Guide for Purchase Wrapping Film, Stretch Wrap & Pallet Wrap

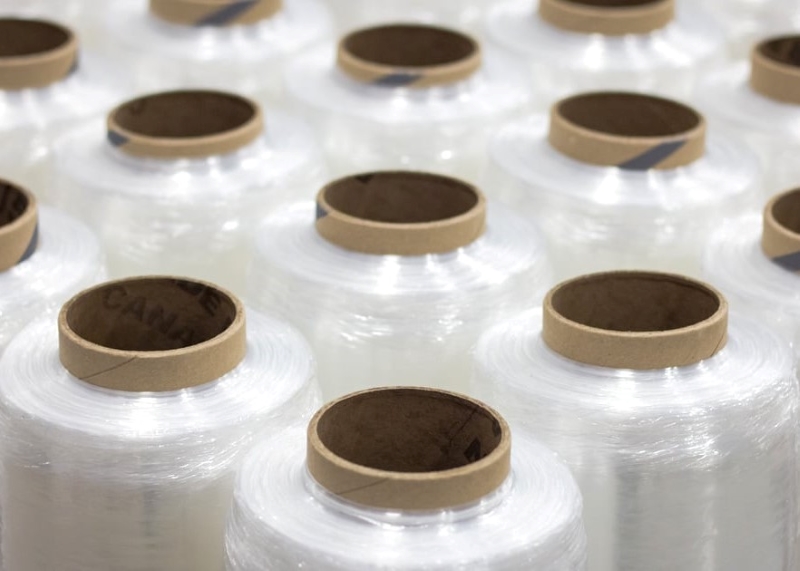

Wrapping film plays a crucial role across various industries due to its versatility and functionality. This highly stretchable material ensures goods are secured during transportation and storage, protecting them from dust, moisture, and tampering. Whether in industrial supply chains, commercial packaging, or household use, wrapping film offers a reliable solution for bundling and stabilizing items. Stretch film is particularly favored for securing pallet loads, while smaller applications, such as packaging individual items, benefit from plastic wrap roll for packing. Its flexibility makes it suitable for different operations, from large-scale warehouses to moving furniture or protecting goods at home. With a wide range of uses, wrapping film remains essential for efficient handling and safe product delivery. Wrapping film is a stretchable plastic used to secure products, bundle items, and wrap furniture, ensuring tamper resistance, stability, and safe handling.

Why Choose Our Stretch Film Over Competitors?

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Product Name | Wrapping Film |

| Material | Polyethylene |

| Features | Moisture-proof, Waterproof, High Temperature Resistant, Good Compliance, Easy to Peel |

| Hardness | Soft |

| Processing Type | Multiple Extrusion, Casting |

| Transparency | Transparent, Opaque |

| Color | Customized |

| Thickness | Customized |

| Length | Customized |

| Width | Customized |

| Size | Customized |

| Weight | Customized |

| Surface | Smooth, Plain, High Gloss, Glossy |

| OEM | Avaliable |

| Printing Process | Digital Printing, Combination Printing |

| Logo Printing | Accept Customized Logo |

| Certificate | ISO |

| Packaging | Standard Carton Packaging |

| Sales Unit | Single Item |

Wrapping film is a highly stretchable plastic film designed for securing goods during storage, handling, and transportation. It serves as an essential packaging material, helping keep items stable and protected from dust, moisture, and potential damage. When applied, wrapping film creates a tight, secure seal by stretching around objects, ensuring that they remain intact during transit. This process makes it especially valuable in various industries that require both short-term and long-term storage solutions.

Stretch film wrap, a type of wrapping film, is known for its elasticity and ability to hold items securely in place. It is most commonly used for stabilizing pallet loads, preventing products from shifting during transportation. In contrast to cling film, which sticks to surfaces without stretching, stretch film wrap elongates during application, creating a firm hold.

Wrapping film is not limited to industrial use; it also plays a crucial role in commercial and household settings. For example, plastic wrapping for furniture is a popular use when moving or storing large items. The film protects furniture from scratches, dust, and moisture while ensuring it stays in place during transport.

Stabilizing Pallet Loads:

One of the most common uses of wrapping film is in stabilizing palletized loads in warehouses, distribution centers, and during transport. Stretch film is often used to secure products on pallets, preventing them from shifting or falling over during handling or transportation. By tightly wrapping the entire pallet, wrapping film helps maintain the integrity of the load, ensuring that items remain organized and undamaged. The film’s high elasticity and stretchability allow it to hold large, bulky products firmly in place, even when exposed to movement or external forces. This makes it an essential tool for industries that handle bulk goods, such as manufacturing, retail, and logistics.

Wrapping Large Items:

When transporting or storing large items, especially furniture or household appliances, wrapping film is an excellent protective solution. Wrapping furniture, electronics, and other delicate items with stretch film helps safeguard them from dust, dirt, moisture, and minor physical damage. The film acts as a protective barrier, preserving the condition of valuable goods while making them easier to move or handle. For furniture, stretch wrap prevents scratches or scuff marks during transit, ensuring that items arrive in the same condition they were packed. Wrapping film is also a great choice for wrapping large or awkwardly shaped objects, providing a versatile and effective way to bundle items of varying sizes.

