as industries seek more sustainable packaging solutions. Traditional VCI Stretch Film can contribute to environmental concerns due to its polyethylene base. However, advancements in eco-friendly VCI film options are addressing the issues associated with traditional VCI film. VCI stretch wrap suppliers are developing VCI Stretch Film with biodegradable additives and recyclable materials, which reduce the film’s overall environmental footprint. These innovations aim to balance the need for effective corrosion protection with a commitment to reducing waste and minimizing harm to the environment. The development of such sustainable VCI Stretch Film options reflects a growing trend towards environmentally responsible packaging solutions.

VCI Stretch Film plays a significant role in reducing material waste compared to other packaging methods. Its high-strength and stretchability mean that less film is required to securely wrap items, resulting in less material usage overall. This efficiency not only decreases the amount of film used per package but also helps in minimizing the environmental impact associated with packaging waste. By using VCI Stretch Film, businesses can optimize their packaging processes, reduce the volume of waste generated, and contribute to more sustainable practices. The ability of VCI Stretch Film to provide effective protection with minimal material underscores its role in advancing eco-friendly packaging solutions.

Using VCI Stretch Film can contribute to energy efficiency in packaging operations. The film’s lightweight nature means that it requires less energy for transportation compared to heavier packaging materials. By reducing the weight of shipments, businesses can lower fuel consumption and greenhouse gas emissions during transit. Additionally, the efficient use of VCI Stretch Film minimizes the number of trips required for shipping, further enhancing energy savings. As industries focus on reducing their carbon footprint, adopting energy-efficient packaging solutions like VCI Stretch Film can play a crucial role in promoting environmentally responsible practices.

The push for sustainable packaging solutions has led to advancements in the recycling potential of VCI Stretch Film. While traditional polyethylene films can be challenging to recycle, the development of recyclable VCI Stretch Film options is gaining traction. These innovations allow businesses to not only protect their products effectively but also ensure that the packaging materials can be repurposed after use. By adopting VCI Stretch Film with enhanced recycling capabilities, companies can contribute to a circular economy, reducing reliance on new plastic production and minimizing overall environmental impact.

The adoption of VCI Stretch Film can significantly reduce the carbon footprint of packaging operations. By requiring less material to achieve the same level of protection, VCI Stretch Film helps decrease the emissions associated with manufacturing and disposing of excess packaging materials. Additionally, its lightweight design reduces shipping weights, which translates into lower transportation emissions. As organizations strive to meet sustainability goals, utilizing VCI Stretch Film can be an effective strategy for minimizing carbon footprints while maintaining high standards of product protection.

PWP Stretch Film is committed to developing eco-friendly innovations in VCI technology. Ongoing research and development efforts focus on creating sustainable alternatives that do not compromise on performance. This commitment reflects a broader industry trend towards responsible manufacturing practices. By investing in the creation of environmentally friendly VCI Stretch Film options, companies can ensure that they meet the demands of consumers seeking sustainable products without sacrificing the effectiveness of corrosion protection. This dedication to eco-friendly innovations positions PWP Stretch Film as a leader in the sustainable packaging landscape.

Metal Type: Ensure the film is compatible with the specific metals you are protecting (e.g., ferrous, non-ferrous, or multi-metal).

Storage Conditions: Choose UV-resistant or heavy-duty films for harsh environments.

Film Thickness: Select the appropriate thickness based on the weight and sharpness of the items being wrapped.

Roll Dimensions: Consider the width, length, and core size to match your wrapping equipment or manual application needs.

Certifications: Look for films that meet industry standards, such as MIL-STD-2073-1 for military applications.

Purchasing Options

Wholesale Buying: Ideal for businesses with high-volume needs, offering cheap VCI stretch wrap price and consistent supply.

Custom Orders: Suppliers can tailor the film’s dimensions, thickness, and VCI concentration to meet specific requirements.

Sample Testing: Many suppliers provide samples to test the film’s effectiveness before bulk purchasing.

PWP Stretch Film combines the strength and ease of use of polyethylene with the corrosion protection of chemical additives. It is durable, elastic, and stays securely in place, offering excellent clarity and cling. This makes it an ideal rust prevention product for oddly shaped or large metal parts during storage and transportation. Standard rolls are 1 mil thick, available in widths of 18 and 20 inches, and lengths of 1,500 and 4,500 feet.

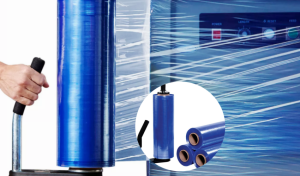

VCI Machine Stretch Film is more elastic than hand-applied film and provides superior corrosion protection. VCI (Vapor Corrosion Inhibitor) technology reduces vapor within wrapped pallets, ensuring maximum protection when fully enclosed, including a top wrap.

Applications: VCI material is perfect for overseas shipping of metal items, as it shields them from moisture and corrosion. For comprehensive protection during transit or storage, it is recommended to fully wrap the top of the cargo with VCI material.

| Parameter | Standard Grade | Premium Grade | Military Grade |

|---|---|---|---|

| VCI Release Rate | 0.25mg/cm²/day | 0.35mg/cm²/day | 0.45mg/cm²/day |

| Corrosion Protection Duration | 2-5 years | 5-10 years | 10+ years |

| ASTM D1748 Compliance | Basic | Enhanced | Full |

| VCI Stretch Film Thickness | 12-15 microns | 15-20 microns | 20-25 microns |

| VCI Stretch Film Vapor Corrosion Inhibitor Concentration | 2-3% | 3-4% | 4-5% |

| Industry | Use Case | Temperature Range | Film Thickness |

|---|---|---|---|

| Aerospace | Engine Component Storage | -40°C to 120°C | 30µm |

| Automotive | Transmission Shipment | -20°C to 80°C | 23µm |

| Electronics | Circuit Board Protection | -10°C to 60°C | 25µm |

| Military | Weapon Storage | -50°C to 90°C | 40µm |

| Oil & Gas | Equipment Shipping | -30°C to 70°C | 35µm |

| Marine | Boat Part Protection | -20°C to 70°C | 28µm |

| Manufacturing | Steel Coil Packaging | -10°C to 50°C | 32µm |

| Heavy Machinery | Machine Parts Protection | -15°C to 65°C | 38µm |

Based on your industry and application needs, you can select the ideal VCI Stretch Film that ensures optimal protection and performance. Our VCI Stretch Films are designed to safeguard against corrosion, dust, and moisture, providing reliable protection for your goods during storage and transportation.

If you have specific requirements, we also offer customization options to match your exact needs, including film thickness, temperature range, and packaging solutions tailored to your business. Contact us for more information or assistance in selecting the perfect VCI Stretch Film for your products!

VCI Stretch Film is a versatile packaging solution that provides corrosion protection and anti-static properties, making it ideal for various industrial applications. Below are some of the key applications of VCI Stretch Film:

| Application | Description |

|---|---|

| Marine Container Corrosion Proof Wrapping | VCI Stretch Film is widely used in marine shipping to protect metal goods from corrosion during long journeys in saltwater environments. Its anti-corrosive properties ensure that products remain in excellent condition upon arrival. |

| Saltwater Resistant Pallet Film | Ideal for packaging products that will be exposed to saltwater environments, VCI Stretch Film offers reliable protection for goods on pallets, preventing damage from moisture and rust. |

| Semiconductor Packaging Anti-Static Film | VCI Stretch Film offers anti-static protection, making it perfect for the safe packaging and storage of sensitive electronic components, such as semiconductors, preventing damage from static charges. |

| CNC Machine Parts Storage Wrap | Used to wrap CNC machine parts, VCI Stretch Film safeguards intricate metal components from corrosion and contamination while in storage or during transport. |

| Automotive Spare Parts Protection | VCI Stretch Film is commonly used to wrap automotive parts, providing protection against rust and moisture, ensuring that critical components remain pristine until needed. |