Small-Scale Use and Household Applications:

Wrapping film is not only used in industrial settings but also offers significant benefits for households and small businesses. For example, it can be used for packaging fragile items like glassware, ceramics, or electronics. By bundling these items together and wrapping them securely with stretch film, it reduces the risk of damage during transport or storage. Small businesses can use wrapping film to organize tools, materials, or equipment, keeping items secure and easily accessible. In households, wrapping film is useful for protecting seasonal items, keeping furniture clean during a move, or even for storing clothes, making it an all-purpose solution for everyday needs.

Organizing and Protecting Stored Items:

For both residential and commercial storage, wrapping film is an effective way to bundle and protect goods. It can be used to group similar items together, making it easier to organize and locate them later. For example, it’s commonly used to wrap boxed goods, books, or seasonal decorations. Wrapping film also prevents dirt, dust, and moisture from affecting stored items. In warehouses or storage units, stretch film helps to maintain order and ensures that items are secured, even in the absence of traditional packaging such as boxes or containers.

Food and Perishable Goods:

Stretch film is widely used in the food industry, particularly for wrapping perishable goods. It is an ideal option for packaging food items like meats, fruits, vegetables, and bakery products, helping to preserve freshness by acting as a barrier against moisture and contaminants. The cling nature of the film helps tightly wrap products, extending their shelf life by reducing exposure to air. In addition to retail use, wrapping film is also used for food packaging during transportation, ensuring that products are protected during the shipping process.

Temporary Surface Protection:

Stretch film is also utilized as a temporary surface protector, particularly in construction and remodeling projects. It can be wrapped around surfaces like flooring, windows, and furniture to shield them from dust, dirt, and paint during renovation work. It’s an easy and cost-effective way to protect delicate or finished surfaces from damage while maintaining cleanliness during work. Its transparent nature allows workers to see through it, so it’s easy to monitor the surface being protected.

Protective Bundling for Retail and Shipping:

For retailers or e-commerce businesses, wrapping film is used to bundle items together for shipping. Whether it’s a group of smaller items or an individual larger product, stretch film can be used to wrap and secure goods for a more organized and secure shipping experience. This reduces the risk of individual items becoming lost or damaged during transit and helps ensure that the products are delivered in the same condition as when they were packed.

Wrapping film is an incredibly versatile packaging material with a wide range of applications across various industries and settings. From stabilizing palletized goods and protecting large items during transport to bundling smaller goods for storage and shipping, wrapping film offers a cost-effective and efficient solution for keeping products secure, clean, and organized. Whether you’re a business owner looking to optimize your logistics or a homeowner in need of protective wrapping for furniture or fragile items, wrapping film provides reliable and effective protection that meets a variety of needs.

While both materials serve packaging purposes, there are significant differences between them. Wrapping film, such as stretch film wrap, stretches to secure large or heavy items. It is often used in industrial applications where the load needs tight containment. On the other hand, cling film is primarily used in kitchens to seal food containers, clinging naturally to smooth surfaces without the need to stretch.

Wrapping film is essential across industries due to its versatility. From stabilizing pallets in warehouses to providing plastic wrapping for furniture, it offers practical solutions for securing goods. Whether for industrial, commercial, or household use, film for wrapping ensures items remain intact and protected during handling and transportation.

Wrapping Film:

Cling Film:

Wrapping Film:

Cling Film:

Wrapping Film:

Cling Film:

Wrapping Film:

Cling Film:

Wrapping Film:

Cling Film:

The primary difference between wrapping film and cling film lies in their intended use, strength, and functionality. Wrapping film, especially stretch film, is designed for heavy-duty industrial applications where strong containment and protection are needed, while cling film is more suited for light, everyday tasks like wrapping food and sealing containers. Wrapping film is elastic, highly durable, and ideal for securing large or heavy loads, whereas cling film is thin, non-stretchable, and primarily used for food storage. Understanding these differences helps in selecting the right material for your specific needs, whether you’re looking for a solution to wrap furniture, stabilize palletized goods, or simply store leftovers.

Wrapping film is a broad category that refers to any plastic film used to wrap and secure items for transport, storage, or protection. It includes different types of films such as stretch film, shrink film, and other flexible plastic materials, each suited to different packaging needs. Wrapping film is commonly used in various industries, from moving and storing household items like furniture to securing products in warehouses. It can be clear or tinted, and its thickness can vary based on the application. The key characteristics of wrapping film are its flexibility and ability to conform tightly to the surface of the object it is wrapping, offering protection from dirt, moisture, and minor physical damage.

Stretch wrap is a specific type of wrapping film known for its high elasticity and ability to stretch up to 300-400% of its original length. This stretchability makes it ideal for securing products on pallets, especially in logistics and shipping. Stretch wrap is typically used to hold items tightly together, preventing them from shifting or toppling during transport. It’s made of low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE), which allows it to stretch and cling tightly to objects. Stretch wrap is available in various forms: machine wrap, which is used with automated stretch-wrapping machines, and hand stretch film, which is manually applied for smaller jobs. The key benefit of stretch wrap is its ability to provide a tight, secure wrap without needing additional adhesives, making it cost-effective and efficient.

Pallet wrap is essentially a specialized form of stretch wrap that is used exclusively for securing goods on pallets. It is designed to stabilize and protect large loads during storage or transit, ensuring that items remain in place and undamaged. Pallet wrap is often thicker and stronger than standard stretch wrap, especially when wrapping heavy or bulk items. It helps reduce the risk of load shifting, providing a tight hold that prevents individual items from moving or falling off the pallet. This film is also used to shield the contents from environmental elements like dirt, moisture, and UV exposure. In addition to regular stretch films, pallet wrap may come with extra features, such as UV resistance or added puncture resistance, to suit specific shipping conditions. The term “pallet wrap” refers to the application of stretch film specifically for securing palletized loads, typically in warehouse and distribution environments.

While all three terms involve films used for securing or protecting items, “wrapping film” is the broadest term, encompassing various types of films, “stretch wrap” is a highly elastic film used for general packaging and load stability, and “pallet wrap” is the specialized use of stretch wrap for stabilizing palletized shipments.

The use of wrapping film varies across industries, depending on the specific needs of the operation. Below is an overview of the key types of stretch film, including their applications and benefits. Each type serves different purposes, from manual use to automated industrial packaging. Understanding these types will help businesses and individuals choose the right solution for their packaging needs.

| Type | Description | Key Benefits | Applications |

|---|---|---|---|

| Hand Stretch Film | Used manually, this film is ideal for wrapping smaller loads or packages. It is available in various roll sizes, such as the stretch wrap roll. | Cost-effective and flexible for small operations. | Small warehouses, retail stores, and homes. |

| Machine Stretch Film | Applied with automated machines for speed and efficiency. This type ensures consistent stretch and reduces labor. | Improves packaging speed, reduces waste, and ensures consistency. | High-volume packaging in large warehouses and distribution centers. |

| Pre-Stretched Film | Manufactured with pre-applied stretch, making it easier to use. It requires less physical effort to apply, reducing fatigue. | Prevents breakage and saves time during application. | Suitable for both manual and automated applications. |

| Color Stretch Film | Color stretch film is a type of stretch film that is dyed to a specific color, typically in black, blue, or green. This film provides all the benefits of traditional clear stretch film, with the added advantage of offering a visual barrier. | Color stretch film offers privacy and security by concealing the contents of a wrapped load, preventing tampering or theft. It also provides enhanced UV protection and can act as a marker for easy identification. | Commonly used for wrapping sensitive or high-value products, palletized loads, and items stored outdoors. It is also used in the logistics industry to prevent theft or to easily identify specific products or shipments. |

| Bundling Stretch Film | Bundling stretch film is designed to secure and wrap multiple items together in a tight, cohesive bundle. It is typically thinner and more flexible than standard stretch film, allowing for efficient bundling of small to medium-sized products. | It is lightweight, cost-effective, and easy to apply, allowing businesses to efficiently bundle products without the need for additional packaging materials. The film sticks to itself, providing a tight hold without the risk of slipping. | Used for bundling products like hardware, tools, small boxes, and consumer goods. It's ideal for both retail packaging and warehouse applications where multiple items need to be grouped together. |

| Mini Stretch Film | Mini stretch film is a smaller, handheld version of standard stretch film, designed for light-duty wrapping tasks. It typically comes in smaller rolls (4–5 inches) that are easy to carry and use manually. | Mini stretch film offers ease of use, portability, and convenience for smaller packaging tasks. It is perfect for quick, on-the-go applications and is ideal for personal or small-scale business use. | Primarily used for wrapping small packages, bundles, or items that need temporary protection, such as individual products, gifts, or small boxes. It’s commonly used in home packing or for small business shipments. |

| VCI Stretch Film (Vapor Corrosion Inhibitor Stretch Film) | VCI stretch film is infused with corrosion inhibitors that protect metal products from rust and corrosion. It is commonly used in industries where metal products are stored or transported and are at risk of environmental factors that cause deterioration. | VCI stretch film provides protection against moisture, rust, and corrosion without needing additional protective coatings. It is an effective solution for safeguarding metal parts and machinery during long-term storage or shipping. | Used in the manufacturing, automotive, and industrial sectors to protect metal components, machinery, and spare parts. It is also commonly employed in warehouses and shipping centers that deal with metal goods. |

| UVI Stretch Film (Ultra-Violet Inhibitor Stretch Film) | UVI stretch film is a type of stretch wrap that has been treated with UV inhibitors, offering protection against the damaging effects of ultraviolet light. This film is designed for outdoor storage and transport. | The primary benefit of UVI stretch film is its ability to shield wrapped products from UV degradation, preventing fading, cracking, or weakening of sensitive materials. It helps maintain product quality when exposed to sunlight. | Ideal for protecting products stored outdoors or exposed to direct sunlight, such as building materials, agricultural goods, or outdoor furniture. It is commonly used in construction, farming, and logistics industries. |

| Breathable Stretch Film | Breathable stretch film is designed with micro-perforations or air holes to allow for airflow. This type of film helps regulate moisture levels and prevent the buildup of condensation on wrapped products. | Breathable stretch film helps reduce the risk of mold and mildew formation, making it ideal for packaging products that need ventilation, like fresh produce, plants, or other perishable goods. It combines the benefits of stretch wrapping with moisture management. | Used in industries such as agriculture, food distribution, and plant care, where ventilation is necessary to maintain product quality. It is ideal for wrapping fresh produce, flowers, or plants during transportation or storage. |