| Industrial Equipment Storage and Transport | Ideal for the storage and transportation of heavy-duty industrial equipment, VCI Stretch Film protects against environmental factors, preserving the quality of machinery and components. |

| Comparison Factor | PWP Stretch Film’s VCI Stretch Film | Other Brand’s VCI Stretch Film |

|---|---|---|

| VCI vs Desiccant Cost per Pallet | PWP Stretch Film’s VCI Stretch Film offers a more affordable solution compared to desiccants, reducing overall packaging costs. | Desiccants often come at a higher cost per pallet due to additional packaging and handling fees. |

| Stretch Film vs Oil Coating ROI | Our VCI Stretch Film provides a higher return on investment due to its multifunctionality as both a protective barrier and stretch film. | Oil coating may provide temporary protection but lacks the stretch capability, leading to additional expenses for packaging materials. |

| Zinc Coating vs VCI Film Longevity | PWP Stretch Film’s VCI Stretch Film offers superior longevity, ensuring long-lasting protection from rust and corrosion, which cuts down on maintenance and replacement costs. | Zinc coating may provide protection but can wear off over time, requiring more frequent reapplication or replacements. |

Lower Plastic VCI Stretch Film Quotes: Our VCI Stretch Film offers an excellent cost-performance ratio, helping you save on both packaging materials and corrosion protection.

Longer Protection: Enjoy extended protection from corrosion with superior longevity and no need for frequent replacements.

Better ROI: With PWP Stretch Film, you get both the benefits of stretch film and VCI protection in one product, maximizing your investment.

VCI (Volatile Corrosion Inhibitor) stretch film is specifically designed to protect metal components from corrosion while providing the strength and flexibility of conventional stretch film. The manufacturing process involves multiple critical stages to ensure that the film offers both excellent wrapping capabilities and reliable corrosion protection. Below is a detailed step-by-step explanation of the VCI stretch film production process.

The process begins with the selection and blending of high-quality polymer resins and specialized VCI additives. The primary resin used is usually linear low-density polyethylene (LLDPE), which provides flexibility, durability, and stretchability. Along with the base resin, various functional additives are incorporated, such as:

All these components are carefully measured and mixed in a high-speed mixer to achieve a homogeneous blend. The consistency of the mixture is crucial to ensure uniform corrosion protection in the final product.

Once the VCI resin mixture is prepared, it is transferred to an extruder, where the actual plastic film formation begins. The extrusion process involves:

The extrusion process can be performed using blown film extrusion (where the molten polymer is inflated like a balloon) or cast film extrusion (where the molten film is pressed onto chilled rollers for cooling).

To ensure uniform and effective corrosion protection, the VCI formulation must be properly distributed across the film surface. This step is carried out using advanced coating technology:

This stage is crucial, as an inconsistent application of the VCI formula could lead to ineffective corrosion protection.

Once the VCI-coated film is prepared, it undergoes stretching and cooling to enhance its mechanical strength. The film is passed through a series of rollers that stretch it longitudinally, improving the following properties:

During this step, the film is also cooled further to stabilize its molecular structure, making it highly flexible while maintaining strong VCI protection.

The final step in the manufacturing process involves converting the large rolls of VCI stretch film into smaller rolls of desired width and length. This is done through:

The manufacturing process of VCI stretch film involves multiple steps, from selecting raw materials to applying VCI coatings and finalizing the product for shipment. The precision in resin mixing, extrusion, and coating ensures that the film provides both excellent wrapping performance and reliable corrosion protection. By following strict quality control measures, manufacturers ensure that the VCI stretch film meets industrial standards and effectively protects metal components during storage and transportation.

The process of making VCI film involves several key steps. First, the base material, usually polyethylene or another polymer, is selected for its flexibility and strength. This base material is then blended with VCI additives, which are corrosion-inhibiting chemicals designed to protect metal surfaces. The film is produced using extrusion techniques, where the polymer blend is melted and formed into thin sheets or rolls. During the extrusion process, the VCI additives are uniformly distributed throughout the film to ensure consistent corrosion protection. Once the film is extruded, it is cooled and wound into rolls or cut into sheets, depending on its intended use. Quality control checks are performed to ensure that the VCI film meets the required specifications for thickness, strength, and corrosion protection.