Hand stretch film is designed for manual wrapping. It is commonly used in environments where packaging needs are minimal, such as small businesses or retail operations. Hand stretch film is often sold in stretch wrap rolls of various sizes, making it easy to use for small loads. This type of film offers flexibility for businesses that need occasional packaging without investing in machines. It is particularly useful for wrapping irregularly shaped items or packaging goods in confined spaces.

Machine stretch film is applied using automatic or semi-automatic machines, making it ideal for high-volume packaging. These machines ensure that the wrapping film is stretched consistently across the entire load, reducing waste and improving packaging efficiency. Machine-applied stretch film also minimizes the physical strain on workers, lowering the risk of injury. This type of film is essential for industries with large-scale operations, such as warehouses, logistics, and manufacturing facilities.

Pre-stretch film is designed to reduce the effort required during application. It is pre-stretched during manufacturing, meaning it requires minimal force to secure loads. This feature minimizes the risk of film breakage, making it highly efficient for both manual and machine applications. Pre-stretched wrapping film also reduces user fatigue and improves productivity, particularly in businesses with frequent packaging needs.

Color stretch film is a versatile packaging material that not only provides the security and stability of traditional stretch film but also offers the added benefit of color-coded protection. Available in various colors like black, blue, or green, it helps conceal the contents of wrapped items, providing an extra layer of privacy and preventing unauthorized access. This type of stretch film is particularly useful in environments where security is a concern or where easy identification of specific pallets or shipments is needed. Its applications extend to industries requiring theft deterrence, UV protection, and product differentiation.

Bundling stretch film is a cost-effective solution for grouping multiple items together in a secure, compact package. This film is designed to wrap small to medium-sized products into cohesive bundles, offering an efficient alternative to traditional packaging methods like shrink wrapping or taping. Its ability to adhere to itself without requiring external adhesives makes it an ideal choice for bundling goods such as hardware, tools, or consumer items. Bundling stretch film is particularly advantageous in retail, logistics, and warehouse operations where items need to be grouped together for easier handling, storage, and transportation.

Mini stretch film offers a portable, user-friendly solution for light-duty packaging tasks, particularly when a smaller, more manageable roll is needed. Typically measuring 4 to 5 inches in width, this compact version of stretch film is ideal for individuals or small businesses who require quick and easy wrapping without the need for large equipment. The mini rolls are lightweight, making them perfect for wrapping small products, gift items, or personal belongings. Due to its convenience and simplicity, mini stretch film is commonly used for household packing, retail bundling, and smaller-scale shipments, where quick protection is needed without the complexities of larger rolls.

VCI stretch film, or Vapor Corrosion Inhibitor stretch film, is a specialized film designed to protect metal products from corrosion caused by moisture, humidity, and other environmental factors. Infused with corrosion-inhibiting chemicals, this stretch film creates a protective barrier around metal parts, tools, machinery, and automotive components, preventing rust and deterioration during storage or transit. Ideal for industries like automotive, aerospace, and heavy manufacturing, VCI stretch film is essential for safeguarding metal products in warehouses, shipping facilities, or long-term storage. It provides a cost-effective, easy-to-use solution for reducing corrosion-related damage without requiring additional coatings or treatments.

UVI stretch film is specifically engineered to offer enhanced protection against the harmful effects of ultraviolet (UV) light. This film incorporates UV inhibitors that block sunlight exposure, preventing products from degrading, fading, or becoming brittle over time. It is an essential material for protecting goods stored outdoors or exposed to direct sunlight during transportation. Industries such as construction, agriculture, and logistics benefit from UVI stretch film, especially for products like building materials, outdoor furniture, and agricultural supplies that need protection from UV rays. Its ability to shield products from environmental factors helps maintain their integrity, quality, and appearance.

Breathable stretch film features micro-perforations that allow air to circulate through the wrapped package, offering significant advantages for products that require ventilation. This type of stretch film is designed to prevent moisture buildup, reduce condensation, and control humidity levels, which can be crucial for perishable goods, plants, and fresh produce. By enabling airflow, breathable stretch film helps prevent mold and mildew growth, making it the preferred choice for industries such as food distribution, agriculture, and floriculture. It ensures that products remain fresh and intact during transit and storage, without compromising the protective qualities of standard stretch wrapping.

The versatility of wrapping film allows businesses to select the appropriate type based on their operational requirements. Whether using stretch wrap roll for small-scale applications or machine stretch film for larger operations, each type offers specific benefits that enhance efficiency and protection during packaging.

Wrapping film comes in various sizes, with the most common being:

When selecting the appropriate wrapping film size for your needs, consider the following factors:

Selecting the right size of wrapping film depends on the nature of your products, the scale of your operation, and the specific needs of your packaging. For smaller, manual tasks, hand stretch film works best, while machine stretch films are essential for high-volume or industrial applications. Always match the film size and thickness to your wrapping requirements to achieve the most efficient and cost-effective solution.

In addition to offering a wide range of standard wrapping films in various sizes, PWP Stretch Film also supports customized wrapping film solutions tailored to meet your specific packaging requirements. Whether you need hand stretch film for smaller tasks, machine stretch film for high-volume operations, or heavy-duty films for large, bulky items, we can provide the right size, thickness, and strength to ensure optimal protection. Our ability to customize wrapping film allows us to offer flexibility in design, ensuring that our products meet the unique demands of your business.

By choosing PWP Stretch Film, you are partnering with a manufacturer that is dedicated to providing superior wrapping film solutions with a focus on quality, customer satisfaction, and innovation. Whether you need standard or customized options, we ensure that our wrapping films meet your specific needs for secure, efficient, and cost-effective packaging.

Wrapping film plays a vital role in various industrial operations, helping businesses secure, protect, and transport products efficiently. Its adaptability ensures that goods are shielded from external elements and remain stable during handling. The following sections explore the core industrial applications of wrapping film across packaging, storage, and furniture protection, highlighting how it enhances operational efficiency in each area.

One of the primary uses of industrial wrapping film is to secure goods during transportation and distribution. In the logistics sector, companies need to ensure that palletized loads remain stable and intact throughout their journey to avoid product damage. Wrapping film achieves this by tightly binding products together, preventing them from shifting or toppling during transit.

Moreover, wrapping film simplifies the handling process by creating a compact and secure load, making it easier for workers to transport goods with forklifts or other equipment. In industries where products must travel long distances, industrial wrapping film ensures that packages remain clean and dry, even when exposed to environmental factors like dust or humidity.

The use of wrapping film also supports operational safety. A well-wrapped pallet reduces the risk of accidents by preventing loose items from falling during loading or unloading. This is particularly important in distribution centers, where heavy loads are moved frequently.

Wrapping film provides essential protection for goods in storage, whether in warehouses or retail environments. It creates a barrier that prevents dust, moisture, and dirt from settling on products, ensuring that they remain in pristine condition even during long-term storage. Retailers and warehouses use wrapping film to cover and seal inventory, safeguarding it from potential contamination or damage.

In addition to protecting goods, wrapping film also helps with product organization. Palletized goods wrapped with industrial wrapping film are easier to identify, transport, and categorize within storage facilities. Transparent wrapping films allow visibility of the items inside, facilitating quick identification without the need to open or unseal the packaging.

Industrial wrapping film is also effective in preventing pilferage and tampering. A tightly wrapped pallet shows visible signs if someone tries to tamper with it, helping companies maintain product integrity. Some businesses use colored or opaque wrapping films to conceal valuable items, further reducing the risk of theft.

Wrapping film is commonly used to protect furniture during transportation and storage. In the moving and relocation industry, companies rely on plastic wrapping for furniture to shield items from scratches, dents, and moisture exposure. Wrapping large furniture pieces with large stretch wrap helps secure drawers, doors, or movable parts, ensuring they stay in place during transit.

In addition to providing physical protection, wrapping film also prevents dust accumulation on furniture, which is particularly useful during long-term storage. Storage facilities often wrap furniture to maintain cleanliness and reduce the need for frequent maintenance. The film also offers some degree of water resistance, which is essential for outdoor or semi-exposed storage spaces.

Using wrapping film for furniture simplifies the moving process. Wrapped items are easier to handle, reducing the risk of damage during loading and unloading. Movers can quickly carry items without worrying about parts coming loose or getting scratched. The application of plastic wrapping for furniture also minimizes the need for additional padding materials, such as blankets or bubble wrap, making the process more efficient.

Choosing the right stretch film roll is crucial for optimizing packaging efficiency and product protection. Stretch film rolls, including jumbo roll stretch film, come in various sizes, thicknesses, colors, and formulations, each tailored to specific applications. Whether you’re working in warehouses, transportation, or furniture storage, selecting the correct type ensures effective use of wrapping film and minimizes waste. Below is a detailed breakdown of the available stretch film roll options, including roll sizes, UV protection, and custom films designed for specialized uses.

Stretch film rolls are available in different sizes and thicknesses, allowing businesses to select the appropriate option based on their packaging needs. Common sizes include 15 cm, 30 cm, and 60 cm rolls. Smaller rolls, such as 15 cm, are ideal for wrapping compact or irregularly shaped items, while larger rolls, like 60 cm, are used for pallet wrapping and securing bulk loads, offering multiple uses for pallet wrap in various industries.

Thickness plays an important role in determining the film’s strength. Thicker films are better suited for heavy-duty applications as they provide higher tensile strength and puncture resistance. These films are ideal for stabilizing large, heavy loads or goods with sharp edges. Thinner films, on the other hand, are lightweight and suitable for smaller packages or fragile goods that require minimal tension. Thinner options also reduce waste and material costs, making them ideal for operations where high-volume wrapping is required without compromising on efficiency.