VCI stretch film, or Vapor Corrosion Inhibitor stretch film, is a specialized packaging material designed to protect metal products from corrosion. This film is engineered with VCI technology, which releases vapors that form a protective layer on metal surfaces, preventing rust and oxidation during storage and transportation. The film often features a transparent blue color, allowing for easy product identification while providing robust protection. Unlike traditional stretch films that primarily serve as a bundling solution, VCI stretch film combines the benefits of stretchability with the added advantage of corrosion inhibition. This makes it an ideal choice for industries that handle metal components, such as automotive, manufacturing, and aerospace, ensuring the integrity and longevity of metal items.

VCI film is widely used in various applications where metal protection is critical. Its primary purpose is to safeguard metal components from rust and corrosion during storage and transit. By wrapping items in VCI film, companies can extend the lifespan of tools, machinery, and other metal products that are prone to oxidation. This film is particularly beneficial for large mechanical parts and engines, where exposure to moisture and air can lead to significant damage. Additionally, VCI film is useful for packaging finished goods, providing a protective barrier against environmental contaminants. Its versatility allows it to be employed in different sectors, ensuring that metal products remain in optimal condition throughout their journey. The incorporation of VCI technology in packaging solutions helps businesses reduce maintenance costs and enhance the durability of their metal assets.

While stretch film and cling film may appear similar and serve some overlapping purposes, they are not the same. Stretch film is a thicker, more robust material designed primarily for wrapping and securing items during shipping and storage. It is made from polyethylene and provides excellent stretchability and strength, allowing it to tightly wrap around various objects. Stretch film is commonly used in industrial applications, such as bundling products on pallets and providing protection against dust and moisture. In contrast, cling film, often referred to as plastic wrap, is thinner and more flexible. It is primarily used in household settings for food storage, as it clings to surfaces to keep food fresh. Cling film is not designed for heavy-duty applications and lacks the protective features of stretch film. Therefore, while both materials can provide some level of coverage, they are tailored for different uses and environments.

Stretch film is a versatile packaging material used in various applications to secure and protect items. Its primary use is in industrial settings, where it is commonly employed to wrap pallets of goods for shipping and storage. Stretch film provides a strong, tight seal that prevents products from shifting during transit, reducing the risk of damage. It is also used for bundling smaller items together, making it easier to handle and transport multiple products at once. Additionally, stretch film offers protection against dust, dirt, and moisture, ensuring that items remain clean and intact. Its clarity allows for easy identification of wrapped products, making it an excellent choice for inventory management. Beyond industrial uses, stretch film can be utilized in retail and household settings for wrapping and securing various items, from furniture to seasonal decorations. Overall, stretch film's adaptability and protective qualities make it an essential tool in many packaging processes.

Preventing rust during overseas shipping is crucial, especially for metal parts and machinery that are susceptible to corrosion. The long shipping times, exposure to moisture, and varying environmental conditions can increase the risk of rust formation. Fortunately, several methods can effectively safeguard metal products from rust during international transport. Use of VCI (Vapor Corrosion Inhibitor) Films: One of the most reliable methods to prevent rust during overseas shipping is by wrapping metal parts in VCI stretch film or VCI sheeting. VCI films release vapor corrosion inhibitors that create a protective molecular layer on the metal surface. This layer shields the metal from moisture, salts, and other environmental factors that can cause corrosion. This method is particularly effective for long-haul shipping because it offers ongoing protection during transit, even in humid or salty sea environments. Proper Packaging: In addition to VCI films, consider using airtight containers or sealed packaging to prevent direct contact with air and moisture. Using shrink wrap or heavy-duty plastic sheeting can help further ensure that moisture does not come in contact with the metal parts. When using shrink wrap, it's important to ensure a tight seal to prevent air and moisture from infiltrating the package. Desiccants and Moisture Absorbers: Placing desiccant packs or moisture-absorbing materials inside the packaging can help absorb any humidity that may cause rust. These are especially beneficial in high-humidity climates or when shipping through areas with unpredictable weather conditions. Protective Coatings: Another effective method is to apply a rust-preventative coating such as an anti-corrosion oil or grease to the metal parts before shipping. This creates a physical barrier between the metal surface and the elements, providing extra protection against moisture and corrosion. Regular Inspection and Maintenance: During the transport process, periodic checks on the cargo can help identify and address any potential issues before they worsen. This is especially important for longer shipments where the environment may change drastically. By combining these methods—VCI films, proper sealing, desiccants, and protective coatings—you can significantly reduce the risk of rust and corrosion on metal parts during overseas shipping, ensuring they arrive in optimal condition.