Using the correct roll size and thickness ensures that the wrapping film functions effectively, providing the right balance between strength and flexibility for each packaging scenario.

For outdoor storage and long-term exposure, businesses often opt for UV-stabilized stretch film rolls. These films contain additives that block ultraviolet (UV) rays, preventing the film from degrading under sunlight. This feature is essential for industries that store goods outside or ship products across long distances where exposure to sunlight is inevitable.

UV-stabilized wrapping film ensures that goods remain protected from environmental damage, such as fading or heat-induced deterioration, during transit and storage. Without UV protection, standard stretch film may weaken and lose its cling, potentially compromising the integrity of the wrapped load.

In agriculture and construction industries, UV-stabilized stretch film is widely used to cover outdoor equipment, raw materials, or pallets stored in open yards. This type of film ensures durability and prevents goods from becoming damaged due to extended exposure to the elements.

Colored and custom stretch films offer additional benefits beyond standard transparent options. These films are available in a variety of opaque and translucent colors, allowing businesses to use them for product identification, branding, and warehouse organization. For example, different colored films can mark products according to categories, ensuring efficient sorting and tracking within a warehouse.

Opaque films offer an added layer of security by concealing high-value items from view, reducing the risk of theft or tampering during transit. This feature is especially useful in retail distribution and logistics, where valuable goods are shipped over long distances.

Custom films can also be produced with specific thicknesses, widths, and properties to meet unique packaging requirements. Some businesses incorporate printed branding or product information directly onto the film, enhancing visibility and professionalism. By choosing colored or custom stretch film, companies can tailor their wrapping film solutions to meet operational needs, while also promoting brand identity.

Wrapping film is a versatile packaging solution that offers significant advantages in both industrial and household applications. Its ability to protect, stabilize, and secure goods makes it an essential tool for businesses across various industries. Below are six key benefits of using wrapping film that demonstrate its value in improving efficiency, reducing costs, and ensuring product integrity.

Wrapping film creates a protective barrier around goods, safeguarding them from dust, dirt, and moisture. In warehouses or during transportation, products are often exposed to environmental elements that can compromise their quality. Wrapping film keeps items clean and dry, ensuring they reach their destination in optimal condition.

Additionally, wrapping film provides tamper-evident security. Once a load is tightly wrapped, any attempt to tamper with it becomes immediately visible, deterring theft and ensuring product integrity. This feature makes wrapping film indispensable for businesses that handle high-value goods or products sensitive to contamination.

During transit, products can shift or become damaged if not properly secured. Wrapping film holds loads tightly together, preventing movement and minimizing the risk of damage. This stabilization is crucial for both large palletized goods and smaller packages, as it ensures they remain intact throughout the journey.

In logistics and distribution, properly stabilized loads reduce the likelihood of accidents and improve safety for handlers. Whether using machine-applied film for large pallets or hand-applied wraps for individual items, wrapping film provides the necessary tension to keep products in place.

Using wrapping film can help businesses reduce costs by minimizing product damage, shipping errors, and the need for additional packaging materials. Wrapping film offers a lightweight yet durable solution, lowering shipping expenses compared to bulkier alternatives. It also reduces waste, as companies can use the exact amount needed to secure each load.

Moreover, wrapping film eliminates the need for complex packaging processes. By simplifying product handling and reducing the chance of errors, businesses can improve operational efficiency and save on labor costs.

One of the greatest strengths of wrapping film is its versatility. It is widely used across various industries, from retail and manufacturing to logistics and agriculture. Industrial applications include pallet wrapping, equipment protection, and bundling raw materials, while in households, wrapping film is frequently used to secure furniture or protect belongings during a move.

The flexibility of wrapping film allows it to adapt to different environments and requirements. Its availability in different sizes and formulations ensures that businesses and individuals can find the right type of film for their specific needs.

Wrapping film is easy to apply, whether by hand or machine. Hand stretch film rolls are lightweight and convenient for small-scale use, while machine-applied film ensures consistency and efficiency in large operations. Pre-stretched options further simplify the process by reducing the physical effort needed for application.

This ease of use makes wrapping film accessible to both professionals and homeowners. Even with minimal training, workers can quickly learn to apply the film correctly, ensuring secure and efficient packaging.

Many manufacturers now offer eco-friendly wrapping film options, including recyclable and biodegradable formulations. These alternatives help businesses reduce their environmental impact by minimizing plastic waste. UV-stabilized and oxo-biodegradable films are also available for industries that store goods outdoors, offering sustainable solutions without compromising on performance.

By choosing sustainable wrapping film options, businesses can meet growing consumer demand for environmentally responsible packaging while maintaining the benefits of traditional wrapping film.