If your metal parts are rusting under stretch wrap, several factors could be at play. Stretch wrap alone typically provides limited protection from corrosion, and if not used properly or in the right environment, it may lead to rust formation. Below are the common reasons why rust can develop under stretch wrap: Moisture Entrapment: One of the primary reasons metal parts rust under stretch wrap is moisture buildup. While stretch wrap is great for holding items tightly, it does not offer a full barrier against moisture. If the metal parts were not dry when they were wrapped or if the packaging is exposed to humid conditions, moisture can become trapped under the film. Once sealed, this moisture has nowhere to escape, and it can cause the metal parts to oxidize, leading to rust formation. Lack of Vapor Corrosion Inhibitors (VCI): Regular stretch wrap does not contain any corrosion-resistant properties. If you use standard stretch film without VCI technology, the film does not release protective vapor molecules to safeguard the metal surfaces from moisture and oxygen. This leaves the metal unprotected and prone to rust. In such cases, it’s advisable to use VCI stretch film, which releases corrosion inhibitors that actively protect the metal surfaces from rusting. Environmental Factors: Shipping or storing metal parts in humid or saline environments, such as near the coast, significantly increases the risk of rusting. Stretch wrap does not prevent the exposure to air or moisture, especially when used in outdoor or unprotected storage settings. In these cases, using additional protective measures such as VCI films, desiccants, or rust-resistant coatings can prevent rust from forming. Improper Sealing: Stretch wrap is designed to secure items tightly, but if it is not sealed properly, there may be small gaps where air and moisture can enter. If the wrap is loosely applied or doesn’t cover the item completely, moisture can get inside the wrap and cause rust. Ensuring the stretch wrap is tightly sealed and covers the item fully is essential in preventing rust. Temperature Fluctuations: Changes in temperature, especially when transitioning between hot and cold environments, can lead to condensation inside the stretch wrap. When the temperature drops, moisture in the air can condense and accumulate on the metal surface, even under a tight wrap. This moisture can then cause rust over time. To address this, it’s important to store or ship metal parts in temperature-controlled environments or to use specialized films that can manage condensation and moisture buildup. To prevent rust under stretch wrap, ensure that the metal parts are thoroughly dry before wrapping, use films that include VCI technology for corrosion protection, and consider additional methods like desiccants, proper sealing, and rust-preventative coatings.

Don't wait - reach out today to ensure timely delivery and exceptional service.

VCI (Vapor Corrosion Inhibitor) stretch film is a specially designed packaging material that protects metal products from rust and corrosion during storage and transportation. The

In industries that work with metal components, corrosion protection is essential to maintain product integrity and longevity. Metal parts are vulnerable to rust and degradation,

VCI Stretch Film incorporates Vapor Corrosion Inhibitor (VCI) technology, which releases corrosion-fighting molecules that bond with metal surfaces to prevent oxidation. This specialized film provides

Corrosion is one of the most common and costly issues faced by exporters, especially when shipping metal parts overseas. Factors such as moisture, salt, and

VCI (Vapor Corrosion Inhibitor) stretch films are specially designed to protect metal parts from rust and corrosion during storage and transportation. These films are infused

VCI stretch film is an innovative protective material widely used in industries to prevent corrosion on metal parts during storage and shipment. Designed with Vapor