While stretch film and cling film serve similar purposes—both are used to wrap and secure objects—they differ significantly in their composition, application, and functionality. Understanding these differences is essential to selecting the right wrapping film for specific tasks. Below is a detailed comparison of stretch film and cling film, followed by a discussion of whether they can be interchanged for certain uses.

| Feature | Stretch Film | Cling Film |

|---|---|---|

| Primary Use | Used for pallet wrapping, bundling goods, and securing large items during transit. | Mainly used for food storage, preserving freshness, and household tasks. |

| Material Composition | Made from linear low-density polyethylene (LLDPE) with high stretch capability. | Made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE). |

| Application | Industrial applications: Securing heavy pallets and equipment. | Household applications: Sealing containers and wrapping food items. |

| Elasticity | Stretches significantly to hold loads together securely. | Clings naturally to surfaces without stretching. |

| Strength | Offers high tensile strength and puncture resistance for large loads. | Lighter, with limited strength, designed for smaller tasks. |

| Transparency | Available in transparent and opaque colors. | Typically transparent for food visibility. |

| UV Protection | Some variants include UV stabilization for outdoor storage. | No UV protection; used indoors for food and household purposes. |

| Can They Be Interchanged? | Can occasionally wrap small household items if cling film is unavailable. | Can wrap small goods but not suitable for industrial use. |

Stretch film, a crucial type of wrapping film, is primarily used in industrial and commercial operations. Its ability to stretch significantly allows it to secure large or heavy loads effectively. Stretch film is commonly used in warehouses and distribution centers to stabilize pallets and ensure products remain intact during shipping. Additionally, it is utilized for wrapping bulky furniture or bundling tools and equipment, especially during relocations or long-term storage.

Some types of stretch film also offer UV stabilization, making them suitable for outdoor storage, where goods may be exposed to sunlight for extended periods. Opaque stretch film variants provide an added layer of security by concealing high-value items from view.

Cling film is designed for household use, where its primary function is to keep food fresh by sealing containers or wrapping individual items. Unlike stretch film, cling film adheres naturally to surfaces without the need for stretching. Its lightweight nature makes it easy to apply but limits its strength, making it unsuitable for heavy-duty applications.

Cling film’s transparency is beneficial for monitoring food without unwrapping, ensuring users can easily check contents. While it performs exceptionally well in kitchens, it lacks the durability and elasticity needed for industrial tasks.

While both films are part of the broader category of wrapping film, they serve distinct purposes and are not always interchangeable. In some cases, stretch film can be used for small household tasks, such as wrapping tools or organizing items, if cling film is unavailable. However, cling film cannot replace stretch film in industrial settings due to its limited strength and inability to stretch.

Businesses handling large loads require the durability and elasticity of stretch film to ensure secure packaging and transportation. Conversely, using stretch film for food storage would be excessive, as it lacks the convenience and ease of application that cling film provides for sealing containers.

When purchasing the right plastic wrap roll for packing, it’s important to consider various factors to ensure you select the most suitable wrapping film for your needs. With wrapping film, such as shrink wrap film, available in various sizes, thicknesses, and strengths, it is essential to choose the right type to optimize efficiency. The size and weight of the items, along with the film’s stretch capacity, play a critical role in determining the best option. Our content is designed to guide you through the process of choosing the right plastic wrap film, helping you make an informed decision when buying by weighing these key aspects.

The size and weight of the items being packed play a major role in determining the best plastic wrap roll to use.

By matching the size of the wrap roll to the size and weight of your items, you’ll minimize film waste and increase efficiency in the packing process. Selecting the right size also helps prevent over-wrapping, saving time and reducing packaging costs.

The strength and stretch capacity of wrapping film are critical factors that directly impact how securely and effectively your items will be packaged. Depending on the load, the film should be able to withstand stress, stretching, and puncture forces.

Stretch capacity is another important consideration. Stretching the film during application can help secure loads tightly, preventing items from shifting or falling apart during transport. Films with a higher stretch capacity, such as 250% or more, are typically more effective for heavy-duty applications, while films with lower stretch capacity (such as 150% stretch) are often used for lighter items or applications that don’t require as much hold.

The specific type of wrapping film and its features should be matched to your application needs. Various films offer different properties that cater to specific use cases.

The ease of use of the plastic wrap roll is another factor that can affect efficiency, especially in high-volume operations.

Cost efficiency is an important factor when selecting a plastic wrap roll. Choosing the right film ensures that you get the best value for your money without compromising on quality.

When purchasing a plastic wrap roll for packing with wrapping film, it’s crucial to consider the size, strength, and stretch capacity of the film, as well as its intended use. By understanding the characteristics of the items you’re wrapping—whether they are large, bulky, delicate, or small—you can purchase the right wrapping film that ensures the security and protection of your goods while optimizing the efficiency of your packaging process. With the right film and the correct application techniques, you’ll achieve cost-effective, reliable packaging that minimizes waste and ensures safe transport and storage.

Wrapping film serves various purposes across industries, providing protection, stability, and organization for goods during storage, handling, and transportation. It is widely used in industrial settings to secure pallets and prevent products from shifting during transit, reducing the risk of damage. Additionally, wrapping film acts as a barrier against dust, moisture, and tampering, ensuring that goods remain in pristine condition. Retailers use it to bundle products for efficient storage and organization. In the logistics sector, wrapping film helps improve operational efficiency by keeping loads compact and easy to transport. Outside of industrial applications, wrapping film is also used to protect large household items, such as furniture, during moving or storage. Its versatility and availability in various types make it essential for businesses and households alike.

Film wrap, commonly known as stretch film or shrink wrap, is a type of plastic film used to wrap items for protection and stability. It is designed to cling tightly to itself or the objects it covers, securing them together. The primary purpose of film wrap is to keep products in place during transport and storage while protecting them from dust, moisture, and other environmental factors. In industrial settings, it is used to stabilize pallet loads, ensuring they remain intact throughout transit. In households, film wrap can be used to bundle and organize items, or to protect furniture during moves. Its elasticity and ability to provide a snug fit make it an essential tool in both commercial and personal applications.

Wrapping film is typically made from linear low-density polyethylene (LLDPE), a type of plastic known for its flexibility and strength. LLDPE offers excellent stretchability, making it ideal for wrapping and securing loads without breaking. In some cases, other types of polyethylene, such as low-density polyethylene (LDPE) or high-density polyethylene (HDPE), may be used for specific applications. Some wrapping films are designed with special additives, such as UV stabilizers, to offer additional protection during outdoor storage. There are also biodegradable and eco-friendly versions made with oxo-degradable additives, allowing the film to break down more easily over time. The choice of material influences the film’s properties, including its elasticity, durability, and resistance to punctures, ensuring it meets the needs of various industries.

Yes, film wrap is a type of plastic, with the most common material being linear low-density polyethylene (LLDPE). As a plastic product, film wrap is highly stretchable, durable, and resistant to tearing, making it suitable for both industrial and household applications. Its plastic composition allows it to cling to objects and surfaces, ensuring a secure fit. While traditional film wraps are made entirely from plastic, there are now biodegradable and recyclable versions available to address environmental concerns. These eco-friendly options contain additives that help the plastic degrade more quickly or make it easier to recycle. Despite its plastic nature, film wrap remains lightweight, which helps reduce shipping costs and improves efficiency in packaging operations. Its versatility and ease of use make it an essential tool across many industries.

Film wrap, also known as stretch film or plastic film wrap, is primarily used for packaging and securing goods. It is widely used in industries like logistics, retail, and food packaging. Film wrap is ideal for bundling products together on pallets, keeping items secured and stable during transport and storage. It is also used for wrapping individual items to protect them from dirt, moisture, and damage. In the food industry, it is often used for wrapping perishables to extend shelf life by providing a tight seal that keeps contaminants out while maintaining product freshness. In retail, film wrap is commonly used for bundling products such as cans, bottles, and other consumer goods. Additionally, film wrap is utilized in moving and storage for securing furniture or protecting delicate items from scratches and environmental factors.

The term “wrap” in the context of film refers to the process of encasing or covering an object or group of objects with a plastic or film material. “Wrap” implies that the film is being used to fully surround and secure the contents, typically for protective, organizational, or shipping purposes. In packaging, wrap means using stretch film, shrink film, or other flexible materials to securely hold items in place while offering protection against elements like dust, dirt, moisture, and impact. The term “wrap” also conveys the idea of a tight, secure covering, whether for bundling products together on a pallet or protecting individual items for storage or transport. The film used for wrapping is often designed to cling or stretch around objects, forming a stable barrier that holds everything together during transit or while in storage.

Wrapping film, particularly stretch film, should be used within a specific temperature range to maintain its effectiveness. Ideally, the temperature for applying stretch film should be between 40°F (4°C) and 85°F (29°C). At lower temperatures, the film may become brittle and difficult to stretch, which can result in tears or breaks. Conversely, at higher temperatures, the film may become too soft, reducing its ability to provide a secure wrap and possibly leading to load instability. For best results, stretch film should be applied in a controlled environment where the temperature is moderate. Additionally, when used for shipping or storage in extreme heat or cold, consider selecting a film specifically designed for such conditions. For example, cold-resistant films are used for freezer environments, while UV-resistant films are chosen for long-term outdoor storage.

Film tape, often referred to as clear tape or plastic tape, is a versatile adhesive tape made from a thin film of plastic, typically polypropylene or polyester. It is primarily used for sealing, bundling, or securing various items in both industrial and consumer settings. Film tape is commonly used for sealing boxes, packages, and envelopes to prevent tampering or to ensure the contents remain secure during transit. In retail packaging, it is used to attach labels, tags, or to hold products in place on shelves. Film tape is also employed in various light-duty applications where a transparent, discreet seal is required. Unlike regular duct or masking tapes, film tapes are generally thin, clear, and offer a smooth finish, making them ideal for packaging materials where visibility of the contents is important or where a more polished, professional appearance is needed.

Wrapping, particularly with vinyl or other types of film, has gained popularity as an alternative to painting for several reasons. One of the main advantages is that wrapping provides a more temporary and customizable solution. Wrapping film, such as vehicle wraps, can be applied and removed without damaging the underlying surface, unlike paint, which is permanent and can be costly to remove or touch up. Wraps also offer greater design flexibility, allowing for intricate graphics, textures, and finishes that would be more difficult to achieve with paint. Additionally, wrapping is faster and can be done without the need for curing time, whereas painting involves multiple coats and drying stages. Wraps are also often more durable than paint, offering protection against UV rays, scratches, and weather conditions. For businesses or individuals looking for a quick, customizable, and reversible solution, wrapping is an effective alternative to traditional paint.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed